Master Sourcing Dutch Wooden Shoes for International

Guide to Dutch Wooden Shoes

- Introduction: Navigating the Global Market for dutch wooden shoes

- Understanding dutch wooden shoes Types and Variations

- Key Industrial Applications of dutch wooden shoes

- Strategic Material Selection Guide for dutch wooden shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for dutch wooden shoes

- Comprehensive Cost and Pricing Analysis for dutch wooden shoes Sourcing

- Spotlight on Potential dutch wooden shoes Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for dutch wooden shoes

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the dutch wooden shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of dutch wooden shoes

- Strategic Sourcing Conclusion and Outlook for dutch wooden shoes

Introduction: Navigating the Global Market for dutch wooden shoes

In today’s interconnected global economy, Dutch wooden shoes—also known as clogs—represent a unique fusion of tradition, craftsmanship, and functional design that appeals to diverse markets worldwide. For international B2B buyers, understanding the strategic importance of these iconic products is essential to capitalizing on niche opportunities and expanding market presence. Dutch wooden shoes are not merely cultural artifacts; they serve functional purposes in various industries such as fashion, souvenirs, hospitality, and eco-friendly footwear, making them a valuable addition to your product portfolio.

This comprehensive guide is designed to equip you with critical insights needed for effective sourcing and procurement. It covers key areas including the different types of wooden shoes, the materials used, manufacturing processes, quality control standards, and reliable supplier networks. Additionally, you’ll find detailed cost analyses, market demand trends, and frequently asked questions that address common concerns in international trade.

For buyers from Africa, South America, the Middle East—including UAE and Saudi Arabia—and Europe, this guide offers actionable strategies to navigate logistical complexities, ensure product authenticity, and foster mutually beneficial supplier relationships. By leveraging these insights, you can make informed decisions that optimize cost efficiency, product quality, and market competitiveness—empowering your business to succeed in the global marketplace for Dutch wooden shoes.

Understanding dutch wooden shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Clogs | Handcrafted, with intricate carvings and natural wood finishes | Cultural exports, artisan markets, souvenirs | Pros: Authentic appeal, high craftsmanship; Cons: Higher cost, limited scalability |

| Industrial-Grade | Made from durable, treated wood with minimal ornamentation | Construction, factory use, heavy-duty work | Pros: Long-lasting, functional; Cons: Less aesthetic appeal, bulkier production |

| Custom-Design Clogs | Tailored to specific client specifications, including branding or logos | Promotional items, corporate gifting, retail | Pros: High customization, brand visibility; Cons: Longer lead times, higher price points |

| Eco-Friendly Variants | Crafted from sustainably sourced wood, often with eco-friendly finishes | Eco-conscious markets, sustainable branding | Pros: Environmentally appealing, compliant with green standards; Cons: Potentially higher raw material costs |

| Fashion & Designer Clogs | Modern, stylized versions incorporating contemporary design elements | Fashion retail, designer collaborations | Pros: Trendy, high-margin; Cons: Niche market, higher design costs |

Traditional Clogs

Traditional Dutch wooden clogs are characterized by their handcrafted nature, often featuring detailed carvings, painted motifs, and natural wood finishes. They are typically made from high-quality hardwoods like willow or poplar, emphasizing authenticity and craftsmanship. These are most suitable for export to markets valuing cultural heritage, such as souvenir shops or artisan boutiques. B2B buyers should consider sourcing from reputable artisans or cooperatives to ensure quality and authenticity. While they command premium prices, their limited scalability and higher production costs are key factors to manage.

Industrial-Grade Clogs

Designed for durability and heavy-duty use, industrial-grade Dutch clogs are constructed from treated, moisture-resistant wood. They are often plain, with minimal decoration, prioritizing function over form. These are ideal for industrial sectors, including construction, agriculture, and manufacturing, where safety and longevity are critical. Buyers should evaluate the wood treatment processes and certifications for safety standards. While offering excellent longevity and practical benefits, their utilitarian design may limit appeal in retail or gift markets, and bulk purchasing requires consideration of supply chain reliability.

Custom-Design Clogs

Custom-designed Dutch clogs offer a tailored approach, incorporating client branding, logos, or specific design elements. They are popular for corporate gifting, promotional campaigns, or retail branding efforts. B2B buyers should focus on establishing clear design specifications and lead times, as customization often extends production timelines. These clogs provide high visibility and brand differentiation, but higher costs and longer production cycles necessitate strategic planning and reliable manufacturing partners.

Eco-Friendly Variants

With increasing demand for sustainable products, eco-friendly Dutch clogs are crafted from sustainably sourced woods such as bamboo or FSC-certified timber. Finishes are often eco-conscious, avoiding toxic paints or adhesives. These are particularly appealing to markets focused on green branding, corporate social responsibility, or eco-conscious consumers. Buyers should verify the sustainability credentials of suppliers and consider the potential premium on raw materials. These variants align well with environmentally responsible branding strategies, though they may involve higher procurement costs.

Fashion & Designer Clogs

Modern reinterpretations of traditional Dutch clogs incorporate contemporary design elements like bold colors, innovative materials, or mixed media. These are targeted at fashion retailers, designer collaborations, and trend-conscious markets. B2B buyers should evaluate the design process, material sourcing, and market positioning to maximize profit margins. While they offer high aesthetic value and appeal to niche markets, their higher production costs and limited mass-market applicability require careful market analysis and targeted distribution channels.

Key Industrial Applications of dutch wooden shoes

| Industry/Sector | Specific Application of dutch wooden shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture & Farming | Protective footwear for farmworkers handling soil, fertilizers, or chemicals | Durable, breathable, and cost-effective protection reduces injury risk and enhances worker comfort | Ensure sourcing from suppliers with proven durability, resistance to moisture, and compliance with safety standards relevant to agricultural environments |

| Construction & Masonry | Anti-slip, impact-resistant footwear for construction sites | Enhances safety, reduces accident-related liabilities, and provides ergonomic support | Seek suppliers offering custom sizing, slip-resistant soles, and certifications for construction safety standards |

| Food Processing & Packaging | Hygienic, easy-to-clean footwear for food plant workers | Maintains hygiene standards, prevents contamination, and complies with health regulations | Prioritize sourcing from manufacturers with food-safe certifications and antimicrobial-treated options |

| Artisanal & Cultural Industries | Custom decorative wooden shoes for souvenirs and branding | Enhances product authenticity and appeal, supporting marketing and cultural storytelling | Look for craftsmanship quality, customizable designs, and reliable supply chains for consistent branding materials |

| Logistics & Warehousing | Protective footwear for warehouse staff handling heavy loads | Provides impact absorption, reduces fatigue, and improves overall safety | Choose suppliers with footwear tested for heavy-duty use, comfort, and long-term durability |

Agricultural & Farming

Dutch wooden shoes are traditionally used as protective footwear for farmworkers, especially in wet or muddy conditions. Their natural breathability and resilience against moisture make them ideal for handling soil, fertilizers, or chemicals. For international B2B buyers, sourcing high-quality wooden shoes ensures worker safety and comfort, reducing injury risks. Suppliers should demonstrate durability, resistance to environmental elements, and adherence to safety standards relevant to agricultural operations, especially in regions with high humidity or varied terrain.

Construction & Masonry

In construction environments, Dutch wooden shoes serve as impact-resistant, slip-proof footwear for workers exposed to uneven surfaces, falling debris, or liquids. They offer ergonomic support, helping reduce fatigue during long shifts. For B2B buyers from regions like the Middle East or Europe, it is critical to source wooden shoes with slip-resistant soles, reinforced toes, and certifications for construction safety. Custom sizing and design flexibility are also important to meet diverse workforce needs and safety regulations.

Food Processing & Packaging

The hygienic properties of wooden shoes make them suitable for food processing plants and packaging facilities. They are easy to clean, helping maintain strict hygiene standards and preventing contamination. International buyers should prioritize suppliers that provide food-safe, antimicrobial-treated wooden shoes, which comply with health regulations such as HACCP or FDA standards. Cost-effective, durable options are essential for continuous, high-volume operations in regions like South America or Africa, where food safety compliance is paramount.

Artisanal & Cultural Industries

Dutch wooden shoes hold cultural significance and are often used as souvenirs or promotional items in artisanal industries. Customizable designs and craftsmanship quality can enhance branding efforts, making them attractive for marketing campaigns or cultural exports. For B2B buyers, sourcing from artisans with reliable supply chains ensures consistent product quality. Emphasizing authentic craftsmanship, unique finishes, and the ability to customize helps in creating market-differentiating products for export to Europe, the Middle East, or specialty retail markets.

Logistics & Warehousing

In logistics, wooden shoes are used as protective footwear for warehouse staff handling heavy or sharp objects. Their impact absorption and slip-resistant soles help prevent workplace injuries and fatigue. For international B2B buyers, selecting suppliers offering footwear tested for heavy-duty use, with long-lasting materials and comfort features, is crucial. Ensuring compliance with regional safety standards, such as OSHA or EU safety directives, enhances safety management and reduces liability risks across diverse operational environments.

Strategic Material Selection Guide for dutch wooden shoes

Material Analysis for Dutch Wooden Shoes

When selecting materials for manufacturing Dutch wooden shoes, B2B buyers must consider a range of factors including durability, cost, manufacturing complexity, and suitability for various environments. The choice of material directly impacts product performance, compliance with international standards, and customer satisfaction across diverse markets such as Africa, South America, the Middle East, and Europe.

1. Maple Wood

Maple wood is one of the most traditional and widely used materials for Dutch wooden shoes. Known for its high density and strength, maple offers excellent durability and resistance to impact, making it suitable for daily wear. Its fine grain also provides a smooth surface that enhances comfort and aesthetic appeal.

Key Properties:

– High hardness and strength

– Moderate moisture resistance

– Good dimensional stability

– Easy to work with for detailed shaping

Pros & Cons:

– Pros: Long-lasting, resistant to cracking, widely accepted in European markets, and compliant with many international standards (e.g., EN standards).

– Cons: Slightly higher cost compared to softer woods, and manufacturing requires precise craftsmanship to avoid splitting.

Impact on Application:

– Suitable for indoor and outdoor use, especially in environments with moderate humidity.

– Less ideal in highly humid or wet conditions unless treated.

International Buyer Considerations:

– Maple wood generally meets ASTM and EN standards, making it compliant for export.

– Buyers from Africa and South America should consider sourcing FSC-certified maple to ensure sustainability.

– In Middle Eastern markets, treatment for moisture and heat resistance enhances product longevity.

2. Birch Wood

Birch is another popular choice, appreciated for its fine grain and smooth finish. It offers a good balance between cost and performance, making it attractive for mass production.

Key Properties:

– Moderate hardness

– Good shock absorption

– Fair moisture resistance

– Easy to machine and finish

Pros & Cons:

– Pros: Cost-effective, readily available, and provides a clean aesthetic.

– Cons: Slightly less durable than maple, susceptible to swelling in high humidity if untreated.

Impact on Application:

– Ideal for indoor use or in dry climates.

– Can be treated for outdoor or humid environments, but treatment adds to cost.

International Buyer Considerations:

– Birch’s compliance with JIS and DIN standards facilitates international trade.

– Buyers in humid climates like parts of South America and the Middle East should prioritize treated birch for durability.

– Certification for sustainable harvesting (FSC or PEFC) is increasingly important for European and Middle Eastern markets.

3. Plywood (Multiple Veneer Layers)

Plywood is a versatile material used in some Dutch wooden shoe designs, especially for lightweight or decorative components.

Key Properties:

– Composed of thin veneer layers bonded under heat and pressure

– Good strength-to-weight ratio

– Varies in moisture resistance depending on grade and adhesive used

– Can be manufactured with water-resistant adhesives (e.g., WBP)

Pros & Cons:

– Pros: Cost-effective, lightweight, and customizable in size and shape.

– Cons: Generally less durable than solid woods, prone to delamination if exposed to excessive moisture, and may have inconsistent grain.

Impact on Application:

– Suitable for decorative or indoor footwear.

– Not recommended for high-moisture environments unless high-grade, water-resistant plywood is used.

International Buyer Considerations:

– Plywood must meet specific standards such as EN 636 or ANSI/APA to ensure quality.

– Buyers should verify adhesive types for compliance with health and safety standards, especially in markets with strict VOC regulations.

– Sustainability certifications (FSC, PEFC) are critical for European and Middle Eastern buyers.

Summary Table

| Material | Typical Use Case for Dutch Wooden Shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Maple Wood | Durable outdoor and indoor footwear | High strength, impact resistance, long-lasting | Higher cost, requires skilled craftsmanship | High |

| Birch Wood | Cost-effective indoor footwear, dry climates | Good balance of cost and performance, smooth finish | Less durable in humid conditions | Medium |

| Plywood | Decorative, lightweight shoes, indoor use | Lightweight, customizable, cost-effective | Less durable, moisture-sensitive unless treated | Low |

| Teak or Iroko | Outdoor and high-humidity environments | Excellent moisture resistance, durability | Higher cost, complex processing | High |

This analysis provides B2B buyers with a clear understanding of material options, enabling strategic sourcing decisions that align with market demands, environmental conditions, and compliance standards. Proper material selection enhances product longevity, reduces costs associated with returns or repairs, and aligns with sustainability commitments prevalent in European and Middle Eastern markets.

In-depth Look: Manufacturing Processes and Quality Assurance for dutch wooden shoes

Manufacturing Processes of Dutch Wooden Shoes

Dutch wooden shoes, also known as clogs, are crafted through a meticulous process that balances traditional craftsmanship with modern quality standards. For international B2B buyers, understanding each stage provides insight into product consistency, cost implications, and quality assurance.

1. Material Preparation

The process begins with sourcing high-quality wood, predominantly poplar, beech, or ash, selected for durability and ease of carving. The raw timber is kiln-dried to reduce moisture content, typically to below 15%, which minimizes warping and cracking during shaping and finishing. Suppliers should provide documentation verifying moisture levels and wood origin, ensuring compliance with international standards.

2. Shaping and Forming

The dried wood is sliced into thin sheets or blocks, then roughly shaped using CNC machinery or traditional hand tools, depending on the manufacturer’s facilities. Modern manufacturers employ CNC carving for precision, ensuring uniformity across batches. The shaping includes forming the sole, heel, and toe contours, adhering to ergonomic and aesthetic specifications. This stage often involves multiple passes to refine the shape, with careful control to prevent structural weaknesses.

3. Assembly and Joining

In some cases, multiple wooden pieces are joined to form the final shape, especially for larger or customized orders. Traditional methods might include dowels or wooden pegs, while advanced facilities may employ adhesives that meet food-safe and environmental standards. The assembly process requires precise alignment to ensure comfort and durability, with glue joints tested for strength and longevity.

4. Finishing

The finishing phase encompasses smoothing surfaces via sanding, often with progressively finer abrasives to achieve a polished feel. Additional processes include carving decorative motifs or branding, followed by sealing with natural oils, waxes, or water-resistant finishes. For export, finishes must meet environmental and safety standards, with suppliers providing certifications such as FSC or PEFC for sustainable sourcing.

Quality Control in Dutch Wooden Shoe Manufacturing

Quality assurance (QA) is integral to maintaining product consistency and meeting international standards. B2B buyers should focus on the implementation of rigorous QC protocols, which typically follow international frameworks like ISO 9001 and industry-specific certifications.

1. International Standards and Certifications

– ISO 9001: Ensures the manufacturer’s quality management system emphasizes continuous improvement, customer satisfaction, and process consistency.

– CE Marking: For shipments to Europe, compliance with safety, health, and environmental directives is essential. The CE mark demonstrates adherence to EU standards, including mechanical strength, surface safety, and chemical content.

– Sustainable Certifications: FSC or PEFC certifications confirm responsible sourcing, which is increasingly valued in markets like the Middle East and South America.

2. Quality Control Checkpoints

– Incoming Quality Control (IQC): Inspection of raw materials, including wood moisture content, defect detection, and supplier documentation verification.

– In-Process Quality Control (IPQC): Monitoring during shaping, assembly, and finishing. This includes dimensional checks, surface smoothness, and adherence to design specifications.

– Final Quality Control (FQC): Comprehensive inspection of finished products for visual defects, structural integrity, and compliance with client specifications.

3. Testing Methods

– Dimensional Accuracy: Using calipers and gauges to ensure conformity to design tolerances.

– Strength and Durability: Mechanical testing such as static load tests and drop tests to assess resilience.

– Chemical Safety: Testing for harmful substances, including formaldehyde, phthalates, and heavy metals, especially if finishes or adhesives are applied.

– Environmental Resistance: Assessing water resistance and weather durability for outdoor use.

4. Verification for International Buyers

B2B buyers should conduct supplier audits or third-party inspections to verify QC processes. This involves reviewing quality manuals, inspecting manufacturing facilities, and sampling products for testing. Maintaining open communication channels with suppliers about QC expectations and documentation is crucial. Many buyers also utilize third-party inspection agencies, such as SGS or Bureau Veritas, to provide independent verification before shipment.

Nuances for International B2B Buyers from Africa, South America, the Middle East, and Europe

1. Cultural and Market-Specific Standards

Buyers from regions like the UAE or Saudi Arabia often require compliance with specific certifications (e.g., Saudi Product Safety Program – SPPP) or environmental standards aligned with local regulations. In South America and Africa, suppliers might vary in their adherence to international standards, so thorough audits and third-party inspections are vital.

2. Communication and Documentation

Ensuring clear communication regarding quality expectations, certification requirements, and testing protocols is essential. Suppliers should provide detailed Quality Assurance Reports, test certificates, and traceability documentation. B2B buyers should also request detailed inspection reports and, where possible, conduct pre-shipment inspections.

3. Supplier Audits and Continuous Monitoring

Regular audits—either on-site or through third-party agencies—help verify ongoing compliance. For high-value or large-volume orders, establishing long-term relationships with certified suppliers who demonstrate consistent quality control is advisable. Digital tools like supplier portals and real-time reporting can facilitate ongoing monitoring.

4. Customization and Certification Adaptation

Buyers often require product modifications to meet regional preferences or safety standards. Suppliers capable of customizing finishes, sizes, or certifications will better serve diverse markets. Negotiating quality agreements that specify certification standards, testing methods, and inspection frequency enhances confidence.

By understanding these manufacturing processes and quality assurance practices, international B2B buyers can make informed decisions, mitigate risks, and establish reliable supply chains for Dutch wooden shoes. Ensuring thorough verification and ongoing quality management fosters long-term partnerships aligned with global standards and regional market demands.

Comprehensive Cost and Pricing Analysis for dutch wooden shoes Sourcing

Cost Structure Breakdown

Understanding the comprehensive cost framework for Dutch wooden shoes is essential for making informed sourcing decisions. The primary cost components include:

- Materials: The core material—typically high-quality hardwood such as beech or oak—constitutes a significant portion of the cost. Material quality directly influences durability, appearance, and certification standards, which can impact pricing.

- Labor: Skilled craftsmanship is vital in Dutch wooden shoe production. Labor costs vary depending on the factory’s location, workforce expertise, and production scale but generally represent a moderate to high share of the total cost.

- Manufacturing Overheads: This encompasses machinery maintenance, utilities, and factory overheads. Efficient factories with advanced equipment may have higher initial investments but lower per-unit costs.

- Tooling & Molds: Since wooden shoes are often handcrafted or produced via molds, tooling costs are upfront but amortized over large production runs. Custom molds for specific designs or sizes increase initial costs.

- Quality Control & Certifications: Ensuring consistent quality and compliance with international standards (e.g., CE marking) can add to costs but is crucial for premium markets.

- Logistics & Shipping: International freight, customs duties, and inland transportation significantly influence landed costs, especially for buyers in Africa, South America, or the Middle East.

- Profit Margin: Suppliers typically include a markup to sustain operations, usually ranging from 10% to 30%, depending on the supplier’s positioning and order volume.

Price Influencers

Several factors directly impact the final pricing of Dutch wooden shoes in the B2B context:

- Order Volume & MOQ: Higher volumes generally lead to lower unit prices due to economies of scale. Many Dutch suppliers offer discounts for bulk orders, but minimum order quantities (MOQs) can be a barrier for smaller buyers.

- Customization & Specifications: Customized designs, sizes, or branding increase production complexity and costs, often resulting in higher unit prices. Standard models are more cost-effective.

- Material Choices: Opting for premium or eco-friendly materials can raise costs but appeal to niche markets demanding sustainability.

- Quality Certifications: Certified products (e.g., ISO, CE) may command premium prices but assure buyers of compliance and safety, critical for markets like Europe or the Middle East.

- Supplier Factors: Established brands or suppliers with a reputation for quality may charge higher prices but offer better reliability and consistency.

- Incoterms & Shipping Terms: The choice of Incoterms (e.g., FOB, CIF, DDP) impacts costs and risk allocation. Buyers should evaluate logistics costs and responsibilities carefully.

Buyer Tips for Cost Optimization

- Negotiate for Better Terms: Leverage order volume, long-term partnerships, or early payments to negotiate discounts or favorable payment terms.

- Focus on Total Cost of Ownership (TCO): Beyond unit price, consider shipping, customs duties, taxes, and potential tariffs. For example, importing to Africa or South America may involve higher import duties, impacting overall cost.

- Consolidate Shipments: Grouping orders can reduce shipping costs significantly, especially for buyers in remote or high-duty markets like the Middle East.

- Evaluate Supplier Certifications & Quality: Opting for suppliers with recognized standards can reduce costs related to rework, returns, or compliance issues.

- Understand Pricing Nuances: Some suppliers may advertise low unit prices but apply hidden costs for customization, packaging, or expedited shipping. Clear communication and detailed quotations are essential.

Price Range and Indicative Costs

While actual prices vary based on specifications and market conditions, typical FOB prices for standard Dutch wooden shoes range from $5 to $15 per pair for bulk orders. Premium or customized options can range from $20 to $40 or more per pair. Shipping costs depend heavily on destination, with inland freight and customs duties potentially adding 20-50% to the landed cost.

Disclaimer: These prices are indicative and subject to fluctuation based on raw material costs, exchange rates, global logistics, and market demand. Buyers should seek detailed quotes tailored to their specific requirements and conduct due diligence on suppliers’ reliability.

By thoroughly understanding these cost components and influencing factors, international buyers—especially from Africa, South America, the Middle East, and Europe—can negotiate more effectively, optimize their total costs, and ensure a sustainable sourcing strategy for Dutch wooden shoes.

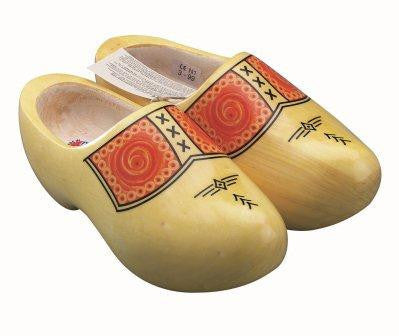

Illustrative Image (Source: Google Search)

Spotlight on Potential dutch wooden shoes Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for dutch wooden shoes.)*

Essential Technical Properties and Trade Terminology for dutch wooden shoes

Critical Technical Properties of Dutch Wooden Shoes

1. Material Grade and Type

Dutch wooden shoes are predominantly crafted from high-quality hardwoods such as maple, beech, or poplar. The material grade indicates the wood’s quality, including factors like grain uniformity, knot presence, and durability. For B2B buyers, selecting shoes made from premium, defect-free wood ensures longer product lifespan and reduced defect rates during manufacturing or use.

2. Dimensional Tolerance

This refers to the permissible variation in the shoe’s dimensions, such as length, width, and height. Tight tolerance levels (e.g., ±2mm) are critical for applications requiring precise fitting, especially in industrial or safety contexts. Consistent sizing enhances customer satisfaction and minimizes return or rework costs.

3. Finish and Surface Quality

The surface finish impacts both aesthetics and safety. A smooth, splinter-free surface reduces injury risks and facilitates easier cleaning or customization. B2B buyers should specify the required finish quality—whether raw, varnished, or painted—to match their end-use requirements.

4. Weight and Density

The weight influences handling, shipping costs, and comfort in wearable applications. Dense hardwoods provide durability but may be heavier, affecting logistics and user comfort. Understanding the density helps in estimating shipping costs and suitability for specific industries like hospitality or manufacturing.

5. Load Capacity and Structural Integrity

This property assesses the shoe’s ability to withstand weight and mechanical stress over time. For industrial use, shoes must meet certain load-bearing standards to ensure safety and durability, especially in heavy-duty environments.

6. Environmental Resistance

Resistance to moisture, temperature fluctuations, and pests is vital, especially for outdoor or humid conditions. Treated or naturally resistant woods extend product lifespan in challenging environments, an important consideration for international buyers operating in diverse climates.

Essential Trade Terms for Dutch Wooden Shoes

1. OEM (Original Equipment Manufacturer)

Refers to the manufacturer producing shoes based on the buyer’s specifications, including design, material, and branding. Understanding OEM capabilities allows buyers to customize products to their branding or functional needs, facilitating differentiation in competitive markets.

2. MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to produce or sell in a single order. For B2B buyers, negotiating MOQ is crucial to balance inventory costs with demand, especially when testing new markets or launching new product lines.

3. RFQ (Request for Quotation)

A formal process where buyers request price, lead time, and terms from suppliers. An RFQ helps buyers compare offers efficiently and ensures clarity on costs, specifications, and delivery expectations before committing to a purchase.

4. Incoterms (International Commercial Terms)

Standardized trade terms published by the International Chamber of Commerce that define responsibilities for shipping, insurance, and tariffs. Common Incoterms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) influence total landed costs and risk management strategies for international shipments.

5. Lead Time

The duration between order placement and product delivery. B2B buyers must align lead times with their supply chain schedules to prevent stockouts or delays, especially when importing from Europe to regions with logistical constraints.

6. Certification and Compliance Terms

Includes standards like FSC (Forest Stewardship Council) certification or CE marking. These assure buyers of sustainable sourcing and product safety compliance, which are increasingly mandatory in international markets.

Understanding these technical properties and trade terms is essential for making informed purchasing decisions, optimizing supply chain efficiency, and ensuring product quality in international markets. Clear communication of specifications and terms reduces risks and fosters long-term supplier relationships.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the dutch wooden shoes Sector

Market Overview & Key Trends

The Dutch wooden shoes sector, historically rooted in Dutch craftsmanship, has evolved into a niche yet globally recognized segment within the footwear and souvenir markets. For international B2B buyers from Africa, South America, the Middle East, and Europe, understanding current market dynamics is essential for effective sourcing and strategic positioning.

Global drivers such as increased demand for authentic, eco-friendly, and culturally distinctive products are fueling interest in Dutch wooden shoes. Emerging trends include the integration of modern design elements with traditional craftsmanship, appealing to both retail and promotional markets worldwide. Additionally, technological advancements—like digital manufacturing and online marketplaces—are simplifying sourcing processes, enabling buyers to connect directly with Dutch artisans and manufacturers.

Market dynamics show a shift towards sustainable and ethically produced wooden shoes, especially in regions where environmental consciousness influences purchasing decisions. Buyers from the Middle East and Europe, in particular, are prioritizing suppliers with transparent supply chains and eco-certifications. For African and South American markets, the appeal lies in the combination of cultural authenticity and affordability, making Dutch wooden shoes a versatile product for both retail and promotional uses.

Furthermore, the sector is witnessing diversification in product offerings—ranging from traditional clogs to customized, branded footwear—allowing B2B buyers to tailor products for specific markets. The rise of e-commerce platforms and B2B marketplaces has also facilitated international sourcing, reducing barriers related to distance and language. For buyers, establishing strong relationships with Dutch suppliers that prioritize quality, innovation, and reliable logistics is key to navigating this evolving landscape effectively.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a cornerstone of the Dutch wooden shoes sector, driven by global environmental concerns and consumer demand for ethically produced goods. For B2B buyers, partnering with suppliers committed to sustainable practices ensures compliance with international standards and enhances brand reputation.

Eco-conscious sourcing begins with the selection of responsibly harvested wood, often certified by standards such as FSC (Forest Stewardship Council) or PEFC (Programme for the Endorsement of Forest Certification). These certifications guarantee that raw materials are sourced sustainably, minimizing deforestation and environmental degradation. Dutch manufacturers increasingly incorporate environmentally friendly treatments and finishes, reducing the use of harmful chemicals and ensuring products are safe for consumers and the environment.

Ethical supply chains are equally important, encompassing fair labor practices, transparent sourcing processes, and adherence to international labor standards. Many Dutch producers are members of industry initiatives promoting fair wages and safe working conditions, which adds value for B2B buyers seeking ethically sourced products. Incorporating ‘green’ certifications and eco-labels into procurement criteria not only aligns with global sustainability goals but also appeals to environmentally conscious consumers in markets like the Middle East and Europe.

For international buyers, engaging with Dutch suppliers who provide detailed sustainability documentation and are willing to share traceability data enhances trust and reduces supply chain risks. This approach ensures that products are not only authentic and high-quality but also ethically produced, aligning with global trends towards responsible consumption.

Brief Evolution/History (Optional)

The Dutch wooden shoe industry has a rich history dating back centuries, rooted in traditional craftsmanship and regional identity. Originally functional footwear for farmers and laborers, the sector has gradually transformed into a cultural and artisanal export product. Modern B2B engagement emphasizes authentic craftsmanship combined with sustainable practices, reflecting the sector’s evolution from utilitarian origins to a premium, ethically conscious niche. Recognizing this heritage adds value for international buyers seeking genuine Dutch products that embody tradition and craftsmanship.

Frequently Asked Questions (FAQs) for B2B Buyers of dutch wooden shoes

- How can I verify the credibility and reliability of Dutch wooden shoe suppliers?

To ensure supplier credibility, conduct thorough due diligence by reviewing their business licenses, certifications, and trade references. Request samples and visit their manufacturing facilities if possible. Look for suppliers with established export experience, positive customer reviews, and transparent communication. Engage in supplier audits or third-party inspections to validate their production capabilities and quality standards. Additionally, verify their compliance with international trade regulations and standards, such as CE or FSC certifications, to mitigate risks associated with counterfeit or substandard products. Building relationships with verified suppliers reduces supply chain disruptions and ensures consistent quality.

Illustrative Image (Source: Google Search)

-

What customization options are available for Dutch wooden shoes, and how do they impact lead times and costs?

Dutch wooden shoes can be customized in various ways, including size, color, branding (logos or slogans), and decorative elements like carvings or painting. Some suppliers also offer bespoke designs tailored to specific markets or brand identities. Customization typically increases lead times by 2-4 weeks and may incur additional setup or tooling costs. To optimize costs, plan ahead and specify your customization requirements early in the order process. Establish clear communication with suppliers regarding design specifications and sample approvals to avoid delays and ensure the final product meets your expectations. -

What are typical MOQs, lead times, and payment terms for bulk orders of Dutch wooden shoes?

Minimum order quantities (MOQs) for Dutch wooden shoes generally range from 200 to 1,000 pairs, depending on the supplier and customization level. Lead times usually span 4 to 8 weeks, factoring in production, quality checks, and logistics. Payment terms are often 30% upfront with the remaining balance paid before shipment, though some suppliers may offer letters of credit or open account arrangements for trusted partners. Negotiating flexible payment terms and clear delivery schedules is crucial, especially for large or recurring orders. Building long-term relationships can also lead to more favorable terms. -

What quality assurance measures and certifications should I look for in Dutch wooden shoe suppliers?

Ensure suppliers adhere to internationally recognized quality standards such as ISO 9001 for quality management or FSC certification for sustainable wood sourcing. Request detailed QA procedures, including inspections during various production stages and pre-shipment quality checks. Suppliers should provide test reports covering durability, finish, and safety standards. Certifications like CE marking (for European markets) or compliance with ASTM standards can also demonstrate adherence to safety and quality benchmarks. Confirm that suppliers maintain traceability records for raw materials, ensuring product authenticity and sustainability. -

How should I manage logistics and shipping for importing Dutch wooden shoes to regions like Africa, the Middle East, or South America?

Coordinate closely with suppliers to determine the most efficient shipping methods—sea freight is common for bulk orders, offering cost-effective transit times, while air freight may be used for urgent deliveries. Choose reliable freight forwarders with experience in handling wooden products, ensuring proper packaging to prevent damage during transit. Clarify customs documentation requirements, tariffs, and import regulations for your destination country. Consider FOB (Free on Board) or CIF (Cost, Insurance, Freight) terms to clearly define responsibilities and costs. Establish tracking and communication channels to monitor shipments and mitigate delays. -

What common disputes might arise in international trade of Dutch wooden shoes, and how can they be effectively resolved?

Disputes often relate to product quality, delivery delays, or payment issues. To mitigate these risks, establish clear contractual terms covering specifications, quality standards, lead times, and dispute resolution procedures, preferably through arbitration clauses in internationally recognized institutions like ICC. Maintain detailed documentation of orders, communications, and inspections. In case of disagreements, initiate amicable negotiations first; if unresolved, escalate to arbitration or legal channels in a neutral jurisdiction. Investing in proper contractual protections and open communication minimizes misunderstandings and expedites resolution. -

How do I ensure compliance with import regulations and standards for Dutch wooden shoes in my country?

Research your country’s import regulations, tariffs, and standards for wooden footwear, including safety, labeling, and environmental requirements. Work with customs brokers familiar with local procedures to streamline clearance. Ensure products meet relevant standards, such as chemical safety (e.g., VOC emissions), labeling accuracy, and sustainability certifications. Keep documentation like invoices, certificates of origin, and compliance reports readily available. Regularly update your knowledge on trade agreements or tariffs that may impact costs, and establish relationships with local authorities or inspectors to facilitate smooth import processes. -

What strategies can I adopt to build long-term, mutually beneficial relationships with Dutch wooden shoe suppliers?

Prioritize transparent communication, prompt payments, and consistent order volumes to foster trust. Offer feedback on product quality and collaborate on new designs or innovations, demonstrating your commitment to a partnership. Consider long-term contracts or volume agreements that provide stability and better terms for both parties. Visiting suppliers, participating in trade shows, and engaging in cultural exchange can deepen relationships. Staying informed about their capacity and market developments allows you to adapt your orders proactively, ensuring mutual growth and sustained supply chain reliability.

Strategic Sourcing Conclusion and Outlook for dutch wooden shoes

Strategic Sourcing Outlook for Dutch Wooden Shoes

Effective strategic sourcing is essential for international B2B buyers seeking to leverage the unique appeal of Dutch wooden shoes. By establishing strong relationships with reputable Dutch suppliers, buyers can ensure product authenticity, quality consistency, and favorable pricing. Diversifying sourcing channels and emphasizing sustainable practices can also enhance brand reputation and meet increasing consumer demand for eco-friendly products.

Illustrative Image (Source: Google Search)

For buyers in Africa, South America, the Middle East, and Europe, including the UAE and Saudi Arabia, understanding local market dynamics and import regulations is crucial. Collaborating with experienced importers or agents can streamline logistics and reduce lead times. Additionally, integrating Dutch wooden shoes into broader product portfolios can open new market segments, such as eco-conscious fashion or cultural souvenirs.

Looking ahead, the continued growth of niche markets and demand for authentic, handcrafted products presents significant opportunities. Strategic sourcing efforts should focus on building long-term partnerships, emphasizing quality, and aligning with sustainability trends. By doing so, international buyers can capitalize on the enduring cultural and commercial value of Dutch wooden shoes, ensuring a competitive edge in their respective markets.