Master Sourcing Authentic Old Money Shoes for International

Guide to Old Money Shoes

- Introduction: Navigating the Global Market for old money shoes

- Understanding old money shoes Types and Variations

- Key Industrial Applications of old money shoes

- Strategic Material Selection Guide for old money shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for old money shoes

- Comprehensive Cost and Pricing Analysis for old money shoes Sourcing

- Spotlight on Potential old money shoes Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for old money shoes

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the old money shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of old money shoes

- Strategic Sourcing Conclusion and Outlook for old money shoes

Introduction: Navigating the Global Market for old money shoes

In the highly competitive and discerning world of luxury footwear, old money shoes have established themselves as a symbol of understated elegance, heritage, and quality. For international B2B buyers—particularly from regions such as Africa, South America, the Middle East, and Europe—understanding the nuances of this niche is crucial to sourcing authentic, high-caliber products that meet the expectations of a sophisticated clientele. As demand for timeless style and craftsmanship grows globally, securing reliable suppliers and understanding market dynamics becomes vital to maintaining a competitive edge.

This comprehensive guide aims to equip you with essential insights into the types of old money shoes, their signature materials, manufacturing standards, and quality control processes. It also explores sourcing strategies, evaluates cost considerations, and identifies key suppliers worldwide. Additionally, it addresses frequently asked questions to clarify common uncertainties faced by international buyers.

By navigating this guide, B2B buyers will be empowered to make informed decisions—whether sourcing from renowned European shoemakers, emerging manufacturers in South America, or established suppliers in the Middle East and Africa. The goal is to streamline your procurement process, mitigate risks, and establish trusted partnerships that uphold the integrity and exclusivity associated with old money shoes. In doing so, you will be better positioned to meet the evolving demands of your high-end clientele and expand your footprint in the global luxury footwear market.

Understanding old money shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Oxford Shoes | Closed lacing system, sleek design, high-quality leather | Luxury retail, corporate gifting, bespoke footwear | Timeless appeal, versatile; higher cost, limited casual use |

| Loafer Shoes | Slip-on design, minimal lacing, often with tassels or penny slots | Executive wear, hospitality, premium retail | Easy to produce at scale, high margin; less formal options may limit audience |

| Derby Shoes | Open lacing system, more relaxed silhouette, often with brogue details | Business casual, high-end casual markets | Flexible styling, good for diverse markets; slightly less formal than Oxfords |

| Monk Strap Shoes | Single or double buckle closure, distinctive strap design | Formal events, luxury boutiques | Unique aesthetic, high perceived value; complex manufacturing may raise costs |

| Balmoral Shoes | Closed lacing, sleek silhouette, minimal embellishments | Formal occasions, executive offices | Classic sophistication, appeals to traditional clientele; limited casual appeal |

Characteristics and Suitability

Classic Oxford Shoes are the epitome of traditional elegance, characterized by their closed lacing system and fine leather craftsmanship. They are highly suitable for luxury retailers targeting high-net-worth individuals and corporate clients seeking timeless, versatile footwear. For B2B buyers, sourcing premium-grade leather and ensuring consistent craftsmanship are critical. Their higher price point demands reliable supply chains and quality assurance, making them ideal for exclusive collections.

Loafer Shoes are distinguished by their slip-on design, offering convenience and a relaxed yet refined look. They are popular in markets emphasizing comfort and style, such as hospitality and executive settings. B2B buyers should focus on scalable manufacturing processes to meet high-volume demands, especially for brands targeting emerging markets where affordability and ease of wear are valued. Their simplicity allows for a broader range of design variations, appealing to diverse customer preferences.

Derby Shoes feature an open lacing system, making them more adaptable and slightly less formal than Oxfords. Their versatility makes them suitable for business casual environments and upscale casual wear. For B2B procurement, sourcing durable yet stylish materials is essential to cater to clients seeking longevity and style. They also serve as a transitional product for markets evolving towards more formal dress codes.

Monk Strap Shoes stand out with their distinctive buckle closure, offering a unique aesthetic that appeals to luxury consumers. Their manufacturing complexity and premium materials justify higher retail prices, making them attractive for high-end boutiques and bespoke shoemakers. B2B buyers should consider supplier expertise and quality control to ensure consistent product excellence, especially when entering markets with discerning clientele.

Balmoral Shoes are characterized by their sleek, minimalistic design with closed lacing, embodying understated elegance. They are ideal for formal occasions and executive settings, especially in European and Middle Eastern markets where tradition and refinement are valued. Sourcing for Balmorals involves attention to fine leather selection and finishing, ensuring they meet the expectations of affluent clients.

B2B Purchasing Considerations

When sourcing old money shoes for international markets, buyers must prioritize quality, craftsmanship, and authentic materials. Understanding regional preferences—such as the preference for traditional styles in Europe or the Middle East—can inform product selection. Establishing relationships with reputable manufacturers or artisans ensures consistency and exclusivity, vital for luxury branding. Additionally, considering scalable production capabilities, customization options, and compliance with local import regulations will facilitate smoother market entry and sustained success.

Key Industrial Applications of old money shoes

| Industry/Sector | Specific Application of old money shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil & Gas | Wellhead and valve sealing using old money shoes | Ensures high-pressure integrity and leak prevention | Material resistance to hydrocarbons, API certification, durability |

| Mining | Heavy machinery and conveyor belt sealing | Enhanced wear resistance and operational longevity | Abrasion resistance, temperature stability, compliance with safety standards |

| Power Generation | Turbine and generator sealing applications | Reduces maintenance downtime, improves efficiency | Thermal stability, compatibility with lubricants, high-pressure tolerance |

| Chemical Processing | Corrosion-resistant sealing in reactors and pipes | Prevents leaks of aggressive chemicals, prolongs equipment lifespan | Chemical compatibility, certification standards, ease of installation |

| Aerospace & Defense | Specialized sealing components for aircraft systems | High reliability, lightweight properties, precision fit | Strict aerospace standards, lightweight materials, high-performance sealing |

Oil & Gas

Old money shoes are critical in the oil and gas sector for sealing wellheads, pipelines, and valves under extreme pressure and corrosive environments. Their robust material properties prevent leaks, ensuring safety and environmental compliance. International B2B buyers from regions like the Middle East and South America require suppliers to meet API standards and provide materials resistant to hydrocarbons and high temperatures. Reliable sourcing ensures operational continuity and reduces costly downtime.

Mining

In mining operations, old money shoes are used to seal heavy machinery and conveyor systems exposed to abrasive materials and harsh conditions. These seals must withstand significant wear and thermal fluctuations. Buyers from Africa and South America prioritize sourcing from manufacturers that offer high abrasion resistance and proven durability, ensuring long-term performance in remote, rugged environments. Proper sourcing minimizes replacement frequency and maintenance costs.

Power Generation

Power plants utilize old money shoes in turbines and generators to maintain high-pressure seals that operate reliably over long periods. The seals contribute to operational efficiency by preventing leaks that can cause outages. International buyers from Europe and the Middle East look for products with thermal stability and compatibility with high-performance lubricants, ensuring seamless integration into existing systems and compliance with industry standards.

Chemical Processing

Chemical plants depend on old money shoes for sealing reactors, pipes, and valves handling aggressive chemicals. These seals must resist corrosion and chemical degradation, maintaining integrity over extended periods. Sourcing considerations include chemical compatibility, certifications (such as FDA or ISO), and ease of installation. Buyers from South America and Africa seek suppliers with proven expertise in chemical-resistant materials to ensure safety and regulatory compliance.

Aerospace & Defense

In aerospace and defense, old money shoes are used in specialized sealing applications where weight, reliability, and precision are paramount. These seals must meet stringent aerospace standards, including lightweight construction and high-performance sealing under extreme conditions. International B2B buyers from Europe and the Middle East prioritize sourcing from certified suppliers capable of delivering high-quality, lightweight components that ensure safety, reliability, and compliance with industry regulations.

Strategic Material Selection Guide for old money shoes

Material Analysis for Old Money Shoes

When selecting materials for old money shoes, B2B buyers must consider not only the aesthetic and performance qualities but also factors such as durability, manufacturing complexity, cost, and compliance with international standards. Below is an in-depth analysis of three common materials—leather, suede, and exotic skins—highlighting their key properties, advantages, limitations, and considerations specific to international markets, particularly Africa, South America, the Middle East, and Europe.

Leather

Leather remains the quintessential material for old money shoes, valued for its timeless appeal and superior durability. It offers excellent breathability, flexibility, and aging characteristics that develop a refined patina over time.

- Key Properties:

- High tensile strength and durability

- Moderate to high flexibility

- Good breathability and moisture regulation

- Can be treated for water resistance

-

Compatibility with various dyes and finishes

-

Pros & Cons:

- Pros: Long-lasting, aesthetically versatile, widely accepted across markets, and can be sourced sustainably with eco-friendly tanning processes.

-

Cons: High manufacturing complexity, especially with premium grades; cost varies significantly based on origin and quality; requires proper maintenance to prevent cracking and drying.

-

Impact on Application:

Leather’s compatibility with various dyes and finishes allows for customization, aligning with the classic, understated luxury associated with old money aesthetics. Its breathability makes it suitable for diverse climates, but in humid regions like parts of Africa and South America, proper treatment is essential to prevent mold and deterioration. -

International Buyer Considerations:

Buyers should prioritize suppliers adhering to international standards such as ASTM or ISO for tanning and processing. Eco-labels and sustainable certifications (e.g., Leather Working Group) are increasingly valued, especially in European markets. In regions like the Middle East, where heat and humidity are prevalent, selecting water-resistant and temperature-resistant leather grades is crucial.

Suede

Suede, a type of leather with a napped finish, offers a softer, more refined look that complements the understated elegance of old money shoes. It is favored for its luxurious texture and aesthetic appeal.

- Key Properties:

- Soft, velvety surface with a nap finish

- Moderate durability compared to full-grain leather

- Sensitive to moisture and staining

-

Requires careful maintenance and protective treatments

-

Pros & Cons:

- Pros: Elegant appearance suitable for formal settings; relatively easier to dye and finish; provides a unique tactile experience.

-

Cons: Less resistant to water, stains, and abrasion; higher maintenance; manufacturing complexity increases with quality control.

-

Impact on Application:

Suede’s sensitivity to environmental factors makes it less ideal for regions with high humidity or dust, common in parts of Africa and South America. Proper sealing and protective coatings are essential for longevity, which can increase costs. -

International Buyer Considerations:

Buyers should ensure suppliers meet standards for environmental safety and quality control, especially for regions with strict import regulations. In Europe, eco-friendly and ethically sourced suede is preferred, while in the Middle East, protective treatments must be compatible with local climate conditions.

Exotic Skins (e.g., Crocodile, Ostrich, Python)

Exotic skins are often used in high-end old money shoes to convey exclusivity and status. They are characterized by distinctive patterns and textures, adding a unique touch to luxury footwear.

- Key Properties:

- Highly durable with specific environmental resistance (varies by species)

- Unique aesthetic with natural patterns

- Requires specialized tanning and finishing processes

-

Often more resistant to water and environmental stress

-

Pros & Cons:

- Pros: Exceptional visual appeal; high market value; long-lasting if properly processed.

-

Cons: High procurement and processing costs; manufacturing complexity; ethical and legal considerations regarding sourcing and trade compliance.

-

Impact on Application:

Exotic skins are suitable for premium, statement pieces. They require careful handling during manufacturing and maintenance, especially in humid or dusty climates typical of Africa and parts of South America. Compliance with CITES and other international trade regulations is mandatory. -

International Buyer Considerations:

Buyers must verify legal sourcing and certification to avoid trade restrictions. Preference should be given to suppliers with transparent supply chains and adherence to ethical standards. In Europe and the Middle East, strict import regulations demand detailed documentation, while in South America, local sourcing can reduce costs but requires rigorous quality assurance.

Summary Table

| Material | Typical Use Case for old money shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather | Classic loafers, oxfords, brogues | Durable, versatile, develops patina over time | High manufacturing complexity, cost varies, maintenance needed | High |

| Suede | Formal shoes with refined aesthetic, loafers | Luxurious appearance, easy to dye, tactile appeal | Sensitive to moisture, stains, requires maintenance | Med |

| Exotic Skins (e.g., Crocodile, Ostrich, Python) | Statement shoes, limited-edition luxury footwear | Unique patterns, high durability, status symbol | High cost, legal and ethical considerations, complex processing | High |

This comprehensive analysis aims to guide international B2B buyers in making informed material choices aligned with their target markets, compliance requirements, and brand positioning. Understanding each material’s properties, advantages, and limitations ensures the selection of optimal materials that uphold the timeless elegance associated with old money shoes across diverse regions.

In-depth Look: Manufacturing Processes and Quality Assurance for old money shoes

Manufacturing Processes for Old Money Shoes

The production of old money shoes is characterized by meticulous craftsmanship, emphasizing high-quality materials and precise techniques. Understanding each stage of the manufacturing process enables B2B buyers to assess supplier capabilities and ensure product consistency.

Material Preparation

The foundation of old money shoes lies in premium materials such as full-grain leather, high-grade suede, and fine linings. Suppliers typically source these from reputable tanneries adhering to international environmental standards (e.g., ISO 14001). Material inspection at this stage involves visual checks for defects, consistency, and moisture content, often supported by lab testing for tensile strength and colorfastness.

Forming and Cutting

Once materials are approved, cutting is performed using either manual templates for bespoke qualities or automated CAD/CAM systems for larger batches. The cutting process must preserve material integrity and minimize waste. Precision in cutting is critical, as it impacts fit and overall aesthetics.

Assembling and Stitching

Assembly involves attaching components such as the upper, lining, insole, and sole. Hand-stitched techniques like Goodyear welt or Blake stitch are preferred for their durability and classic appearance. B2B buyers should verify whether suppliers employ traditional craftsmanship or modern machinery, as this influences quality and authenticity.

Finishing and Detailing

The finishing phase includes polishing, dyeing, and adding decorative elements. Techniques such as burnishing and hand-polishing are hallmarks of old money shoes, emphasizing subtle elegance. Final quality checks focus on symmetry, color uniformity, and surface smoothness.

Quality Assurance (QC) in Manufacturing

Robust quality management is essential to meet international standards and ensure product excellence. For B2B buyers, understanding the QC framework helps in evaluating supplier reliability and compliance.

International Standards Compliance

Most reputable manufacturers operate under ISO 9001 standards, ensuring a systematic approach to quality management. For specific markets, additional certifications may be relevant:

– CE Marking (European Economic Area): Indicates conformity with health, safety, and environmental requirements.

– API Standards (for certain materials or components): Ensure safety and performance, especially for high-end or bespoke shoes.

QC Checkpoints

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival for defects, consistency, and compliance with specifications. This includes visual checks and laboratory testing for physical and chemical properties.

– In-Process Quality Control (IPQC): Continuous monitoring during manufacturing, including stitch integrity, dimensional accuracy, and adherence to craftsmanship standards. Skilled inspectors verify that processes follow documented procedures.

– Final Quality Control (FQC): Before shipment, products undergo comprehensive inspection—visual assessment, measurement verification, and functional testing (e.g., flexibility, sole adhesion).

Testing Methods

– Visual Inspection: Detects surface flaws, stitching errors, and color inconsistencies.

– Dimensional Checks: Ensures precise sizing and fit.

– Material Testing: Uses tensile testing, colorfastness tests, and abrasion resistance evaluations.

– Durability Testing: Simulates wear conditions to assess longevity, especially important for high-end shoes expected to last decades.

Verifying Supplier Quality for International B2B Transactions

For B2B buyers from Africa, South America, the Middle East, and Europe, verifying manufacturing quality is critical to mitigate risks and ensure product standards. Several strategies can be employed:

- Factory Audits: Conduct on-site inspections or hire third-party audit firms familiar with local and international standards. Audits should cover production capacity, quality management systems, working conditions, and compliance documentation.

- Inspection Reports: Request detailed inspection reports, including photographs, test results, and QC logs. These documents should align with international standards and be reviewed by independent experts if possible.

- Third-Party Inspection Services: Engage firms like SGS, Bureau Veritas, or Intertek to perform pre-shipment inspections. These agencies provide unbiased assessments and certify compliance, giving buyers confidence in supplier claims.

- Samples and Prototypes: Before large orders, order samples for detailed evaluation—checking craftsmanship, materials, and finish. This step is vital for high-value transactions and bespoke orders.

- Supplier Certifications: Verify relevant certifications such as ISO 9001, environmental management standards, and market-specific approvals (e.g., CE marking). Authenticity can be confirmed through certification bodies or supplier documentation.

QC Nuances for International B2B Buyers

Different regions have unique expectations and regulatory requirements that influence QC processes:

- Africa and South America: Buyers should prioritize suppliers with documented compliance to international standards and transparent QC procedures. Local regulations may vary, so ensuring supplier awareness of regional requirements is essential.

- Middle East (e.g., UAE): Emphasize certifications related to safety and environmental standards. Suppliers should demonstrate adherence to ISO standards and possess necessary export certifications to facilitate customs clearance.

- Europe (e.g., Colombia): Buyers should verify compliance with EU standards, including CE marking and REACH regulations concerning chemical safety. An emphasis on sustainability and ethical sourcing is also common, necessitating supplier transparency and documentation.

Key Takeaways for B2B Buyers

- Due Diligence: Always verify supplier certifications, conduct or commission audits, and review QC reports before engagement.

- Standards Alignment: Ensure manufacturing processes align with recognized international standards, reducing compliance risks.

- Sample Validation: Use samples to assess craftsmanship, materials, and finish quality, especially for bespoke or high-value orders.

- Ongoing Monitoring: Establish regular QC checkpoints, especially for large or long-term orders, to maintain consistent quality over time.

- Leverage Third-Party Inspections: Employ independent agencies for unbiased verification, crucial for cross-border transactions and diverse regulatory environments.

By understanding these manufacturing and quality assurance intricacies, B2B buyers can confidently establish reliable supply partnerships, ensuring the delivery of authentic, durable, and high-quality old money shoes to their markets worldwide.

Comprehensive Cost and Pricing Analysis for old money shoes Sourcing

Cost Components in Old Money Shoes Sourcing

Understanding the detailed cost structure is essential for international B2B buyers aiming to optimize procurement strategies. The primary cost components include:

-

Materials: High-quality leathers, suedes, and premium textiles define the luxury aesthetic of old money shoes. Material costs vary significantly based on origin, grade, and sourcing volume. European tanneries, for example, often charge a premium but provide consistent quality, while emerging suppliers from South America or Africa may offer more competitive rates with similar standards.

-

Labor: Skilled craftsmanship is critical, especially for bespoke or handcrafted models. Labor costs differ by country—European and Middle Eastern workshops tend to have higher wages but also higher standards of craftsmanship, whereas factories in South America or Africa may offer cost advantages but require rigorous quality control oversight.

-

Manufacturing Overhead: This encompasses facility costs, machinery depreciation, and operational expenses. Efficient factories with modern equipment tend to have lower overhead per unit, influencing the overall price.

-

Tooling and Development: Initial tooling costs can be substantial, especially for custom designs or limited editions. These are often amortized over production runs, so larger volumes reduce per-unit costs.

-

Quality Control (QC): Ensuring consistent craftsmanship and material standards is vital for maintaining brand reputation. QC costs are higher for intricate designs or when sourcing from less established suppliers but are non-negotiable for luxury footwear.

-

Logistics and Customs: Shipping costs depend on origin-destination pairs, shipment volume, and chosen Incoterms. Customs duties and taxes vary widely; for example, importing into the UAE may involve different tariffs compared to Colombia or European countries.

-

Profit Margin: Markup percentages depend on brand positioning, exclusivity, and target markets. Typically, margins range from 20% to 50% for luxury footwear, but this can fluctuate based on volume discounts and negotiation.

Price Influencers and Their Impact

Several factors significantly influence the final sourcing price of old money shoes:

-

Order Volume & MOQ: Larger orders benefit from economies of scale, reducing per-unit costs. Many suppliers offer discounts for MOQs above 500 pairs, though this varies depending on supplier capacity and product complexity.

-

Specifications & Customization: Tailored designs, bespoke finishes, or specific material requests increase costs due to additional labor and tooling. Buyers should balance customization needs with cost implications.

-

Material Choices: Premium leathers and rare textiles elevate costs but also enhance perceived value. Sourcing from regions with established leather industries (e.g., Italy, France) can offer authenticity but at a premium.

-

Quality Certifications: Certifications like ISO or leather sustainability labels can influence pricing, especially for buyers targeting eco-conscious markets. Suppliers with certified quality processes often charge a premium but provide added assurance.

-

Supplier Factors: Supplier reputation, production capacity, and reliability impact costs. Established suppliers with a track record of luxury craftsmanship might command higher prices but offer better consistency.

-

Incoterms & Logistics: FOB (Free On Board) prices are common, shifting shipping responsibilities to the buyer, which can reduce upfront costs but introduce logistical complexity. DDP (Delivered Duty Paid) simplifies importation but typically increases the price due to added logistics and duties.

Actionable Tips for International B2B Buyers

-

Negotiate for Volume Discounts: Focus on building long-term relationships to unlock better pricing tiers, especially when ordering above MOQ thresholds.

-

Assess Total Cost of Ownership (TCO): Beyond unit price, consider shipping, customs duties, potential tariffs, and QC costs. For example, importing into the UAE may involve minimal duties, whereas Colombia might impose higher tariffs, affecting overall profitability.

-

Leverage Incoterms Strategically: FOB terms can reduce initial costs but require in-house logistics expertise. DDP offers convenience but at a premium—balance these options based on your logistical capacity.

-

Prioritize Quality & Certification: Investing in suppliers with recognized quality standards may initially cost more but reduces risk and rework costs, especially critical in luxury segments.

-

Factor in Lead Times & Flexibility: Customization and tooling lead times can impact costs. Plan orders well in advance to avoid expedited shipping charges or rushed manufacturing premiums.

-

Understand Market Nuances: Pricing can vary due to regional economic factors, currency fluctuations, and local supplier competition. Regular market analysis and supplier benchmarking are advisable.

Disclaimer

Prices for old money shoes sourcing are highly variable based on design complexity, order volume, supplier location, and market conditions. Indicative unit costs can range from $50 to $150 for standard models at larger volumes, with bespoke or highly customized products potentially exceeding $200 per pair. Always conduct specific supplier negotiations and request detailed quotes to obtain accurate pricing tailored to your needs.

Spotlight on Potential old money shoes Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for old money shoes.)*

Essential Technical Properties and Trade Terminology for old money shoes

Critical Technical Properties

1. Material Grade and Quality Standards

High-quality old money shoes typically utilize premium leathers such as full-grain or top-grain leather. These materials are valued for their durability, aesthetic appeal, and aging properties. For B2B buyers, specifying material grade ensures consistency and meets the expectations of luxury clientele. Suppliers often adhere to recognized standards like the Leather Working Group (LWG) certification, which indicates responsible sourcing and processing.

2. Sole Composition and Construction

The sole’s material—whether leather, rubber, or a combination—affects durability and comfort. Old money shoes often feature leather soles with detailed craftsmanship, sometimes reinforced with cork or rubber inserts for longevity. Precise specifications regarding sole thickness, stitch density, and attachment method (e.g., Goodyear welt or Blake stitch) are critical for quality assurance and pricing.

3. Tolerance Levels and Fit Precision

Manufacturers maintain strict tolerance levels in sizing and finishing to ensure that shoes fit perfectly and maintain a consistent appearance across batches. Typical tolerances might be within ±0.5 mm for length and width. These specifications directly impact customer satisfaction and reduce returns or exchanges, making tight control over tolerances essential.

4. Stitching and Finish Quality

The craftsmanship of stitching—such as double-stitched or hand-stitched details—reflects the shoe’s luxury status. Specifications include stitch count per inch, thread type, and tension. High-quality stitching enhances durability and aesthetic appeal, which are non-negotiable for old money style shoes.

5. Color and Finish Consistency

Color uniformity and finishing techniques, such as burnishing or polishing, are crucial for luxury branding. Suppliers should provide detailed color codes (e.g., Pantone or custom matches) and finishing standards to ensure the shoes meet aesthetic expectations across production runs.

Key Trade Terms

1. OEM (Original Equipment Manufacturer)

Refers to companies that produce shoes or components based on the buyer’s specifications and branding. Understanding OEM capabilities helps B2B buyers evaluate manufacturing flexibility, customization options, and lead times, especially when sourcing bespoke or signature styles.

2. MOQ (Minimum Order Quantity)

The smallest quantity a supplier agrees to produce in a single batch. For luxury shoes, MOQs can vary significantly, often influenced by material costs and craftsmanship complexity. Clear MOQs help buyers plan inventory and negotiate pricing effectively.

3. RFQ (Request for Quotation)

A formal process where buyers solicit detailed price proposals from suppliers. An RFQ typically includes specifications, quality standards, and delivery timelines. Mastering RFQ procedures ensures competitive pricing and clear communication of technical requirements.

4. Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and tariffs. Common Incoterms like FOB (Free On Board) and CIF (Cost, Insurance, and Freight) influence cost structure and risk management. Familiarity with Incoterms helps buyers optimize logistics and budget planning.

5. Lead Time and Production Schedule

The duration from order placement to delivery. For high-end shoes, lead times can range from several weeks to months depending on complexity. Accurate understanding of production schedules allows buyers to align inventory planning with market demand, especially for seasonal collections.

6. Quality Certification and Compliance Standards

Certifications such as ISO, ethical sourcing (e.g., Leather Working Group), and country-specific regulations (e.g., REACH in Europe) verify product authenticity and sustainability. These standards are vital for maintaining brand integrity and meeting regional legal requirements.

By understanding these technical properties and trade terminologies, B2B buyers from Africa, South America, the Middle East, and Europe can make informed decisions, negotiate effectively, and ensure their supply chain aligns with the luxury standards expected of old money shoes.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the old money shoes Sector

Market Overview & Key Trends

The global market for ‘old money shoes’—luxury, heritage-inspired footwear—continues to evolve under the influence of shifting consumer preferences, technological advancements, and supply chain innovations. Key drivers include a sustained demand for artisanal craftsmanship, exclusivity, and timeless design, particularly among affluent consumers in Europe, the Middle East, and parts of South America. These markets value authenticity and heritage, making them crucial for B2B buyers seeking premium sourcing partners.

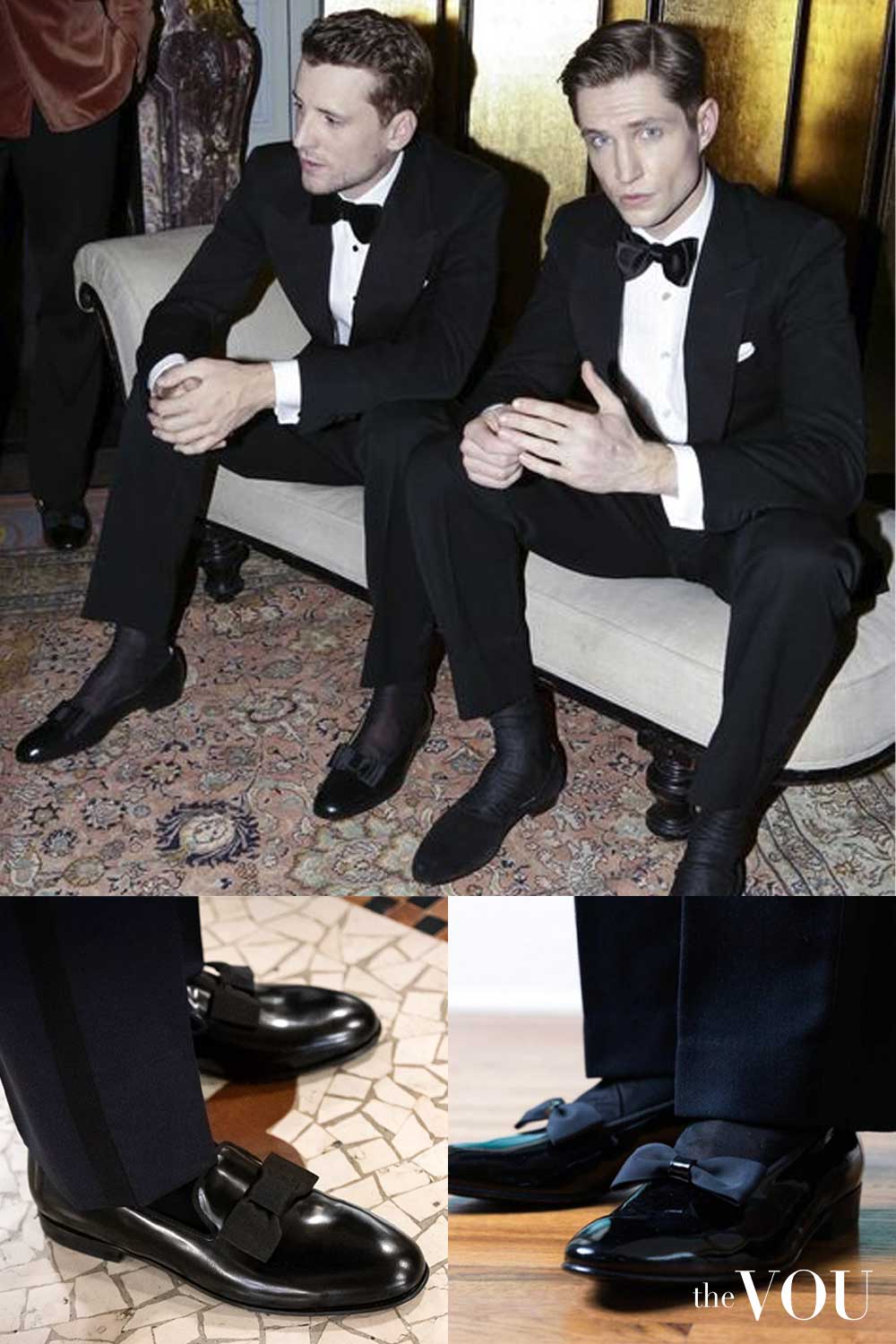

Illustrative Image (Source: Google Search)

Emerging trends emphasize digital transformation, with B2B platforms streamlining procurement processes and enhancing transparency. Advanced sourcing tools such as blockchain for traceability and AI-driven demand forecasting are becoming commonplace, enabling buyers from Africa, South America, and the Middle East to access real-time data and optimize inventory management. Sustainability initiatives are increasingly integrated into sourcing strategies, driven by consumer demand and regulatory pressures.

Illustrative Image (Source: Google Search)

Market dynamics are also shaped by geopolitical factors, trade agreements, and tariffs, which influence sourcing costs and logistics. For instance, European manufacturers often have established supply chains rooted in traditional craftsmanship, but rising raw material costs necessitate diversification. African and South American suppliers are gaining traction by offering unique, high-quality leathers and eco-friendly materials, aligning with global sustainability trends.

For international B2B buyers, especially from emerging markets like the UAE or Colombia, establishing strong partnerships with reputable manufacturers is vital. Leveraging regional trade agreements and local expertise can facilitate smoother logistics and better pricing. Staying attuned to innovations in sustainable sourcing and embracing digital procurement tools will be critical for maintaining competitive advantage in this niche sector.

Sustainability & Ethical Sourcing in B2B

Sustainability and ethical sourcing are increasingly non-negotiable in the ‘old money shoes’ sector. Consumers and regulators alike demand transparency across the supply chain, emphasizing environmental responsibility and fair labor practices. For B2B buyers, integrating sustainable practices can unlock access to premium markets and enhance brand reputation.

Environmental impact mitigation involves sourcing eco-friendly materials such as vegetable-tanned leathers, recycled textiles, and biodegradable packaging. Certifications like Forest Stewardship Council (FSC), Global Organic Textile Standard (GOTS), and Leather Working Group (LWG) are critical benchmarks that authenticate sustainable sourcing claims. These certifications not only ensure compliance but also serve as trust signals to end consumers.

Ethical considerations extend beyond materials to encompass fair labor practices and community engagement. Partnering with suppliers committed to fair wages, safe working conditions, and local community development can differentiate a brand in a crowded marketplace. B2B buyers should prioritize suppliers with transparent audits and third-party certifications, fostering long-term, responsible relationships.

Adopting ‘green’ practices can also lead to operational efficiencies—reducing waste, energy use, and carbon footprint—ultimately lowering costs. Digital traceability platforms enable buyers to verify ethical claims and monitor supply chain sustainability in real-time. For buyers from regions like Africa and South America, working with certified suppliers can open access to eco-conscious markets and align their sourcing strategies with global sustainability standards.

Illustrative Image (Source: Google Search)

Brief Evolution/History (Optional)

The heritage of ‘old money shoes’ is rooted in European craftsmanship traditions dating back centuries, characterized by meticulous handwork, premium materials, and understated elegance. Historically, these shoes symbolized social status and exclusivity, often crafted by family-owned ateliers and bespoke shoemakers.

In recent decades, the sector has seen a shift from purely bespoke production to a blend of artisanal techniques and modern manufacturing technologies. This evolution has expanded accessibility while maintaining the sector’s heritage appeal. Digital innovations, such as 3D modeling and automated cutting, have improved efficiency without compromising craftsmanship.

For B2B buyers, understanding this history underscores the importance of sourcing from authentic, heritage-driven suppliers who uphold traditional techniques while integrating sustainable and technological advancements. This blend of history and innovation offers a compelling value proposition for markets seeking both authenticity and modernity in luxury footwear.

Frequently Asked Questions (FAQs) for B2B Buyers of old money shoes

1. How can I effectively vet suppliers of old money shoes to ensure quality and authenticity?

To vet suppliers effectively, start by requesting comprehensive documentation such as company registration, export licenses, and quality certifications (e.g., ISO, leather authenticity certificates). Review their portfolio, client references, and industry reputation through trade platforms or B2B marketplaces like Alibaba or Global Sources. Conduct virtual or on-site audits if possible, and request samples before placing large orders. Additionally, verify their compliance with international standards and inquire about their sourcing and manufacturing processes to ensure consistency and authenticity. Building a relationship with trusted intermediaries or sourcing agents in the supplier’s region can also mitigate risks.

2. What customization options are typically available for old money shoes, and how do they impact lead times?

Most suppliers offer customization in areas such as leather color, sole design, branding (logos, monograms), and packaging. Advanced customization like unique stitching or bespoke sizing may require additional lead time. Standard lead times for customized orders generally range from 4 to 8 weeks, but complex designs or large volumes can extend this period. To manage expectations, clearly define your specifications upfront and request a detailed production timeline. Establishing a clear communication channel with the supplier helps ensure timely updates and adjustments, minimizing delays and aligning production schedules with your market demands.

3. What are typical MOQs, lead times, and payment terms for bulk orders of old money shoes?

Minimum Order Quantities (MOQs) for old money shoes often range from 200 to 1,000 pairs, depending on the manufacturer and customization level. Lead times typically span 6 to 12 weeks, influenced by order complexity, supplier capacity, and shipping logistics. Payment terms vary but commonly include 30% upfront deposit with the balance paid before shipment or upon delivery. Some suppliers may offer flexible terms for repeat buyers or large-volume orders. Negotiating payment terms and MOQs upfront can help optimize cash flow and ensure production aligns with your inventory planning.

4. What quality assurance measures and certifications should I look for in suppliers?

Reliable suppliers should provide quality assurance documentation such as third-party inspection reports, leather authenticity certificates, and compliance with safety standards (e.g., REACH, ISO). Request detailed product specifications, sample approvals, and quality control procedures like pre-shipment inspections or third-party audits. Certifications like Leather Working Group (LWG) or environmental compliance attest to sustainable practices. Establish clear quality benchmarks in your purchase agreement and consider engaging third-party inspection services during production and before shipment to minimize defects and ensure product consistency.

5. How can I efficiently manage logistics and shipping for international orders of old money shoes?

Effective logistics management involves selecting reliable freight forwarders experienced in international shipments, especially to your region. Consider options like sea freight for bulk orders to reduce costs or air freight for faster delivery. Collaborate with suppliers to understand shipping timelines and customs documentation requirements, including commercial invoices, packing lists, and certificates of origin. Work with customs brokers to facilitate smooth clearance and avoid delays. Establish tracking systems to monitor shipments in real-time and plan inventory replenishments accordingly. Building strong logistics partnerships minimizes disruptions and ensures timely delivery to your distribution channels.

6. How should I handle disputes related to quality, delivery, or payment with international suppliers?

Disputes should be addressed promptly through clear contractual clauses specifying resolution procedures. Always include detailed terms on quality standards, delivery timelines, and payment conditions. If issues arise, document discrepancies with photographs, inspection reports, and communication records. Engage in direct negotiations first, aiming for amicable solutions like replacements or partial refunds. If unresolved, consider arbitration or mediation in neutral jurisdictions, as stipulated in your contract, to avoid costly litigation. Maintaining professional communication and thorough documentation helps safeguard your interests and facilitates swift resolution.

7. What legal and compliance considerations should I be aware of when importing old money shoes internationally?

Ensure compliance with both your country’s import regulations and the supplier’s export standards. Verify the product’s compliance with safety, environmental, and labor laws, including restrictions on hazardous materials like certain dyes or glues. Obtain necessary import permits, tariffs, and customs declarations to avoid delays or penalties. Use Incoterms to clearly define responsibilities for shipping, insurance, and customs clearance. Staying informed about trade agreements or sanctions affecting your region can prevent legal complications. Consulting with legal or trade compliance experts can streamline the import process and mitigate risks.

8. What are best practices for building long-term relationships with international suppliers of old money shoes?

Building long-term partnerships relies on consistent communication, transparency, and mutual trust. Start with small, manageable orders to evaluate reliability and quality before scaling up. Regularly visit suppliers or conduct virtual meetings to discuss production, innovations, and feedback. Promptly address issues or concerns to demonstrate professionalism. Consider long-term contracts with favorable terms or volume discounts to incentivize supplier commitment. Keeping abreast of market trends and providing feedback fosters collaboration. Developing personal relationships with key decision-makers in the supplier company can enhance loyalty, improve negotiation leverage, and ensure priority treatment during peak demand periods.

Strategic Sourcing Conclusion and Outlook for old money shoes

Strategic Sourcing Conclusion and Outlook for old money shoes

Effective strategic sourcing is essential for B2B buyers seeking to capitalize on the timeless appeal and premium quality of old money shoes. By establishing relationships with reputable, sustainable manufacturers—particularly in Italy, Portugal, and other key production hubs—buyers can ensure authenticity, craftsmanship, and consistent supply. Diversifying sourcing channels and prioritizing suppliers with transparent practices will mitigate risks and enhance brand reputation across markets.

For international buyers in Africa, South America, the Middle East, and Europe, understanding regional market nuances and leveraging local trade networks can unlock competitive advantages. Emphasizing quality assurance, ethical sourcing, and flexible logistics will position your offerings favorably in discerning markets such as the UAE, Colombia, and beyond.

Looking ahead, the demand for luxury and heritage footwear is expected to grow, driven by rising affluence and a global appreciation for craftsmanship. Strategic sourcing today not only secures access to premium products but also builds resilient supply chains capable of adapting to evolving market dynamics. Actively engaging with trusted suppliers and embracing innovation will enable you to meet the rising expectations of your clients and secure a sustainable competitive edge.