Roof Shoes Guide: Type,Cost,Material…

Introduction: Navigating the Global Market for roof shoes

In the competitive landscape of construction and roofing, sourcing the right roof shoes can pose significant challenges for international B2B buyers. With varying roofing materials and surfaces across regions—from the steep slopes of South American homes to the flat roofs common in the Middle East—finding footwear that provides optimal grip, comfort, and safety is essential. This guide serves as a comprehensive resource, addressing the diverse types of roof shoes available, their specific applications, and key considerations for supplier vetting and cost analysis.

Buyers will gain insights into the latest innovations in roofing footwear, including traction-enhancing features tailored for specific roofing materials, ensuring worker safety and productivity. The guide further explores regional compliance standards and best practices, empowering buyers from Africa, South America, Europe, and the Middle East, such as Germany and Saudi Arabia, to make informed purchasing decisions. By navigating the complexities of the global market for roof shoes, businesses can enhance their operational efficiency and ensure the safety of their workforce, ultimately contributing to successful project outcomes and client satisfaction.

Understanding roof shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traction Boots | Enhanced grip, slip-resistant soles, ankle support | Roofing contractors, maintenance teams | Pros: High stability, superior traction. Cons: Can be heavy and less breathable. |

| Overshoe Sandals | Interchangeable sole system for various surfaces | Roofers on different material types | Pros: Versatile, customizable traction. Cons: May require additional investment for soles. |

| Lightweight Roofing Shoes | Breathable materials, lightweight design | Residential roofing, inspections | Pros: Comfortable for prolonged wear. Cons: Less protection on steep surfaces. |

| Steel-Toed Roofing Boots | Reinforced toe protection, rugged construction | Industrial roofing, heavy-duty work | Pros: Excellent protection from falling objects. Cons: Can be bulky and limit flexibility. |

| Waterproof Roofing Boots | Waterproof materials, slip-resistant soles | Wet climate roofing, repairs | Pros: Keeps feet dry in adverse conditions. Cons: May be less breathable, leading to discomfort. |

What Are the Characteristics of Traction Boots for Roofers?

Traction boots are specifically designed for roofing tasks, featuring slip-resistant soles that provide superior grip on various surfaces, including shingles and metal. They often include additional ankle support to prevent injuries while navigating steep pitches. For B2B buyers, investing in high-quality traction boots can significantly enhance worker safety and productivity, especially in challenging environments. However, these boots can be heavier and may reduce breathability, which is a consideration for prolonged wear.

How Do Overshoe Sandals Enhance Versatility for Roofers?

Overshoe sandals, such as those with interchangeable sole systems, offer roofers the ability to customize their footwear based on the roofing material they are working on. This adaptability allows for optimal traction on surfaces ranging from smooth metal to textured shingles. B2B buyers should consider the cost-effectiveness of these sandals, as they may require purchasing additional soles for different applications. While they provide versatility, the need for extra soles can lead to higher initial investment costs.

Why Choose Lightweight Roofing Shoes for Residential Work?

Lightweight roofing shoes are crafted from breathable materials, making them ideal for residential roofing and inspection tasks where comfort is paramount. They allow for easier mobility and reduce fatigue during long work hours. However, B2B buyers should be cautious, as these shoes may not provide the necessary protection on steep or slippery surfaces. When selecting lightweight options, consider the specific work environment and whether additional protective gear may be needed.

What Benefits Do Steel-Toed Roofing Boots Provide for Heavy-Duty Work?

Steel-toed roofing boots are designed to offer maximum protection against falling objects and other hazards common in industrial roofing environments. Their rugged construction ensures durability, making them suitable for heavy-duty applications. For B2B buyers, the investment in steel-toed boots is justified by the enhanced safety they provide. However, the bulkiness of these boots can limit flexibility, which is an important factor for workers who need to move quickly on roofs.

How Do Waterproof Roofing Boots Perform in Wet Conditions?

Waterproof roofing boots are essential for roofing tasks in wet climates or during repairs in adverse weather conditions. These boots keep feet dry and comfortable, contributing to overall worker safety. B2B buyers should consider the trade-off between waterproofing and breathability, as waterproof materials can sometimes lead to moisture buildup inside the boot. Understanding the specific environmental conditions in which the boots will be used is crucial for making the right purchasing decision.

Key Industrial Applications of roof shoes

| Industry/Sector | Specific Application of Roof Shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Roofing | Residential and Commercial Roofing Work | Enhances worker safety and productivity on-site | Look for shoes with high traction, comfort, and durability. |

| Oil & Gas | Maintenance on Industrial Roofs | Reduces slip-related accidents in hazardous areas | Ensure compliance with industry safety standards. |

| Telecommunications | Installation and Maintenance of Antennas | Provides stability on various roof types | Consider shoes designed for specific roof materials. |

| Renewable Energy | Solar Panel Installation | Improves safety while working on inclined surfaces | Seek footwear with specialized grip for diverse roofing materials. |

| Facility Management | Routine Roof Inspections | Minimizes risk of falls, enhancing inspection efficiency | Evaluate for comfort and breathability for long hours. |

How Are Roof Shoes Used in Construction and Roofing?

In the construction and roofing industry, roof shoes are crucial for both residential and commercial projects. Workers frequently navigate steep pitches and various surfaces, which can be slippery. High-quality roofing shoes provide essential grip and stability, reducing the risk of falls and enhancing overall productivity. Buyers should prioritize shoes with reinforced soles and ankle support, particularly in regions with varying climate conditions, such as Africa and the Middle East, where extreme weather can affect roof safety.

What Role Do Roof Shoes Play in Oil & Gas Maintenance?

In the oil and gas sector, maintenance on industrial roofs often occurs in challenging environments. Roof shoes designed for this industry help prevent slips and falls, which are critical in maintaining safety standards. The shoes must meet specific safety requirements, such as chemical resistance and durability. International buyers should ensure that the footwear complies with local regulations and is suitable for the rugged conditions typical in oil and gas operations.

How Are Roof Shoes Utilized in Telecommunications?

Telecommunications professionals often work on rooftops to install and maintain antennas, requiring footwear that offers superior grip and stability. Roof shoes designed for this application provide the necessary traction on various materials, including metal and shingle roofs. Buyers should focus on shoes with features that enhance comfort and minimize fatigue during long hours of work, particularly in regions with extreme weather variations like Europe.

Why Are Roof Shoes Important for Solar Panel Installations?

The renewable energy industry, particularly in solar panel installation, demands footwear that can handle various roofing surfaces. Roof shoes designed for this purpose improve safety while working on inclined surfaces and can adapt to different materials. Buyers should look for shoes that offer excellent slip resistance and comfort, as workers often spend extended periods on rooftops. This is especially relevant in sunny regions of South America and the Middle East, where heat can impact worker performance.

How Do Roof Shoes Benefit Facility Management Inspections?

In facility management, routine roof inspections are critical for maintenance and safety. Roof shoes enhance the safety of inspectors by providing traction and comfort on potentially slippery surfaces. When sourcing footwear for this application, businesses should consider options that offer breathability and durability, ensuring that inspectors can perform their duties efficiently. This is particularly important in diverse climates across Europe and Africa, where weather conditions can vary significantly.

3 Common User Pain Points for ‘roof shoes’ & Their Solutions

Scenario 1: Inconsistent Traction on Varied Roof Surfaces

The Problem: B2B buyers often face the challenge of ensuring their roofing crews have adequate traction across different roofing materials. For instance, walking on metal roofs can be significantly different from navigating asphalt shingles. The risk of slips and falls increases when workers transition from one surface to another, leading to potential injuries and costly delays. Buyers may find that standard roofing shoes do not provide the necessary grip for all conditions, which can create safety concerns and impact productivity.

The Solution: To address this issue, buyers should invest in roofing shoes that feature interchangeable soles, such as the Korkers TuffTrax system. This versatile solution allows workers to customize their footwear based on the specific roofing material they are working on. For instance, using soft foam soles for metal roofs enhances grip, while medium-density foam soles can be used for asphalt shingles. When procuring these shoes, buyers should prioritize suppliers that offer a variety of sole options and emphasize the importance of training their teams on how to switch soles depending on the work environment. This proactive approach not only ensures safety but also maintains workflow efficiency.

Scenario 2: Discomfort Leading to Reduced Productivity

The Problem: Many roofing professionals endure long hours on their feet, often resulting in discomfort or fatigue that can detract from their performance. B2B buyers may notice that their teams are less productive or more prone to mistakes when wearing shoes that do not provide adequate support or comfort. This scenario can be particularly prevalent in regions with extreme weather conditions, where inadequate footwear can exacerbate physical strain.

The Solution: Buyers should consider sourcing roofing shoes specifically designed with ergonomic features, such as cushioned insoles and arch support. Brands that focus on comfort and functionality, like Cougar Paws, offer footwear with shock-absorbing properties and breathable materials. When selecting these products, buyers should also evaluate options that provide additional ankle support and moisture-wicking capabilities to enhance comfort during prolonged use. Educating crews on the importance of wearing the right shoes and encouraging them to report discomfort can lead to timely adjustments in footwear choices, ultimately improving productivity and job satisfaction.

Scenario 3: Compliance with Safety Standards

The Problem: In many regions, compliance with safety regulations is critical for B2B buyers in the roofing industry. Buyers often find it challenging to ensure that their roofing shoes meet local safety standards, which can vary widely across countries and regions. Failing to comply with these regulations not only poses safety risks to workers but can also lead to legal repercussions and damage to a company’s reputation.

The Solution: To mitigate this risk, buyers should familiarize themselves with the specific safety requirements relevant to their region and ensure that the roofing shoes they purchase comply with these standards. It’s advisable to partner with manufacturers who can provide documentation and certifications that attest to the safety features of their products. Additionally, buyers can conduct regular audits of their footwear inventory to ensure compliance and keep abreast of any changes in safety regulations. Investing in high-quality roofing shoes that meet or exceed safety standards not only protects workers but also enhances the company’s credibility in the industry, fostering trust with clients and stakeholders.

Strategic Material Selection Guide for roof shoes

What Are the Key Materials Used in Roof Shoes?

When selecting roof shoes for various applications, understanding the materials involved is crucial for ensuring safety, durability, and performance. Here, we analyze four common materials used in the manufacturing of roof shoes, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

What Are the Key Properties of Rubber in Roof Shoes?

Rubber is a popular choice for roofing footwear due to its excellent grip and flexibility. It typically offers good temperature resistance, making it suitable for a range of climates. Rubber can withstand various environmental conditions, including moisture and UV exposure, which is vital for roofing applications.

Pros: Rubber shoes are generally durable, providing good slip resistance on various surfaces. They are also relatively inexpensive and easy to manufacture.

Cons: However, rubber may degrade over time with prolonged exposure to extreme temperatures or chemicals, which could limit their lifespan. Additionally, they may not provide adequate support for prolonged wear.

Impact on Application: Rubber shoes are particularly effective on shingle roofs and can perform well on metal surfaces, but they may not be as effective on steep pitches without additional traction features.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure compliance with local safety standards, as rubber footwear may not meet specific requirements in certain countries.

How Do Synthetic Materials Enhance Roof Shoe Performance?

Synthetic materials, such as thermoplastic elastomers (TPE) and polyurethane (PU), are increasingly used in roofing shoes due to their lightweight and durable nature. These materials typically offer excellent abrasion resistance and can handle a wide range of temperatures.

Pros: Synthetic roof shoes are often lighter than rubber, providing enhanced comfort for long-duration wear. They also tend to be more resistant to chemicals and oils.

Cons: The manufacturing process for synthetic materials can be more complex and costly than for rubber. Additionally, some synthetics may lack the same level of grip as rubber.

Impact on Application: These materials are ideal for environments where chemical exposure is a concern, such as commercial roofing applications. They can also be tailored for specific surfaces, enhancing performance.

Considerations for International Buyers: Compliance with ASTM and DIN standards is essential for synthetic materials, especially in Europe, where regulations are stringent.

What Are the Advantages of Leather in Roof Shoe Construction?

Leather is often regarded as a premium material for roofing shoes due to its natural durability and comfort. It offers good breathability and can mold to the wearer’s foot over time, enhancing fit.

Pros: Leather shoes provide excellent support and comfort, making them suitable for long hours of work. They also have a classic appearance and can be treated for water resistance.

Cons: The main drawback is cost; leather shoes tend to be more expensive than rubber or synthetic options. Additionally, they require more maintenance to prevent cracking and drying.

Impact on Application: Leather is particularly suitable for flat roofs and environments where aesthetics are important, such as residential roofing.

Considerations for International Buyers: Buyers in Europe and South America should ensure that leather products comply with environmental regulations regarding tanning and chemical treatments.

How Do Composite Materials Benefit Roof Shoe Design?

Composite materials, which may include blends of rubber, plastics, and other materials, are designed to provide a balance of durability, comfort, and performance. They often feature advanced technologies for enhanced grip and slip resistance.

Pros: Composite shoes can be engineered for specific applications, providing tailored solutions for different roofing surfaces. They are often lighter than traditional materials, enhancing comfort.

Cons: The complexity of manufacturing composite materials can lead to higher costs. Additionally, not all composites are created equal, and quality can vary significantly between manufacturers.

Impact on Application: Composite shoes are versatile and can be used across various roofing applications, from residential to commercial.

Considerations for International Buyers: It’s crucial for buyers to verify the quality and performance standards of composite materials, especially in regions with varying safety regulations.

Summary Table of Material Properties for Roof Shoes

| Material | Typical Use Case for Roof Shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Rubber | Shingle roofs | Excellent grip and flexibility | Degrades with extreme exposure | Low |

| Synthetic | Commercial roofing | Lightweight and chemical resistant | More costly and complex to produce | Medium |

| Leather | Flat roofs | Superior comfort and support | High maintenance and cost | High |

| Composite | Various roofing applications | Tailored performance solutions | Variable quality and higher costs | Medium |

This strategic material selection guide provides B2B buyers with essential insights into the materials used in roof shoes, enabling informed purchasing decisions tailored to specific applications and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for roof shoes

What Are the Main Stages in the Manufacturing Process of Roof Shoes?

The manufacturing process of roof shoes involves several critical stages, each contributing to the overall quality and performance of the final product. Understanding these stages is essential for B2B buyers looking to source high-quality roofing footwear.

Material Preparation: Sourcing and Selecting Quality Materials

The foundation of any roofing shoe is the materials used. Manufacturers typically source high-grade rubber, synthetic fabrics, and foam for insulation and comfort. The selection process includes rigorous testing to ensure materials meet necessary durability and slip-resistance standards. For instance, rubber compounds are often evaluated for their grip and wear resistance, while foams are assessed for comfort and shock absorption.

Forming: Shaping the Components

In the forming stage, raw materials are molded into the various components of the shoe. Injection molding is a common technique used to create rubber outsoles, ensuring a precise fit and optimal traction. Simultaneously, the upper materials are cut and shaped to provide a comfortable and secure fit. Advanced techniques such as 3D knitting may also be employed to enhance breathability and flexibility.

Assembly: Constructing the Final Product

Once the components are ready, the assembly process begins. This stage typically involves stitching the upper to the sole, a critical area where quality control is paramount. High-strength threads and reinforced seams are often used to enhance durability. Manufacturers may also incorporate additional features, such as waterproofing or slip-resistant technologies, during assembly to meet specific performance standards.

Finishing: Quality Enhancements and Aesthetics

The final stage involves finishing touches, including the application of protective coatings and the addition of branding elements. This stage may also include quality inspections to ensure that the shoes meet aesthetic and functional standards. The finishing process not only enhances the shoe’s appearance but also contributes to its overall longevity and performance.

How Is Quality Assurance Implemented in Roof Shoe Manufacturing?

Quality assurance (QA) is critical in the manufacturing of roof shoes, as it directly impacts safety and performance. Understanding the QA processes can help B2B buyers ensure they are sourcing reliable products.

What International Standards Govern Roof Shoe Quality?

Manufacturers often adhere to international quality standards such as ISO 9001, which focuses on consistent quality management systems. In addition, specific industry standards like CE marking in Europe ensure that products meet essential health, safety, and environmental protection requirements. Buyers should look for these certifications when assessing suppliers to ensure compliance with international safety standards.

What Are the Key Quality Control Checkpoints?

Quality control is integrated throughout the manufacturing process, with several checkpoints:

-

Incoming Quality Control (IQC): This initial checkpoint focuses on raw materials. Each batch of materials is tested for compliance with quality standards before it enters the production line.

-

In-Process Quality Control (IPQC): During the manufacturing stages, periodic inspections are conducted to ensure that processes are followed correctly. This may include checks on the forming and assembly stages to identify any deviations early.

-

Final Quality Control (FQC): Once the shoes are assembled, final inspections are conducted to assess the product’s overall quality. This includes testing for durability, slip resistance, and other performance metrics.

What Common Testing Methods Are Used for Roof Shoes?

Testing methods are critical for verifying the performance and safety of roofing shoes. Manufacturers typically employ a range of tests, including:

- Slip Resistance Testing: This measures the shoe’s grip on various surfaces, simulating real-world conditions roofers face.

- Durability Testing: Shoes undergo stress tests to assess how they hold up under extreme conditions, including wear and tear over time.

- Water Resistance Testing: Ensuring that shoes can withstand exposure to moisture is crucial, especially for roofing applications.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, verifying a supplier’s quality control measures is essential for ensuring product reliability. Here are some strategies:

Conducting Supplier Audits

Regular audits of suppliers can provide insights into their manufacturing processes and quality control practices. Buyers should inquire about the frequency of these audits and the criteria used to evaluate compliance with industry standards.

Reviewing Quality Assurance Reports

Requesting quality assurance reports can help buyers understand the outcomes of testing and inspections. These documents should detail the testing methodologies used and any corrective actions taken in response to identified issues.

Engaging Third-Party Inspectors

Utilizing third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. These inspectors can verify compliance with international standards and provide recommendations for improvement.

What Are the Quality Control Nuances for International B2B Buyers?

For international buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, it is crucial to be aware of the specific quality control nuances:

-

Regulatory Compliance: Different countries may have varying regulations regarding safety and performance standards. Buyers must ensure that suppliers comply with local regulations in their respective markets.

-

Cultural Considerations: Understanding the cultural context of the supplier’s country can provide insights into their approach to quality and customer service. This can influence negotiations and long-term partnerships.

-

Logistics and Shipping: Quality control does not end at the factory; it extends to the shipping process. Buyers should verify that suppliers maintain quality standards during transportation to prevent damage or degradation of the product.

By understanding the manufacturing processes and quality assurance practices in the production of roof shoes, B2B buyers can make informed decisions, ensuring they source products that meet their safety and performance needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘roof shoes’

To assist B2B buyers in sourcing high-quality roof shoes, this guide outlines essential steps to ensure effective procurement. Selecting the right roofing footwear not only enhances worker safety and comfort but also improves productivity on the job site. Follow this checklist to navigate the sourcing process efficiently.

Step 1: Define Your Technical Specifications

Establish the specific requirements for the roof shoes based on your operational needs. Consider factors such as the type of roofing materials your team will be working on (e.g., shingles, metal, or tile) and the unique conditions of your projects, such as slope and weather. This clarity will help you narrow down options that are best suited for your requirements.

Step 2: Research Compliance and Safety Standards

Ensure that the roof shoes you are considering meet relevant safety regulations and industry standards. While OSHA does not have specific footwear requirements, it’s essential to verify compliance with general safety guidelines. Look for features such as slip resistance, ankle support, and durability that can protect your workers from potential hazards.

Step 3: Evaluate Potential Suppliers

Before making a commitment, conduct thorough evaluations of potential suppliers. Request detailed company profiles, product samples, and references from other businesses within your industry. This diligence helps ensure that you are partnering with a reliable supplier who can deliver quality products consistently.

- Supplier Reputation: Look for reviews and testimonials from other customers to gauge their reliability.

- Experience in the Industry: Suppliers with a proven track record in roofing footwear will likely understand your specific needs better.

Step 4: Assess Product Features and Innovations

Examine the unique features of various roof shoes that cater specifically to roofers’ needs. Consider innovations such as interchangeable soles for different traction requirements, moisture-wicking materials, and additional ankle support. These features can significantly enhance safety and comfort during long working hours.

Step 5: Request and Analyze Samples

Whenever possible, request samples of the roof shoes you are considering. Testing the footwear in real-world conditions will allow you to evaluate their performance and suitability for your team. Pay attention to comfort, grip, and fit, as these factors are crucial for worker safety and efficiency on the job.

Step 6: Negotiate Pricing and Terms

Once you have identified potential suppliers and products, engage in negotiations to secure favorable pricing and terms. Consider bulk purchase discounts, warranties, and return policies. A strong negotiation can lead to long-term savings and better service agreements.

Step 7: Make a Decision and Plan for Future Needs

After thorough evaluation and negotiation, finalize your purchase decision. Additionally, consider your future sourcing needs by establishing relationships with multiple suppliers. This approach can provide flexibility and ensure that you always have access to quality roof shoes as your business grows.

By following this comprehensive sourcing checklist, you will be well-equipped to procure roof shoes that meet the demands of your business while ensuring the safety and comfort of your workforce.

Comprehensive Cost and Pricing Analysis for roof shoes Sourcing

Understanding the comprehensive cost structure and pricing analysis for roof shoes is essential for B2B buyers aiming to make informed purchasing decisions. This section will delve into the various cost components involved in sourcing roof shoes, the factors that influence pricing, and practical tips for buyers, particularly those operating in diverse international markets.

What Are the Key Cost Components of Roof Shoes?

The cost structure for roof shoes generally consists of several critical components:

-

Materials: The choice of materials significantly impacts the overall cost. High-quality rubber, synthetic materials for waterproofing, and specialized traction pads can increase expenses but enhance durability and safety. Buyers should prioritize materials that meet local safety standards.

-

Labor: Labor costs vary by region and can influence the pricing of roof shoes. Countries with higher labor costs may result in increased pricing, while manufacturers in regions with lower labor rates can offer more competitive pricing.

-

Manufacturing Overhead: This includes costs related to factory maintenance, utilities, and administrative expenses. Efficient manufacturing processes can reduce overhead costs, thus lowering the final product price.

-

Tooling: Investment in specialized tooling for production can be significant, particularly for customized designs. This cost is often amortized over the production volume, affecting per-unit pricing.

-

Quality Control (QC): Ensuring that roof shoes meet safety and quality standards incurs additional costs. Rigorous QC processes are crucial, especially for products used in high-risk environments like roofing.

-

Logistics: Shipping and handling costs must be factored in, particularly for international transactions. Incoterms will play a vital role in determining who bears these costs and risks.

-

Margin: Finally, the manufacturer’s desired profit margin will influence the final price. This margin can vary widely based on market conditions and competition.

What Influences the Pricing of Roof Shoes?

Several factors can significantly influence the pricing of roof shoes:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases typically lead to lower per-unit costs. Buyers should negotiate MOQs to optimize pricing.

-

Specifications and Customization: Custom features or specific design requests can increase production costs. Buyers should weigh the benefits of customization against potential price increases.

-

Material Quality and Certifications: Shoes that comply with specific safety certifications may command higher prices. However, investing in high-quality, certified footwear can lead to reduced injury rates and lower long-term costs.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established brands may have premium pricing due to perceived quality, while emerging suppliers might offer competitive rates to build market presence.

-

Incoterms: Understanding the implications of different Incoterms can help buyers manage costs effectively. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can dictate who is responsible for shipping costs and risks.

What Are the Best Buyer Tips for Sourcing Roof Shoes?

To navigate the complexities of sourcing roof shoes, B2B buyers should consider the following strategies:

-

Negotiate Terms: Effective negotiation can lead to better pricing. Discuss volume discounts, payment terms, and other factors that can lower costs.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider the TCO, which includes maintenance, replacement, and potential injury costs associated with inferior products. Investing in higher-quality shoes may yield long-term savings.

-

Understand Pricing Nuances for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should be aware of regional pricing dynamics. Currency fluctuations, import duties, and local market demand can impact costs.

-

Seek Multiple Quotes: Obtaining quotes from several suppliers can provide leverage in negotiations and ensure competitive pricing.

Conclusion

By understanding the cost components, price influencers, and strategic tips outlined in this analysis, B2B buyers can make informed decisions when sourcing roof shoes. This insight is particularly valuable for those operating in diverse international markets, enabling them to optimize their purchasing strategy and enhance workplace safety effectively. Always remember to validate suppliers and seek indicative pricing to ensure the best deals in a fluctuating market.

Alternatives Analysis: Comparing roof shoes With Other Solutions

Exploring Alternatives to Roof Shoes for Roofing Safety

In the roofing industry, ensuring worker safety and efficiency is paramount. While specialized roof shoes are designed to provide optimal traction and comfort on steep surfaces, there are alternative solutions worth considering. This section compares roof shoes with other methods, helping B2B buyers make informed decisions based on their specific needs.

| Comparison Aspect | Roof Shoes | Korkers Overshoe Sandal | Safety Harness Systems |

|---|---|---|---|

| Performance | High traction on various surfaces | Customizable traction options | Prevents falls but does not aid mobility |

| Cost | Moderate to high (varies by brand) | Moderate ($89.99) | High (often $200+) |

| Ease of Implementation | Easy to wear and remove | Simple installation over existing shoes | Requires training for proper use |

| Maintenance | Moderate; replaceable parts available | Low; replace soles as needed | High; regular inspections required |

| Best Use Case | Ideal for regular roofing tasks | Versatile for multiple surfaces | Best for high-risk environments |

What Are the Pros and Cons of Korkers Overshoe Sandals?

Korkers Overshoe Sandals serve as a flexible alternative to traditional roof shoes. With their innovative 3-in-1 interchangeable sole system, users can adapt the traction to suit various roofing surfaces, from smooth metal to steep shingles. This adaptability allows for increased safety on different types of roofs, making them a versatile choice for contractors working across diverse projects. However, they may not provide the same level of direct foot support as dedicated roofing shoes, potentially leading to fatigue during extended use.

How Do Safety Harness Systems Compare?

Safety harness systems are crucial for fall protection in high-risk roofing scenarios. While they do not enhance traction like roof shoes, they offer vital safety features that can prevent serious injuries. These systems are necessary for compliance with safety regulations and provide peace of mind when working at heights. On the downside, harness systems can be cumbersome and may require additional training for proper usage, increasing the complexity of the work environment. They also come with a higher cost and require regular maintenance to ensure safety standards are met.

Conclusion: How Should B2B Buyers Choose the Right Roofing Solution?

When evaluating roofing solutions, B2B buyers should consider their specific operational needs and safety requirements. Roof shoes are ideal for everyday roofing tasks that demand comfort and traction, while Korkers Overshoe Sandals offer flexibility for varied surfaces. Safety harness systems are indispensable for high-risk situations but may complicate day-to-day operations. Ultimately, the choice will depend on factors such as project type, budget constraints, and compliance with local safety regulations. By assessing these aspects, buyers can select the most effective solution for their roofing teams, enhancing both safety and productivity.

Essential Technical Properties and Trade Terminology for roof shoes

What Are the Key Technical Properties of Roof Shoes That B2B Buyers Should Consider?

When selecting roof shoes for professional use, understanding their technical properties is crucial for ensuring safety, comfort, and performance. Here are several critical specifications to consider:

-

Material Composition

Roof shoes are typically made from a combination of synthetic materials, rubber, and leather. The choice of materials impacts durability, slip resistance, and comfort. For instance, rubber soles offer superior grip on various surfaces, while leather uppers provide breathability and protection. B2B buyers should prioritize shoes with high-quality materials that can withstand harsh conditions typical in roofing environments. -

Traction Ratings

The traction capabilities of roof shoes are paramount, especially when working on steep or slippery surfaces. Many products are tested against specific traction standards, which indicate how well they perform on different materials like shingles, metal, or tile. Selecting shoes with a high traction rating can significantly reduce the risk of slips and falls, enhancing worker safety and productivity. -

Weight Support and Comfort Features

Roof shoes should provide adequate support for prolonged periods of standing and walking. Features such as cushioned insoles, arch support, and lightweight construction contribute to overall comfort. B2B buyers should consider shoes designed with ergonomic principles to reduce fatigue, thereby improving worker efficiency on the job. -

Water Resistance

Given that roofing work often involves exposure to the elements, water-resistant properties are essential. Roof shoes with waterproof materials or treated surfaces help keep feet dry, which is important for maintaining comfort and preventing injuries from wet conditions. B2B purchasers should look for products that specify their water resistance capabilities. -

Fit and Sizing Options

A secure fit is critical for safety and comfort. Roof shoes should be available in a range of sizes and widths to accommodate different foot shapes. Some manufacturers offer adjustable features like straps or buckles to ensure a snug fit. Ensuring that employees have the right fit can prevent blisters and other foot injuries. -

Sole Interchangeability

Some roof shoes come with interchangeable soles that can be swapped based on the working surface. For example, a soft foam sole might be best for metal roofs, while a spiked rubber sole is suited for wood-shake roofs. This versatility allows roofing professionals to adapt to different job requirements, making it a valuable feature for B2B buyers.

What Are Common Trade Terms Related to Roof Shoes?

Understanding industry terminology is essential for effective communication and negotiation. Here are some common terms that B2B buyers should be familiar with:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of roof shoes, buyers may work directly with OEMs for customized footwear solutions. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. For roof shoes, understanding the MOQ is crucial for managing inventory and budgeting for purchases. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. B2B buyers often use RFQs when seeking competitive bids for bulk orders of roof shoes. -

Incoterms (International Commercial Terms)

These are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps B2B buyers understand shipping costs, risks, and delivery responsibilities when procuring roof shoes from overseas suppliers. -

Lead Time

This term refers to the time taken from placing an order to receiving the product. Knowing the lead time for roof shoes can help B2B buyers plan projects and ensure they have the necessary footwear on site when needed. -

Certification Standards

Many roofing shoes are tested against specific safety and performance standards. Certifications can include slip resistance ratings or compliance with regional safety regulations. B2B buyers should seek products that meet or exceed these standards to ensure worker safety and compliance with industry regulations.

In summary, understanding the technical properties and trade terminology associated with roof shoes empowers B2B buyers to make informed decisions that enhance workplace safety, efficiency, and compliance.

Navigating Market Dynamics and Sourcing Trends in the roof shoes Sector

What Are the Current Market Dynamics in the Roof Shoes Sector?

The global roofing shoes market is currently experiencing robust growth driven by several key factors. Increased construction activities, particularly in developing regions such as Africa and South America, are boosting demand for specialized footwear that enhances safety and productivity on job sites. Furthermore, with the rise of stringent safety regulations in the construction industry, the need for high-quality roofing shoes that comply with safety standards is becoming paramount. In Europe and the Middle East, particularly in countries like Germany and Saudi Arabia, there is a growing emphasis on worker safety, which is pushing roofing contractors to invest in advanced footwear solutions.

Emerging technologies in the roofing shoe sector, such as customizable sole systems and materials with enhanced grip, are gaining traction. For instance, products like Korkers’ TuffTrax offer a 3-in-1 interchangeable sole system that adapts to various job conditions, making them attractive to B2B buyers looking for versatility. Additionally, digital platforms for sourcing roofing shoes are evolving, allowing international buyers to easily access a broader range of products and suppliers, thus enhancing supply chain efficiency. This evolution is particularly beneficial for buyers in remote regions, as it simplifies procurement processes and reduces lead times.

How Are Sustainability and Ethical Sourcing Influencing the Roof Shoes Market?

As environmental concerns gain prominence, sustainability and ethical sourcing are becoming critical factors in the roof shoes market. International buyers are increasingly prioritizing products that minimize environmental impact. This shift is reflected in the growing availability of roofing shoes made from eco-friendly materials, such as recycled plastics and sustainable rubber. Manufacturers are also adopting greener production processes to reduce their carbon footprint, making it essential for B2B buyers to consider the sustainability credentials of their suppliers.

Moreover, the importance of ethical supply chains cannot be overstated. Buyers are now scrutinizing the sourcing practices of manufacturers to ensure that they align with corporate social responsibility (CSR) values. Certifications like Fair Trade and environmentally sustainable labels are becoming essential for buyers who wish to enhance their brand image and appeal to environmentally conscious consumers. By choosing roofing shoes from suppliers with robust sustainability practices, businesses can not only improve their market positioning but also contribute positively to global environmental goals.

What Is the Evolution of Roofing Shoes and Its Significance for B2B Buyers?

The evolution of roofing shoes has been marked by a significant shift from basic protective footwear to highly specialized, technologically advanced products. Historically, roofers relied on standard work boots that often lacked the necessary grip and comfort for steep and slippery surfaces. However, as the industry recognized the critical role of footwear in ensuring safety and productivity, manufacturers began to innovate.

Today’s roofing shoes are designed with features such as enhanced traction, breathable materials, and ergonomic designs tailored to the specific demands of roofing work. This evolution is crucial for B2B buyers who are looking for products that not only meet safety standards but also enhance the overall efficiency of their workforce. As the market continues to evolve, buyers should remain vigilant about emerging trends and innovations that could impact their purchasing decisions and operational effectiveness.

Frequently Asked Questions (FAQs) for B2B Buyers of roof shoes

-

How do I choose the right roof shoes for my roofing business?

Choosing the right roof shoes involves evaluating several factors, including the type of roofing material you work with, the surfaces you’ll be walking on, and the specific safety features you require. Look for shoes with excellent grip and traction, especially on sloped surfaces. Consider features like ankle support, waterproofing, and comfort for long wear. Consult with suppliers about the best options for your specific needs, and don’t hesitate to request samples to ensure the fit and functionality meet your expectations. -

What is the best type of roof shoes for metal roofs?

For metal roofs, the best type of roof shoes typically feature soft foam soles that provide superior grip on smooth surfaces. Look for shoes with a specialized traction system, such as interchangeable soles, which can be tailored for various conditions. Brands that focus on roofing-specific footwear often offer designs with added safety features, such as raised heels and secure straps, to enhance stability while working on inclined surfaces. -

What are the safety standards for roofing shoes in different countries?

Safety standards for roofing shoes can vary significantly by country. In Europe, for instance, CE marking indicates compliance with specific safety directives, while in the United States, ANSI/OSHA regulations apply. It’s essential to research the local regulations in your target market, such as those in Saudi Arabia or South Africa, to ensure that the roofing shoes you import or distribute meet the necessary safety requirements and certifications. -

How can I vet suppliers for quality roofing shoes?

To vet suppliers effectively, start by checking their reputation within the roofing industry. Look for certifications, customer testimonials, and case studies that demonstrate their track record. Request samples to evaluate the quality of their roofing shoes firsthand. Additionally, consider visiting their manufacturing facilities if possible, and inquire about their quality assurance processes to ensure they adhere to international standards. -

What is the minimum order quantity (MOQ) for roofing shoes?

The minimum order quantity (MOQ) for roofing shoes varies by supplier and can range from a few dozen pairs to several hundred. Factors influencing MOQ include the type of shoe, customization options, and production capacity. Discuss your specific needs with potential suppliers to negotiate an MOQ that aligns with your business requirements while ensuring you receive the best pricing and terms. -

Can I customize roofing shoes for my brand?

Yes, many suppliers offer customization options for roofing shoes, including brand logos, color schemes, and specific design features. Customization can enhance your brand visibility and cater to the specific needs of your market. When discussing customization with suppliers, clarify the available options, lead times, and any additional costs involved to ensure the final product aligns with your branding strategy. -

What payment terms are typical for international purchases of roofing shoes?

Payment terms for international purchases of roofing shoes can vary widely, but common practices include advance payment, net 30, or net 60 terms. It’s advisable to establish clear payment conditions before finalizing any agreements, including methods of payment (e.g., wire transfer, credit terms) and any applicable currency exchange considerations. Discussing these terms upfront helps avoid misunderstandings and ensures smooth transactions. -

What logistics considerations should I keep in mind when sourcing roofing shoes internationally?

When sourcing roofing shoes internationally, consider factors such as shipping methods, customs regulations, and potential tariffs. Select a reliable logistics partner experienced in international trade to navigate these complexities. Additionally, factor in delivery times to align with your business needs and ensure that your supply chain can handle fluctuations in demand. Communication with your supplier regarding shipping schedules and tracking is crucial for effective logistics management.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Roof Shoes Manufacturers & Suppliers List

1. Cougar Paws – Roofing Boots and Tools

Domain: cougarpaws.com

Registered: 1999 (26 years)

Introduction: Cougar Paws offers a range of roofing boots and tools designed specifically for roofers, appraisers, and others in the industry. Their products include boots for metal roofs and shingle roofs, traction boots, replaceable traction pads, and anti-slip accessories. Founded in 1996 by Dan Cougar, the brand focuses on product innovation and utilizes the latest technology to enhance grip, traction, and …

2. Big Rock Supply – Roofing Overshoe Sandals

Domain: bigrocksupply.com

Registered: 2000 (25 years)

Introduction: This company, Big Rock Supply – Roofing Overshoe Sandals, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Roofing Shoes – Essential Features and Recommendations

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The post discusses the importance of choosing the right shoes for roofing work. Key considerations include grip, comfort, and safety features. Recommended types of shoes include work boots with good traction, non-slip soles, and waterproof materials. Some users mention specific brands and models that have worked well for them, emphasizing the need for shoes that provide stability on sloped surface…

4. Toolexperts – Korkers Overshoe Sandal

Domain: toolexperts.com

Registered: 1997 (28 years)

Introduction: Korkers Overshoe Sandal for Roofs is a versatile boot accessory designed for safety while walking on roofs. It features a 3-in-1 interchangeable sole system that allows users to customize the sole for specific applications. The overshoe comes with a Soft Foam sole, ideal for smooth surfaces like metal and tile, even when wet or oily. Additional sole options include Medium Density Foam soles for as…

5. Roofing Shoes – Comfort & Durability

Domain: roofing-shoes.com

Registered: 2023 (2 years)

Introduction: This company, Roofing Shoes – Comfort & Durability, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Walmart – Men’s Genuine Leather Work Boots

Domain: walmart.com

Registered: 1995 (30 years)

Introduction: This company, Walmart – Men’s Genuine Leather Work Boots, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Timberland – Garmont Men’s T8 NFS 670 Tactical Boots

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Roofing Shoes for sale on eBay. Brands include Timberland, Lucchese, Ariat, Danner, and Harley-Davidson. Popular items include Garmont Men’s T8 NFS 670 Regular Tactical Military Boots, Red Wing Boots Work DynaForce 1204, Carhartt Men’s Moc Toe 6″ Wedge Work Boot, and Georgia Giant Revamp Steel Toe Waterproof Work Boot. Sizes and conditions vary, with options for new and used items.

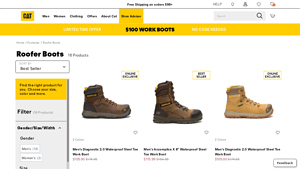

8. Cat Footwear – Roofer Boots

Domain: catfootwear.com

Registered: 1997 (28 years)

Introduction: Roofer Boots: 16 Products available. Gender: Men’s (14), Women’s (2). Sizes: 5 to 14. Width: Medium (16), Wide (14). Colors: Black, Brown, Grey, Tan. Styles: Boots (16), 6″ Boots (1), Winter Boots (1). Toe Types: Composite Toe (5), Steel Toe (7), Soft Toe (1), Carbon Composite Toe (3). Features: Electrical Hazard (16), Insulated (1), Slip Resistant (16), Waterproof (14), Non-Metallic (7), Thinsula…

Strategic Sourcing Conclusion and Outlook for roof shoes

In the evolving landscape of roofing footwear, strategic sourcing emerges as a critical component for B2B buyers aiming to enhance safety and productivity. By investing in high-quality roof shoes tailored for diverse roofing applications, businesses can mitigate risks associated with slips and falls, a common hazard in the industry. The right footwear not only provides superior grip and comfort but also contributes to overall job efficiency, allowing roofers to work more effectively across various surfaces, from shingles to metal.

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should prioritize sourcing from established manufacturers who emphasize innovation and reliability. Brands such as Cougar Paws and Korkers exemplify this commitment by offering products designed specifically for the unique challenges faced by roofers.

Looking ahead, as the demand for sustainable and safe roofing practices continues to grow, investing in premium roofing shoes will be essential. We encourage you to explore partnerships with trusted suppliers to enhance your operational safety and efficiency. The right strategic sourcing decisions today will pave the way for a safer, more productive tomorrow in the roofing industry.