Master Sourcing and Quality Control of Diamond Turf Shoes

Guide to Diamond Turf Shoes

- Introduction: Navigating the Global Market for diamond turf shoes

- Understanding diamond turf shoes Types and Variations

- Key Industrial Applications of diamond turf shoes

- Strategic Material Selection Guide for diamond turf shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for diamond turf shoes

- Comprehensive Cost and Pricing Analysis for diamond turf shoes Sourcing

- Spotlight on Potential diamond turf shoes Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for diamond turf shoes

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the diamond turf shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of diamond turf shoes

- Strategic Sourcing Conclusion and Outlook for diamond turf shoes

Introduction: Navigating the Global Market for diamond turf shoes

In today’s competitive footwear industry, diamond turf shoes have emerged as a vital product segment, combining durability, style, and innovative design to meet diverse consumer demands worldwide. For international B2B buyers—especially those from Africa, South America, the Middle East, and Europe—understanding the nuances of sourcing these specialized shoes is essential to capitalize on market opportunities and mitigate risks. As demand for premium turf shoes continues to rise across sports, fashion, and corporate sectors, a strategic approach to sourcing can unlock significant competitive advantages.

This comprehensive guide is designed to empower B2B buyers with critical insights into the entire supply chain—from identifying reliable manufacturers and understanding material specifications to evaluating quality control practices and cost structures. It covers key aspects such as product types, sourcing regions, manufacturing standards, and supplier evaluation criteria, ensuring informed decision-making. Additionally, the guide addresses frequently asked questions and market trends, equipping buyers with actionable intelligence tailored to diverse regional contexts.

By leveraging this knowledge, buyers can optimize procurement processes, negotiate better terms, and establish resilient supply partnerships. Whether sourcing from emerging markets in Africa and South America or established manufacturing hubs in Europe and the Middle East, this guide provides the foundational tools needed for successful international sourcing of diamond turf shoes. Ultimately, it aims to facilitate smarter, more strategic purchasing decisions that enhance competitiveness and drive growth in a dynamic global marketplace.

Understanding diamond turf shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Diamond Turf Shoes | Classic design with durable synthetic or leather uppers, rubber outsole | Sports footwear, casual wear, retail distribution | Pros: Widely available, cost-effective, versatile. Cons: Limited innovation, standard quality. |

| Performance-Enhanced Models | Incorporate advanced cushioning, lightweight materials, and enhanced grip | Professional sports teams, high-performance retail | Pros: High quality, durability, appeal to premium markets. Cons: Higher procurement costs, longer lead times. |

| Customizable Diamond Turf Shoes | Modular components allowing branding, color, and logo customization | Corporate gifting, promotional campaigns, brand collaborations | Pros: Strong brand visibility, tailored designs. Cons: Increased MOQ requirements, longer customization cycles. |

| Eco-Friendly Variants | Made with sustainable materials like recycled rubber and biodegradable components | Eco-conscious brands, specialty retail, regional markets with sustainability mandates | Pros: Aligns with green initiatives, appeals to eco-aware consumers. Cons: Potentially higher raw material costs, limited supplier options. |

| Limited Edition and Collector’s Models | Unique designs, limited production runs, often with premium finishes | Niche markets, collectors, exclusive brand collaborations | Pros: High margin potential, brand prestige. Cons: Limited scalability, inventory risks. |

Characteristics and Suitability

Standard Diamond Turf Shoes are the backbone of the market, characterized by their durability and affordability. They suit bulk procurement needs for retail chains, sports academies, and regional distributors seeking reliable, everyday footwear. Their straightforward design simplifies logistics and reduces costs, making them an ideal entry point for buyers entering the diamond turf shoes segment. However, their lack of innovation may limit appeal in competitive markets.

Performance-Enhanced Models are designed for athletes and high-performance sports markets, featuring lightweight materials, superior cushioning, and enhanced grip technology. These shoes are suitable for professional teams, sports retailers, and specialty outlets targeting premium consumers. While they command higher prices, buyers should consider longer lead times and the need for reliable supply chains that can meet quality specifications consistently.

Customizable Diamond Turf Shoes enable brands to embed their identity through color schemes, logos, and special features. They are particularly valuable in corporate gifting, promotional campaigns, and regional branding efforts. Buyers should evaluate minimum order quantities and customization lead times carefully, ensuring suppliers can deliver within campaign timelines without compromising quality.

Eco-Friendly Variants respond to increasing demand for sustainable products. Made with recycled or biodegradable materials, these shoes appeal to eco-conscious markets across Africa, South America, and Europe. Sourcing eco-friendly materials may involve higher costs and limited supplier options, but they can differentiate brands and meet regional sustainability standards, making them strategic for brands aiming to enhance their green credentials.

Limited Edition and Collector’s Models target niche markets and brand enthusiasts, often featuring exclusive designs or collaborations. These shoes can generate significant margins and elevate brand prestige. However, buyers should plan for inventory management challenges, as limited production runs carry higher risks of unsold stock and require precise market timing.

By understanding these variations, B2B buyers can tailor their procurement strategies to match regional market demands, consumer preferences, and brand positioning, ensuring a competitive edge in the global diamond turf shoes market.

Key Industrial Applications of diamond turf shoes

| Industry/Sector | Specific Application of diamond turf shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Mining & Quarrying | Heavy-duty footwear for underground and surface mining operations | Enhanced durability and safety for workers in abrasive environments | Material strength, slip resistance, certification standards, regional supply chain reliability |

| Construction | Protective footwear for construction sites and infrastructure projects | Increased worker safety, reduced injury risk, compliance with safety standards | Compliance with regional safety regulations, comfort for prolonged wear, supply chain flexibility |

| Oil & Gas | Footwear for offshore and onshore drilling crews | Resistance to chemicals, oils, and extreme conditions, ensuring operational continuity | Chemical resistance, durability under harsh conditions, international certification |

| Agriculture & Forestry | Durable shoes for fieldwork in rugged terrains | Improved traction, longevity, and comfort in challenging outdoor environments | Adaptability to terrain, weather resistance, local sourcing options |

| Manufacturing & Industrial | Safety shoes for factory and industrial settings | Protection against mechanical hazards, electrical risks, and slips | Certification for industrial safety standards, customization options, regional logistics |

Mining & Quarrying

Diamond turf shoes are vital in mining and quarrying sectors where workers operate in highly abrasive and unpredictable environments. These shoes provide exceptional durability, resistance to wear, and enhanced grip, reducing the risk of slips and falls. For international B2B buyers, especially from Africa and South America where mining is prevalent, sourcing shoes with certified safety standards (such as ASTM or ISO) ensures compliance and safety. Reliable supply chains are crucial to prevent operational delays, and selecting suppliers with regional manufacturing capabilities can optimize logistics and costs.

Construction

In construction, diamond turf shoes serve as protective gear for workers exposed to heavy machinery, falling objects, and uneven surfaces. The shoes’ robustness minimizes injuries and downtime, while their slip-resistant soles improve safety on wet or oily surfaces. European and Middle Eastern buyers should prioritize shoes that meet local safety regulations and standards like EN ISO. Additionally, comfort for long shifts and ease of procurement through regional distributors can significantly enhance project efficiency and worker well-being.

Oil & Gas

Offshore and onshore oil and gas operations demand footwear that withstands extreme conditions, including exposure to chemicals, oils, and saltwater. Diamond turf shoes are engineered with resistant materials that prevent degradation and provide reliable traction on slippery surfaces. For buyers in the Middle East and Africa, sourcing shoes with certifications such as ATEX or IECEx for explosive atmospheres is critical. Establishing partnerships with suppliers capable of delivering consistently high-quality products across regions ensures operational safety and compliance.

Agriculture & Forestry

In rugged terrains typical of agricultural and forestry operations, diamond turf shoes offer superior traction, durability, and comfort. Their resistance to mud, water, and rough terrain reduces fatigue and enhances productivity. Buyers from South America and Africa should focus on sourcing shoes with weather-resistant features and regional availability to minimize lead times. Customization options for specific environmental challenges can further optimize operational outcomes and worker safety.

Manufacturing & Industrial

Industrial environments pose risks such as mechanical impacts, electrical hazards, and slippery floors. Diamond turf shoes provide essential protection, combining slip resistance with impact absorption. For European and Middle Eastern manufacturers, compliance with safety standards like EN 20345 or ASTM F2413 is non-negotiable. Sourcing from suppliers with robust quality assurance processes and regional logistics solutions ensures timely delivery, reducing downtime and enhancing workplace safety.

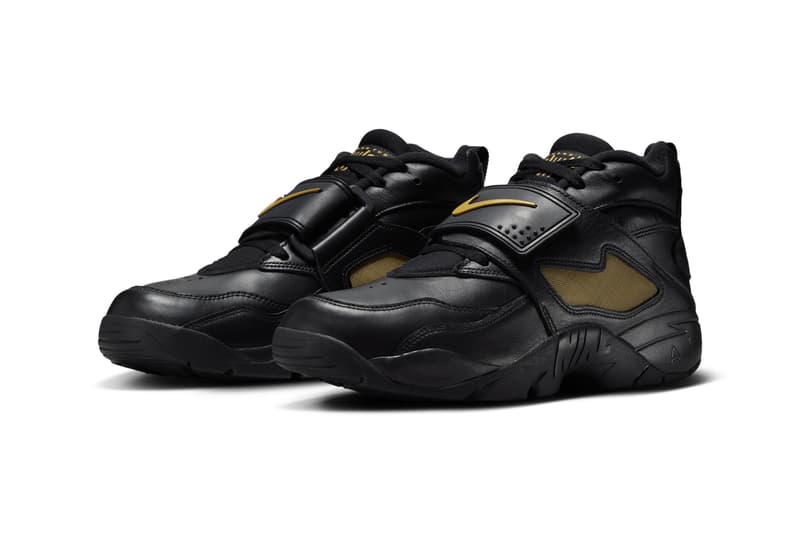

Illustrative Image (Source: Google Search)

Strategic Material Selection Guide for diamond turf shoes

Material Analysis for Diamond Turf Shoes

Selecting the appropriate materials for diamond turf shoes is critical to ensure optimal performance, durability, and compliance with international standards. For B2B buyers across Africa, South America, the Middle East, and Europe, understanding the properties, advantages, and limitations of common materials helps in making informed procurement decisions that align with regional standards and operational conditions.

1. Rubber (Natural and Synthetic)

Rubber remains a primary choice for the outsole of diamond turf shoes due to its excellent grip, flexibility, and shock absorption. Natural rubber offers superior elasticity and resilience, while synthetic variants like EVA or TPU provide enhanced weather resistance and cost benefits.

- Key Properties:

- Temperature tolerance: -20°C to 60°C (varies by formulation)

- Resistance to wear and tear

- Good chemical and water resistance (especially synthetic types)

-

Moderate UV and ozone resistance (synthetic rubber)

-

Pros & Cons:

- Pros: High durability, excellent traction, relatively easy to mold, cost-effective especially with synthetic options

-

Cons: Natural rubber can degrade under prolonged UV exposure; synthetic rubber may be more expensive; environmental concerns regarding vulcanization processes

-

Impact on Application:

- Suitable for outdoor turf applications, providing traction on varied terrains

-

Resistance to oil and water makes it ideal for diverse environmental conditions

-

International Considerations:

- Compliance with ASTM D2000 or ISO standards for rubber materials is essential for export markets

- Buyers in Europe and Germany often prefer eco-friendly, low-VOC formulations

- African and Middle Eastern markets may prioritize cost and weather resistance over certification

2. Polyurethane (PU)

Polyurethane is widely used for midsole components and sometimes for outsole layers, offering a balance of comfort and durability. Its customizable properties make it suitable for specialized applications within diamond turf shoes.

- Key Properties:

- High abrasion resistance

- Moderate flexibility

- Good chemical resistance

-

Temperature tolerance: -30°C to 80°C

-

Pros & Cons:

- Pros: Excellent durability, lightweight, good energy return, resistant to cracking

-

Cons: Higher manufacturing complexity and cost, potential environmental concerns during production, limited recyclability

-

Impact on Application:

- Ideal for shock absorption and long-lasting performance in high-impact zones

-

Suitable for environments requiring chemical resistance, such as industrial or agricultural settings

-

International Considerations:

- European standards (e.g., DIN EN 71-3) emphasize safety and low toxicity, influencing material selection

- Buyers in Africa and South America should verify compliance with local import regulations and environmental standards

- Cost considerations may lead to choosing lower-grade PU variants in price-sensitive markets

3. Stainless Steel (for Structural Components)

Stainless steel is often used in hardware components such as eyelets, hooks, or reinforcement plates within diamond turf shoes, especially in high-stress areas.

- Key Properties:

- Excellent corrosion resistance

- High tensile strength

-

Temperature tolerance: -196°C to 870°C (depends on grade)

-

Pros & Cons:

- Pros: Long-lasting, maintains structural integrity in harsh environments

-

Cons: Higher material and manufacturing costs, weight considerations, requires precise manufacturing for optimal fit

-

Impact on Application:

- Suitable for outdoor use in humid, salty, or corrosive environments common in coastal or industrial regions

-

Ensures longevity and safety in high-stress zones of the shoe

-

International Considerations:

- Compliance with ASTM A240 or DIN 1.4301 standards ensures quality and corrosion resistance

- European buyers often prefer 304 or 316 grades for superior corrosion resistance

- Buyers from Africa and the Middle East should consider local environmental conditions and may need additional protective coatings

4. High-Performance Fabrics (for Upper Materials)

Advanced textiles such as ripstop nylon, Kevlar, or breathable mesh fabrics are used for the upper portion of diamond turf shoes, balancing weight, breathability, and durability.

- Key Properties:

- Breathability and moisture-wicking capabilities

- Tear and abrasion resistance

-

UV and weather resistance varies by fabric type

-

Pros & Cons:

- Pros: Lightweight, comfortable, customizable for specific environmental needs

-

Cons: Potentially higher cost, lower structural support compared to leather or synthetic leather

-

Impact on Application:

- Suitable for sports, outdoor, and industrial applications where ventilation and durability are critical

-

Compatibility with waterproof coatings enhances performance in wet climates

-

International Considerations:

- Compliance with OEKO-TEX or REACH standards is often required for European markets

- African and Middle Eastern buyers should prioritize fabrics with proven UV and heat resistance

- South American markets may favor cost-effective options with good durability and breathability

Summary Table of Material Options

| Material | Typical Use Case for diamond turf shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Rubber (Natural/Synthetic) | Outsole traction and durability | Excellent grip, shock absorption | Environmental concerns, UV degradation in natural rubber | Low |

| Polyurethane (PU) | Midsole, shock absorption, structural reinforcement | Durable, lightweight, good energy return | Higher cost, manufacturing complexity | Med |

| Stainless Steel | Structural hardware, reinforcement in high-stress zones | Corrosion resistance, high strength | Higher cost, weight, manufacturing precision | High |

| High-Performance Fabrics | Upper material, breathability, moisture control | Lightweight, breathable, tear-resistant | Costlier, lower structural support | Med to High |

This comprehensive analysis guides international B2B buyers in selecting materials that meet regional standards, environmental conditions, and cost considerations, ensuring optimal performance and compliance for diamond turf shoes across diverse markets.

In-depth Look: Manufacturing Processes and Quality Assurance for diamond turf shoes

Manufacturing Processes of Diamond Turf Shoes

The production of diamond turf shoes involves a series of meticulously controlled stages, each critical to ensuring product quality, durability, and aesthetic appeal. For international B2B buyers, understanding these processes helps in evaluating supplier capabilities and ensuring compliance with global standards.

Material Preparation

The process begins with sourcing high-quality raw materials, primarily synthetic or natural turf fibers, durable rubbers or plastics for the sole, and decorative elements such as rhinestones or diamond-like embellishments. Suppliers often pre-treat or customize materials to enhance adhesion, flexibility, and visual appeal. For durability, many manufacturers incorporate UV-resistant and weatherproof coatings, especially important for outdoor use.

Forming and Molding

The primary shaping of the shoe components occurs through injection molding, compression molding, or thermoforming techniques. These methods allow for precise control over dimensions and surface finish. For diamond turf shoes, the upper is often molded separately from the sole to facilitate complex decorative features and ensure a snug fit.

Assembly

Assembly involves multiple steps: attaching the upper to the sole, embedding decorative elements (like rhinestones or embedded diamonds), and reinforcing stress points with stitching or adhesives. Modern manufacturers utilize automated robotic assembly for consistency, while manual assembly is common for intricate decorative work. Special adhesives with high bonding strength, such as polyurethane-based glues, are used to ensure longevity, particularly in high-stress areas.

Finishing

The finishing stage includes surface treatments, polishing, and quality embellishments. Surface coatings enhance weather resistance and aesthetic appeal, while final inspections verify the placement of decorative elements. Some manufacturers apply protective coatings or anti-slip treatments to improve safety and performance. The shoes undergo a thorough cleaning and polishing process to meet visual standards before packaging.

Quality Assurance (QA) and Control (QC) Protocols

Maintaining consistent quality in diamond turf shoes demands rigorous QC measures aligned with international standards such as ISO 9001, which emphasizes quality management systems. Industry-specific certifications, like CE (for European markets) or API (for certain manufacturing standards), further validate product safety and compliance.

Key QC Stages

-

Incoming Quality Control (IQC): Raw materials are inspected upon arrival. This includes verifying material certifications, conducting physical tests (e.g., tensile strength, colorfastness), and ensuring compliance with specified standards. Suppliers should provide detailed test reports for traceability.

-

In-Process Quality Control (IPQC): During manufacturing, checkpoints ensure adherence to dimensions, assembly accuracy, and decorative element placement. Techniques such as 3D scanning, visual inspections, and automated measurement systems are employed. For decorative features like rhinestones or embedded diamonds, visual inspection under magnification ensures proper adhesion and placement.

-

Final Quality Control (FQC): The finished shoes undergo comprehensive testing, including durability tests (flexing, abrasion), slip resistance assessments, and visual inspections for defects or inconsistencies. Functional tests such as waterproofing or UV resistance are also performed if specified.

Testing Methods

- Mechanical Testing: Tensile, peel, and shear tests evaluate adhesive bonds and component robustness.

- Environmental Testing: Exposure to UV light, water, and temperature variations assesses product resilience.

- Visual Inspection: High-resolution cameras and magnification tools detect surface defects, misalignments, or missing embellishments.

- Performance Testing: Anti-slip and wear tests simulate real-world use to verify safety and durability.

Verification and Compliance for International B2B Buyers

B2B buyers from Africa, South America, the Middle East, and Europe should adopt a comprehensive approach to verifying supplier QC processes:

- Audits: Conduct on-site audits focusing on manufacturing facilities, QC procedures, and raw material sourcing. Audits help verify compliance with ISO 9001 and industry-specific certifications.

- Inspection Reports: Require detailed third-party inspection reports, especially for critical components or high-value embellishments like diamonds or rhinestones.

- Third-Party Inspection Services: Engage reputable inspection agencies (e.g., SGS, Bureau Veritas) to perform random sampling and certification verification, ensuring products meet specified standards before shipment.

- Sample Testing: Request pre-shipment samples for independent testing aligned with relevant standards such as CE or ASTM to validate quality claims.

- Traceability and Documentation: Ensure suppliers maintain transparent records of QC processes, batch tracking, and material certifications to facilitate traceability.

Nuances for Different Regional Markets

-

Europe (e.g., Germany): Emphasis on compliance with CE marking, REACH regulations, and sustainability standards. B2B buyers should verify that suppliers adhere to EU environmental and safety directives, including restricted substances and eco-friendly manufacturing practices.

-

Africa & Middle East: Focus on durability and weather resistance, given climate conditions. Suppliers should provide evidence of testing under extreme temperatures, UV exposure, and moisture. Additionally, certifications like ISO 9001 are valued for establishing credibility.

-

South America: Buyers should prioritize supplier transparency and certification authenticity, especially when sourcing from regions with diverse manufacturing standards. Inspection reports and third-party audits are critical for risk mitigation.

-

Germany & Europe: Stringent standards necessitate comprehensive documentation, adherence to REACH and RoHS directives, and possibly eco-label certifications (e.g., OEKO-TEX). B2B buyers should insist on detailed compliance documentation to ensure market acceptance.

Final Insights for B2B Buyers

Engaging with manufacturers who incorporate robust manufacturing and QC protocols minimizes risks and enhances product reliability. Establish clear quality benchmarks, request detailed documentation, and leverage third-party inspections to validate supplier claims. For international trade, especially in regions with varying standards, fostering transparent communication and verifying compliance through audits and testing is essential for building long-term, trustworthy partnerships in the diamond turf shoe market.

Comprehensive Cost and Pricing Analysis for diamond turf shoes Sourcing

Cost Structure Breakdown

Understanding the comprehensive cost structure of diamond turf shoes is essential for effective sourcing and pricing negotiations. The primary components include:

-

Materials: High-quality synthetic or leather uppers combined with durable rubber or polyurethane soles typically constitute the bulk of material costs. Diamond embellishments or reflective elements, if included, can significantly influence costs, especially if they require specialized manufacturing or sourcing from niche suppliers.

-

Labor: Labor costs vary widely based on the manufacturing country. For instance, sourcing from Asian suppliers may offer lower wages, whereas European or Middle Eastern factories might have higher labor expenses but often provide better quality assurance.

-

Manufacturing Overheads: These include facility costs, machinery depreciation, and utility expenses. Advanced automation can reduce overheads, but craftsmanship-intensive designs or customization increases these costs.

-

Tooling & Molds: For customized or limited-edition designs, tooling costs can be substantial upfront but amortized over production volume. This expense is a key consideration for buyers planning small batch or bespoke orders.

-

Quality Control (QC): Ensuring consistent quality is vital, especially for international markets with strict standards. QC costs include inspections, testing, and certification processes, which may vary depending on destination country requirements.

-

Logistics & Shipping: Freight costs depend on shipment volume, weight, and destination. Buyers from Africa, South America, or Europe should factor in potential delays, customs duties, and import taxes, which can add 10-30% to the landed cost.

-

Margins: Suppliers typically add a markup ranging from 15% to 40%, depending on the competitiveness of the market, order size, and relationship strength. Large-volume buyers may secure better margins through negotiation.

Price Influencers and Variability

Several factors influence the final unit price of diamond turf shoes:

-

Order Volume & MOQ: Higher volumes generally lead to lower unit costs due to economies of scale. Many suppliers offer tiered pricing, with discounts increasing at larger order sizes. Minimum order quantities (MOQs) can range from 500 to 2,000 pairs, influencing initial investment.

-

Specifications & Customization: Customized designs, special colors, or branding increase costs. Special features like embedded diamonds or reflective surfaces also add to production complexity and expense.

-

Material Selection: Premium materials or eco-friendly alternatives command higher prices. Suppliers with access to certified sustainable materials may charge premiums but can offer added value for brands targeting environmentally conscious consumers.

-

Quality & Certification Standards: Compliance with standards such as ISO, CE, or local market certifications can influence costs. Higher quality assurance often correlates with higher manufacturing costs but reduces return and warranty expenses.

-

Supplier Factors: Supplier reputation, production capacity, and geographic location impact pricing. Established factories with advanced technology and quality certifications may charge higher prices but provide reliability and consistency.

-

Incoterms & Delivery Terms: FOB (Free on Board) pricing is common, allowing buyers to handle shipping and customs. CIF (Cost, Insurance, Freight) includes shipping costs, simplifying logistics but increasing upfront costs. Buyers should evaluate these terms carefully to optimize total landed costs.

Buyer Tips for Effective Cost Management

-

Negotiate for Volume Discounts: Engage suppliers early to secure tiered pricing, especially if planning larger orders. Demonstrating long-term partnership potential can unlock better margins.

-

Focus on Total Cost of Ownership (TCO): Consider not just the unit price but also shipping, customs, quality assurance, and after-sales support. A slightly higher initial cost may result in lower overall expenses if it ensures better durability and fewer defects.

-

Leverage Local Sourcing & Logistics: For buyers in Africa, South America, or the Middle East, exploring regional suppliers can reduce shipping costs and lead times. European buyers should consider proximity to manufacturing hubs for faster delivery.

-

Understand Pricing Nuances: Be aware that quotes often exclude taxes, duties, and incidental costs. Request detailed quotations to compare true landed costs effectively.

-

Build Strategic Relationships: Developing trust with suppliers can lead to better pricing, priority production, and improved customization options, especially in markets where quality standards are critical.

Indicative Price Range (Disclaimer)

While actual prices fluctuate based on specifications, order volume, and market conditions, a general estimate for diamond turf shoes ranges from $20 to $50 per pair for standard models in bulk. Premium or highly customized versions can exceed $60 per pair. Buyers should conduct localized supplier research and request detailed quotes to obtain accurate pricing tailored to their specific needs.

By thoroughly understanding these cost components, influencers, and negotiation strategies, international B2B buyers from Africa, South America, the Middle East, and Europe can optimize their sourcing approach, achieve cost efficiencies, and ensure quality standards are met—all while maintaining competitive pricing in their target markets.

Spotlight on Potential diamond turf shoes Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for diamond turf shoes.)*

Essential Technical Properties and Trade Terminology for diamond turf shoes

Critical Technical Specifications for Diamond Turf Shoes

1. Material Grade and Composition

The choice of materials—such as synthetic fibers, rubber, or leather—directly impacts durability, performance, and price point. Higher-grade materials, often certified for toughness and resistance, are essential for shoes intended for rigorous sports or extended outdoor use. B2B buyers should specify the desired material standards (e.g., ASTM, ISO) to ensure consistency across batches and suppliers.

2. Sole Thickness and Composition

The sole’s thickness influences shock absorption, grip, and overall comfort. Standard specifications often range from 15mm to 25mm depending on the turf type. The composition, whether rubber, TPU, or specialized composites, affects traction and wear resistance. Clear communication of these specs helps prevent mismatched expectations and quality issues.

3. Tolerance Levels and Manufacturing Precision

Tolerance refers to acceptable deviations during manufacturing, such as size variance (+/- 1mm) or weight differences. Tight tolerances are critical for uniformity, especially when large orders are involved, reducing returns and ensuring compatibility with existing sports equipment. B2B buyers should negotiate and specify tolerances upfront in purchase agreements.

4. Color Fastness and UV Resistance

For outdoor turf shoes, color fastness and UV resistance are vital to maintain aesthetic appeal over time. These properties ensure that shoes do not fade or degrade prematurely, which is crucial for branding and customer satisfaction. Suppliers should provide testing certifications for these properties.

5. Weight and Flexibility

The weight of the shoe influences athlete performance and fatigue. Lightweight designs (under 300 grams) are preferred for speed, while flexibility ensures natural movement. Specifications should detail acceptable weight ranges and flexibility tests to align product offerings with end-user needs.

Essential Industry and Trade Terms

1. OEM (Original Equipment Manufacturer)

Refers to companies that produce shoes branded under another company’s name. Understanding OEM arrangements is crucial for B2B buyers seeking customized products or private labeling, as it affects pricing, minimum order quantities, and intellectual property rights.

2. MOQ (Minimum Order Quantity)

The smallest quantity a supplier agrees to produce per order. Knowledge of MOQ helps buyers plan procurement budgets and timelines, especially when entering new markets or testing product demand. Negotiating flexible MOQs can be advantageous for smaller or emerging markets.

3. RFQ (Request for Quotation)

A formal document issued by buyers to solicit pricing, lead times, and terms from suppliers. Efficient RFQ processes streamline procurement and enable better comparison of supplier offerings. Clear specifications in RFQs reduce misunderstandings and lead to more accurate quotes.

4. Incoterms (International Commercial Terms)

Standardized trade terms published by the ICC that define responsibilities for shipping, insurance, and tariffs. Familiarity with Incoterms (e.g., FOB, CIF, DDP) helps buyers clarify costs and logistics responsibilities, minimizing disputes during international transactions.

5. Lead Time

The period from order placement to delivery. Accurate knowledge of lead times enables better inventory planning and ensures timely product availability, especially critical for seasonal or event-driven sales cycles.

6. Quality Certification and Compliance

Terms like ISO, CE, or ASTM certifications indicate adherence to international safety and quality standards. Ensuring suppliers have the necessary certifications reduces risk, especially when exporting to regulated markets like Europe or Egypt.

By understanding these key technical properties and trade terms, international B2B buyers from Africa, South America, the Middle East, and Europe can make informed purchasing decisions. Clear specifications and familiarity with trade jargon facilitate smoother negotiations, reduce risks, and ensure product quality aligns with end-user expectations.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the diamond turf shoes Sector

Market Overview & Key Trends

The global diamond turf shoes sector is experiencing robust growth driven by evolving consumer preferences, technological advancements, and expanding distribution channels. Notably, emerging markets in Africa, South America, the Middle East, and parts of Europe such as Germany and Egypt are becoming critical hubs for sourcing and distribution. These regions are characterized by increasing urbanization, rising disposable incomes, and a growing youth demographic seeking stylish yet durable footwear.

International B2B buyers are increasingly leveraging digital platforms and advanced analytics to optimize sourcing strategies. E-commerce marketplaces, B2B platforms, and virtual trade shows facilitate more transparent and efficient procurement processes, reducing lead times and costs. Additionally, customization and innovation—such as incorporating eco-friendly materials or smart features—are gaining prominence, allowing brands to differentiate in competitive markets.

Illustrative Image (Source: Google Search)

Market dynamics are also influenced by fluctuating raw material costs, geopolitical stability, and trade policies. For example, tariffs or import restrictions in key markets like Europe or the Middle East can impact pricing and supply chain planning. As sustainability becomes a central concern, buyers are seeking suppliers with transparent sourcing practices and compliance with international standards.

In terms of sourcing trends, there is a noticeable shift toward regional manufacturing hubs to mitigate supply chain disruptions. Countries with established footwear manufacturing expertise, such as Vietnam, China, and increasingly African nations like Ethiopia, are attracting more B2B partnerships. These regions offer a combination of cost efficiencies, skilled labor, and proximity to emerging markets, making them strategic sourcing destinations.

For B2B buyers from Africa, South America, the Middle East, and Europe, understanding these market drivers and leveraging digital sourcing tools can enhance procurement agility. Building relationships with reliable, compliant suppliers—especially those adopting innovative technologies—will be key to maintaining a competitive edge and meeting evolving market demands.

Sustainability & Ethical Sourcing in B2B

Sustainability is no longer optional but a fundamental criterion in sourcing diamond turf shoes. Environmental impacts associated with raw material extraction, manufacturing processes, and waste management are scrutinized by global consumers and regulatory bodies alike. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to reducing carbon footprints, minimizing waste, and utilizing eco-friendly materials.

Ethical sourcing practices are equally vital, particularly concerning labor standards, fair wages, and supply chain transparency. The diamond turf shoe sector often involves complex supply chains, making it essential for B2B buyers to verify compliance through third-party certifications such as Fair Trade, ISO 14001, or SA8000. These certifications help ensure that materials like synthetic turf or rubber are sourced responsibly and that manufacturing facilities adhere to humane working conditions.

Adopting ‘green’ certifications and materials can enhance brand reputation and meet the growing demand from environmentally conscious consumers. For instance, utilizing recycled rubber, biodegradable synthetics, or natural turf components can significantly reduce environmental impact. Additionally, traceability tools—such as blockchain—are increasingly employed to verify origin and sustainability claims, fostering trust among B2B partners.

For European and Middle Eastern buyers, aligning with suppliers committed to sustainability can open access to premium markets and facilitate compliance with stringent regulations. African and South American buyers can leverage sustainability standards to improve market access, especially in regions where consumers are demanding ethically produced footwear. Building partnerships with certified suppliers and integrating sustainability into procurement criteria will be crucial for future-proofing supply chains.

Brief Evolution/History (Optional)

The diamond turf shoes sector has evolved from simple, functional footwear to a highly innovative and design-driven industry. Initially rooted in basic athletic and casual shoes, the sector has seen significant technological integration, including the use of high-performance synthetic turf and lightweight materials. This evolution was driven by consumer demand for durability, style, and versatility.

Over the past decade, sustainability has emerged as a core focus, prompting manufacturers to adopt eco-friendly materials and transparent supply chain practices. The integration of digital tools for sourcing, design customization, and quality control has further transformed the industry, enabling more efficient global trade and collaboration.

Understanding this evolution helps B2B buyers appreciate the sector’s innovation trajectory and the importance of aligning with forward-thinking suppliers who prioritize quality, sustainability, and technological adaptation. As the industry continues to evolve, those who embrace sustainable innovation and digital integration will be best positioned for long-term success in the global market.

Frequently Asked Questions (FAQs) for B2B Buyers of diamond turf shoes

1. How can I effectively vet suppliers to ensure product quality and reliability?

To ensure supplier credibility, start by requesting comprehensive company documentation, including business licenses, export licenses, and quality certifications (ISO, BSCI, etc.). Review their production capacity, client references, and past export history, especially to regions similar to yours. Conduct factory audits or virtual inspections when possible, and verify their compliance with international standards. Additionally, consider visiting trade shows or engaging third-party inspection services to validate their claims. Building a transparent communication channel and setting clear expectations upfront helps establish trust and reduces risks associated with poor quality or unreliable delivery.

2. What customization options are typically available for diamond turf shoes, and how do they impact MOQ and lead times?

Most manufacturers offer a range of customization options, including colorways, branding (logos or labels), sole patterns, and material finishes. Custom designs often require higher MOQs—generally starting at 1,000 pairs—due to setup costs and production complexity. Lead times for customized orders typically range from 4 to 12 weeks, depending on complexity and supplier capacity. To optimize timelines, communicate your specifications early and consider working with suppliers experienced in international B2B customization. Some suppliers may offer semi-custom options with lower MOQs, which can be advantageous for testing markets or limited launches.

3. What are typical MOQ, lead times, and payment terms for bulk orders of diamond turf shoes?

MOQ varies widely but generally ranges between 500 to 5,000 pairs, influenced by the supplier’s production scale and customization level. Lead times are usually between 6 to 16 weeks, including sampling, production, and shipping. Common payment terms include 30% upfront deposit with the balance payable before shipment, or letter of credit for larger orders. Negotiating flexible terms, especially for repeat or large-volume orders, can improve cash flow. Always clarify payment methods accepted (bank transfer, PayPal, letters of credit) and seek terms that mitigate currency fluctuation risks.

4. What quality assurance (QA) standards and certifications should I look for in suppliers?

Reliable suppliers should have internationally recognized certifications such as ISO 9001 for quality management, and possibly social compliance certifications like BSCI or Sedex. They should provide detailed QA procedures, including pre-production samples, in-line inspections, and final product audits. Request test reports for materials (e.g., sole durability, upper material compliance), and ensure compliance with your target markets’ standards (e.g., REACH, ASTM). Establish clear quality benchmarks in your contract, and consider engaging third-party inspectors during production to verify adherence before shipment.

5. How do I manage logistics and shipping for international B2B purchases of diamond turf shoes?

Coordinate closely with suppliers to determine the most cost-effective and reliable shipping options—air freight for urgent or high-value orders, sea freight for bulk, cost-sensitive shipments. Confirm incoterms (e.g., FOB, CIF) that define responsibilities and costs. Work with experienced freight forwarders familiar with your destination country to handle customs clearance, taxes, and duties efficiently. Ensure all shipping documentation (commercial invoice, packing list, bill of lading, certificates of origin) are accurate to prevent delays. Establish tracking systems and maintain communication with your logistics partners for real-time updates.

6. What common dispute issues arise in international B2B transactions and how can they be mitigated?

Disputes often involve product quality, delivery delays, payment issues, or contractual misunderstandings. To mitigate these risks, draft clear, detailed contracts specifying product specs, inspection rights, delivery timelines, payment terms, and dispute resolution mechanisms (preferably arbitration). Use escrow services or letters of credit to secure payments. Maintain transparent communication and documentation throughout the process. Employ third-party inspection agencies to verify product quality before shipment. Building strong relationships and choosing reputable, verified suppliers also significantly reduce the likelihood of disputes.

Illustrative Image (Source: Google Search)

7. How can I ensure compliance with import regulations and standards in my country?

Research your country’s import regulations, tariffs, and standards for footwear, especially for specialized products like diamond turf shoes. Consult local customs authorities or trade associations for guidance. Ensure your supplier provides all necessary certificates, such as Certificates of Origin and safety compliance documents. Consider engaging a customs broker to facilitate clearance and compliance processes. Staying updated on trade policies and tariffs helps optimize costs and avoid delays. Also, verify that the product labeling and packaging meet local legal requirements to prevent rejection or fines.

8. What steps should I take to build long-term, reliable partnerships with diamond turf shoe suppliers?

Start by establishing clear, transparent communication channels and setting mutual expectations early. Focus on building trust through consistent quality, timely delivery, and fair payment practices. Visit suppliers’ facilities when possible, or conduct virtual audits to assess operational standards. Foster ongoing relationships through regular feedback, shared market insights, and collaborative product development. Consider supplier diversification to reduce dependency risks. Long-term partnerships are strengthened by mutual growth, so explore opportunities for volume discounts, joint marketing, or exclusive arrangements that benefit both parties.

Strategic Sourcing Conclusion and Outlook for diamond turf shoes

Conclusion and Future Outlook

Effective strategic sourcing of diamond turf shoes presents a significant opportunity for international B2B buyers to capitalize on emerging market trends and consumer demand. By prioritizing supplier reliability, quality assurance, and cost efficiency, buyers from Africa, South America, the Middle East, and Europe can strengthen their supply chains and gain a competitive edge. Diversifying sourcing channels and establishing strong supplier relationships are crucial steps toward mitigating risks and ensuring consistent product availability.

Looking ahead, technological advancements such as digital procurement platforms and supply chain transparency tools will further streamline sourcing processes and enhance decision-making accuracy. Sustainable and ethically sourced materials are also becoming vital differentiators in the global marketplace, aligning with evolving consumer preferences and regulatory standards.

For B2B buyers in these regions, embracing a proactive, informed approach to strategic sourcing will be essential to navigate fluctuating market conditions and capitalize on new growth opportunities. Now is the time to forge resilient partnerships, leverage innovative sourcing strategies, and position your business for long-term success in the diamond turf shoe industry.