Master Sourcing Skechers Waterproof Shoes for Global

Guide to Skechers Waterproof Shoes

- Introduction: Navigating the Global Market for skechers waterproof shoes

- Understanding skechers waterproof shoes Types and Variations

- Key Industrial Applications of skechers waterproof shoes

- Strategic Material Selection Guide for skechers waterproof shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for skechers waterproof shoes

- Comprehensive Cost and Pricing Analysis for skechers waterproof shoes Sourcing

- Spotlight on Potential skechers waterproof shoes Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for skechers waterproof shoes

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the skechers waterproof shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of skechers waterproof shoes

- Strategic Sourcing Conclusion and Outlook for skechers waterproof shoes

Introduction: Navigating the Global Market for skechers waterproof shoes

In today’s highly competitive global footwear market, Skechers waterproof shoes have emerged as a vital product category, offering durability, comfort, and weather resistance—attributes highly valued across diverse climates and markets. For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, sourcing high-quality waterproof footwear is essential to meet rising consumer demands and capitalize on expanding retail and distribution channels.

This comprehensive guide is designed to empower you with critical insights into the Skechers waterproof shoes market. It covers essential aspects such as product varieties, innovative materials, manufacturing standards, quality control practices, sourcing options, cost considerations, and market trends. Additionally, it addresses frequently asked questions to help you navigate the complexities of international procurement confidently.

By understanding the nuances of product specifications, supplier landscapes, and compliance requirements, B2B buyers can make informed sourcing decisions that optimize quality and cost-effectiveness. Whether you’re expanding your product portfolio or establishing new supplier relationships, this guide provides actionable intelligence tailored to the needs of markets in Africa, South America, the Middle East, and Europe.

Ultimately, mastering the intricacies of Skechers waterproof shoes enables you to deliver superior products to your customers, enhance your competitive edge, and build sustainable, profitable partnerships in the global footwear industry.

Understanding skechers waterproof shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Casual Waterproof Sneakers | Lightweight, flexible materials with waterproof membrane technology | Retail, wholesale distribution, outdoor apparel | Pros: Versatile, popular for everyday wear; Cons: Limited heavy-duty protection |

| Work & Safety Waterproof Boots | Rugged construction with reinforced toe caps and slip-resistant soles | Industrial, construction, logistics | Pros: Durable, high safety standards; Cons: Heavier, higher procurement cost |

| Hiking & Outdoor Waterproof Shoes | Advanced waterproof membranes (e.g., Gore-Tex), rugged soles for traction | Sporting goods, outdoor gear suppliers | Pros: High performance in extreme conditions; Cons: Higher price point |

| Fashion-Forward Waterproof Footwear | Trendy designs incorporating waterproof features, stylish finishes | Fashion retailers, boutique distributors | Pros: Meets consumer demand for style and function; Cons: Limited durability |

| Slip-Resistant Waterproof Shoes | Special outsole designs for enhanced grip, waterproof upper materials | Hospitality, healthcare, service industries | Pros: Safety-focused, reduces liability; Cons: May be less breathable |

Casual Waterproof Sneakers

This category features lightweight, flexible shoes with waterproof membranes like Gore-Tex or proprietary tech. They are ideal for everyday wear and casual outdoor activities. For B2B buyers, these shoes appeal to mass-market retailers and online platforms targeting urban consumers seeking comfort and weather resistance. When sourcing, consider the balance between quality waterproofing and cost, as well as the style preferences of local markets. Bulk purchasing can benefit from supplier discounts, but ensure quality consistency across batches.

Work & Safety Waterproof Boots

Designed for industrial environments, these boots emphasize durability, safety, and slip resistance. They typically incorporate reinforced toes (steel or composite) and rugged soles suitable for demanding conditions. B2B buyers in sectors like construction, logistics, and manufacturing should prioritize certifications (e.g., ASTM, EN standards) to meet safety regulations. While these boots have higher upfront costs, their longevity and safety features can reduce long-term expenses and liabilities, making them a strategic procurement choice.

Hiking & Outdoor Waterproof Shoes

Built for performance in rugged terrains, these shoes feature high-grade waterproof membranes (such as Gore-Tex) and specialized soles for traction. They are popular among outdoor retailers and specialty sporting goods distributors. For B2B buyers, the focus should be on sourcing from reputable manufacturers to ensure product authenticity and durability. The higher price point requires careful volume negotiations, but these shoes cater to a niche market willing to pay a premium for quality and performance.

Fashion-Forward Waterproof Footwear

Blending style with functionality, this variation includes trendy designs that incorporate waterproofing without sacrificing aesthetics. Suitable for boutique stores and fashion-focused distributors, these shoes meet consumer demand for versatile footwear. B2B buyers should assess the balance between design innovation and waterproof efficacy, ensuring products appeal to local fashion trends. Sourcing from established brands with reliable quality control is essential to maintain brand reputation and customer satisfaction.

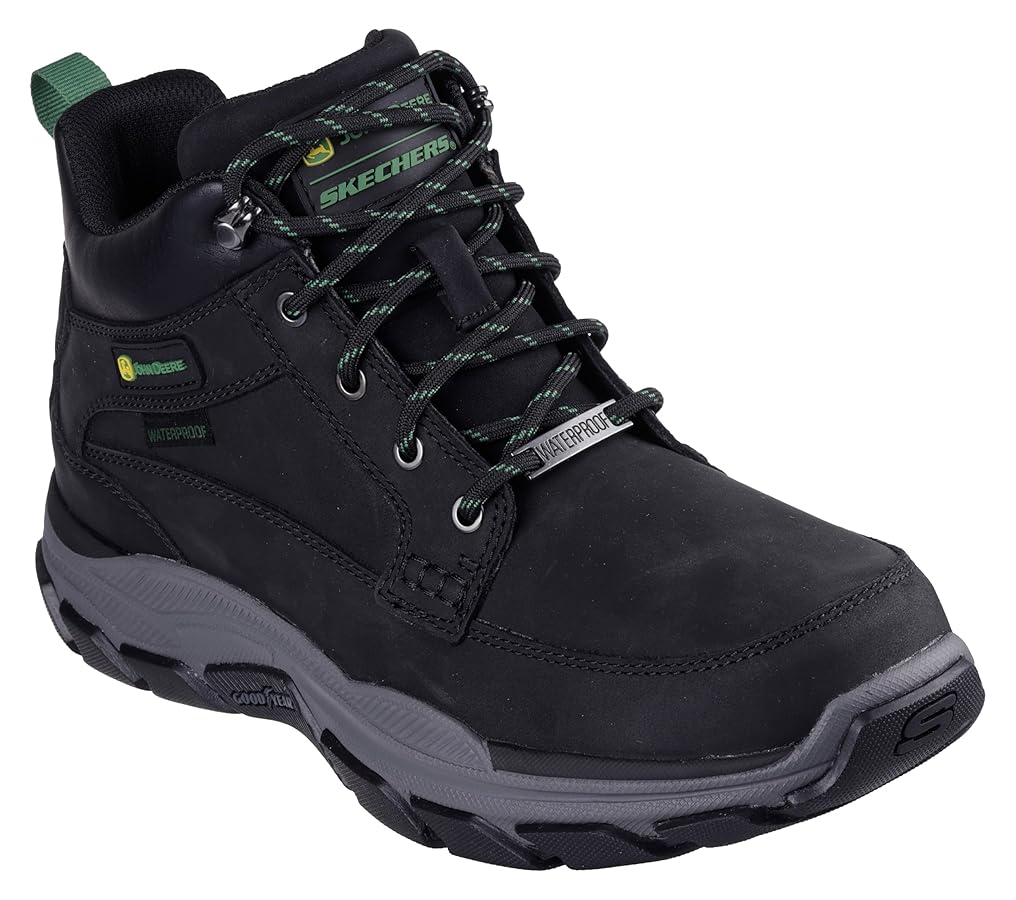

Illustrative Image (Source: Google Search)

Slip-Resistant Waterproof Shoes

This category emphasizes safety features, especially in environments prone to slips and falls, such as hospitals, restaurants, and warehouses. Waterproof materials prevent water ingress, while specially designed outsoles enhance grip. For B2B buyers, compliance with safety standards and certifications is critical. These shoes often have a steady demand, and bulk procurement can leverage economies of scale. Prioritize suppliers with proven track records in safety footwear to ensure consistent quality and performance.

Key Industrial Applications of skechers waterproof shoes

| Industry/Sector | Specific Application of Skechers Waterproof Shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Infrastructure | Workers operating in muddy, wet, or uneven terrains on construction sites | Ensures safety, reduces slip-and-fall risks, and minimizes downtime due to footwear failure | Durability standards, slip resistance, comfort for prolonged wear, supply chain reliability |

| Agriculture & Farming | Farmworkers exposed to wet fields, muddy conditions, or irrigation zones | Protects feet from water ingress, enhances safety, and reduces health risks | Water resistance level, comfort, ease of cleaning, availability for bulk procurement |

| Oil & Gas Industry | Personnel working around pipelines, rigs, and offshore platforms | Prevents water ingress in harsh environments, ensuring safety and operational efficiency | Material compatibility with oil/chemical exposure, slip resistance, compliance with safety standards |

| Logistics & Warehousing | Staff handling goods in refrigerated or damp storage facilities | Keeps feet dry in moist environments, maintaining hygiene and reducing injury risk | Breathability, slip resistance, comfort for extended shifts, scalable sourcing options |

| Urban & Municipal Services | Municipal workers, maintenance crews in rainy or wet urban environments | Enhances worker safety and operational efficiency during adverse weather | Weatherproofing quality, durability, comfort, and ease of maintenance |

Construction & Infrastructure

In construction environments, especially in regions with frequent rain or muddy conditions such as parts of Nigeria or South Africa, Skechers waterproof shoes provide essential safety and comfort. They help prevent slips and falls, which are common hazards on uneven, wet surfaces. For international B2B buyers, sourcing shoes with high slip resistance, durable waterproofing, and comfort for all-day wear is critical. Ensuring supply chain reliability and compliance with local safety standards further enhances operational continuity and worker safety.

Agriculture & Farming

Farmers and agricultural workers often operate in wet fields, irrigated zones, or during rainy seasons across South America and Africa. Waterproof shoes from Skechers protect against waterborne infections, reduce fatigue, and improve productivity by keeping feet dry and comfortable. B2B buyers should prioritize shoes with high water resistance, ease of cleaning, and robustness to withstand harsh outdoor conditions. Bulk procurement strategies should also consider local climate variations and supply consistency.

Oil & Gas Industry

Personnel working on pipelines, offshore rigs, or refineries face challenging environments with exposure to water, chemicals, and rough terrains. Skechers waterproof shoes designed with chemical-resistant materials and slip-resistant soles help ensure safety and operational efficiency. For international buyers, especially in regions like the Middle East or West Africa, sourcing shoes that meet safety standards (e.g., ASTM or ISO certifications) and are compatible with harsh environments is vital for compliance and worker protection.

Logistics & Warehousing

In cold storage facilities or damp warehouses across Europe and South America, workers require footwear that prevents water ingress while maintaining comfort during long shifts. Skechers waterproof shoes offer moisture protection, slip resistance, and ergonomic support, reducing injury risks and enhancing productivity. Sourcing considerations include ensuring consistent supply, selecting models with breathability to prevent overheating, and scalability for large workforce needs.

Urban & Municipal Services

Municipal workers involved in street maintenance, sewer work, or public infrastructure repairs often operate under rainy or wet conditions. Waterproof shoes from Skechers improve safety by preventing slips and keeping feet dry, which is essential in urban environments prone to sudden weather changes. International buyers should focus on durability, ease of cleaning, and compliance with local safety regulations, ensuring that procurement supports both operational efficiency and worker health standards.

Strategic Material Selection Guide for skechers waterproof shoes

Analysis of Common Materials for Skechers Waterproof Shoes

1. Synthetic Leather (PU and PVC)

Synthetic leather, primarily polyurethane (PU) and polyvinyl chloride (PVC), is a prevalent material in waterproof footwear due to its affordability and versatility. It offers excellent water resistance, making it suitable for waterproof shoes designed for diverse climates and media exposure. PU-based synthetic leather tends to be more flexible and breathable than PVC, which is often stiffer but more resistant to harsh chemicals.

Key Properties:

– Water-resistant and often treated for enhanced waterproofing.

– Moderate flexibility; PU is more pliable than PVC.

– Generally resistant to cracking and peeling with proper manufacturing.

Pros & Cons:

– Pros: Cost-effective, easy to manufacture, lightweight, and offers good aesthetic options.

– Cons: Less durable than genuine leather, susceptible to abrasion, and may degrade under prolonged UV exposure. PVC can emit VOCs during manufacturing and disposal, raising environmental concerns.

Impact on Application:

Synthetic leather performs well in media with moderate exposure to water and dirt but may struggle in extreme conditions like heavy rain or prolonged submersion unless specially treated. It is compatible with standard shoe manufacturing processes, including bonding and lamination.

International Buyer Considerations:

Buyers in Africa, South America, the Middle East, and Europe should verify compliance with local environmental standards (e.g., REACH in Europe, chemical safety regulations in Africa and South America). Synthetic leather is widely accepted, but eco-friendly formulations are increasingly preferred, especially in European markets. Durability and breathability are critical for customer satisfaction in regions with high temperatures or humidity.

2. Rubber (Natural and Synthetic)

Rubber remains a cornerstone in waterproof footwear, especially for soles and waterproof membranes. Its inherent water resistance and flexibility make it ideal for footwear that needs to withstand wet conditions and rough terrains.

Key Properties:

– Excellent waterproofing and chemical resistance.

– Highly elastic and durable under repeated flexing.

– Can withstand extreme temperatures, from cold to hot environments.

Pros & Cons:

– Pros: Superior durability, excellent grip, and resistance to abrasion and chemicals.

– Cons: Heavier than other materials, can be less breathable, and synthetic variants may emit VOCs.

Impact on Application:

Rubber is especially suitable for outsoles and waterproof membranes, providing reliable protection in muddy, rainy, or coastal environments. It performs well in media with constant moisture exposure and is compatible with various manufacturing techniques like molding and vulcanization.

International Buyer Considerations:

Rubber products must meet local standards such as ASTM or DIN for safety and quality. Buyers should consider sourcing from suppliers with environmentally responsible manufacturing practices, especially in regions with strict VOC regulations. In markets like Nigeria or South Africa, durability and grip are highly valued, making rubber a preferred choice despite its weight.

3. Gore-Tex and Membrane Technologies

Gore-Tex and similar advanced membrane materials are engineered for waterproof yet breathable footwear. These materials are often used in high-performance Skechers waterproof shoes aimed at outdoor or active consumers.

Key Properties:

– Waterproof and windproof with high breathability.

– Microporous structure allows vapor transfer but blocks water ingress.

– Typically lightweight and flexible.

Pros & Cons:

– Pros: Superior comfort in hot or humid climates, excellent moisture management, and durability.

– Cons: Higher cost, potential sensitivity to punctures, and limited repair options.

Impact on Application:

Ideal for high-performance or outdoor models, Gore-Tex and similar membranes excel in environments with high humidity or temperature fluctuations. They are compatible with various manufacturing processes, including lamination and bonding.

International Buyer Considerations:

Buyers should ensure certification standards (e.g., ISO, ASTM) for waterproof and breathability performance. In regions like Europe, eco-labels and sustainability certifications for membrane materials are increasingly influential. Proper supplier vetting is essential to ensure authenticity and performance consistency.

4. Thermoplastic Elastomers (TPE)

TPE materials are gaining popularity for their flexibility, durability, and eco-friendliness. They are used in waterproof shoe components such as overlays, linings, and flexible membranes.

Key Properties:

– Good elasticity and flexibility.

– Water-resistant and resistant to many chemicals.

– Can be formulated to meet specific temperature and pressure ratings.

Pros & Cons:

– Pros: Recyclable, environmentally friendly, cost-effective, and lightweight.

– Cons: May not match the durability of rubber in extreme conditions, and formulation consistency can vary.

Impact on Application:

TPEs are suitable for flexible parts that require waterproofing and comfort, especially in lightweight or fashion-forward Skechers models. They are compatible with injection molding and lamination processes.

International Buyer Considerations:

Buyers should verify compliance with environmental standards (e.g., REACH, RoHS). TPE’s eco-friendly profile aligns well with European and increasingly eco-conscious markets in Africa and South America. Durability and temperature resistance should be evaluated based on regional climate conditions.

Summary Table

| Material | Typical Use Case for Skechers Waterproof Shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Synthetic Leather (PU/PVC) | Upper material, aesthetic overlays | Cost-effective, versatile, lightweight | Less durable, environmental concerns, less breathable | Med |

| Rubber | Outsoles, waterproof membranes | Superior durability, waterproof, excellent grip | Heavy, less breathable | Med |

| Gore-Tex & Membranes | Breathable waterproof linings | High breathability, reliable waterproofing | High cost, puncture sensitivity | High |

| Thermoplastic Elastomers (TPE) | Flexible overlays, linings, seals | Eco-friendly, flexible, recyclable | Less durable under extreme conditions, variable quality | Med |

This detailed analysis and comparative overview enable international B2B buyers to make informed decisions aligned with regional market demands, environmental standards, and end-user expectations. Selecting the appropriate materials ensures product performance, compliance, and competitive advantage across diverse markets.

Illustrative Image (Source: Google Search)

In-depth Look: Manufacturing Processes and Quality Assurance for skechers waterproof shoes

Manufacturing Processes of Skechers Waterproof Shoes

The production of Skechers waterproof shoes involves a series of meticulously controlled stages designed to ensure durability, waterproof integrity, and consumer safety. For B2B buyers, understanding these key manufacturing processes can facilitate supplier evaluation and quality assurance.

1. Material Preparation and Selection

The process begins with sourcing high-quality, waterproof materials such as Gore-Tex, waterproof membranes, or proprietary water-resistant fabrics. Leather or synthetic uppers undergo treatments like coating or lamination to enhance water resistance. Suppliers often pre-test these materials for permeability, tensile strength, and environmental compliance, ensuring they meet international standards.

2. Cutting and Forming

Automated cutting machines precisely shape uppers and linings based on CAD designs, minimizing material waste and ensuring consistency. The forms or molds used in shaping the shoe components are calibrated to maintain dimensional accuracy. For waterproof shoes, special attention is paid to sealing seams during this stage, often employing heat or ultrasonic welding techniques to prevent water ingress.

3. Assembly and Bonding

The assembly stage involves attaching the upper to the sole via adhesive bonding, stitching, or a combination of both. Waterproof bonding adhesives must withstand environmental stressors and maintain flexibility. Seam sealing is critical; waterproof membranes are taped or sealed with heat-welded seams to prevent water penetration. Advanced manufacturing facilities employ automated stitching and sealing equipment to ensure uniformity.

4. Finishing and Quality Checks

Final touches include adding insoles, laces, and branding elements. The shoes undergo finishing processes such as polishing and surface treatments to enhance appearance and water resistance. During this phase, preliminary inspections are conducted to identify defects like improper sealing, misalignments, or surface imperfections.

Quality Assurance Protocols and Industry Standards

Robust quality assurance (QA) mechanisms are vital for ensuring that Skechers waterproof shoes meet international and industry-specific standards. B2B buyers should verify that their suppliers adhere to these protocols to mitigate risks associated with product failures and non-compliance.

1. International Standards Compliance

– ISO 9001: Most reputable manufacturers operate under ISO 9001 quality management systems, ensuring consistent production processes and continuous improvement. Suppliers should provide valid ISO certificates and audit reports.

– Waterproof and Breathability Certifications: Standards such as ISO 20344 (footwear testing) and ASTM D737 (air permeability) are relevant. For European markets, CE marking signifies compliance with EU directives on safety and environmental impact.

– Environmental and Safety Certifications: LEED, REACH, and other environmental standards are increasingly important, especially for European and Middle Eastern markets emphasizing sustainable manufacturing.

2. Industry-Specific Certifications

– CE Certification: For shoes intended for European markets, CE marking indicates conformity with health, safety, and environmental protection standards.

– API and Other Industry Certifications: While more common in industrial footwear, certain waterproof shoes may require certifications like API standards if used in specialized applications.

Quality Control (QC) Frameworks

Effective QC in footwear manufacturing incorporates multiple checkpoints throughout the production cycle, aligning with international best practices.

1. Incoming Quality Control (IQC)

Raw materials such as fabrics, membranes, adhesives, and trims are inspected upon arrival. Tests include tensile strength, water resistance, and chemical safety (e.g., VOC emissions). Suppliers should provide detailed test reports, and third-party lab certifications can bolster confidence.

2. In-Process Quality Control (IPQC)

During manufacturing, continuous inspections monitor seam sealing integrity, bonding strength, and dimensional accuracy. Automated vision systems can detect misalignments or stitching defects. Sealed seams are tested via water spray or pressure tests to verify waterproof integrity.

3. Final Quality Control (FQC)

Before shipment, finished shoes undergo comprehensive testing, including water ingress tests, flexibility assessments, and durability simulations. Random sampling ensures batch consistency. B2B buyers should request detailed QC reports and, where feasible, conduct third-party audits.

Testing Methods and Verification for International B2B Buyers

1. Water Resistance Testing

– Hydrostatic Pressure Test: Shoes are subjected to water pressure to assess their resistance level.

– Spray Tests: Simulate rain exposure to evaluate seam and material waterproofing.

2. Durability and Mechanical Testing

– Flex Testing: Ensures shoes can withstand repeated bending without seam failure.

– Abrasion Testing: Assesses surface durability, especially for outsole and upper materials.

3. Breathability and Comfort

– Permeability Tests: Measure air and moisture vapor transmission rates.

– Comfort Assessments: Involves subjective and objective evaluations, including cushioning and fit.

4. Certification Verification

B2B buyers should request copies of relevant test reports and certifications, verifying authenticity through issuing laboratories or certification bodies. Engaging third-party inspection agencies like SGS, Intertek, or Bureau Veritas provides unbiased verification.

How B2B Buyers from Africa, South America, the Middle East, and Europe Can Verify Supplier QC

1. Conduct Regular Audits

Engage in on-site audits focusing on manufacturing practices, quality controls, and compliance documentation. Use local audit firms or third-party inspectors familiar with regional manufacturing conditions.

2. Review Quality Documentation

Require comprehensive quality reports, test certificates, and process documentation. Cross-reference these with international standards and perform spot checks to validate claims.

3. Implement Third-Party Inspection and Testing

Employ reputable inspection agencies for pre-shipment inspections and testing. This is especially crucial when dealing with suppliers in regions with varying quality control maturity, such as Nigeria or South Africa.

4. Establish Clear Quality Agreements

Define quality benchmarks, inspection procedures, and corrective action protocols in contractual agreements. Ensure penalties or remedies are specified for non-conformance.

5. Leverage Digital Tools and Certifications

Use digital platforms for real-time QC reporting, supplier audits, and certification tracking. Verify supplier certifications through recognized accreditation bodies to avoid counterfeit or outdated documentation.

Considerations for International B2B Buyers

- Cultural and Regulatory Awareness: Different regions may have varying standards and compliance expectations. Engage local experts or consultants to navigate regional requirements effectively.

- Supply Chain Transparency: Prioritize suppliers with transparent manufacturing practices, traceability, and a proven track record of compliance.

- Customization and Flexibility: Work with manufacturers willing to adapt QC processes to meet specific regional standards, especially for markets demanding high environmental or safety certifications.

By thoroughly understanding manufacturing processes and implementing rigorous QC verification strategies, international B2B buyers from Africa, South America, the Middle East, and Europe can confidently source high-quality Skechers waterproof shoes that meet their market standards and consumer expectations.

Illustrative Image (Source: Google Search)

Comprehensive Cost and Pricing Analysis for skechers waterproof shoes Sourcing

Cost Structure Breakdown for Skechers Waterproof Shoes

Understanding the cost components involved in sourcing Skechers waterproof shoes is essential for effective negotiation and profitability analysis. The primary cost drivers include:

-

Materials: High-quality waterproof fabrics, adhesives, and durable outsole compounds significantly influence costs. Bulk purchasing and establishing long-term supplier relationships can reduce material costs. Variations in material quality or custom specifications will impact unit prices.

-

Labor: Manufacturing labor costs vary considerably by country. For African and South American suppliers, wages may be lower, but quality control and compliance standards must be maintained. European and Middle Eastern manufacturers often have higher labor costs but may offer superior craftsmanship and adherence to stringent standards.

-

Manufacturing Overhead: This encompasses factory expenses, machinery depreciation, and energy costs. Efficient factories with modern equipment can lower overhead per unit, but initial setup costs may be higher.

-

Tooling & Development: Initial tooling investments for molds and prototypes can be substantial but are amortized over large production runs. Custom designs or unique features increase tooling costs.

-

Quality Control & Certification: Ensuring waterproof integrity and durability involves rigorous QC procedures. Certifications (e.g., ISO, CE) add to costs but are often necessary for market access, especially in Europe and the Middle East.

-

Logistics & Shipping: International freight, customs duties, and inland transportation significantly influence landed costs. FOB (Free on Board) prices might appear attractive but can obscure final costs, especially with fluctuating fuel prices and import tariffs.

-

Profit Margin: Suppliers typically add a margin of 10-30%, depending on volume, exclusivity, and relationship strength. Larger orders often negotiate better margins.

Price Influencers and Their Impact

Several factors directly influence the final price of Skechers waterproof shoes in the B2B market:

-

Order Volume & MOQ: Larger orders usually attract lower unit prices due to economies of scale. Many suppliers prefer Minimum Order Quantities (MOQs) ranging from 1,000 to 5,000 pairs, which can be negotiated downward for smaller buyers or through long-term commitments.

-

Customization & Specs: Custom features like branding, specific waterproof technologies, or unique designs increase costs. Suppliers may charge premiums for tailored specifications, but these can be offset by higher retail prices or exclusivity agreements.

-

Materials & Certifications: Premium waterproof fabrics and eco-friendly materials tend to elevate costs. Certifications for waterproof standards and safety regulations also influence pricing, especially in regulated markets like Europe and the Middle East.

-

Supplier Factors: Supplier reputation, production capacity, and geographic location impact pricing. European manufacturers may command higher prices but offer faster lead times and higher quality assurance, whereas Asian or African suppliers might provide more competitive prices with longer lead times.

-

Incoterms & Delivery Terms: FOB prices are common but may not include shipping and customs clearance, which are crucial for total landed cost calculations. DDP (Delivered Duty Paid) agreements simplify logistics but include higher costs.

Strategic Tips for International B2B Buyers

Negotiation & Cost Efficiency:

Engage in transparent negotiations emphasizing long-term partnerships. Leverage your purchase volume and willingness to commit to favorable terms. Consider bundling orders to reduce per-unit costs and explore flexible MOQs.

Total Cost of Ownership (TCO):

Factor in all costs—material procurement, manufacturing, shipping, customs, taxes, and after-sales support—beyond initial purchase prices. This holistic view helps avoid unexpected expenses and ensures profitability.

Pricing Nuances & Market Considerations:

Prices can vary significantly based on regional market conditions. For example, African buyers from Nigeria or South Africa might benefit from lower manufacturing costs but face higher shipping or import duties. European buyers may pay premium prices but gain advantages in quality assurance and compliance.

Indicative Price Range:

As a general guide, FOB prices for Skechers waterproof shoes from Asian suppliers typically range between $10 to $20 per pair for large-volume orders. Smaller orders or customized models may see prices upward of $25-$30 per pair. Always verify current market rates and consider fluctuations in raw material and freight costs.

Final Considerations

Sourcing Skechers waterproof shoes requires a strategic approach to cost management and supplier selection. Prioritize building strong relationships with reputable manufacturers, negotiate flexible terms, and thoroughly analyze the total landed cost to ensure competitive pricing without compromising quality. Tailoring your sourcing strategy to regional market conditions and leveraging volume discounts can significantly enhance profitability and market competitiveness.

Spotlight on Potential skechers waterproof shoes Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for skechers waterproof shoes.)*

Essential Technical Properties and Trade Terminology for skechers waterproof shoes

Key Technical Properties for Skechers Waterproof Shoes

1. Material Grade and Composition

The durability and waterproof performance of Skechers shoes heavily depend on the quality of materials used. High-grade waterproof membranes, such as Gore-Tex or proprietary Hydrotech fabrics, offer superior water resistance while maintaining breathability. For B2B buyers, sourcing shoes with certified, high-quality materials ensures product longevity and customer satisfaction, especially in regions with heavy rainfall or high humidity like Nigeria or parts of South America.

2. Waterproofing Technology and Seal Integrity

This property refers to the shoe’s ability to prevent water ingress through seams, uppers, and soles. Techniques such as taped seams, sealed edges, and waterproof membranes are critical. Industry standards often specify testing methods like hydrostatic pressure tests, with ratings indicating the maximum water height the shoe can withstand. Ensuring shoes meet these standards is vital for durability claims and brand reputation.

3. Tolerance and Manufacturing Precision

Tolerance levels define the acceptable variation in manufacturing, affecting fit and performance. Precise tolerances ensure consistent waterproof performance across batches, reducing returns and warranty claims. For international buyers, verifying that suppliers adhere to strict tolerance standards indicates quality control and reliable product delivery.

4. Sole and Traction Properties

Rubber compounds used in outsoles should provide slip resistance, especially in wet conditions. The tread pattern and rubber hardness are crucial for grip. B2B buyers should specify the required traction standards relevant to the target markets’ terrain and climate, ensuring safety and reducing liability.

5. Flexibility and Comfort

While waterproofing is essential, comfort cannot be compromised. Materials should allow flexibility without sacrificing waterproof integrity. This balance is critical in markets where consumers expect both protection and comfort, such as in Europe or Middle Eastern markets where prolonged wear is common.

6. Weight and Breathability

Lightweight shoes with breathable membranes reduce fatigue and improve wearer comfort. In warmer climates like parts of Africa and South America, breathability directly impacts customer satisfaction and product competitiveness.

Common Trade Terms for Skechers Waterproof Shoes

1. OEM (Original Equipment Manufacturer)

Refers to companies that produce shoes branded and sold by another company. For international buyers, OEM agreements often mean lower costs and customized designs, but require clear specifications to ensure product quality and waterproof standards.

2. MOQ (Minimum Order Quantity)

The smallest number of units a manufacturer agrees to produce per order. Understanding MOQ helps buyers plan inventory and negotiate pricing. Larger MOQs typically reduce unit costs but require significant upfront investment, especially relevant for new market entrants.

3. RFQ (Request for Quotation)

A formal process where buyers solicit price and delivery terms from suppliers. An RFQ ensures competitive pricing and clarifies technical specifications, including waterproof features, materials, and compliance standards.

4. Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and tariffs between buyers and sellers. For example, FOB (Free on Board) or CIF (Cost, Insurance, Freight) terms influence cost calculations and delivery timelines, vital for managing logistics across different regions.

5. Certification Standards

Terms like ISO, ASTM, or regional quality marks specify compliance with safety, environmental, and performance standards. Ensuring that waterproof shoes meet relevant certifications is critical for market acceptance, especially in strict regulatory environments like Europe or South Africa.

6. Lead Time

The period from order placement to delivery. Accurate understanding of lead times allows buyers to plan inventory and avoid stockouts, particularly important when dealing with seasonal demand or urgent market needs.

Final Insights for B2B Buyers

Understanding these technical properties and trade terms equips buyers to make informed decisions, negotiate effectively, and establish reliable supply chains for Skechers waterproof shoes. Clear specifications on material quality, waterproofing standards, and manufacturing tolerances ensure product performance aligns with market expectations. Familiarity with trade terminology like OEM, MOQ, RFQ, and Incoterms streamlines procurement processes and minimizes risks in international transactions. By mastering these aspects, B2B buyers from Africa, South America, the Middle East, and Europe can secure competitive, high-quality waterproof footwear tailored to their specific market needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the skechers waterproof shoes Sector

Market Overview & Key Trends

The global market for waterproof footwear, including Skechers waterproof shoes, is experiencing robust growth driven by increasing urbanization, rising disposable incomes, and a heightened consumer emphasis on functional fashion. For international B2B buyers from Africa, South America, the Middle East, and Europe, understanding these drivers is crucial to capitalize on emerging opportunities.

Technological advancements, such as innovative waterproofing materials and seamless construction techniques, are transforming product offerings, enabling brands like Skechers to deliver lightweight, durable, and stylish waterproof shoes. The adoption of advanced manufacturing processes—such as automation and 3D printing—reduces costs and enhances customization, making it easier for buyers to source tailored products.

Market dynamics are also influenced by shifting consumer preferences toward sustainable and ethically produced goods. Buyers from regions like South Africa, Nigeria, Brazil, and the Middle East are increasingly demanding transparent supply chains and environmentally friendly products. This trend is complemented by digital sourcing platforms and B2B marketplaces that streamline procurement, reduce lead times, and facilitate supplier vetting.

Emerging B2B sourcing trends include the rise of nearshoring and regional manufacturing hubs, which help reduce logistics costs and improve supply chain resilience. Additionally, the integration of digital tools such as blockchain for traceability and AI-driven demand forecasting allows buyers to make more informed purchasing decisions.

For B2B buyers in these regions, establishing strong relationships with manufacturers that prioritize innovation, quality, and sustainability is essential. Diversifying sourcing channels—combining traditional imports with local or regional production—can mitigate risks associated with geopolitical instability, tariffs, or supply chain disruptions.

Overall, staying abreast of technological innovations, consumer trends, and regional market shifts will enable international buyers to competitively source Skechers waterproof shoes that meet both market demands and sustainability standards.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a key consideration in the sourcing of Skechers waterproof shoes, driven by increasing regulatory pressures and consumer awareness. For international B2B buyers, aligning procurement strategies with environmental and ethical standards not only mitigates risks but also enhances brand reputation in their local markets.

Environmental impact reduction begins with sourcing materials such as waterproof membranes and synthetic leathers that are produced with minimal chemical use and low emissions. Recycled materials, such as PET-based fabrics and bio-based polymers, are gaining traction as sustainable alternatives. B2B buyers should prioritize suppliers that hold certifications like Global Recycled Standard (GRS), OEKO-TEX, or Bluesign, which verify eco-friendly production processes and material integrity.

Ethical sourcing extends beyond environmental considerations to include fair labor practices, safe working conditions, and supply chain transparency. Engaging with suppliers that adhere to standards such as SA8000 or Fair Trade ensures compliance with international labor laws and promotes social responsibility. Digital traceability tools, including blockchain, can provide visibility across the supply chain, allowing buyers to verify compliance and avoid reputational risks associated with unethical practices.

Incorporating sustainability into procurement also involves evaluating a supplier’s commitment to reducing carbon footprints through energy-efficient manufacturing and logistics practices. Some manufacturers are adopting circular economy principles, designing products for recyclability and reuse, which aligns with the global shift toward sustainable consumption.

For B2B buyers, establishing long-term partnerships with suppliers committed to ‘green’ certifications and ethical practices can lead to more reliable supply chains and greater consumer trust. Investing in supplier development programs and audits can further ensure adherence to sustainability standards, ultimately positioning buyers as responsible stewards in their respective markets.

Brief Evolution/History (Optional)

The waterproof shoe sector, including Skechers waterproof shoes, has evolved significantly over the past two decades. Initially focused on utilitarian outdoor footwear, the industry has shifted toward a blend of fashion, comfort, and performance. Advances in waterproof technologies—such as Gore-Tex and other membrane systems—have made waterproof shoes more breathable and lightweight, broadening their appeal beyond outdoor enthusiasts to mainstream consumers.

For B2B buyers, this evolution has translated into increased product innovation and differentiation, requiring suppliers to stay at the forefront of material science and manufacturing techniques. As sustainability became a global priority, waterproof shoe manufacturers integrated eco-friendly materials and ethical practices into their development cycles, aligning with international standards and consumer expectations.

Understanding this evolution helps buyers anticipate future trends, such as the integration of smart textiles and IoT-enabled features, which could further enhance product value. Staying informed about technological and material advancements enables strategic sourcing decisions, ensuring competitiveness in dynamic markets worldwide.

Frequently Asked Questions (FAQs) for B2B Buyers of skechers waterproof shoes

1. How can I verify the credibility and reliability of a Skechers waterproof shoe supplier?

To ensure supplier credibility, start by requesting certifications such as ISO, CE, or other relevant industry standards. Review their business licenses, and ask for references from other international buyers, especially from your region. Conduct virtual or in-person audits if possible, focusing on production capacity, quality control processes, and compliance with safety standards. Additionally, assess their communication responsiveness and transparency. Partnering with suppliers who have a proven track record in international trade, and positive reviews from reputable buyers, minimizes risks and ensures a stable supply chain.

2. What customization options are available for Skechers waterproof shoes to suit regional markets?

Many suppliers offer customization in design, branding, and packaging to cater to regional preferences. Options include logo placement, color variants, sole design, and packaging language. Clarify whether the supplier supports OEM or ODM services, and discuss minimum order quantities (MOQs) for custom orders. Be aware that customization may influence lead times and costs, so establish clear specifications upfront. Local market trends, climatic conditions, and consumer preferences should guide your customization choices to improve market acceptance and sales.

3. What are typical minimum order quantities (MOQs), lead times, and payment terms for international bulk orders?

MOQs for Skechers waterproof shoes often range from 500 to 2,000 pairs, depending on the supplier and customization level. Lead times generally vary from 4 to 12 weeks, influenced by order complexity and production capacity. Payment terms commonly include 30% upfront and 70% before shipment, but flexible arrangements can be negotiated, especially for trusted partners. It’s advisable to establish clear contractual terms, including penalties for delays, to safeguard your investment and ensure timely delivery.

4. What quality assurance certifications and testing should I request before importing Skechers waterproof shoes?

Request suppliers to provide quality certifications such as ISO 9001, CE, or ASTM standards, depending on your target market. Ensure the shoes undergo rigorous testing for waterproof efficacy, slip resistance, durability, and safety compliance. Ask for test reports from accredited laboratories, and consider third-party inspections during production and pre-shipment. Implementing a comprehensive QA process minimizes the risk of defective products reaching your customers, reducing returns and enhancing brand reputation.

5. How can I manage logistics and shipping efficiently for large international orders?

Partner with suppliers experienced in international freight, who can assist with customs documentation, Incoterms, and freight forwarding. Choose reliable logistics providers with regional expertise to optimize shipping routes and costs. Consider consolidating shipments to reduce expenses, and ensure the supplier provides tracking information. Additionally, familiarize yourself with import duties, taxes, and regulations specific to your country to avoid delays. Establishing clear communication channels with your logistics partners ensures smooth delivery and inventory management.

6. What are common dispute resolution mechanisms if quality or delivery issues occur?

Proactively include dispute resolution clauses in your purchase agreements, specifying arbitration or mediation under internationally recognized standards such as ICC rules. Maintain detailed records of communications, inspections, and test reports to support your claims. Engaging third-party inspection agencies at critical stages can provide impartial assessments. Cultivating a collaborative approach with your supplier and establishing transparent communication helps resolve issues efficiently, preserving business relationships and minimizing financial losses.

7. How do I ensure compliance with regional import regulations and standards?

Research your country’s import regulations, including product safety standards, labeling requirements, and environmental laws. Request from your supplier all necessary compliance documents, such as test reports and certificates, to facilitate customs clearance. Consider hiring local compliance consultants or customs brokers to navigate complex regulatory environments. Staying updated on regional trade agreements and tariffs can also optimize costs and streamline import processes. Compliance not only ensures legal entry but also enhances consumer trust in your products.

8. What strategies can I use to build long-term relationships with Skechers waterproof shoe suppliers?

Focus on transparent communication, prompt payments, and consistent order volumes to foster trust. Provide feedback on product quality and delivery performance to help suppliers improve. Consider establishing long-term contracts with favorable terms, including volume discounts and priority production slots. Visiting suppliers or hosting virtual tours can strengthen partnerships and ensure alignment of quality expectations. Maintaining a collaborative approach, along with ongoing market insights, helps secure reliable supply chains and favorable pricing in the competitive international market.

Strategic Sourcing Conclusion and Outlook for skechers waterproof shoes

Strategic Sourcing Outlook for Skechers Waterproof Shoes

Effective strategic sourcing is crucial for international buyers seeking to optimize their supply chains and secure high-quality Skechers waterproof shoes. By establishing strong relationships with reliable manufacturers—particularly in regions with advanced manufacturing capabilities—buyers can ensure product consistency, competitive pricing, and faster turnaround times. Diversifying sourcing channels across key regions such as Asia, Africa, and South America can also mitigate risks associated with geopolitical shifts or supply disruptions.

For buyers in Africa, South America, the Middle East, and Europe, understanding regional manufacturing strengths and logistical considerations is essential. Leveraging local trade agreements and exploring nearshoring options can reduce costs and lead times, enhancing competitiveness in local markets. Additionally, fostering transparent communication and quality assurance processes will help maintain product standards and customer satisfaction.

Looking ahead, the demand for durable, waterproof footwear is expected to grow as climate variability and urbanization increase. International B2B buyers should seize this opportunity by adopting strategic sourcing practices that prioritize agility, quality, and sustainability. Proactively engaging with trusted suppliers now will position your business for long-term success in the global footwear market.