Master Sourcing Dolce & Gabbana Shoes for Global Markets:

Guide to Dolce & Gabbana Shoes

- Introduction: Navigating the Global Market for dolce & gabbana shoes

- Understanding dolce & gabbana shoes Types and Variations

- Key Industrial Applications of dolce & gabbana shoes

- Strategic Material Selection Guide for dolce & gabbana shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for dolce & gabbana shoes

- Comprehensive Cost and Pricing Analysis for dolce & gabbana shoes Sourcing

- Spotlight on Potential dolce & gabbana shoes Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for dolce & gabbana shoes

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the dolce & gabbana shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of dolce & gabbana shoes

- Strategic Sourcing Conclusion and Outlook for dolce & gabbana shoes

Introduction: Navigating the Global Market for dolce & gabbana shoes

In the highly competitive luxury footwear industry, Dolce & Gabbana shoes stand out as a symbol of Italian craftsmanship, exclusivity, and trendsetting design. For international B2B buyers, understanding the nuances of sourcing these iconic products is crucial to gaining a competitive edge in diverse markets such as Africa, South America, the Middle East, and Europe. Whether you are looking to import boutique collections, expand retail offerings, or develop private label lines, a strategic approach to sourcing Dolce & Gabbana shoes can unlock significant growth opportunities.

This comprehensive guide offers a detailed overview of the key aspects essential for successful B2B engagement. It covers the various types of Dolce & Gabbana footwear—from classic leather loafers to limited-edition sneakers—highlighting the premium materials and craftsmanship involved. Additionally, it provides insights into manufacturing standards, quality control processes, and reliable supplier networks to ensure authenticity and consistency.

Furthermore, the guide explores cost considerations, market trends, and regional import regulations, empowering buyers to make informed, cost-effective purchasing decisions. It also addresses frequently asked questions, helping buyers navigate potential challenges in sourcing luxury footwear globally. By leveraging this knowledge, B2B buyers from Africa, South America, the Middle East, and Europe can establish sustainable partnerships, optimize procurement strategies, and confidently position Dolce & Gabbana shoes within their local markets.

Understanding dolce & gabbana shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Leather Loafers | Smooth leather finish, slip-on design, minimal embellishments | Luxury retail, boutique stores | Pros: High demand, versatile, timeless appeal. Cons: Seasonal demand fluctuations, premium pricing. |

| Elegant Pumps | High heel, pointed toe, often adorned with embellishments or branding | High-end boutiques, department stores | Pros: High margin potential, strong brand association. Cons: Limited to formal or fashion-forward segments. |

| Casual Sneakers | Sporty design, comfort-focused, often with D&G branding or patterns | Lifestyle retail, online marketplaces | Pros: Growing global demand, broad consumer base. Cons: Price competition, need for consistent quality control. |

| Sandals & Espadrilles | Open-toe, lightweight, often featuring summer motifs or embellishments | Resort wear, seasonal collections | Pros: Seasonal demand, good for bulk seasonal orders. Cons: Limited year-round sales, seasonal inventory management. |

| Boots & Ankle Boots | Varied materials, often with bold design elements or embellishments | Fall/Winter collections, luxury segments | Pros: High-end appeal, extended seasonal sales. Cons: Higher manufacturing costs, size-specific inventory considerations. |

Classic Leather Loafers

Dolce & Gabbana’s leather loafers epitomize timeless luxury with their sleek, slip-on design and high-quality craftsmanship. They are highly versatile, suitable for both formal and casual settings, making them a staple in luxury retail inventories. For B2B buyers, sourcing these requires attention to authentic leather sourcing, consistent quality, and reliable supply chains to meet seasonal demand fluctuations. Pricing tends to be premium, but the high perceived value can justify healthy profit margins. They are ideal for markets with a strong affinity for classic luxury, such as Europe and affluent Middle Eastern regions.

Elegant Pumps

D&G’s elegant pumps feature high heels, often with pointed toes and intricate embellishments, aligning with high fashion trends. They are primarily suited for luxury boutiques and department stores targeting premium consumers. Buyers should prioritize authentic sourcing channels, as counterfeit issues can impact brand reputation. The margin potential is significant, especially when offering limited editions or exclusive designs. However, these shoes cater mainly to formal or fashion-conscious segments, so market analysis is essential to avoid overstocking in regions with less demand for high-end footwear.

Casual Sneakers

The brand’s sneakers blend sporty comfort with luxury aesthetics, often incorporating signature patterns or embellishments. They appeal broadly across age groups and are increasingly popular in online retail channels. For B2B buyers, ensuring consistent quality and authentic branding is crucial to maintain consumer trust. The global surge in athleisure and casual luxury makes these sneakers a lucrative product line, especially in markets like South America and Africa where casual fashion is rapidly growing. Competitive pricing and effective marketing are key to capturing market share.

Sandals & Espadrilles

D&G’s sandals and espadrilles emphasize summer fashion, often featuring bold motifs, embellishments, and lightweight materials. They are particularly suitable for resort wear, seasonal collections, and markets with warm climates. For bulk purchasing, buyers should consider seasonal inventory planning, as these shoes see peak demand during spring and summer. They offer good margins in high-end markets but require careful quality control to meet brand standards. These shoes are ideal for expanding product lines in Mediterranean, Middle Eastern, and South American markets, where summer fashion is prominent.

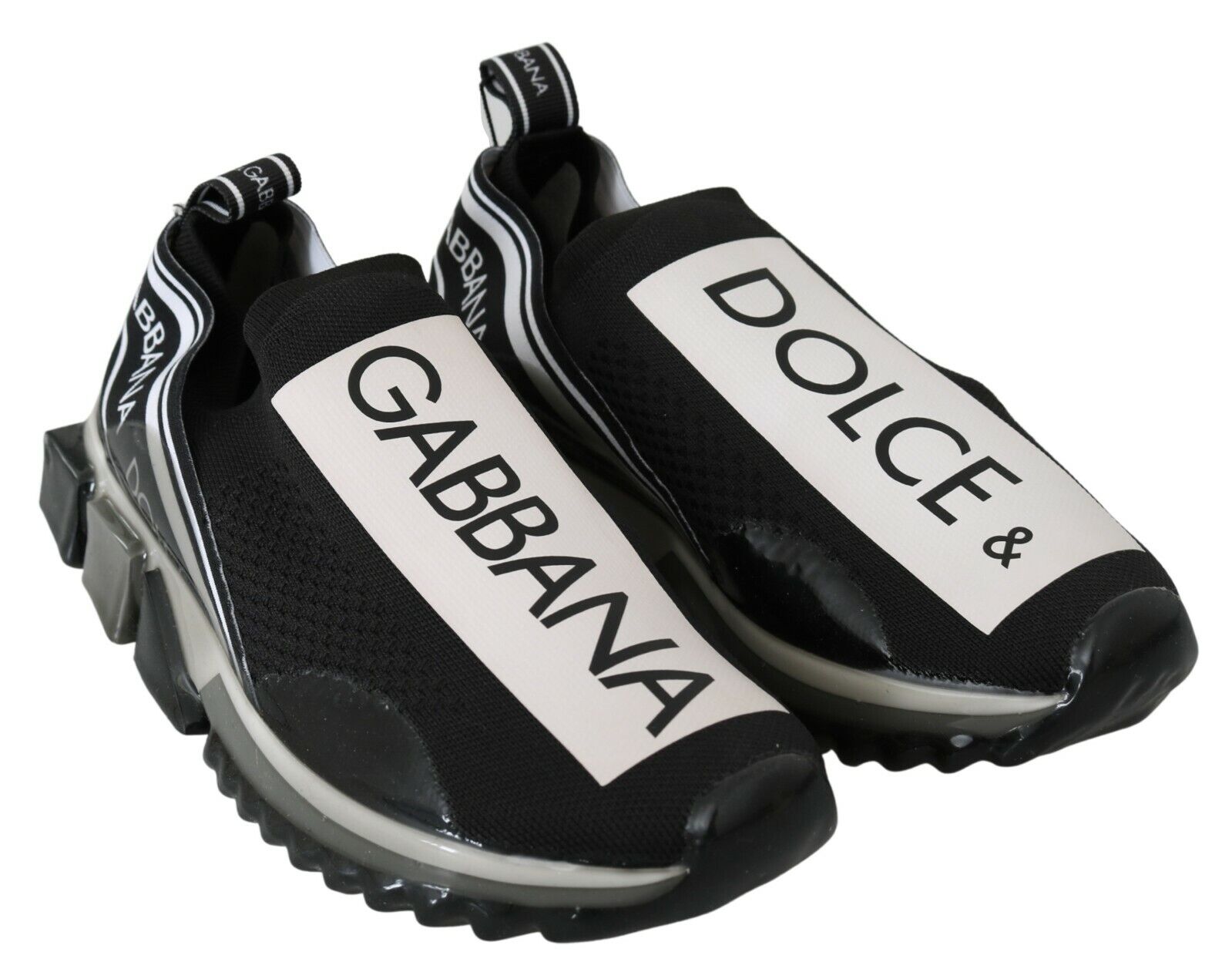

Illustrative Image (Source: Google Search)

Boots & Ankle Boots

Boots from Dolce & Gabbana showcase bold designs, luxurious materials, and intricate detailing. They are essential for fall and winter collections, appealing to consumers seeking statement footwear. B2B buyers should focus on sourcing high-quality materials and understanding regional seasonal trends to optimize inventory. The extended sales window and high-end appeal can justify higher markups, but manufacturing costs and inventory risks are higher due to size and style variations. These shoes are especially attractive in European and Middle Eastern markets with distinct seasonal shifts and demand for luxury winter footwear.

Key Industrial Applications of dolce & gabbana shoes

| Industry/Sector | Specific Application of Dolce & Gabbana Shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Luxury Fashion & Retail | Premium product offerings for high-end boutiques and flagship stores | Enhances brand prestige, attracts affluent clientele, boosts sales | Authenticity verification, supply chain transparency, luxury packaging standards |

| Hospitality & Luxury Hotels | Exclusive guest amenities and staff uniforms featuring designer footwear | Elevates guest experience, reinforces luxury branding, differentiates services | Consistent quality control, sourcing from reputable suppliers, customization options |

| Entertainment & Events | Celebrity endorsements, fashion shows, and exclusive event footwear | Increases brand visibility, drives demand through aspirational marketing | Timely delivery, flexible order quantities, collaboration with fashion stylists |

| Corporate & Business Gifts | Customized Dolce & Gabbana shoes as premium corporate gifts | Strengthens corporate relationships, enhances brand image | Customization capabilities, lead time management, bulk order discounts |

| E-commerce & Wholesale Distribution | Distribution through online luxury platforms and specialty retailers | Expands market reach, facilitates international sales, boosts margins | Authentic product sourcing, compliance with import/export regulations, secure logistics |

Luxury Fashion & Retail

Dolce & Gabbana shoes serve as a cornerstone for luxury fashion brands aiming to elevate their product lines. For B2B buyers, sourcing authentic, high-quality footwear is essential to meet the expectations of affluent consumers across Africa, South America, the Middle East, and Europe. These shoes can be showcased in flagship stores or high-end boutiques, attracting a clientele seeking exclusivity and craftsmanship. Ensuring the authenticity of products and maintaining supply chain transparency are critical to uphold brand integrity and avoid counterfeit risks in international markets.

Hospitality & Luxury Hotels

Luxury hotels and resorts frequently incorporate Dolce & Gabbana shoes into their guest amenities and staff uniforms to reinforce their premium positioning. For international B2B buyers, especially in regions like the Middle East and Europe, sourcing genuine designer footwear can significantly enhance guest experiences and operational branding. It’s vital to establish reliable supply channels that ensure consistent quality and timely delivery, while also exploring options for customization to align with specific branding or regional preferences.

Entertainment & Events

Fashion shows, celebrity endorsements, and exclusive events often feature Dolce & Gabbana shoes to maximize visibility and aspirational appeal. B2B buyers involved in event management or celebrity styling should focus on sourcing shoes that meet strict delivery deadlines and can be customized for specific themes or personalities. Collaborations with fashion stylists and event organizers require flexible order quantities and swift logistics to capitalize on marketing opportunities across diverse markets, including the Middle East and South America.

Corporate & Business Gifts

Offering Dolce & Gabbana shoes as premium corporate gifts can significantly strengthen business relationships and enhance brand prestige. B2B buyers such as corporate gifting agencies or large multinationals in Africa and Europe should prioritize sourcing authentic, customizable options with reliable lead times. Bulk purchasing agreements and customization capabilities allow for tailored branding, making these shoes a memorable token that aligns with corporate identity and regional tastes.

E-commerce & Wholesale Distribution

The rise of online luxury platforms and specialty retailers has expanded the reach of Dolce & Gabbana shoes into global markets. International B2B buyers can leverage this channel to grow their market share in regions like South America, Africa, and the Middle East. Ensuring authentic product sourcing, compliance with import/export regulations, and secure logistics are essential to build consumer trust and maintain brand reputation. Partnering with reputable distributors and leveraging local market insights can optimize sales and margins across diverse territories.

Strategic Material Selection Guide for dolce & gabbana shoes

Analysis of Common Materials for Dolce & Gabbana Shoes

When selecting materials for luxury footwear such as Dolce & Gabbana shoes, B2B buyers must consider not only aesthetic qualities but also performance, durability, and compliance with international standards. Below is an analysis of four prevalent materials used in high-end shoe manufacturing, emphasizing their properties, advantages, limitations, and considerations for global markets.

Leather (Full-Grain and Top-Grain)

Key Properties:

Leather remains the most traditional and preferred material for luxury shoes due to its excellent breathability, flexibility, and aesthetic appeal. Full-grain leather offers superior durability and develops a unique patina over time, while top-grain leather provides a smoother surface with enhanced uniformity. Leather’s natural properties enable it to conform to the foot’s shape, ensuring comfort.

Pros & Cons:

Leather’s primary advantage lies in its durability and luxurious appearance, making it highly desirable for high-end brands. It is also biodegradable, aligning with eco-conscious trends. However, leather production involves significant resource use, and quality can vary based on tanning processes. High-grade leather is expensive, and sourcing consistent quality can be challenging for international buyers.

Impact on Application:

Leather’s permeability makes it suitable for shoes intended for indoor or moderate climate use. However, in extremely humid or wet environments, untreated leather may degrade unless properly treated or coated.

International Buyer Considerations:

Compliance with environmental standards such as REACH (Europe) or EPA regulations (U.S.) is crucial. Buyers from Africa, South America, and the Middle East should verify that suppliers adhere to sustainable tanning practices to meet local import standards. Additionally, certifications like ISO 9001 for quality management can facilitate smoother customs clearance.

Patent and Synthetic Materials

Key Properties:

Patent leather and synthetic alternatives are characterized by their glossy finish and uniform appearance. Patent leather is typically coated with a high-gloss lacquer, while synthetics are made from various polymers such as polyurethane (PU) or polyvinyl chloride (PVC). These materials are lightweight, water-resistant, and easy to clean.

Pros & Cons:

The main advantage is cost-effectiveness and consistent appearance, reducing manufacturing complexity. They also provide excellent water resistance, making them suitable for outdoor or humid climates. However, synthetic materials tend to be less breathable, which can impact comfort over prolonged wear. They may also be less durable over time, especially if exposed to harsh conditions.

Impact on Application:

Ideal for fashion-forward designs requiring high gloss or vibrant colors. Not suitable for environments demanding high breathability or extreme durability, such as rugged outdoor use.

International Buyer Considerations:

Regulatory standards for synthetic materials vary globally. Buyers should ensure compliance with local chemical safety regulations, such as the EU’s REACH or South American standards. Sourcing from manufacturers with ISO 14001 environmental certifications can mitigate risks associated with chemical emissions and waste management.

Rubber and Thermoplastic Elastomers (TPE)

Key Properties:

Rubber and TPE are flexible, resilient materials often used for soles and decorative elements. They exhibit excellent shock absorption, grip, and weather resistance. TPEs can be formulated to mimic natural rubber or leather-like textures.

Pros & Cons:

These materials are highly durable and resistant to abrasion, making them ideal for soles. They are also lightweight and cost-effective. Conversely, their appearance may be less refined compared to leather, limiting their use to specific shoe components rather than entire upper structures.

Impact on Application:

Perfect for outsole construction, especially in casual or athletic-inspired luxury shoes. Their resistance to environmental factors makes them suitable for diverse climates, including the Middle East and tropical regions.

International Buyer Considerations:

Buyers should verify that TPE and rubber components comply with local standards such as ASTM or JIS. Additionally, sourcing from suppliers with environmentally friendly manufacturing processes can help meet regional sustainability expectations, particularly in Europe and Australia.

Summary Table

| Material | Typical Use Case for dolce & gabbana shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather (Full/Top Grain) | Upper, lining, and decorative elements | Luxurious appearance, durability, breathability | High cost, resource-intensive production, variability | High |

| Patent and Synthetic Materials | Fashion accents, glossy finishes, linings | Cost-effective, water-resistant, uniform look | Less breathable, lower durability over time | Low to Med |

| Rubber and TPE | Outsoles, decorative accents | Resilient, weather-resistant, shock absorption | Less refined appearance, limited to specific parts | Med |

This comprehensive understanding of material properties and market considerations enables international B2B buyers from Africa, South America, the Middle East, and Europe to make informed sourcing decisions. Prioritizing compliance, sustainability, and quality consistency will ensure that Dolce & Gabbana shoes meet both brand standards and regional market expectations.

In-depth Look: Manufacturing Processes and Quality Assurance for dolce & gabbana shoes

Manufacturing Processes of Dolce & Gabbana Shoes

The manufacturing of Dolce & Gabbana shoes exemplifies a meticulous blend of craftsmanship and advanced production techniques, emphasizing luxury, durability, and aesthetic appeal. The process typically unfolds through several key stages:

-

Material Preparation

– High-quality raw materials such as fine leathers, exotic skins, textiles, and embellishments are sourced globally, often from specialized suppliers.

– Raw materials undergo rigorous inspection for authenticity, quality, and compliance with safety standards, including tests for contaminants and durability.

– Tanning and finishing processes are employed to enhance leather properties, involving techniques like vegetable tanning or chrome tanning, depending on the design requirements. -

Forming and Cutting

– Precise patterning is achieved through computer-aided design (CAD) systems, enabling consistent replication of complex shoe shapes.

– Cutting is performed via automated or manual methods, with laser cutting increasingly common for intricate details, ensuring minimal waste and high precision.

– Skilled artisans may also manually cut and shape materials for bespoke or limited-edition lines, emphasizing craftsmanship. -

Assembly and Construction

– Components such as uppers, insoles, outsoles, and linings are assembled through a combination of hand-stitching, machine sewing, and adhesive bonding.

– Techniques like Goodyear welt, Blake stitch, or cementing are selected based on the shoe style and durability requirements.

– The assembly process often involves multiple quality checkpoints to ensure alignment, stitching integrity, and proper bonding. -

Finishing and Detailing

– Final touches include polishing, painting, embossing, and adding embellishments, with artisans paying attention to details such as stitching, hardware placement, and surface finish.

– Quality control at this stage involves inspecting for surface imperfections, color consistency, and adherence to design specifications.

Quality Assurance Standards and Protocols

Dolce & Gabbana’s manufacturing process adheres to stringent quality management systems to meet both internal standards and international compliance requirements, ensuring the final product’s excellence.

International Standards

– ISO 9001 Certification:

– Most authorized manufacturers operate under ISO 9001, which emphasizes a systematic approach to quality management, continuous improvement, and customer satisfaction.

– This standard mandates documented procedures for all production and QC activities, with regular audits to ensure compliance.

- Industry-Specific Certifications:

- CE Marking: For shoes intended for the European market, compliance with CE standards ensures safety, chemical safety, and environmental directives are met.

- REACH Compliance: Ensures chemical substances used in dyes, adhesives, and finishes are within safe limits, vital for European and Middle Eastern markets.

Quality Control (QC) Checkpoints

-

Incoming Quality Control (IQC)

– Raw materials and components are inspected upon receipt for quality, authenticity, and compliance with specifications.

– Common tests include visual inspection, chemical analysis, and physical testing (e.g., tensile strength, colorfastness). -

In-Process Quality Control (IPQC)

– Continuous monitoring during manufacturing ensures adherence to standards.

– Techniques include dimensional checks, stitching quality assessments, and bond strength tests.

– Use of statistical process control (SPC) methods helps detect deviations early. -

Final Quality Control (FQC)

– Completed shoes undergo comprehensive inspections, including visual examination for surface defects, accurate assembly, and finishing quality.

– Functional tests such as flexibility, sole adhesion, and durability assessments are performed.

Testing Methods and Tools

– Physical Tests: Tensile, shear, and peel tests to verify bonding strength.

– Visual Inspection: High-resolution magnification and light tables to detect surface flaws.

– Chemical Tests: For dyes, adhesives, and finishes to ensure chemical safety and compliance with REACH or other regulations.

– Environmental Testing: Simulated wear, exposure to moisture, and temperature cycling to assess durability.

How B2B Buyers Can Verify and Ensure Quality

For international buyers, especially from Africa, South America, the Middle East, and Europe, verifying supplier quality involves multiple proactive measures:

-

Supplier Audits and Factory Visits

Conduct comprehensive audits focusing on manufacturing facilities, quality management systems, and compliance documentation. Visiting the factory provides firsthand insight into process controls, cleanliness, and craftsmanship standards. -

Third-Party Inspections and Certifications

Engage reputable inspection agencies (e.g., SGS, Bureau Veritas, Intertek) to perform pre-shipment inspections, ensuring QC reports align with contractual standards. Certification verification confirms adherence to ISO 9001 and industry-specific standards. -

Review of Quality Documentation

Request detailed QC reports, test certificates, and material traceability documentation. Transparent record-keeping indicates robust internal controls and compliance. -

Sample Testing and Pilot Orders

Before large-scale procurement, commission independent testing of samples to validate quality claims, especially for exotic or sensitive materials. -

Ongoing Quality Monitoring

Establish regular communication channels with suppliers, including periodic audits, real-time quality data sharing, and feedback loops to address issues proactively.

Special Considerations for International B2B Buyers

B2B buyers from diverse regions face unique challenges and opportunities in ensuring quality:

-

Regulatory Compliance

Buyers in Europe and Australia must ensure products meet strict chemical and safety standards (e.g., REACH, ASTM). Middle Eastern and African buyers should verify local import regulations and certifications. -

Cultural and Market Expectations

Different markets have varying expectations regarding craftsmanship, material authenticity, and finishing. Clear communication about standards and specifications is essential. -

Supply Chain Transparency

Establishing traceability of materials and manufacturing stages helps mitigate risks related to counterfeit components or non-compliance. -

Language and Documentation

Ensure all QC documentation, certificates, and reports are available in accessible languages and formats suitable for local authorities and partners. -

Building Long-term Partnerships

Developing relationships with trusted manufacturers with proven track records reduces risks and ensures consistent quality. Regular audits and shared quality improvement initiatives foster mutual trust.

Conclusion

Understanding the detailed manufacturing processes and rigorous quality assurance protocols of Dolce & Gabbana shoes provides B2B buyers with the insights necessary to select reliable suppliers and ensure product excellence. Emphasizing certification verification, proactive inspection, and transparent communication enables international buyers from Africa, South America, the Middle East, and Europe to mitigate risks, meet regulatory standards, and uphold their brand reputation. Adopting these best practices fosters long-term, mutually beneficial partnerships in the high-end footwear industry.

Comprehensive Cost and Pricing Analysis for dolce & gabbana shoes Sourcing

Cost Structure Breakdown for Dolce & Gabbana Shoes

Understanding the comprehensive cost architecture of Dolce & Gabbana shoes is essential for international B2B buyers aiming to optimize procurement strategies. The primary cost components include:

-

Materials: High-quality leather, exotic skins, textiles, and embellishments contribute significantly to costs. Premium materials can account for 40-60% of the manufacturing expense, especially when sourcing authentic Italian leather or luxury embellishments.

-

Labor: Skilled craftsmanship in Italy or other sourcing regions influences labor costs, which typically range from 10-20% of the total cost. Variations depend on the complexity of designs and craftsmanship standards.

-

Manufacturing Overhead: Factory expenses, including utilities, machinery depreciation, and quality control, usually make up 10-15%. Regions with advanced manufacturing infrastructure may have higher overheads but often ensure superior quality.

-

Tooling & Development: Initial design tooling and prototypes can be a substantial upfront investment, particularly for customized or limited-edition collections. These costs are amortized over production runs.

-

Quality Control & Certification: Ensuring compliance with international standards (e.g., ethical sourcing, environmental certifications) may add 2-5% to costs but are critical for brand integrity and market access.

-

Logistics & Shipping: FOB (Free on Board) prices typically include basic logistics, but international shipping, customs clearance, and insurance can significantly impact total landed costs. Shipping costs vary based on destination, volume, and shipping method.

-

Profit Margin: Suppliers generally add a markup of 15-30%, depending on order volume, exclusivity, and buyer-supplier relationships. Larger volumes often attract better pricing terms.

Price Influencers and Their Impact

Several factors influence the final pricing and negotiating power:

-

Order Volume & MOQ: Higher volumes and lower Minimum Order Quantities (MOQs) can significantly reduce unit costs. Bulk orders enable better leverage during negotiations, especially for buyers from Africa, South America, and the Middle East.

-

Specifications & Customization: Customized designs, special materials, or unique packaging increase costs due to additional tooling, labor, or sourcing premium materials. Clear specifications upfront help avoid unexpected expenses.

-

Materials & Certification Standards: Sourcing genuine Italian leather or exotic skins raises costs compared to synthetic alternatives. Certified materials (e.g., eco-friendly, ethically sourced) also add to the price but improve marketability.

-

Quality & Certifications: Meeting international standards (e.g., ISO, Fair Trade, environmental certifications) may increase initial costs but can facilitate access to premium markets.

-

Supplier Factors: The reputation, reliability, and capacity of the supplier influence pricing. Established manufacturers with quality certifications tend to command higher prices but offer consistent quality.

-

Incoterms & Delivery Terms: FOB, CIF, DDP—these terms affect total landed costs. Buyers should evaluate logistics costs and risks associated with each Incoterm, especially when importing to regions with complex customs procedures.

Strategic Tips for International B2B Buyers

-

Negotiate for Volume Discounts & Flexible MOQs: Larger orders often translate into better unit prices. Engage with suppliers early to discuss volume commitments that benefit both parties.

-

Evaluate Total Cost of Ownership (TCO): Beyond unit price, consider costs related to customs clearance, tariffs, warehousing, and potential delays. For example, importing to Saudi Arabia or Australia might involve significant customs duties, impacting overall profitability.

-

Leverage Long-term Relationships: Building trust can unlock favorable terms, priority production slots, and better payment conditions. Consistent orders also enable suppliers to offer more competitive pricing.

-

Understand Pricing Nuances for Different Markets: Pricing may vary due to regional tariffs, import taxes, or certification requirements. For instance, European buyers might benefit from existing trade agreements, whereas African or South American buyers should account for higher import duties.

-

Request Clear, Detailed Quotes: Ensure quotes specify all components—materials, tooling, shipping, taxes—to facilitate accurate comparison and budgeting.

Price Range Estimates (Indicative)

While actual prices fluctuate based on specifications and order size, typical FOB prices for Dolce & Gabbana shoes range approximately from $150 to $300 per pair for standard models. Custom or limited-edition pieces can significantly exceed this range. Buyers should approach these figures as benchmarks rather than fixed rates and always seek multiple quotes for comparison.

Illustrative Image (Source: Google Search)

Disclaimer: Prices are indicative and subject to change based on market conditions, order specifics, and negotiation outcomes. Engaging directly with authorized suppliers or sourcing agents is recommended for precise quotations tailored to your requirements.

Spotlight on Potential dolce & gabbana shoes Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for dolce & gabbana shoes.)*

Essential Technical Properties and Trade Terminology for dolce & gabbana shoes

Critical Technical Properties for Dolce & Gabbana Shoes

1. Material Grade and Composition

The quality of materials used in luxury footwear significantly impacts durability, appearance, and brand reputation. Common materials include genuine leather (e.g., full-grain, top-grain), textiles, and specialized synthetics. For B2B transactions, specifying the material grade—such as European Leather Standard (e.g., EC 94/27)—ensures consistent quality. High-grade materials reduce defect rates and enhance customer satisfaction, making them vital for premium brands like Dolce & Gabbana.

2. Manufacturing Tolerance and Precision

Tolerance levels define the permissible variation in dimensions during production, such as sole thickness or upper height. Tight tolerances (e.g., ±0.2 mm) are crucial for ensuring fit consistency across batches, especially for high-end shoes where fit affects comfort and brand perception. B2B buyers should verify manufacturer tolerance standards to avoid costly rework or returns.

3. Sole Composition and Durability

Sole materials—such as rubber, leather, or synthetic compounds—must balance aesthetics with durability. For luxury shoes, outsole quality impacts wear resistance and slip resistance. Specifications regarding sole thickness and flexibility are essential, especially when sourcing for markets with diverse climate conditions, like the Middle East or South America.

4. Finishing and Detailing Quality

Details such as stitching, embossing, and lining quality are indicators of craftsmanship. High-quality finishing reduces the risk of defects and impacts the overall perception of luxury. For international buyers, requesting detailed quality reports or certifications helps ensure consistency across production runs.

5. Compliance and Certification Standards

Shoes must adhere to regional safety, environmental, and labor standards. For example, compliance with the EU REACH regulations or ISO certifications for manufacturing processes ensures legal market access and reduces import risks. Confirming these standards is critical for smooth customs clearance and brand integrity.

Essential Trade Terms for B2B Engagements

1. OEM (Original Equipment Manufacturer)

Refers to a manufacturer producing shoes that are branded and sold by another company. Understanding OEM relationships helps buyers negotiate pricing, quality standards, and intellectual property rights, especially when sourcing from different regions.

2. MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to produce or sell per order. For luxury shoes, MOQs can vary based on material costs and production complexity. Clear MOQ agreements help plan inventory and manage cash flow effectively.

3. RFQ (Request for Quotation)

A formal request sent by buyers to suppliers seeking price estimates, lead times, and terms for specific shoe models. Responding to RFQs promptly with detailed specifications ensures competitive pricing and timely procurement.

4. Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities between buyer and seller for shipping, insurance, and customs. Common Incoterms like FOB (Free On Board) or CIF (Cost, Insurance, Freight) clarify who bears costs and risks at each stage, essential for smooth international logistics.

5. Lead Time

The period from order placement to shipment readiness. Luxury footwear often requires longer lead times due to craftsmanship. Accurate lead time estimates are crucial for aligning supply chain schedules, especially when catering to seasonal demand cycles.

6. Quality Assurance (QA) and Certification

Procedures and standards to ensure products meet specified quality levels. Certifications such as ISO 9001 or specific regional standards assure buyers of consistent quality, reducing the risk of returns and enhancing brand reputation.

Summary:

For international B2B buyers, understanding these technical properties and trade terms is vital to making informed purchasing decisions, negotiating effectively, and ensuring compliance across markets. Clear communication of material standards, tolerances, and contractual terms minimizes risks and fosters long-term supplier relationships, especially when sourcing high-end Dolce & Gabbana shoes across diverse regions.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the dolce & gabbana shoes Sector

Market Overview & Key Trends

The global luxury footwear sector, particularly high-end brands like Dolce & Gabbana, is experiencing dynamic shifts driven by technological innovation, evolving consumer preferences, and geopolitical factors. For international B2B buyers from Africa, South America, the Middle East, and Europe, understanding these drivers is crucial for effective sourcing and market positioning.

Emerging trends include the integration of advanced manufacturing technologies such as 3D printing and AI-driven design, which streamline production and enable customization at scale. Digital platforms, including B2B marketplaces and virtual showrooms, facilitate more efficient procurement processes and foster closer relationships between brands and suppliers worldwide. Additionally, the rise of direct-to-consumer (DTC) channels means brands are increasingly controlling their supply chains, demanding more transparency and traceability from their sourcing partners.

Market dynamics are influenced by fluctuating raw material costs, geopolitical tensions, and trade policies. For instance, tariffs or import restrictions in certain regions may impact sourcing strategies, prompting buyers to diversify suppliers or regions. For buyers in Africa, South America, and the Middle East, proximity to emerging manufacturing hubs in Southern Europe or North Africa offers opportunities for reduced lead times and cost efficiencies, provided quality standards are maintained.

Furthermore, sustainability and ethical sourcing are becoming non-negotiable criteria, with consumers demanding greater accountability. B2B buyers must stay ahead of trends by partnering with suppliers who leverage innovative sourcing methods, such as using recycled or eco-friendly materials, to meet both regulatory standards and consumer expectations. Navigating these market dynamics requires agility, strategic sourcing, and an emphasis on transparency to capitalize on emerging opportunities while mitigating risks.

Illustrative Image (Source: Google Search)

Sustainability & Ethical Sourcing in B2B

Sustainability is increasingly central to the luxury footwear sector, with brands like Dolce & Gabbana under pressure to demonstrate responsible practices across their supply chains. Environmental impact mitigation involves sourcing eco-friendly materials, reducing waste, and minimizing carbon footprints throughout production.

For B2B buyers, partnering with suppliers that hold recognized sustainability certifications—such as Global Organic Textile Standard (GOTS), Leather Working Group (LWG), or Fair Trade—can enhance brand reputation and compliance. Utilizing ‘green’ materials like recycled leathers, plant-based dyes, and biodegradable packaging aligns with both consumer demands and regulatory requirements, especially in regions like Europe and the Middle East where environmental standards are stringent.

Ethical sourcing extends beyond environmental concerns to social responsibility. Ensuring fair labor practices, safe working conditions, and transparent supply chains is critical. Buyers should prioritize suppliers committed to certifications like SA8000 or Ethical Trading Initiative (ETI), which verify adherence to ethical standards. Incorporating blockchain technology can further enhance traceability, providing immutable records of material origin and manufacturing processes.

Investing in sustainable practices not only mitigates reputational risks but also creates long-term value through cost savings and brand loyalty. As global consumers become more conscious, B2B buyers who proactively embed sustainability and ethics into their sourcing strategies will position themselves as responsible partners in the luxury footwear industry.

Brief Evolution and Its Significance for B2B

The luxury footwear industry, including brands like Dolce & Gabbana, has evolved from traditional artisanal craftsmanship to a blend of heritage techniques and cutting-edge technology. This evolution impacts B2B sourcing by emphasizing the importance of innovation, flexibility, and traceability.

Historically, the focus was on exclusivity and handcrafted quality, but today, efficiency and scalability are equally vital. Modern supply chains are increasingly digitized, enabling real-time monitoring, inventory management, and demand forecasting. For international B2B buyers, this means greater visibility into production timelines, quality control, and compliance.

Understanding this evolution helps buyers identify reliable partners who combine traditional craftsmanship with modern technology—ensuring product authenticity and quality while meeting volume demands. Furthermore, the shift towards sustainability and transparency is reshaping supplier relationships, making it essential for buyers to vet partners thoroughly.

In a competitive landscape, those who adapt to this evolution—embracing technological integration and ethical standards—will have a strategic advantage. They can better anticipate market shifts, respond swiftly to consumer trends, and build resilient, future-proof supply chains aligned with the sophisticated demands of the luxury footwear market.

Frequently Asked Questions (FAQs) for B2B Buyers of dolce & gabbana shoes

1. How can I verify the authenticity and reliability of a Dolce & Gabbana shoe supplier?

Verifying supplier authenticity is crucial to mitigate risks of counterfeit or substandard products. Start by requesting official business licenses, VAT registration, and certifications such as ISO or industry-specific quality standards. Conduct background checks through trusted B2B platforms, industry associations, and references from existing clients. Request samples before committing to bulk orders to assess quality firsthand. Additionally, verify the supplier’s reputation via online reviews, trade show participation, and their membership in recognized trade organizations. Engaging with suppliers that have a physical office or showroom in Italy or established distribution channels enhances credibility and ensures compliance with brand standards.

2. Can I customize Dolce & Gabbana shoes for my market? What are the typical options and limitations?

Dolce & Gabbana offers limited customization options primarily for wholesale or bulk buyers, often focused on branding, packaging, or specific design requests aligned with their brand identity. Customization may include exclusive colorways, packaging, or private labeling, but extensive alterations to the design or materials are usually restricted due to brand integrity. Engage directly with authorized distributors or brand representatives to understand available options and minimum order quantities (MOQs). Be aware that customization typically involves longer lead times and higher costs. For large-scale B2B partnerships, negotiate terms upfront to ensure that the customization aligns with your market needs without compromising brand standards.

3. What are typical minimum order quantities, lead times, and payment terms for importing Dolce & Gabbana shoes?

Minimum order quantities (MOQs) for Dolce & Gabbana shoes usually range from 50 to several hundred pairs, depending on the supplier and product line. Lead times can vary from 4 to 12 weeks, influenced by order size, customization, and logistics. Payment terms often include a 30-50% upfront deposit with the balance payable before shipment or upon delivery. Some suppliers may offer flexible terms for trusted partners or repeat buyers. It’s essential to establish clear communication and contractual agreements early, including detailed timelines and payment schedules, to avoid delays and ensure smooth procurement processes.

4. What certifications and quality assurance processes should I expect from authentic Dolce & Gabbana suppliers?

Authentic Dolce & Gabbana suppliers should provide certifications confirming product authenticity, such as official brand authorization letters, and quality standards like ISO 9001. They should also adhere to strict quality assurance procedures, including material testing, craftsmanship inspections, and packaging standards. Request detailed documentation on sourcing, manufacturing practices, and compliance with international trade standards. Regular quality audits and third-party inspections are advisable, especially for high-volume orders. Ensuring these certifications and processes protects your brand reputation and guarantees that the shoes meet both Dolce & Gabbana’s and your market’s quality expectations.

5. How should I handle logistics and shipping when importing Dolce & Gabbana shoes internationally?

Effective logistics management involves selecting reliable freight forwarders experienced in luxury goods and customs clearance. Choose shipping methods based on your timeline and budget—air freight for faster delivery or sea freight for cost efficiency. Ensure that your supplier provides comprehensive documentation, including commercial invoices, packing lists, and certificates of origin. Be aware of import duties, taxes, and local regulations in your country; these costs can significantly impact your margins. Negotiating Incoterms (such as FOB or CIF) helps clarify responsibilities. Establishing a strong relationship with customs brokers and logistics providers minimizes delays and ensures secure, timely delivery.

6. What are common dispute resolution mechanisms if quality or delivery issues arise?

Establish clear contractual terms that specify dispute resolution procedures before placing orders. Preferably, include clauses for mediation or arbitration within internationally recognized institutions like the ICC or local trade chambers. Document all communications, inspections, and quality reports to substantiate claims. In case of disputes, initiate a formal review process involving third-party inspectors if necessary. Maintaining open communication with your supplier and setting performance benchmarks from the outset can prevent conflicts. Always include provisions for corrective actions, refunds, or replacements to protect your investment and ensure compliance with agreed standards.

7. How can I ensure compliance with import regulations and prevent counterfeit products in my market?

Stay informed about import regulations, tariffs, and trade restrictions relevant to luxury footwear in your country. Work with customs brokers and legal experts to ensure all documentation, certifications, and labeling meet local standards. Only source from authorized distributors or directly from Dolce & Gabbana’s official channels to mitigate counterfeit risks. Conduct regular product authentication checks, especially for high-value items, and educate your sales team about distinguishing genuine products. Utilizing serialization, holograms, or RFID tags can enhance traceability. Building strong relationships with trusted suppliers and verifying their credentials is key to maintaining a compliant and reputable supply chain.

8. What steps should I take if I encounter quality or delivery disputes with my supplier?

Immediately document the issue with detailed photographs, inspection reports, and correspondence records. Communicate directly with your supplier to address the problem, referencing contractual terms and agreed standards. If unresolved, escalate the matter through formal dispute resolution channels outlined in your contract, such as mediation or arbitration. Consider engaging independent inspectors or third-party quality auditors to assess the dispute objectively. Maintain a professional approach focused on finding mutually acceptable solutions, such as replacements, refunds, or corrective actions. Developing a contingency plan, including alternative suppliers or logistical options, ensures business continuity while resolving disputes efficiently.

Strategic Sourcing Conclusion and Outlook for dolce & gabbana shoes

Conclusion and Future Outlook for Strategic Sourcing of Dolce & Gabbana Shoes

Effective strategic sourcing is essential for international B2B buyers seeking to capitalize on the luxury footwear market, particularly with a renowned brand like Dolce & Gabbana. Prioritizing quality assurance, authentic supply channels, and sustainable practices can significantly mitigate risks and enhance brand reputation. For buyers across Africa, South America, the Middle East, and Europe, establishing strong relationships with trusted suppliers and leveraging regional trade agreements can facilitate more efficient procurement and cost optimization.

Looking ahead, the evolving landscape of global trade—driven by technological advancements and shifting consumer preferences—presents new opportunities for sourcing excellence. Embracing digital platforms, supplier diversification, and sustainability initiatives will be critical for maintaining competitive advantage.

We encourage B2B buyers to proactively refine their sourcing strategies, foster collaborative partnerships, and stay informed on market trends. Doing so will not only ensure access to authentic Dolce & Gabbana shoes but also position your business for sustainable growth in the luxury footwear segment. Now is the time to leverage strategic sourcing as a key driver of success in this dynamic industry.