Master Sourcing Top-Quality Keen Hiking Shoes for Global

Guide to Keen Hiking Shoes

- Introduction: Navigating the Global Market for keen hiking shoes

- Understanding keen hiking shoes Types and Variations

- Key Industrial Applications of keen hiking shoes

- Strategic Material Selection Guide for keen hiking shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for keen hiking shoes

- Comprehensive Cost and Pricing Analysis for keen hiking shoes Sourcing

- Spotlight on Potential keen hiking shoes Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for keen hiking shoes

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the keen hiking shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of keen hiking shoes

- Strategic Sourcing Conclusion and Outlook for keen hiking shoes

Introduction: Navigating the Global Market for keen hiking shoes

In the fiercely competitive landscape of outdoor footwear, keen hiking shoes have emerged as a vital product category for global B2B buyers seeking quality, innovation, and market differentiation. As demand for durable, high-performance hiking footwear grows across regions such as Africa, South America, the Middle East, and Europe—including key markets like Saudi Arabia and South Africa—understanding the nuances of sourcing these products becomes paramount. Effective procurement not only enhances your product portfolio but also strengthens your competitive edge in diverse markets.

This comprehensive guide is designed to equip international B2B buyers with critical insights into the entire value chain of keen hiking shoes. It covers essential topics such as the various types of hiking shoes suited for different terrains and climates, the materials that influence durability and comfort, and the manufacturing and quality control standards to ensure product reliability. Additionally, it provides actionable guidance on sourcing reputable suppliers, evaluating costs, and understanding market trends, alongside answers to frequently asked questions.

By leveraging this guide, buyers from emerging and established markets can make informed, strategic sourcing decisions that align with regional preferences, regulatory requirements, and consumer expectations. Whether you are expanding your product offerings or entering new markets, this resource empowers you to navigate the complexities of the global hiking shoe market with confidence—ultimately fostering stronger supplier relationships and driving sustainable growth.

Understanding keen hiking shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Lightweight Hiking Shoes | Minimalist design, low-profile cushioning, breathable materials | Trekking agencies, outdoor retailers, travel gear suppliers | Pros: Cost-effective, high comfort, easy to stock; Cons: Less durability for rugged terrain |

| Mid-Cut Hiking Boots | Ankle support, reinforced uppers, durable outsoles | Specialty outdoor stores, adventure tour operators | Pros: Enhanced ankle protection, versatile for varied terrains; Cons: Heavier, higher price point |

| Waterproof Hiking Shoes | Waterproof membranes (e.g., Gore-Tex), sealed seams | Retailers targeting wet climates, hunting, fishing gear | Pros: Appeal in wet regions, increased customer satisfaction; Cons: Higher manufacturing costs, potentially heavier |

| Trail Running Shoes | Lightweight, flexible, aggressive tread pattern | Sports stores, outdoor activity centers, specialty retailers | Pros: Popular among younger demographics, quick turnover; Cons: Limited suitability for rugged, prolonged hikes |

| Insulated Hiking Shoes | Thermal insulation, insulated linings, weather-resistant outer shells | Retailers in cold climates, winter sports suppliers | Pros: High appeal in cold regions, increased product variety; Cons: Higher production costs, niche market |

Lightweight Hiking Shoes

Lightweight hiking shoes are designed for comfort and agility, featuring minimal cushioning and breathable uppers. They are ideal for day hikes on well-maintained trails, appealing to casual hikers and travel-focused consumers. B2B buyers should consider sourcing options that balance cost and quality, ensuring the shoes meet local demand for comfort without sacrificing durability. They are well-suited for markets with high outdoor activity levels but less rugged terrain, such as parts of South America and Europe.

Mid-Cut Hiking Boots

Mid-cut hiking boots provide substantial ankle support and are constructed with reinforced uppers for durability. They are favored by serious hikers and adventure tour operators who require footwear capable of handling varied and challenging terrains. For B2B buyers, selecting models with reliable waterproofing and sturdy outsoles can enhance appeal in regions prone to rain or snow, such as parts of South Africa or the Middle East. Bulk purchasing of versatile models can streamline inventory for retailers targeting diverse outdoor markets.

Waterproof Hiking Shoes

These shoes incorporate waterproof membranes like Gore-Tex, making them ideal for wet climates and terrains. They are highly attractive to consumers in regions with high rainfall or humid conditions, including parts of Africa and South America. B2B buyers should focus on sourcing shoes with proven waterproof performance and breathability to meet customer expectations. While they tend to be more expensive to produce, their added functionality can command premium pricing and foster brand loyalty.

Trail Running Shoes

Trail running shoes are lightweight, highly flexible, and feature aggressive tread patterns for traction. They cater to a niche segment of outdoor enthusiasts who prefer speed and agility over ruggedness. B2B buyers in specialty sports retail or adventure centers should consider stocking these for markets with active, younger demographics. While less suitable for prolonged or technical hikes, they offer fast turnover and high margins in urban or recreational outdoor markets.

Insulated Hiking Shoes

Designed for cold climates, insulated hiking shoes feature thermal linings and weather-resistant shells, making them suitable for winter trekking and alpine adventures. They are vital for retailers in colder regions of Europe, the Middle East, or South America, where winter tourism and outdoor activities are prevalent. B2B buyers should prioritize sourcing reliable insulation and waterproofing to meet seasonal demand, ensuring a competitive edge in niche cold-weather markets.

Key Industrial Applications of keen hiking shoes

| Industry/Sector | Specific Application of keen hiking shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Infrastructure | On-site worker safety and mobility in rugged terrains | Enhanced worker safety, reduced injury risk, increased productivity | Durability, slip resistance, comfort for extended wear, local availability |

| Oil & Gas | Exploration and maintenance in remote, uneven terrains | Reliable footwear for harsh environments, minimizing downtime | Resistance to oil, chemicals, high grip, compliance with safety standards |

| Agriculture & Forestry | Fieldwork in uneven, muddy, or forested environments | Improved traction and foot protection, reducing fatigue | Waterproofing, breathability, rugged outsole, cost-effectiveness |

| Tourism & Adventure Travel | Guided hikes and eco-tourism activities in challenging terrains | Enhanced safety and comfort for guides and tourists | Lightweight design, durability, non-marking soles, regional sourcing options |

| Manufacturing & Warehousing | Indoor and outdoor logistics operations | Comfortable, slip-resistant footwear for long shifts | Slip resistance, ergonomic support, compliance with occupational safety standards |

Construction & Infrastructure

In the construction and infrastructure sector, keen hiking shoes are vital for workers operating on uneven, rocky, or debris-laden sites. These shoes provide essential grip, ankle support, and durability, helping prevent slips and injuries. For international buyers in Africa, South America, or the Middle East, sourcing shoes that meet local safety standards and withstand harsh conditions is critical. The focus should be on high-quality, rugged materials that offer long-term wear and comfort during extended shifts, reducing downtime and boosting overall site safety.

Oil & Gas

Oil and gas exploration often occurs in remote, challenging environments with rugged terrains and exposure to chemical or oil spills. Keen hiking shoes designed for these conditions offer chemical resistance, high traction, and waterproofing to ensure worker safety and operational efficiency. International B2B buyers should prioritize sourcing footwear with compliance certifications (e.g., OSHA, ISO) and materials resistant to oil, chemicals, and extreme weather. Reliable, durable shoes reduce injury risks and operational delays, especially in regions like the Middle East or South America.

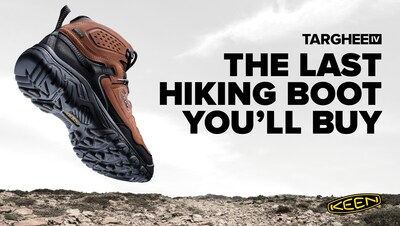

Illustrative Image (Source: Google Search)

Agriculture & Forestry

Agricultural and forestry operations demand footwear that can handle muddy, uneven, and sometimes slippery terrains. Keen hiking shoes equipped with waterproof features, rugged soles, and breathable materials help workers maintain traction, reduce fatigue, and protect against environmental hazards. For buyers in South Africa or Latin America, sourcing options should emphasize durability, cost-effectiveness, and regional availability to ensure timely supply. Proper footwear enhances productivity and safety in demanding outdoor environments.

Tourism & Adventure Travel

Eco-tourism and adventure travel industries rely heavily on guided hikes through challenging terrains. Keen hiking shoes provide tourists and guides with superior grip, comfort, and foot protection, ensuring safety during long excursions. For international B2B buyers, sourcing lightweight, non-marking, and durable shoes that align with regional preferences and environmental standards is essential. These shoes help enhance the overall experience, reduce injury risks, and promote sustainable tourism practices.

Manufacturing & Warehousing

In manufacturing and warehousing sectors, especially those with outdoor logistics or warehouse operations in variable climates, keen hiking shoes offer slip resistance, ergonomic support, and durability. They are suitable for long shifts and diverse indoor/outdoor conditions. For buyers in Europe or Africa, sourcing shoes that comply with occupational safety standards (like EN or OSHA) and are available locally can optimize supply chains. Proper footwear reduces workplace accidents and increases operational efficiency.

Strategic Material Selection Guide for keen hiking shoes

Material Analysis for Keen Hiking Shoes

Selecting the appropriate materials for hiking shoes is crucial for ensuring durability, comfort, and performance across diverse terrains and climates. For international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, understanding the properties and limitations of key materials enables informed procurement decisions that align with market demands and compliance standards.

Leather (Full-Grain and Nubuck)

Key Properties:

Leather, especially full-grain and nubuck, offers excellent durability, breathability, and natural water resistance when properly treated. It maintains strength under repeated flexing and resists tearing, making it ideal for rugged outdoor use. Leather also conforms to the foot over time, enhancing comfort.

Pros & Cons:

– Pros: High durability, natural aesthetics, good moisture management, and ease of repair.

– Cons: Heavier than synthetic alternatives, higher manufacturing complexity, and requires regular maintenance to prevent cracking and deterioration.

Impact on Application:

Leather performs well in dry to moderately wet conditions but may require waterproofing treatments for heavy rain or snow. It is compatible with various environmental media but can degrade if exposed to prolonged moisture without proper treatment.

International Buyer Considerations:

Leather must comply with environmental and animal welfare standards, especially in Europe where regulations like REACH and the Leather Working Group certification are prevalent. For African and Middle Eastern markets, sourcing from suppliers adhering to sustainable practices can enhance product appeal. Leather’s weight and maintenance needs should be communicated clearly to end-users to align with regional preferences.

Synthetic Textiles (e.g., Nylon, Polyester)

Key Properties:

Synthetic textiles are lightweight, flexible, and resistant to environmental factors such as moisture, UV radiation, and abrasion. They are often used in mesh panels for breathability and in durable overlays for structural support.

Pros & Cons:

– Pros: Cost-effective, easy to manufacture, quick-drying, and resistant to rot and mold.

– Cons: Generally less durable than leather, susceptible to tearing if overstressed, and can degrade under prolonged UV exposure.

Impact on Application:

Ideal for hot and humid climates, synthetic materials help maintain airflow and reduce weight, which is advantageous for long-distance trekking. However, in regions with high UV exposure, UV stabilizers or protective coatings are recommended to prolong material lifespan.

International Buyer Considerations:

Synthetic textiles must meet standards such as ASTM D5034 for tear strength or ISO 105-B02 for color fastness. Buyers should verify supplier certifications for UV and weather resistance, especially for markets with intense sunlight like the Middle East. Cost considerations make synthetics attractive for mass-market footwear, but durability claims should be validated through testing.

Rubber and Thermoplastic Urethane (TPU)

Key Properties:

Rubber and TPU are primarily used in outsoles and protective overlays. They provide excellent grip, shock absorption, and abrasion resistance. TPU offers added flexibility and can be formulated for enhanced chemical resistance.

Pros & Cons:

– Pros: High wear resistance, excellent grip, and weatherproofing capabilities.

– Cons: Rubber can be heavy and may degrade over time with exposure to oils and solvents; TPU manufacturing can be more complex and costly.

Impact on Application:

Rubber outsoles are suitable for diverse terrains, including rocky and muddy environments common in South America and Africa. TPU overlays improve structural integrity and can be customized for specific performance needs.

International Buyer Considerations:

Rubber and TPU materials should conform to standards such as DIN EN ISO 140-8 for abrasion resistance or ASTM D2240 for hardness. Suppliers should provide certifications to ensure compliance with local environmental regulations, especially in eco-sensitive markets like Europe. For Middle Eastern climates, heat-resistant formulations are essential to prevent outsole melting or deformation.

Summary Table

| Material | Typical Use Case for keen hiking shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather | Upper material, structural support | High durability, natural aesthetics, repairability | Heavy, high maintenance, manufacturing complexity | High |

| Synthetic Textiles | Mesh panels, lightweight overlays | Lightweight, quick-drying, cost-effective | Less durable, UV susceptible, tear-prone in some cases | Low |

| Rubber & TPU | Outsoles, protective overlays | Excellent grip, abrasion resistance, weatherproofing | Rubber can be heavy, TPU manufacturing costlier | Med |

This detailed understanding of material properties and regional considerations enables B2B buyers to select optimal materials tailored to their target markets, ensuring product performance, compliance, and customer satisfaction across diverse geographic and climatic conditions.

Illustrative Image (Source: Google Search)

In-depth Look: Manufacturing Processes and Quality Assurance for keen hiking shoes

Manufacturing Processes for Keen Hiking Shoes

The production of high-quality keen hiking shoes involves a series of meticulously controlled stages, each critical to ensuring durability, comfort, and safety. The process typically begins with material preparation, where raw materials such as leather, synthetic fabrics, rubber, and specialized membranes (like GORE-TEX) are sourced and tested for compliance with international standards. Suppliers often work with suppliers certified under ISO 9001 to ensure consistent quality of raw inputs.

Next is forming and cutting, which utilizes advanced CAD/CAM technology for precision. Cutting is performed via automated machinery, minimizing waste and ensuring uniformity. The upper assembly involves stitching, bonding, and lamination, employing techniques such as heat sealing and ultrasonic welding for waterproofing and durability. The sole attachment employs durable adhesives, vulcanization, or direct injection molding, depending on the design specifications.

Finishing includes quality checks, surface polishing, and adding aesthetic features like logos or reflective elements. Final assembly ensures that each component aligns with ergonomic standards, providing optimal fit and support. During this stage, manufacturers also perform waterproof testing and flexibility assessments to confirm that shoes meet performance expectations.

Quality Control (QC) Protocols and International Standards

To guarantee product integrity, keen hiking shoe manufacturers adhere to rigorous Quality Control (QC) procedures aligned with international standards such as ISO 9001. This certification emphasizes a systematic approach to quality management, ensuring processes are consistent and improvements are ongoing.

QC checkpoints are embedded throughout production:

-

Incoming Quality Control (IQC): Raw materials are inspected upon arrival for defects, compliance with specifications, and environmental standards. For instance, leather must meet specific tensile strength and water resistance criteria.

-

In-Process Quality Control (IPQC): During manufacturing, critical steps like stitching, bonding, and sole attachment are monitored. Techniques such as visual inspections, dimensional checks, and bond strength tests are employed. Automated inspection systems can detect stitching errors or material inconsistencies in real-time.

-

Final Quality Control (FQC): The finished product undergoes comprehensive testing, including flexibility, waterproofness, abrasion resistance, and load-bearing capacity. Functional tests simulate real-world conditions to verify performance.

Common testing methods include:

- Accelerated wear testing to predict lifespan.

- Waterproof testing via pressure chambers.

- Slip resistance testing following standards like ASTM D2047.

- Tensile and adhesion tests to assess bonding strength.

Industry-Specific Certifications and Standards

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, understanding the certification landscape is vital.

- CE Marking (European Conformity): Indicates compliance with EU safety, health, and environmental requirements, crucial for sales within European markets.

- ISO 9001 Certification: Demonstrates adherence to quality management systems, ensuring consistent product quality.

- Additional certifications: Depending on regional requirements, suppliers might also hold ASTM standards for slip resistance or REACH compliance for chemical safety.

In certain markets, API standards or ISO 20345 (personal protective equipment) might be relevant, especially if the shoes are marketed for professional or industrial use.

Verifying Supplier QC and Ensuring Product Consistency

B2B buyers should implement thorough verification procedures to assess supplier QC capabilities:

-

Supplier Audits: Conduct on-site audits focusing on manufacturing facilities, quality management systems, and personnel training. Audits should verify adherence to ISO 9001, environmental standards, and regional certifications.

-

Review of QC Reports: Request detailed QC documentation, including inspection reports, test certificates, and process control records. These reports should include results from standardized tests and any non-conformance issues addressed.

-

Third-party Inspections: Engage independent inspection agencies (e.g., SGS, Bureau Veritas, Intertek) to perform pre-shipment inspections and random sampling tests. These inspections can validate compliance with specifications and international standards.

-

Sample Testing: Conduct independent testing of product samples for key performance indicators such as waterproofing, durability, and slip resistance, especially when sourcing from new suppliers.

-

Certification Verification: Confirm authenticity of certifications through issuing bodies or certification databases, especially for CE, ISO, or regional standards.

Special Considerations for International B2B Buyers from Diverse Regions

Buyers from Africa, South America, the Middle East, and Europe face unique challenges and opportunities in QC verification:

-

Regional Regulatory Compliance: Ensure that suppliers understand and meet specific regional standards, such as SANS 1539 in South Africa, REACH in Europe, or GSO standards in Saudi Arabia. This may involve additional testing or certification.

-

Supply Chain Transparency: Prioritize suppliers with transparent supply chains, traceable raw material sourcing, and clear documentation to mitigate risks related to counterfeit or substandard components.

-

Cultural and Environmental Factors: Consider climatic conditions—such as high humidity or extreme temperatures—that influence material selection and testing protocols. Suppliers should provide evidence of durability tests under relevant environmental conditions.

-

Capacity for Customization and Certifications: Ensure suppliers are capable of customizing products to meet regional preferences and obtain necessary certifications for local markets, facilitating smoother market entry.

Conclusion

For B2B buyers, understanding the detailed manufacturing processes and rigorous quality assurance measures underpin successful sourcing of keen hiking shoes. Emphasizing transparent QC practices, adherence to international standards, and supplier verification ensures product quality, safety, and compliance across diverse markets. Establishing strong, verified supplier partnerships rooted in quality management excellence will result in durable, high-performance hiking footwear that meets the demands of global consumers.

Comprehensive Cost and Pricing Analysis for keen hiking shoes Sourcing

Cost Structure Breakdown

Understanding the comprehensive cost structure for Keen hiking shoes is essential for effective sourcing and pricing negotiations. The primary components include:

-

Materials: The quality of fabrics, rubber soles, insoles, and waterproof membranes significantly influences costs. High-performance materials with specialized features (e.g., Gore-Tex, Vibram soles) tend to increase material expenses but can justify premium pricing.

-

Labor: Manufacturing costs vary based on the sourcing country. Countries like Vietnam, China, and Indonesia typically offer lower labor costs, whereas Eastern European suppliers may charge higher wages but offer closer proximity to European markets.

-

Manufacturing Overheads: Factory operational expenses, including machinery depreciation, energy, and maintenance, are factored into unit costs. Larger factories with higher automation may have higher initial investments but lower variable costs.

-

Tooling and Setup Costs: These are fixed costs associated with mold creation, pattern making, and initial setup, often amortized over large order volumes. For small runs or customizations, these costs can significantly inflate per-unit prices.

-

Quality Control (QC): Rigorous QC processes, including testing for durability, waterproofing, and safety certifications, add to the overall cost but are crucial for brand reputation and customer satisfaction.

-

Logistics and Shipping: Freight costs depend on order size, destination, and shipping method (air vs. sea). For Africa, South America, or remote Middle Eastern markets, shipping can constitute a substantial portion of the total cost, especially if expedited freight is required.

-

Margins: Suppliers typically apply a markup to cover risks, profit margins, and future investments. Margins can vary based on market competition, order volume, and relationship strength.

Price Influencers

Several factors impact the final pricing and sourcing decisions:

-

Order Volume & MOQ: Larger orders generally lower per-unit costs due to economies of scale. Many suppliers offer discounts for MOQs exceeding 1,000 pairs, which is advantageous for bulk buyers.

-

Specifications & Customization: Custom features such as branding, color schemes, or specific technical specifications increase costs. Standard models are more cost-effective but may limit differentiation.

-

Material Choices: Premium materials like waterproof membranes or high-grip soles elevate costs but can command higher retail prices and improve product positioning.

-

Quality Certifications: Certifications such as ISO, REACH compliance, or environmental standards may add to costs but are often required for market entry, especially in Europe or Middle Eastern markets.

-

Supplier Factors: Experience, reputation, and production capacity influence pricing. Established manufacturers with proven quality control may charge higher but offer reliability.

-

Incoterms & Delivery Terms: The choice of Incoterm (e.g., FOB, CIF, DDP) affects who bears shipping and insurance costs, impacting the total landed cost for buyers.

Strategic Buyer Tips

-

Negotiate Pricing & Terms: Leverage volume commitments and long-term partnerships to negotiate better unit prices and favorable payment terms. Be aware that prices can fluctuate based on raw material costs and currency exchange rates.

-

Focus on Total Cost of Ownership (TCO): Consider all costs, including shipping, customs, taxes, and after-sales support, rather than just FOB or EXW prices. This holistic view helps avoid budget overruns.

-

Understand Pricing Nuances: Prices may vary based on order timing, currency fluctuations, and market demand. Request detailed quotes that specify cost components to identify potential savings.

-

Customs & Import Duties: Be aware of import tariffs and VAT applicable in your country. For example, South Africa imposes specific tariffs on footwear, while Middle Eastern countries may have different import duties, influencing landed costs.

-

Quality & Certification Requirements: Ensure suppliers meet your market’s safety and environmental standards. Non-compliance can lead to delays and additional costs.

Disclaimer on Price Indications

Indicative pricing for Keen hiking shoes can range from $15 to $35 per pair FOB for standard models in large volumes. Premium or customized variants may cost upwards of $40 to $70 per pair. Shipping costs can add significantly depending on destination and freight method, especially for remote markets like parts of Africa or South America. Always request detailed quotations and consider the full supply chain costs for accurate budgeting.

By understanding these cost components and influencing factors, international B2B buyers can make more informed sourcing decisions, optimize negotiations, and ensure competitive pricing aligned with market expectations.

Spotlight on Potential keen hiking shoes Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for keen hiking shoes.)*

Essential Technical Properties and Trade Terminology for keen hiking shoes

Key Technical Properties for Keen Hiking Shoes

Material Grade and Composition

The quality of materials used in hiking shoes directly impacts durability, comfort, and performance. For B2B buyers, understanding the grade of materials—such as premium leather, high-denier nylon, or specialized synthetic fabrics—is essential. Higher-grade materials typically offer increased lifespan and better weather resistance, making them more suitable for demanding terrains. Suppliers should provide detailed specifications, including tensile strength and wear resistance, to ensure the shoes meet your target markets’ expectations.

Sole Composition and Tread Pattern

The outsole material—commonly rubber or Vibram compounds—affers grip and durability. A rugged, multi-directional tread pattern enhances traction on varied surfaces, critical for outdoor activities. For international buyers, verifying sole hardness and slip-resistance ratings ensures the shoes perform reliably in different climatic conditions, such as muddy trails or rocky paths prevalent in regions like South Africa or the Middle East.

Waterproofing and Breathability Technologies

Advanced waterproof membranes (e.g., Gore-Tex or proprietary equivalents) are vital for keeping feet dry in wet conditions without sacrificing breathability. This balance is crucial for customer satisfaction, especially in humid or rainy regions. Confirm the waterproofing standards and breathability ratings to gauge how well the shoes will perform across diverse environments.

Fit Tolerance and Manufacturing Precision

Consistent sizing and manufacturing tolerances are key to reducing returns and ensuring customer satisfaction. Suppliers should adhere to international standards like ISO or ASTM for dimensional accuracy. For B2B buyers, requesting samples and certification of manufacturing precision can help assess quality consistency across batches.

Weight and Comfort Features

Lighter shoes reduce fatigue during long hikes, which is attractive to end-users. Incorporate specifications on shoe weight per size and comfort features such as cushioned insoles or ergonomic design. These properties can differentiate your product in competitive markets.

Common Industry and Trade Terms

OEM (Original Equipment Manufacturer)

An OEM produces hiking shoes based on your specifications and branding. Understanding OEM relationships helps buyers negotiate customization, branding, and private label options, enabling tailored product offerings for regional markets.

MOQ (Minimum Order Quantity)

This is the smallest quantity a supplier requires for a production run. Knowledge of MOQ helps buyers plan inventory and manage cash flow, especially when entering new markets or testing product acceptance in regions like Africa or South America.

RFQ (Request for Quotation)

An RFQ is a formal request to suppliers for pricing, lead times, and terms based on specific product requirements. Effective RFQs streamline procurement and enable comparative analysis to select the best value supplier.

Incoterms (International Commercial Terms)

Standardized trade terms, such as FOB (Free On Board) or CIF (Cost, Insurance, and Freight), define responsibilities for shipping, insurance, and customs clearance. Understanding Incoterms ensures clarity on costs and risk distribution, which is crucial for international trade across diverse regions.

Lead Time

The duration from order placement to product delivery. Accurate knowledge of lead times helps in planning inventory replenishment, especially when dealing with international logistics complexities.

Quality Certification Standards

Certifications like ISO 9001 or environmental standards such as REACH compliance can influence market acceptance, particularly in regions with strict regulations like Europe or the Middle East. Ensuring suppliers hold relevant certifications reduces compliance risks and enhances product credibility.

By understanding these technical properties and trade terms, international B2B buyers can make informed decisions, optimize procurement processes, and ensure the hiking shoes supplied meet regional market demands effectively.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the keen hiking shoes Sector

Market Overview & Key Trends

The global market for hiking shoes, including keen hiking shoes, is experiencing robust growth driven by increasing outdoor recreational activities, rising health consciousness, and expanding middle-class populations in emerging markets. For international B2B buyers from Africa, South America, the Middle East, and Europe, understanding these drivers is crucial for strategic sourcing and distribution.

Technological advancements are shaping sourcing trends significantly. Innovations such as 3D printing, advanced material composites, and smart manufacturing enable faster, more flexible production cycles while reducing costs. E-commerce platforms and digital supply chain solutions are streamlining procurement processes, allowing buyers to connect directly with manufacturers and suppliers worldwide. This transparency is particularly beneficial for buyers in regions like South Africa, Saudi Arabia, and South America, where localized sourcing can reduce logistics costs and lead times.

Market dynamics are also influenced by fluctuating raw material prices—particularly rubber, synthetic fabrics, and eco-friendly leathers—and by geopolitical factors affecting trade agreements. Buyers should monitor tariffs, import regulations, and trade policies, especially in regions with evolving trade relations, such as between Europe and emerging markets.

Emerging trends include a shift towards customization and niche product lines tailored to specific climates and terrains. For instance, buyers from desert climates like Saudi Arabia are seeking lightweight, breathable hiking shoes, while South American markets demand durable, rugged designs suitable for varied terrains. Sustainability is increasingly integrated into product development, with consumers and regulators pushing for eco-friendly and ethically sourced materials, creating new sourcing opportunities for suppliers that align with these values.

Sustainability & Ethical Sourcing in B2B

Sustainability is no longer a peripheral concern but a core component of strategic sourcing for keen hiking shoes. Environmental impacts of manufacturing, such as water consumption, chemical use, and carbon emissions, are scrutinized by global buyers. Incorporating eco-friendly materials like recycled PET fabrics, plant-based leathers, and natural rubber can significantly reduce a product’s environmental footprint.

Ethical sourcing ensures fair labor practices, transparent supply chains, and adherence to international labor standards. B2B buyers are increasingly demanding suppliers with certifications such as Fair Trade, Global Organic Textile Standard (GOTS), and Forest Stewardship Council (FSC). These certifications not only demonstrate compliance but also enhance brand reputation in markets like Europe and South America, where consumer awareness around sustainability is high.

For buyers in regions like Africa and the Middle East, engaging with suppliers committed to sustainability can provide a competitive edge. It aligns with regional governmental incentives for green manufacturing and appeals to environmentally conscious consumers. Establishing direct partnerships with manufacturers who prioritize renewable energy use, waste reduction, and ethical labor practices can foster long-term supply chain resilience.

Investing in traceability technologies—such as blockchain—can enhance transparency, verify sustainable claims, and mitigate risks related to unethical practices. Overall, integrating sustainability into sourcing strategies not only meets regulatory and consumer expectations but also drives innovation and efficiency in the keen hiking shoes sector.

Brief Evolution/History (Optional)

The keen hiking shoes industry has evolved from basic, utilitarian footwear to a sophisticated market emphasizing performance, comfort, and sustainability. Early designs prioritized durability for rugged terrains but lacked technological integration. Over the last two decades, advancements in materials—such as lightweight EVA midsoles and moisture-wicking fabrics—have transformed product offerings.

In recent years, sustainability has become a pivotal focus, driven by consumer demand and regulatory pressures. Brands now incorporate recycled materials, eco-conscious manufacturing processes, and ethical sourcing standards. This evolution reflects a broader industry shift towards responsible production, appealing to environmentally aware markets across Europe, South America, and the Middle East.

For B2B buyers, understanding this trajectory is vital for sourcing modern, compliant products that meet evolving standards. Early adoption of sustainable practices and innovative materials can provide competitive advantages, especially in regions where eco-conscious consumers influence purchasing decisions. The industry’s progression underscores the importance of aligning procurement strategies with technological and ethical advancements to sustain growth and market relevance.

Frequently Asked Questions (FAQs) for B2B Buyers of keen hiking shoes

1. How can I effectively vet Keen hiking shoe suppliers to ensure product quality and reliability?

To vet suppliers effectively, start by requesting comprehensive company credentials, including business licenses, export licenses, and certifications such as ISO or environmental standards. Request samples for quality inspection and verify their manufacturing processes, preferably through factory audits or third-party inspection services. Check references and seek feedback from previous international clients. Additionally, review their compliance with safety and environmental standards relevant to your target markets. Establish clear communication channels and ask for detailed product specifications, production capacity, and quality control procedures to ensure consistency and reliability in supply.

2. What customization options are typically available for Keen hiking shoes in B2B orders?

Most Keen suppliers offer a range of customization options to meet your branding and functional needs. Common options include logo placement via embroidery or printing, color variations, and packaging customization. Some suppliers also provide design modifications such as sole patterns, upper materials, or specialized features like waterproofing or enhanced grip. Be sure to discuss minimum order quantities (MOQs) for customized products, as they may be higher than standard orders. Early collaboration with the supplier’s design team ensures your specifications are feasible and aligned with production capabilities, reducing delays and costs.

3. What are typical MOQs, lead times, and payment terms for international B2B orders of Keen hiking shoes?

MOQs for Keen hiking shoes generally range from 300 to 1,000 pairs, depending on the supplier and customization level. Lead times vary from 4 to 12 weeks, influenced by order size, customization, and manufacturing schedules. Payment terms often include a 30% deposit upfront, with the balance payable before shipment or upon delivery, though some suppliers may offer letter of credit or open account terms for trusted buyers. Negotiating flexible payment options and clear lead times upfront helps avoid cash flow issues and ensures timely delivery aligned with your market planning.

4. What certifications and quality assurance measures should I look for in Keen hiking shoes for international markets?

Ensure the supplier provides relevant certifications such as CE, ASTM, or ISO standards, especially if targeting markets with strict safety or environmental regulations. Quality assurance measures should include detailed inspection reports, pre-shipment audits, and possibly third-party testing for durability, waterproofing, and slip resistance. Request documentation of their quality control processes, including incoming raw material testing, in-process inspections, and final product audits. These measures reduce the risk of non-compliance or product recalls, protecting your brand reputation in international markets.

5. How should I handle logistics and shipping to optimize costs and ensure timely delivery?

Start by selecting suppliers experienced in international freight and familiar with your target regions. Consider sea freight for bulk orders in Africa, South America, or Europe for cost efficiency, and air freight for urgent shipments. Work with freight forwarders who offer consolidated shipping and customs clearance services to reduce delays and costs. Clarify Incoterms (e.g., FOB, CIF) early to understand responsibilities and costs. Building strong logistics partnerships and maintaining clear communication channels with suppliers and logistics providers ensures transparency, tracks shipments effectively, and mitigates risks of delays or damages.

6. What common disputes might arise with international suppliers, and how can I prevent or resolve them?

Disputes often relate to quality inconsistencies, delayed shipments, or payment disagreements. To prevent these, establish detailed contracts covering specifications, quality standards, delivery timelines, and payment terms. Use clear communication and regular updates during production. In case of disputes, document all correspondence and inspection reports. Engage third-party mediators or arbitration services recognized internationally, such as ICC arbitration, to resolve issues efficiently. Building a strong, transparent relationship with your supplier and setting mutually agreed expectations from the outset reduces the likelihood of conflicts and facilitates quicker resolutions.

7. How do I ensure compliance with local regulations and standards when importing Keen hiking shoes into my country?

Research your country’s import regulations, including safety standards, labeling requirements, and import duties. Ensure the supplier provides necessary compliance documentation, such as test reports and certificates. Work with customs brokers or compliance consultants familiar with your region to navigate tariffs, taxes, and certification procedures. Additionally, verify that the shoes meet regional standards like CE marking for Europe or ASTM standards for North America. Proper documentation and adherence to local laws prevent customs delays, fines, or product seizures, ensuring a smooth market entry.

8. What are best practices for building long-term relationships with Keen hiking shoe suppliers?

Develop open, transparent communication channels and establish clear expectations from the start. Regularly review supplier performance through audits and feedback sessions, focusing on quality, delivery, and responsiveness. Consider starting with smaller trial orders to assess reliability before scaling up. Maintain timely payments and foster mutual trust through consistent engagement. Exploring joint development opportunities or exclusive partnerships can deepen collaboration. Building a strong relationship based on reliability, transparency, and mutual benefit positions you for better pricing, priority production, and innovation support in the long term.

Illustrative Image (Source: Google Search)

Strategic Sourcing Conclusion and Outlook for keen hiking shoes

Strategic Sourcing Outlook and Actionable Recommendations

Effective strategic sourcing of Keen hiking shoes offers B2B buyers a competitive advantage by ensuring product quality, cost efficiency, and supply chain resilience. Key takeaways include the importance of diversifying sourcing channels, fostering strong supplier relationships, and prioritizing sustainable practices to meet increasing consumer and regulatory demands. For buyers across Africa, South America, the Middle East, and Europe, aligning sourcing strategies with regional market dynamics can unlock new growth opportunities and mitigate risks associated with geopolitical or logistical disruptions.

To capitalize on these opportunities, international buyers should leverage local market insights, engage in long-term supplier collaborations, and explore innovative procurement models such as nearshoring or joint ventures. Staying adaptable and proactive in sourcing approaches will be critical amid evolving global trade landscapes and consumer preferences.

Looking ahead, embracing a strategic, data-driven sourcing framework will be essential for maintaining competitiveness and ensuring supply chain stability. B2B buyers from emerging markets and established regions alike are encouraged to invest in supplier development and sustainability initiatives. By doing so, they can secure reliable access to high-quality Keen hiking shoes and foster sustainable growth in their respective markets.