Master Sourcing Skechers Orthopedic Shoes for Global

Guide to Skechers Orthopedic Shoes

- Introduction: Navigating the Global Market for skechers orthopedic shoes

- Understanding skechers orthopedic shoes Types and Variations

- Key Industrial Applications of skechers orthopedic shoes

- Strategic Material Selection Guide for skechers orthopedic shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for skechers orthopedic shoes

- Comprehensive Cost and Pricing Analysis for skechers orthopedic shoes Sourcing

- Spotlight on Potential skechers orthopedic shoes Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for skechers orthopedic shoes

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the skechers orthopedic shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of skechers orthopedic shoes

- Strategic Sourcing Conclusion and Outlook for skechers orthopedic shoes

Introduction: Navigating the Global Market for skechers orthopedic shoes

In today’s increasingly interconnected healthcare and footwear markets, Skechers orthopedic shoes stand out as a vital product category for international B2B buyers seeking quality, comfort, and innovation. As global awareness of foot health and mobility solutions grows, the demand for reliable orthopedic footwear continues to surge across regions such as Africa, South America, the Middle East, and Europe. For importers, distributors, and retailers in these markets, understanding the nuances of Skechers’ orthopedic offerings is essential to meet evolving consumer needs while maintaining competitive advantage.

This comprehensive guide is designed to empower international B2B buyers with actionable insights into Skechers orthopedic shoes, covering key aspects such as product varieties, sourcing materials, manufacturing standards, quality control, and supplier options. Additionally, it explores cost considerations, market trends, and frequently asked questions to facilitate smarter procurement decisions. Whether you are seeking to expand your product portfolio, improve customer satisfaction, or establish reliable supply chains, this resource aims to streamline your sourcing process.

By leveraging this guide, B2B buyers from diverse regions can better navigate the complexities of the global orthopedic footwear market. It equips you with the knowledge needed to identify reputable suppliers, assess quality benchmarks, and optimize costs—ultimately enabling you to deliver superior orthopedic footwear solutions tailored to your local markets’ unique demands.

Understanding skechers orthopedic shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Casual Orthopedic Sneakers | Cushioned insoles, flexible midsoles, supportive arch design | Retail, online sales, outpatient clinics | Pros: Popular among consumers, high market demand; Cons: May require frequent inventory replenishment due to trend shifts |

| Formal Orthopedic Shoes | Sleek design, orthotic-friendly insoles, discreet support features | Specialty footwear stores, clinics, hospitals | Pros: Appeals to professional demographics; Cons: Higher manufacturing costs, limited style variety |

| Sport/Active Orthopedic Shoes | Enhanced shock absorption, breathable materials, stability features | Sports clinics, physiotherapy centers, sports retailers | Pros: Growing segment, high functional appeal; Cons: May have higher MOQ requirements, specialized sizing |

| Therapeutic/Medical Orthopedic Shoes | Customizable fit, medical-grade materials, advanced support technology | Medical supply chains, pharmacies, hospitals | Pros: High demand for medical needs, potential for premium pricing; Cons: Longer lead times, regulatory compliance |

| Children’s Orthopedic Shoes | Smaller sizes, reinforced support, flexible yet durable materials | Pediatric clinics, specialty stores | Pros: Growing pediatric market; Cons: Smaller order sizes, specialized manufacturing |

Casual Orthopedic Sneakers

Casual orthopedic sneakers are designed for everyday wear, combining comfort with subtle orthopedic features. They typically feature cushioned insoles, flexible midsoles, and supportive arches, making them suitable for a broad consumer base. These shoes are ideal for B2B buyers looking to supply mainstream retail outlets or online marketplaces targeting health-conscious or aging populations. When purchasing, consider the balance between style and function, as consumer preferences shift rapidly. Inventory management should account for seasonal trends and rapid style changes to avoid obsolescence.

Formal Orthopedic Shoes

Formal orthopedic shoes blend classic aesthetics with functional support, appealing to professionals and older adults seeking discreet orthopedic solutions. They often feature sleek designs with orthopedic insoles that do not compromise on appearance. For B2B buyers, these shoes are suitable for specialty stores, clinics, and healthcare providers. Key considerations include sourcing quality materials to ensure durability and comfort, as well as understanding regional preferences for formal footwear styles. Pricing strategies should reflect the premium nature of these products, and inventory planning must accommodate varying sizes and customizations.

Sport/Active Orthopedic Shoes

This category caters to active individuals requiring orthopedic support during physical activities. Features include shock absorption, breathable fabrics, and stability-enhancing designs. These shoes are increasingly popular in physiotherapy centers, sports clinics, and retail outlets targeting athletes or fitness enthusiasts. B2B buyers should evaluate MOQ requirements, as these shoes often involve specialized manufacturing processes. Additionally, regional climate and activity levels influence product demand, so tailoring inventory to local sports trends can boost sales.

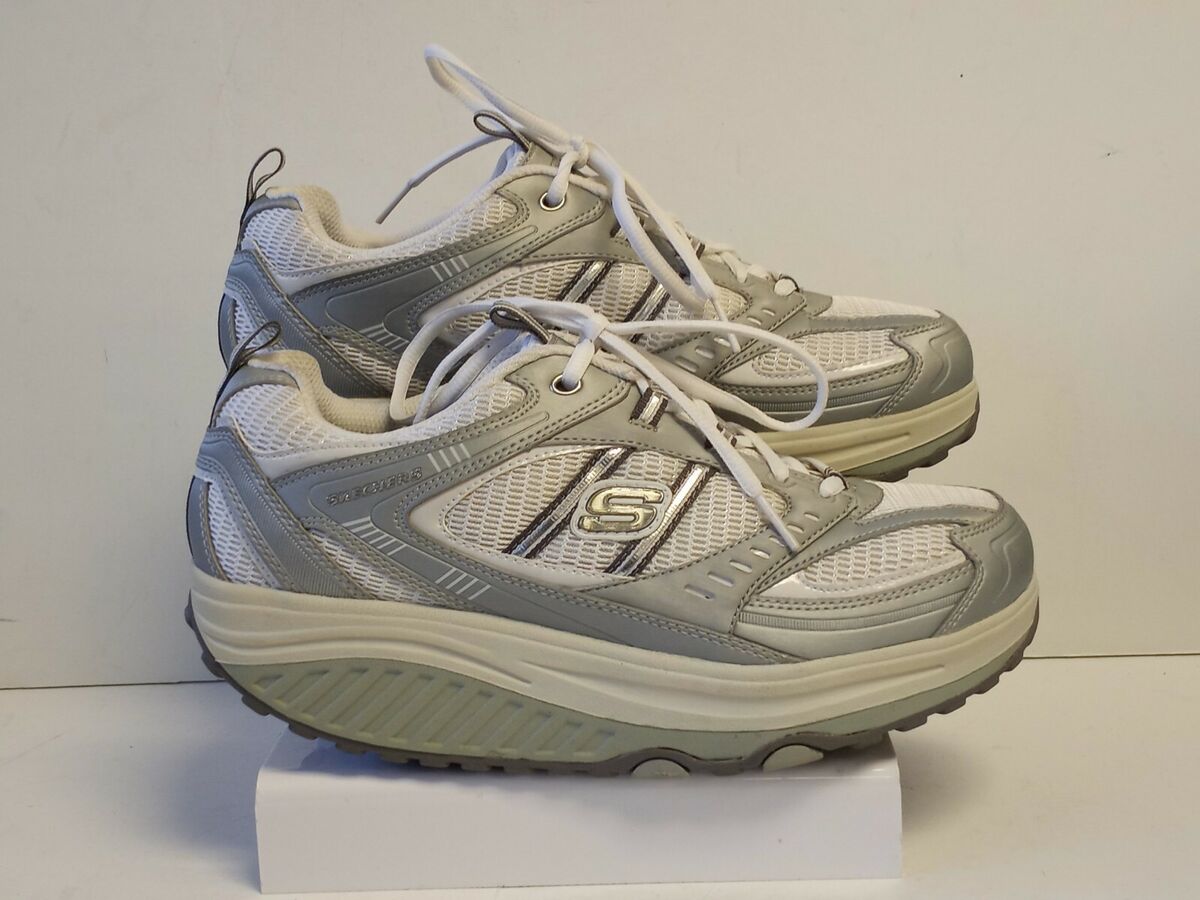

Illustrative Image (Source: Google Search)

Therapeutic/Medical Orthopedic Shoes

Therapeutic orthopedic shoes are designed for individuals with specific medical conditions such as diabetic foot issues, arthritis, or post-surgical needs. They often involve customizable features, medical-grade materials, and advanced support technology. These shoes are sold through medical supply chains, hospitals, and pharmacies. B2B buyers must prioritize compliance with medical standards and consider longer lead times due to customization and regulatory approvals. They also represent a premium segment with higher profit margins, but require precise inventory management and strong supplier relationships.

Children’s Orthopedic Shoes

Children’s orthopedic shoes focus on small sizes with reinforced support to promote healthy foot development. They are flexible yet durable, with features that accommodate growth and activity levels. These shoes are essential for pediatric clinics and specialty retail stores. B2B buyers should focus on reliable manufacturing partners capable of producing small, precise sizes and maintaining consistent quality. The market is growing due to increased awareness of childhood foot health, but order sizes tend to be smaller, requiring efficient inventory turnover strategies.

Key Industrial Applications of skechers orthopedic shoes

| Industry/Sector | Specific Application of skechers orthopedic shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare & Medical | Patient footwear for post-operative and chronic care management | Enhances patient comfort, reduces risk of pressure sores, supports mobility | Certification of medical-grade quality, compliance with healthcare standards, reliable supply chain for consistent delivery |

| Industrial & Construction | Worker safety footwear for long shifts on hard surfaces | Provides superior shock absorption, reduces fatigue, minimizes injury risk | Durability under tough conditions, slip resistance, availability in bulk quantities, adherence to safety regulations |

| Hospitality & Tourism | Staff footwear in hotels, resorts, and cruise lines | Improves staff comfort, promotes a professional appearance, reduces fatigue | Customization options, bulk procurement discounts, adaptability to diverse environments |

| Sports & Recreational | Supportive footwear for sports facilities, gyms, and active leisure | Offers enhanced arch support, injury prevention, and comfort during physical activity | High-performance features, durability, compliance with sport safety standards |

| Logistics & Warehousing | Footwear for warehouse workers and delivery personnel | Ensures comfort during prolonged standing/movement, reduces fatigue and injury | Lightweight design, slip resistance, large order capacity, cost-effectiveness |

Healthcare & Medical

In the healthcare sector, skechers orthopedic shoes are widely used as post-operative and chronic care footwear. They are designed to provide optimal support and pressure distribution, which is crucial for patients recovering from surgery or managing conditions like diabetes or arthritis. For B2B buyers in regions such as Africa and South America, sourcing medical-grade orthopedic shoes that meet local health standards is vital. Reliable supply chains and certifications ensure these shoes can be integrated seamlessly into healthcare facilities, enhancing patient outcomes and reducing liability risks.

Industrial & Construction

In the industrial and construction sectors, workers often spend long hours on hard, uneven surfaces. Skechers orthopedic shoes offer superior shock absorption and support, significantly reducing fatigue and the risk of musculoskeletal injuries. For buyers in the Middle East and Europe, durability and safety certifications (like slip resistance and impact protection) are essential. Procuring these shoes in bulk, with consistent quality, ensures worker safety and productivity, especially in demanding environments.

Hospitality & Tourism

Staff in hospitality and tourism frequently spend extended periods on their feet. Skechers orthopedic shoes provide the necessary comfort and support to maintain high service standards without compromising employee well-being. For international buyers from regions such as Colombia and Saudi Arabia, flexibility in customization—such as branding or specific ergonomic features—is advantageous. Bulk purchasing options and durable, stylish designs support operational efficiency and employee satisfaction.

Sports & Recreational

Sports facilities and gyms require footwear that combines support, comfort, and durability. Skechers orthopedic shoes are suitable for staff and active users, helping prevent injuries and fatigue during physical activities. For B2B buyers, especially those supplying sports centers in diverse climates, selecting shoes with high-performance features like moisture-wicking materials and slip resistance is critical. Ensuring consistent quality and availability for large orders supports ongoing operational needs.

Logistics & Warehousing

In logistics and warehousing, workers endure prolonged standing and frequent movement, increasing fatigue and injury risks. Skechers orthopedic shoes provide essential cushioning and support, improving worker comfort and safety. For buyers in emerging markets and mature economies alike, sourcing lightweight, slip-resistant shoes in bulk at competitive prices is key. These features help optimize workforce productivity and reduce downtime due to foot-related issues.

Strategic Material Selection Guide for skechers orthopedic shoes

Material Analysis for Skechers Orthopedic Shoes

Selecting the appropriate materials for Skechers orthopedic shoes is crucial for ensuring product performance, durability, and compliance across diverse international markets. Below is an in-depth analysis of three common materials used in the manufacturing of these shoes: EVA (Ethylene Vinyl Acetate), Thermoplastic Polyurethane (TPU), and Leather. Each material offers unique advantages and limitations, which are vital considerations for B2B buyers from Africa, South America, the Middle East, and Europe.

EVA (Ethylene Vinyl Acetate)

Key Properties:

EVA is a lightweight, flexible foam material with excellent cushioning properties. It exhibits good shock absorption, making it ideal for insoles and midsoles in orthopedic footwear. EVA performs well within a temperature range of approximately -30°C to 80°C and is resistant to water and many chemicals, though it can degrade under prolonged UV exposure.

Pros & Cons:

* Pros:*

– Cost-effective and widely available, making it suitable for mass production.

– Excellent cushioning and shock absorption, enhancing comfort for orthopedic applications.

– Easy to mold and process, reducing manufacturing complexity.

- Cons:*

- Lower durability compared to harder materials; prone to compression set over time.

- Susceptible to UV degradation if not properly treated, which can affect product lifespan outdoors.

- Limited resistance to high temperatures, which may cause deformation in hot climates.

Impact on Application:

EVA’s water resistance and cushioning make it ideal for insoles and midsoles, especially in markets with high humidity or frequent exposure to water, such as in parts of Africa and South America.

International Considerations:

EVA complies with many international standards like ASTM and EN, but buyers should verify specific certifications for chemical safety and environmental compliance, especially in the European Union (REACH) regulations. For markets with strict environmental standards, sourcing EVA with low VOC emissions is advisable.

Thermoplastic Polyurethane (TPU)

Key Properties:

TPU is a versatile polymer known for its excellent abrasion resistance, elasticity, and chemical stability. It withstands a broad temperature range (-40°C to 80°C) and exhibits high tensile strength and flexibility. TPU is resistant to oils, greases, and many solvents, making it suitable for high-wear components.

Pros & Cons:

* Pros:*

– High durability and resistance to environmental stressors, extending product lifespan.

– Good flexibility and elasticity, aiding in orthopedic support and fit.

– Recyclable, aligning with sustainability goals prevalent in European markets.

- Cons:*

- Higher manufacturing complexity and cost compared to EVA.

- Requires specialized processing equipment, which may increase initial investment.

- Limited transparency and aesthetic options compared to other plastics.

Impact on Application:

TPU is ideal for outsoles, heel counters, and supportive components that require durability and flexibility, especially in climates with high wear and tear, such as in Middle Eastern or European markets.

International Considerations:

TPU materials often meet international standards like ISO, ASTM, and DIN. Buyers should ensure suppliers provide documentation on chemical safety and environmental compliance, particularly for export to Europe where REACH regulations are stringent.

Leather

Key Properties:

Leather remains a traditional and premium material used in orthopedic shoes for its breathability, aesthetic appeal, and natural flexibility. It performs well within a temperature range of -20°C to 30°C and can be treated for water resistance.

Pros & Cons:

* Pros:*

– High breathability, reducing moisture buildup and enhancing foot health.

– Natural durability and aesthetic appeal, aligning with consumer preferences in Europe and upscale markets in South America.

– Can be treated to improve water resistance and longevity.

- Cons:*

- Higher cost and longer manufacturing times.

- Requires maintenance and proper care to prevent cracking and deterioration.

- Variability in quality depending on source and processing, which can impact consistency.

Impact on Application:

Leather is suitable for upper components, especially in orthopedically supportive shoes aimed at premium segments. In humid or hot climates, untreated leather may pose issues unless properly treated.

International Considerations:

Compliance with international standards like ISO 9001 for quality management and environmental certifications (e.g., LWG Leather Working Group) is essential. Buyers should verify that leather suppliers adhere to ethical sourcing and environmental regulations, particularly in regions with strict import standards like Europe and the Middle East.

Summary Table

| Material | Typical Use Case for Skechers Orthopedic Shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| EVA (Ethylene Vinyl Acetate) | Insoles, midsoles | Lightweight, excellent cushioning, cost-effective | Lower durability, UV sensitivity | Low |

| Thermoplastic Polyurethane (TPU) | Outsoles, heel counters, support components | High durability, chemical resistance, flexible | Higher manufacturing cost, processing complexity | Med |

| Leather | Upper components, premium orthopedic shoes | Breathability, aesthetic appeal, natural comfort | Higher cost, maintenance required | High |

Final Recommendations for International B2B Buyers

For markets like Africa and South America, where water exposure and cost considerations are prominent, EVA offers a balanced solution for cushioning and affordability. In regions with harsh environmental conditions or high wear, such as the Middle East, TPU provides superior durability and resilience, justifying its higher cost. European markets, with their emphasis on sustainability and premium quality, favor leather and high-grade TPU, often requiring compliance with strict environmental and safety standards.

Illustrative Image (Source: Google Search)

By understanding these material properties and considerations, B2B buyers can make informed decisions that align with local market demands, regulatory requirements, and cost constraints, ensuring the successful export and distribution of Skechers orthopedic shoes globally.

In-depth Look: Manufacturing Processes and Quality Assurance for skechers orthopedic shoes

Manufacturing Processes of Skechers Orthopedic Shoes

The production of Skechers orthopedic shoes involves a meticulously coordinated series of stages designed to ensure durability, comfort, and compliance with international standards. Understanding these stages helps B2B buyers evaluate manufacturing capabilities and ensure quality consistency.

1. Material Preparation

The process begins with sourcing high-quality raw materials tailored for orthopedic functionality, including specialized foams, supportive insoles, durable yet flexible outsoles, and medical-grade adhesives. Suppliers often select materials that meet or exceed industry standards such as ISO 9001 for quality management and specific certifications like OEKO-TEX for safety. Material inspection at this stage includes checks for defects, consistency in density, and compliance with regional safety standards.

2. Forming and Component Manufacturing

In this stage, components such as the midsole, insole, and outsole are molded and shaped. Techniques such as injection molding, compression molding, and thermoforming are prevalent, depending on the component. For orthopedic shoes, precision is critical—molds are designed to produce consistent shapes that support biomechanical correction. Advanced machinery ensures tight tolerances, vital for achieving the desired fit and support characteristics.

3. Assembly and Integration

The assembled shoes involve attaching insoles, securing upper materials, and integrating supportive structures like arch supports or heel counters. Automated and semi-automated assembly lines enhance efficiency, while manual quality checks ensure proper alignment and attachment. Special attention is paid to the bonding processes, with adhesives tested for durability and safety, ensuring the final product withstands daily wear.

4. Finishing and Quality Control

Final stages include trimming excess material, applying finishing touches, and performing aesthetic inspections. Surface treatments, such as anti-slip coatings or waterproofing, are also applied at this stage. The shoes undergo thorough visual and functional inspections to confirm that they meet design specifications and orthopedic standards.

Quality Assurance Framework for Skechers Orthopedic Shoes

Robust quality assurance (QA) practices are integral to maintaining product integrity, especially for orthopedic footwear that directly impacts health. B2B buyers should understand the QA landscape to verify supplier reliability and compliance with international and regional standards.

1. International Standards and Certifications

– ISO 9001: Most reputable manufacturers adhere to ISO 9001, ensuring systematic quality management processes. This standard emphasizes continuous improvement, customer satisfaction, and defect prevention.

– CE Marking (Europe): For products sold within the European Economic Area, CE marking confirms conformity with health, safety, and environmental protection standards. Skechers orthopedic shoes often carry CE certification, indicating compliance with EU directives.

– Other Certifications: Depending on regional markets, certifications like ASTM (United States), API (Middle East, if applicable), or regional safety standards may be relevant.

2. Quality Control Checkpoints

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival for defects, compliance, and specifications. This includes physical tests (e.g., tensile strength, elongation), chemical composition checks, and safety assessments.

– In-Process Quality Control (IPQC): During manufacturing, checkpoints monitor critical parameters such as mold precision, bonding strength, and assembly accuracy. Techniques like dimensional inspection, functional testing, and in-line visual inspections are employed.

– Final Quality Control (FQC): Before shipment, finished shoes undergo comprehensive testing, including visual inspections, dimensional accuracy, and functional tests like flexibility, slip resistance, and shock absorption.

3. Testing Methods and Equipment

– Mechanical Testing: Includes flexural tests, compression tests, and durability assessments to simulate real-world wear.

– Biomechanical Testing: Ensures orthopedic features like arch support and heel stability meet specified therapeutic functions.

– Safety and Compliance Testing: Impact tests, slip resistance tests, and toxicity assessments (e.g., chemical leaching tests) confirm safety standards are met.

4. Verifying Supplier Quality for International Buyers

– Supplier Audits: Conduct on-site audits focusing on manufacturing processes, quality management systems, and compliance documentation. Engaging third-party inspection firms can provide unbiased evaluations, especially critical in regions with variable quality standards.

– Inspection Reports and Certificates: Require detailed QC reports, test certificates, and process documentation to verify adherence to agreed standards.

– Third-party Inspection and Certification: Employ independent agencies (e.g., SGS, Bureau Veritas) for pre-shipment inspections and certification verification, especially important for buyers from Africa, South America, the Middle East, and Europe where standards may vary.

Regional Considerations for B2B Buyers

Africa and South America:

Buyers should prioritize suppliers with ISO 9001 certification and regional compliance certifications like CE or ASTM. Due diligence through on-site audits or trusted third-party inspections can mitigate risks associated with inconsistent manufacturing standards. Establish clear communication channels to ensure specifications are understood and met.

Middle East:

Given regional regulatory nuances, verify that suppliers hold certifications such as API (if applicable) and comply with local safety standards. Many Middle Eastern markets emphasize product safety and durability, so testing reports should substantiate these claims.

Europe:

European buyers must ensure that orthopedic shoes are CE-marked and compliant with EU regulations like REACH for chemical safety. Rigor in QC documentation and adherence to EU directives is critical, and engaging with suppliers experienced in navigating EU certification processes is advisable.

Actionable Recommendations for B2B Buyers

- Develop a comprehensive supplier qualification process that includes audits, review of QC reports, and verification of certifications.

- Establish clear quality benchmarks and inspection criteria aligned with regional standards to ensure consistency.

- Leverage third-party inspection services for pre-shipment verification, especially in regions with variable manufacturing quality.

- Request detailed documentation such as test reports, process audits, and certification copies to substantiate quality claims.

- Foster ongoing communication and quality monitoring through regular audits and feedback loops to maintain supplier accountability.

By understanding and scrutinizing each stage of manufacturing and quality assurance, international B2B buyers can confidently source Skechers orthopedic shoes that meet regional standards and customer expectations, ensuring long-term success and compliance in diverse markets.

Illustrative Image (Source: Google Search)

Comprehensive Cost and Pricing Analysis for skechers orthopedic shoes Sourcing

Cost Structure Breakdown

Understanding the detailed cost components involved in sourcing Skechers orthopedic shoes is crucial for international buyers aiming to optimize their procurement strategies. The primary cost drivers include:

-

Materials: High-quality, medical-grade foams, supportive insoles, durable fabrics, and orthopedic-specific components contribute significantly to material costs. Premium materials, especially those with certifications (e.g., ISO, OEKO-TEX), tend to increase the base price but also enhance product credibility and appeal.

-

Labor: Manufacturing labor costs vary notably by region. Countries with lower labor costs (e.g., certain Asian manufacturing hubs) can offer more competitive prices. However, skilled labor for orthopedic shoe assembly, which requires precision, may command higher wages, influencing overall costs.

-

Manufacturing Overhead: This encompasses equipment depreciation, factory utilities, and administrative expenses. Factories with advanced automation or certifications (e.g., ISO 9001) might have higher overheads but can also ensure consistent quality.

-

Tooling and Setup Costs: Initial mold creation and tooling are significant upfront investments, especially for customized orthopedic features. These costs are amortized over production volume, so higher MOQ (Minimum Order Quantity) can reduce per-unit costs.

-

Quality Control (QC): Rigorous QC processes, including testing for durability, comfort, and safety certifications, add to costs but are vital for orthopedic products to meet international standards.

-

Logistics and Shipping: Costs depend heavily on the sourcing country, destination, shipping mode (air freight vs. sea freight), and Incoterms. For instance, FOB (Free on Board) terms shift certain costs to the buyer, whereas DDP (Delivered Duty Paid) includes all logistics and duties.

-

Profit Margin: Suppliers typically include a margin that reflects their operational costs, market positioning, and negotiation leverage. Margins can range from 10% to 30% depending on the supplier’s scale and reputation.

Key Price Influencers

Several factors can influence the final pricing and should be carefully negotiated:

-

Order Volume and MOQ: Larger orders usually attract discounts due to economies of scale. Buyers from Africa, South America, and the Middle East should aim for higher MOQ agreements to leverage better unit prices.

-

Product Specifications and Customization: Custom orthopedic features, branding, packaging, and specific design requirements increase costs. Clear communication of specifications upfront helps avoid unexpected expenses.

-

Material Choices: Opting for premium or certified materials elevates product quality but also raises costs. Conversely, cost-effective material options can be considered if they meet safety and durability standards.

-

Certifications and Standards: Meeting international safety, health, and quality standards (e.g., CE, ISO) often entails additional testing and certification costs, but these are essential for market acceptance, especially in regulated regions.

-

Supplier Factors: The size and reputation of the supplier, their production capacity, and geographic location influence pricing. Larger, established manufacturers may offer better stability and quality but may also command higher prices.

-

Incoterms and Shipping Arrangements: FOB terms favor buyers in negotiating shipping costs, while DDP simplifies logistics but at a premium. Buyers should analyze total landed costs, including tariffs, duties, and taxes.

Buyer Tips for Cost Optimization

-

Negotiate Effectively: Leverage larger volume commitments, flexible payment terms, or longer-term contracts to negotiate better prices. Building strong relationships with suppliers fosters trust and potential discounts.

-

Focus on Total Cost of Ownership (TCO): Consider not only the unit price but also costs related to shipping, customs clearance, quality assurance, and after-sales support. Sometimes, paying a slightly higher price upfront can reduce downstream costs.

-

Understand Pricing Nuances: Be aware of hidden costs such as certification fees, testing, or additional customization charges. Request detailed quotations that specify all cost components.

-

Leverage Regional Advantages: For buyers in regions like Colombia or Saudi Arabia, consider sourcing from nearby suppliers to reduce shipping times and costs. Alternatively, explore suppliers in countries with favorable trade agreements (e.g., African Growth and Opportunity Act for certain US imports, or regional trade blocs within Europe).

-

Prepare for Fluctuations: Raw material prices, currency exchange rates, and geopolitical factors can influence costs. Establish flexible pricing agreements or include escalation clauses in contracts.

Disclaimer

Indicative prices for Skechers orthopedic shoes can vary widely based on specifications, order volume, and sourcing country. For example, unit prices might range from $20 to $50 FOB for standard models, but customized or certified products can command higher prices. Always obtain multiple quotations and conduct thorough due diligence before finalizing agreements.

By comprehensively understanding these cost components and influencing factors, international buyers from Africa, South America, the Middle East, and Europe can strategically plan their sourcing to optimize costs, ensure quality, and maintain competitive market positioning.

Spotlight on Potential skechers orthopedic shoes Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for skechers orthopedic shoes.)*

Essential Technical Properties and Trade Terminology for skechers orthopedic shoes

Critical Technical Properties for Skechers Orthopedic Shoes

1. Material Grade and Composition

The quality of materials used in orthopedic shoes directly impacts durability, comfort, and compliance with health standards. Common materials include medical-grade EVA, memory foam, and specialized orthotic insoles. For B2B transactions, specifying the material grade (e.g., FDA-approved, ISO-certified) ensures that products meet international safety and quality benchmarks, reducing risk of rejection or returns.

2. Manufacturing Tolerance

Tolerance levels define the permissible variation in dimensions and structural features of the shoes, such as width, length, and heel height. Tight tolerances (e.g., ±0.5 mm) are critical for ensuring consistent fit, especially for orthotics integration. Precise tolerance control enhances customer satisfaction and reduces logistical issues related to returns or adjustments.

3. Support and Flexibility Ratings

Orthopedic shoes are evaluated based on support levels—such as arch support, heel stability, and flexibility. These properties are often rated according to industry standards (e.g., stiff, semi-rigid, flexible). Clear specifications enable buyers to match products to specific medical or comfort needs, ensuring optimal therapeutic outcomes.

4. Weight and Breathability

Lightweight construction reduces fatigue during prolonged wear, while breathable materials improve hygiene and comfort. These properties are particularly important for mobility-impaired users. Suppliers should provide detailed technical sheets showing weight per pair and fabric breathability indices, aiding buyers in assessing suitability for different climates and usage scenarios.

5. Compliance Certifications

Ensure that the shoes meet relevant international standards, such as CE marking (Europe), ASTM standards (North America), or ISO certifications. Certification guarantees that the products have undergone rigorous testing for safety, durability, and medical efficacy—key factors for procurement decisions in regulated markets.

Essential Trade Terms for Skechers Orthopedic Shoes

1. OEM (Original Equipment Manufacturer)

Refers to factories that produce shoes branded by other companies. Understanding OEM relationships helps buyers negotiate pricing, customization, and intellectual property rights, especially when sourcing from international suppliers.

2. MOQ (Minimum Order Quantity)

The smallest number of units a supplier is willing to produce or sell in a single order. Clarifying MOQ is vital for planning procurement budgets and inventory levels, particularly for new market entries or pilot programs.

3. RFQ (Request for Quotation)

A formal process where buyers solicit detailed price and specification proposals from multiple suppliers. An RFQ allows for apples-to-apples comparison, ensuring transparency and competitiveness in pricing for orthopedic shoes.

4. Incoterms (International Commercial Terms)

Standardized trade terms published by the ICC that define responsibilities for shipping, insurance, and customs clearance. Familiarity with Incoterms (e.g., FOB, CIF, DDP) helps international buyers clarify costs, risks, and delivery timelines, reducing misunderstandings during cross-border transactions.

5. Lead Time

The period from order confirmation to product shipment or delivery. Accurate knowledge of lead times enables buyers to plan inventory replenishment and avoid stockouts, especially in markets with long customs clearance processes.

6. Quality Assurance (QA) and Testing Protocols

Procedures to verify that orthopedic shoes meet specified standards. Understanding QA processes—such as batch testing, certification audits, and compliance checks—ensures product reliability and reduces risks associated with defective shipments or regulatory non-compliance.

Strategic Insights for International B2B Buyers

For buyers from regions like Africa, South America, the Middle East, and Europe, grasping these technical properties and trade terms is fundamental to establishing reliable supply chains. Prioritize suppliers who transparently communicate material standards, support certification compliance, and adhere to clear trade practices. This approach minimizes risks, optimizes costs, and ensures that orthopedic footwear meets local health standards and customer expectations.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the skechers orthopedic shoes Sector

Market Overview & Key Trends

The global orthopedic footwear sector, exemplified by brands like Skechers, is experiencing robust growth driven by demographic shifts, technological innovation, and evolving consumer preferences. Increasing prevalence of musculoskeletal issues, aging populations, and a rising awareness of foot health are fueling demand across diverse markets. For international B2B buyers from Africa, South America, the Middle East, and Europe, this growth presents significant opportunities for sourcing high-quality orthopedic shoes with tailored features.

Emerging sourcing trends include the integration of advanced manufacturing technologies such as 3D printing and automation, which enhance production efficiency and allow for customization at scale. Digital platforms and e-commerce solutions are transforming supply chain management, enabling real-time tracking and more agile inventory management. Additionally, there’s a notable shift toward near-shoring and regional manufacturing hubs to reduce lead times and mitigate geopolitical risks, especially pertinent for buyers in regions like Colombia and Saudi Arabia.

Market dynamics are influenced by increasing consumer demand for comfort, durability, and style, prompting manufacturers to innovate with materials and design. Sustainable and eco-friendly materials are gaining prominence, driven by regulatory pressures and consumer expectations. For B2B buyers, establishing partnerships with suppliers who leverage these trends can improve product competitiveness and market responsiveness. Understanding regional regulatory landscapes, such as import tariffs and quality standards, is essential for seamless market entry and expansion.

Sustainability & Ethical Sourcing in B2B

Sustainability is no longer a peripheral concern but a core aspect of sourcing orthopedic shoes, especially from brands like Skechers that emphasize environmental responsibility. Buyers from Africa, South America, the Middle East, and Europe should prioritize suppliers committed to reducing environmental impacts through ethical sourcing practices. This includes adherence to internationally recognized standards such as Fair Trade, ISO 14001, and SA8000, which ensure fair labor practices and environmentally sound operations.

Eco-conscious materials—such as recycled plastics, natural rubber, and bio-based foams—are increasingly integrated into orthopedic shoe manufacturing. Suppliers that can demonstrate transparent supply chains and possess green certifications offer a competitive advantage, aligning with the growing consumer demand for ethically produced footwear. Additionally, sustainable packaging and waste reduction initiatives contribute to overall environmental impact mitigation.

For B2B buyers, establishing long-term relationships with suppliers committed to sustainability can mitigate risks associated with regulatory non-compliance and reputational damage. Incorporating sustainability criteria into sourcing decisions not only enhances brand value but also aligns with global trends toward circular economy principles. In markets like Europe and the Middle East, where environmental regulations are stringent, such commitments facilitate smoother market entry and consumer acceptance.

Brief Evolution/History (Optional)

The orthopedic shoe market has evolved significantly over the past few decades, transitioning from basic functional designs to highly specialized, technologically advanced products. Initially driven by medical necessity, these shoes now blend comfort with style, appealing to a broader consumer base. Skechers, in particular, has capitalized on this evolution by integrating innovative materials and ergonomic designs, making orthopedic shoes more fashionable and accessible.

This transformation has opened new B2B opportunities, as healthcare providers, retailers, and distributors seek reliable partners capable of delivering high-quality, innovative footwear. Understanding this historical context helps buyers appreciate the importance of R&D investment and quality assurance in sourcing decisions. It also highlights the importance of staying ahead of market trends and technological advancements to maintain competitiveness in a rapidly evolving sector.

Frequently Asked Questions (FAQs) for B2B Buyers of skechers orthopedic shoes

1. How can I verify the credibility and reliability of Skechers orthopedic shoe suppliers?

To ensure supplier credibility, start by requesting comprehensive company documentation, including business licenses, export licenses, and quality certifications (ISO, FDA, CE, etc.). Conduct virtual or in-person audits where possible, focusing on manufacturing facilities, quality control processes, and compliance standards. Seek references from existing international clients, especially those in your region, to gauge their experience. Engaging with reputable trade platforms and industry associations can also provide verified supplier lists. Establish clear communication channels and inquire about their track record in fulfilling international orders to mitigate risks.

2. Are Skechers orthopedic shoes customizable for regional markets, and what are the typical options?

Yes, Skechers offers customization options suitable for regional preferences and market needs. Common customizations include branding (logo placement), packaging, and specific design features like color schemes or orthotic inserts. Some suppliers may also accommodate modifications in sizing standards or material choices to meet local regulations or consumer preferences. To facilitate customization, establish detailed specifications early in negotiations and request samples for approval before mass production. Working with suppliers experienced in international markets ensures smoother adaptation to regional requirements and reduces lead times.

3. What are the typical minimum order quantities (MOQs), lead times, and payment terms for Skechers orthopedic shoes?

MOQs vary depending on the supplier and product complexity but generally range from 500 to 2,000 pairs for orthopedic shoes. Lead times usually span 4 to 8 weeks from order confirmation to shipment, depending on order size and customization. Payment terms commonly include a 30% upfront deposit with the balance payable before shipment or upon receipt, but flexible terms can be negotiated for large or repeat orders. Establish clear contractual agreements early, and consider using secure payment methods such as letters of credit or escrow services to mitigate risks in international transactions.

4. What quality assurance measures and certifications should I look for when sourcing Skechers orthopedic shoes?

Ensure the supplier adheres to internationally recognized quality standards such as ISO 9001 for quality management, as well as certifications specific to orthopedic footwear like CE marking or FDA approval if applicable. Request detailed quality assurance protocols, including material testing reports, durability assessments, and compliance with regional safety standards. Suppliers should provide traceability documentation for materials and manufacturing processes. Conduct pre-shipment inspections or third-party audits to verify product quality. Consistently maintaining quality standards reduces the risk of returns, complaints, and reputational damage in your target markets.

5. How can I manage logistics effectively when importing Skechers orthopedic shoes to my country?

Effective logistics management involves selecting reliable freight forwarders experienced in handling footwear shipments. Consider options such as sea freight for large quantities to reduce costs, or air freight for urgent deliveries. Clarify Incoterms (e.g., FOB, CIF) with your supplier to define responsibilities clearly. Ensure proper packaging to prevent damage during transit and inquire about customs clearance procedures in your country to avoid delays. Establish clear communication channels with your logistics providers and consider using tracking systems for real-time updates. Building strong logistics partnerships minimizes delays and ensures timely delivery to your customers.

6. How should I handle potential disputes or quality issues with Skechers orthopedic shoe suppliers?

Proactively include dispute resolution clauses in your contracts, specifying arbitration or legal jurisdiction aligned with your region. Maintain detailed documentation of all communications, purchase agreements, and inspection reports to support claims. If quality issues arise, communicate promptly with the supplier and request corrective actions, such as replacements or refunds. Consider engaging third-party inspection firms during production and pre-shipment to catch issues early. Building a relationship of transparency and trust with suppliers can facilitate smoother resolution processes, reducing costs and protecting your brand reputation in international markets.

7. What are the key factors to consider for pricing negotiations with Skechers orthopedic shoe suppliers?

Focus on total landed cost, including product price, shipping, customs duties, taxes, and potential tariffs specific to your country. Leverage volume commitments or long-term partnership potential to negotiate better unit prices. Clarify payment terms and inquire about discounts for larger orders or early payments. Request detailed quotations that specify all costs upfront to avoid surprises. Also, consider the supplier’s flexibility on MOQ and lead times, as these can impact your inventory and cash flow. A well-negotiated price should balance competitiveness with sustainable profit margins.

8. How can I ensure ongoing compliance with regional regulations and standards for orthopedic footwear?

Stay informed about regional safety, health, and labeling standards through local regulatory bodies and industry associations. Request documentation from your supplier confirming compliance with these standards, including relevant certifications and test reports. Incorporate compliance checks into your quality assurance process, including periodic audits and product testing. Maintain open communication with local authorities to adapt quickly to any regulatory updates. Establishing a compliance management system ensures your orthopedic shoes meet market requirements, reducing the risk of fines, shipment delays, or product recalls, and enhancing consumer trust in your brand.

Strategic Sourcing Conclusion and Outlook for skechers orthopedic shoes

Conclusion and Future Outlook

Effective strategic sourcing is crucial for international B2B buyers seeking to capitalize on the growing demand for Skechers orthopedic shoes. By establishing strong relationships with reliable manufacturers, prioritizing quality assurance, and leveraging global supply chain efficiencies, buyers can secure competitive pricing and ensure product consistency. Diversifying sourcing channels—such as exploring suppliers in Asia, Eastern Europe, or local manufacturing hubs—can mitigate risks and enhance supply chain resilience.

Looking ahead, the orthopedic footwear market is poised for continued expansion, driven by increasing awareness of foot health and rising healthcare standards worldwide. For buyers in Africa, South America, the Middle East, and Europe, embracing innovative sourcing strategies will be vital to meet evolving market demands and customer expectations.

Actionable Takeaway:

– Conduct thorough supplier assessments, focusing on compliance, quality, and capacity.

– Invest in building long-term partnerships for better negotiation leverage and reliability.

– Stay informed about market trends and technological advancements to remain competitive.

By adopting a strategic, forward-thinking approach, international buyers can unlock sustainable growth opportunities in the orthopedic shoe sector and establish a resilient supply chain capable of adapting to global market shifts.