Your Ultimate Guide to Sourcing Capezio Shoes

Guide to Capezio Shoes

- Introduction: Navigating the Global Market for capezio shoes

- Understanding capezio shoes Types and Variations

- Key Industrial Applications of capezio shoes

- Strategic Material Selection Guide for capezio shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for capezio shoes

- Comprehensive Cost and Pricing Analysis for capezio shoes Sourcing

- Spotlight on Potential capezio shoes Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for capezio shoes

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the capezio shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of capezio shoes

- Strategic Sourcing Conclusion and Outlook for capezio shoes

Introduction: Navigating the Global Market for capezio shoes

In today’s highly competitive global footwear market, Capezio shoes have established themselves as a premier choice for dance studios, performing arts institutions, and specialty retailers worldwide. Their reputation for quality, durability, and innovative design makes them a vital product for B2B buyers seeking reliable, high-performance footwear. For international buyers—particularly from Africa, South America, the Middle East, and regions like Thailand and Brazil—understanding the intricacies of sourcing Capezio shoes is crucial to maximizing value and ensuring a seamless supply chain.

This comprehensive guide offers actionable insights into every facet of the Capezio supply ecosystem. From exploring various product types and materials to understanding manufacturing standards and quality control processes, it equips buyers with the knowledge needed to make informed sourcing decisions. Additionally, it covers sourcing options—direct from manufacturers, authorized distributors, and trusted suppliers—highlighting key considerations like pricing strategies, import regulations, and logistical complexities.

By delving into market trends, cost considerations, and frequently asked questions, this guide empowers B2B buyers to navigate the complexities of international procurement confidently. Whether you are expanding your product portfolio or establishing long-term supply partnerships, understanding these critical factors will help you optimize costs, ensure consistent quality, and capitalize on emerging market opportunities across diverse regions. Ultimately, this resource aims to streamline your sourcing process, reducing risk and enhancing your competitive edge in the global dancewear industry.

Understanding capezio shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Ballet Shoes | Soft leather or canvas, thin sole, minimal structure | Dance academies, theatrical productions, retail | Affordable, lightweight, flexible; limited durability, less supportive |

| Pointe Shoes | Reinforced toe box, stiff shank, specialized fit | Professional ballet companies, high-end studios | High precision fit, premium quality; expensive, longer lead times |

| Jazz & Contemporary Shoes | Flexible sole, low profile, often with elastic straps | Dance studios, fitness centers, performance groups | Good grip and flexibility, versatile; may wear out faster with heavy use |

| Character Shoes | Low heel, sturdy construction, often with straps | Musical theater, stage performances, costume suppliers | Durable, stylish for stage; heavier and less comfortable for daily wear |

| Tap Shoes | Hard sole with metal tap plates, reinforced construction | Tap dance schools, performance groups, costume suppliers | Clear sound quality, specialized; heavier, higher cost for quality components |

Classic Ballet Shoes

Classic ballet shoes are crafted from soft leather or canvas, featuring a thin, flexible sole that allows for maximum movement and sensitivity. They are primarily used in dance academies, theatrical productions, and retail channels targeting beginner to intermediate dancers. For B2B buyers, these shoes offer a cost-effective option with quick lead times and widespread availability. However, their limited durability makes them less suitable for heavy or professional use, requiring buyers to consider volume discounts and supplier reliability to ensure consistent stock.

Pointe Shoes

Pointe shoes are specialized ballet footwear with reinforced toe boxes and stiff shanks, designed for advanced dancers executing en pointe. They are typically purchased by professional ballet companies, high-end dance studios, and theatrical costume suppliers. B2B buyers should prioritize suppliers with a proven track record for quality and consistency, as pointe shoes require precise fitting and quality control. The high cost and longer manufacturing lead times necessitate strategic inventory planning, especially for large orders or seasonal productions.

Jazz & Contemporary Shoes

These shoes are characterized by their flexible soles, low profile, and often elastic straps for secure fit. They are versatile, suitable for various dance styles, fitness classes, and performance groups. For international buyers, sourcing these shoes involves evaluating supplier flexibility in styles and sizes, as well as quality for frequent use. Their relative affordability and adaptability make them appealing, but buyers should consider potential rapid wear and establish relationships with manufacturers that offer reliable quality assurance for bulk orders.

Character Shoes

Designed with a sturdy construction and a low heel, character shoes often include straps for added support. They are essential in musical theater, stage performances, and costume supply channels. B2B buyers should focus on durability and aesthetic appeal, ensuring that suppliers can meet theatrical standards and provide consistent styling. While their heavier build provides longevity, it may impact comfort for extended wear, so bulk purchasing should include options for varying sizes and styles to accommodate different productions.

Tap Shoes

Tap shoes feature a hard sole with metal tap plates embedded for producing rhythmic sounds, making them a specialized product for tap dance performers. They are mainly purchased by tap dance schools, performance groups, and costume suppliers. Buyers should verify the quality of tap plates and sole reinforcement, as these directly impact sound clarity and durability. Due to the specialized nature and higher costs associated with quality components, bulk orders should be negotiated with suppliers capable of providing consistent quality and timely delivery to meet performance schedules.

Key Industrial Applications of capezio shoes

| Industry/Sector | Specific Application of Capezio Shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Performing Arts & Dance | Professional dance performances and rehearsals | Enhances performer comfort, durability, and aesthetic appeal | Require high-quality materials, consistent sizing, and reliable supply chains |

| Healthcare & Rehabilitation | Therapeutic and rehabilitation footwear for patients | Supports mobility, reduces injury risk, and improves patient outcomes | Need for specialized designs, compliance with health standards, and bulk procurement options |

| Retail & Specialty Stores | Distribution through dancewear and specialty footwear outlets | Expands product portfolio, attracts niche markets, and boosts sales | Focus on brand authenticity, variety in sizing and styles, and regional distribution capabilities |

| Hospitality & Entertainment | Use in themed performances, events, and costume applications | Adds authenticity and visual appeal, enhancing guest experiences | Customization options, quick delivery, and durability for frequent use |

| Educational Institutions | Dance schools, academies, and training centers | Provides students with professional-grade footwear, fostering skill development | Bulk sourcing, consistent quality, and availability of different sizes and styles |

Performing Arts & Dance

Capezio shoes are renowned in the performing arts industry, especially for ballet, jazz, tap, and contemporary dance. They are used by professional dancers and academies worldwide to ensure optimal performance and comfort. For international B2B buyers in regions like Africa, South America, and Europe, sourcing reliable, high-quality dance footwear is crucial to meet the demanding standards of performers and institutions. Durable materials, precise sizing, and aesthetic versatility are key factors that influence purchasing decisions, ensuring that dancers can perform at their best without footwear-related issues.

Healthcare & Rehabilitation

In the healthcare sector, Capezio shoes are utilized in therapeutic settings for rehabilitation and mobility support. Their specialized designs help reduce injury risks and assist patients recovering from foot or leg issues. B2B buyers such as hospitals, clinics, and rehabilitation centers in emerging markets like Brazil or Middle Eastern countries need footwear that complies with health standards, offers comfort, and supports diverse foot conditions. Bulk procurement with consistent quality and compliance with medical standards are essential for building trust and ensuring effective patient care.

Retail & Specialty Stores

Capezio’s presence in retail outlets and specialty dance stores offers B2B buyers an opportunity to tap into niche markets. Distributing these shoes through local or regional retail channels can significantly boost sales, especially in markets with vibrant dance communities like Thailand or European capitals. Buyers should prioritize authentic sourcing, a wide variety of styles and sizes, and reliable supply chains to meet customer demands effectively. Establishing strong relationships with authorized distributors ensures product authenticity and timely delivery.

Hospitality & Entertainment

In themed performances, entertainment venues, and costume applications, Capezio shoes add authenticity and visual appeal. For international buyers in entertainment hubs or cultural centers, sourcing durable, stylish footwear that withstands frequent use is vital. Customization options, quick turnaround times, and high durability are critical considerations. These shoes help venues deliver immersive experiences, making them a valuable addition to costume and performance supply chains.

Educational Institutions

Dance schools and academies across Africa, South America, and Europe rely on Capezio shoes for training and performance purposes. Bulk sourcing of consistent, high-quality footwear supports student development and maintains professional standards. Buyers should focus on establishing reliable supply channels, ensuring a range of sizes, and maintaining inventory levels to meet seasonal and enrollment fluctuations. Providing affordable, durable options enhances reputation and supports the growth of local dance communities.

Strategic Material Selection Guide for capezio shoes

Material Analysis for Capezio Shoes

Selecting the appropriate materials for Capezio shoes is critical for ensuring product performance, durability, and compliance across diverse international markets. Different regions impose varying standards, environmental conditions, and consumer preferences, making a strategic approach to material choice essential for B2B buyers from Africa, South America, the Middle East, and Europe.

Leather (Genuine and Synthetic)

Leather remains a traditional and highly favored material for dance and performance shoes due to its excellent flexibility, breathability, and aesthetic appeal. Genuine leather offers superior durability and molds well to the foot over time, providing comfort and support. However, it tends to be more expensive and requires careful manufacturing processes, including tanning and finishing, which can influence cost and lead times.

Pros:

– High durability and longevity

– Breathable, comfortable for extended wear

– Aesthetic versatility and premium feel

Cons:

– Higher cost, especially for genuine leather

– Sensitive to moisture and environmental conditions, requiring proper care

– Manufacturing complexity varies depending on leather grade and tanning process

Impact on Application:

Leather’s breathability and flexibility make it suitable for various dance forms and performance settings. However, in humid or wet climates (e.g., parts of Brazil or Southeast Asia), leather shoes may require additional waterproofing treatments to maintain integrity.

International Considerations:

Buyers in regions with strict import regulations on animal products (e.g., some European countries) must ensure leather sourcing complies with environmental and animal welfare standards. Additionally, adherence to standards like ASTM or EN is vital for quality assurance.

PVC (Polyvinyl Chloride)

PVC is a synthetic plastic material commonly used for affordable, lightweight, and water-resistant dance shoes. Its production is relatively straightforward, making it a cost-effective choice for mass manufacturing.

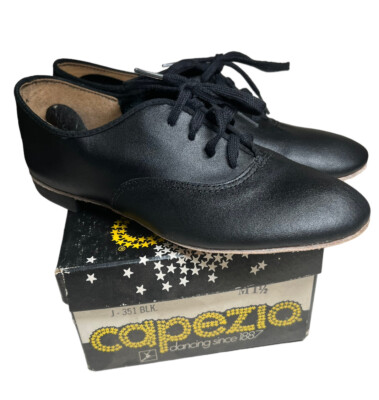

Illustrative Image (Source: Google Search)

Pros:

– Low cost and widely available

– Water-resistant and easy to clean

– Lightweight, reducing fatigue during extended performances

Cons:

– Less durable, prone to cracking over time

– Less breathable, which can cause discomfort in hot climates

– Environmental concerns related to PVC disposal and production

Impact on Application:

PVC is ideal for costume or practice shoes where cost efficiency is prioritized. It performs well in dry environments but may degrade faster in humid or tropical climates, common in regions like Brazil and Southeast Asia.

International Considerations:

Many countries are imposing restrictions on PVC due to environmental concerns. Buyers should verify local import regulations and consider eco-friendly alternatives or recycled PVC options.

EVA (Ethylene Vinyl Acetate)

EVA foam is popular for insoles, padding, and lightweight components within Capezio shoes. Its shock-absorbing properties enhance comfort, especially for dancers and performers engaging in high-impact routines.

Pros:

– Excellent cushioning and shock absorption

– Lightweight and flexible

– Cost-effective for internal components

Cons:

– Less durable for external shoe parts

– Can degrade under prolonged UV exposure

– Not suitable for structural elements requiring high strength

Impact on Application:

EVA is best used in insoles and padding rather than as a primary upper material. Its impact resistance makes it suitable for performance shoes that require comfort without sacrificing mobility.

International Considerations:

Buyers should confirm EVA formulations meet local safety standards, such as REACH in Europe or similar regulations elsewhere. Proper sourcing ensures compliance and reduces risk of product recalls.

Summary Table

| Material | Typical Use Case for Capezio Shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather (Genuine/Synthetic) | Upper, support structures, and flexible components | Durable, breathable, premium appearance | Higher cost, sensitive to moisture | High |

| PVC | Cost-effective, water-resistant outer shells or costume shoes | Low cost, water-resistant, lightweight | Less durable, environmental concerns | Low |

| EVA | Insoles, padding, shock absorption components | Excellent cushioning, lightweight | Less durable externally, UV sensitive | Low |

| Rubber (Natural/Synthetic) | Outsoles and grip-enhancing parts | High grip, flexible, slip-resistant | Wear over time, environmental impact varies | Med |

Final Insights for International B2B Buyers

When sourcing materials for Capezio shoes, regional environmental conditions, import standards, and consumer preferences must be carefully considered. For example, African markets might prioritize durability and cost, favoring synthetic options like PVC or EVA, while European markets may demand higher compliance with environmental standards, favoring leather or eco-certified synthetics. Middle Eastern buyers should consider climate resilience, especially heat and humidity, influencing material choices like moisture-resistant leather or synthetic composites.

Illustrative Image (Source: Google Search)

By understanding these material properties and regional considerations, B2B buyers can make informed decisions that optimize product performance, compliance, and cost-efficiency across diverse markets.

In-depth Look: Manufacturing Processes and Quality Assurance for capezio shoes

Manufacturing Processes of Capezio Shoes

The production of Capezio shoes involves a series of meticulously controlled stages designed to ensure durability, comfort, and aesthetic appeal. Understanding these processes is crucial for international B2B buyers aiming to assess supplier capabilities and ensure product quality.

1. Material Preparation

The manufacturing journey begins with sourcing high-quality raw materials, primarily leather, synthetic fabrics, and specialized adhesives. Suppliers typically select materials that meet international standards such as ISO 9001, ensuring consistency in quality. Material inspection at this stage involves visual checks for defects, measurements, and testing for durability and flexibility.

2. Forming and Cutting

In this stage, materials are cut into precise patterns using computer-controlled cutting machines, which minimize waste and ensure accuracy. Leather and synthetic upper components are shaped and molded using thermoforming or stamping techniques, often with heat presses to achieve the desired contours. For dance shoes, particular attention is given to flexibility and fit, requiring specialized tooling.

3. Assembly and Stitching

The assembled components—upper, lining, insole, and outsole—are stitched together using industrial sewing machines. High-frequency or lockstitch machines are common, with some manufacturers employing automated or semi-automated systems for consistency. Adhesives, such as water-based or solvent-based glues, are applied precisely to bond parts securely, especially for the sole attachment.

4. Finishing and Quality Control

Final touches include trimming excess material, polishing, and applying branding elements like logos or decorative features. For performance and dance shoes, additional features such as elastic straps or reinforcement patches are added. The shoes undergo initial inspection for defects and adherence to design specifications.

Quality Assurance (QA) and Industry Standards

Robust Quality Assurance (QA) protocols underpin the manufacturing process to meet both international standards and industry-specific requirements.

1. International Standards Compliance

Most reputable Capezio manufacturers adhere to ISO 9001 standards for quality management systems. This ensures a systematic approach to quality, from raw material sourcing to final product inspection. For specific markets, compliance with standards like CE marking (European Economic Area), API standards (for safety and performance), or ASTM standards (for performance footwear) may also be required.

2. Quality Control Checkpoints

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival, including visual inspection, tensile strength testing, and chemical composition analysis. This prevents substandard materials from entering production.

– In-Process Quality Control (IPQC): Throughout manufacturing, checkpoints verify dimensions, stitching quality, adhesive application, and material consistency. Non-conformance is flagged immediately for correction.

– Final Quality Control (FQC): Before packaging, shoes are examined for defects, correct assembly, and compliance with design specifications. This may include visual inspection, dimensional checks, and functional testing.

3. Testing Methods

– Durability Testing: Shoes undergo flex tests, abrasion resistance tests, and adhesion tests to ensure longevity under normal use.

– Comfort and Fit: Bending and compression tests simulate wear conditions, especially critical for dance shoes requiring flexibility.

– Environmental Testing: Some suppliers perform tests for resistance to humidity, temperature fluctuations, and UV exposure, ensuring product stability in diverse climates.

Verifying Supplier Quality for International Buyers

International B2B buyers must implement strategies to verify manufacturing quality and ensure suppliers meet expected standards.

1. Audits and Factory Visits

Conduct comprehensive on-site audits focusing on production processes, quality management systems, and working conditions. For buyers from Africa, South America, the Middle East, or regions like Thailand and Brazil, local partnerships or third-party inspection agencies can facilitate audits, especially when direct visits are challenging.

2. Inspection Reports and Certification Verification

Request detailed inspection reports, test certificates, and certification copies (ISO 9001, CE, ASTM, etc.). These documents should be recent, traceable, and verifiable through issuing agencies.

3. Third-Party Inspection Services

Engage reputable third-party inspection firms (e.g., SGS, Bureau Veritas, Intertek) to perform pre-shipment inspections. These inspections cover quality, quantity, and compliance with specifications, providing an unbiased assessment.

4. Sample Testing

Before large orders, request samples for independent testing or third-party laboratory analysis. Testing for material composition, durability, and safety standards can preempt issues upon shipment.

Nuances for International B2B Buyers

Different regions present unique challenges and considerations for quality assurance:

-

Africa & South America: Variability in manufacturing infrastructure may necessitate more frequent audits and reliance on third-party inspections. Buyers should prioritize suppliers with recognized certifications and transparent quality records.

-

Middle East: Climate considerations such as high temperatures and humidity require testing for material stability and resistance. Ensuring compliance with regional safety standards (e.g., Gulf Standards) is also essential.

-

Europe (e.g., Portugal, Spain): Stringent enforcement of CE marking and environmental standards (REACH, RoHS) means suppliers must provide comprehensive compliance documentation. Buyers should verify these certifications through official channels.

-

Thailand & Brazil: These manufacturing hubs often have well-established quality systems, but due diligence remains vital. Engaging local inspection agencies familiar with regional manufacturing practices can improve reliability.

Practical Tips for B2B Buyers

- Develop Clear Specifications: Define precise quality standards, testing requirements, and certification needs upfront to streamline supplier selection.

- Build Long-term Relationships: Regular audits and supplier development programs foster trust and continuous improvement.

- Leverage Technology: Utilize digital platforms for document verification, video audits, and remote monitoring where physical visits are impractical.

- Stay Informed on Local Regulations: Keep abreast of regional compliance requirements to avoid delays or legal issues.

By understanding the detailed manufacturing processes and establishing rigorous quality assurance protocols, international B2B buyers can confidently source Capezio shoes that meet their market demands, ensuring customer satisfaction and brand reputation across diverse regions.

Comprehensive Cost and Pricing Analysis for capezio shoes Sourcing

Cost Structure Breakdown for Capezio Shoes Sourcing

Understanding the comprehensive cost structure of Capezio shoes is essential for international B2B buyers aiming to optimize procurement strategies. The primary cost components include raw materials, labor, manufacturing overheads, tooling, quality control, logistics, and profit margins.

Materials: The core cost driver, especially given Capezio’s focus on performance fabrics, leather, and specialized components. Sourcing high-quality, durable materials may increase upfront costs but can reduce returns and warranty claims. Buyers from regions like Africa and South America should explore local or regional suppliers to potentially reduce material costs and lead times.

Labor: Manufacturing labor costs vary significantly based on the sourcing location. Countries like Thailand and certain Eastern European nations offer competitive labor rates without compromising quality, while factories in Europe may incur higher wages but often provide superior craftsmanship and certifications.

Manufacturing Overheads: These include facility expenses, machinery depreciation, and energy costs. Efficient factories with modern equipment tend to have lower overheads, which can translate into more competitive pricing for buyers.

Tooling and Development: Initial tooling costs are often amortized over large production runs. For customized designs or special features, expect higher upfront costs, but these can be negotiated based on order volume.

Quality Control and Certifications: Ensuring compliance with international standards (e.g., ISO, CE, ASTM) can influence costs. Certified suppliers may command premium prices but reduce the risk of non-compliance issues that could delay shipments or incur penalties.

Logistics and Incoterms: Shipping costs depend on order volume, destination, and chosen Incoterms. FOB (Free on Board) or CIF (Cost, Insurance, and Freight) are common terms; buyers should evaluate insurance, customs duties, and local taxes, especially when importing to regions like Brazil or Middle Eastern countries.

Profit Margin: Suppliers typically add a markup to cover risks and ensure profitability. Margins vary but generally range from 10% to 30%, depending on order size and relationship strength.

Key Price Influencers for International Buyers

Several factors can significantly influence the final pricing of Capezio shoes:

-

Order Volume and MOQ: Larger orders benefit from economies of scale, often reducing per-unit costs. Buyers should negotiate for favorable MOQs, especially when entering new markets or testing demand.

-

Customization and Specs: Unique designs, special materials, or specific certifications increase production complexity and costs. Clear specifications and bulk orders can help mitigate these expenses.

-

Material Choices: Premium or specialized materials, such as eco-friendly fabrics or high-performance synthetics, tend to elevate costs but may command higher retail prices and market differentiation.

-

Quality Certifications: Suppliers with established compliance credentials may charge premium prices, but this reduces risks related to product recalls, legal liabilities, or customs delays.

-

Supplier Factors: Factory reputation, production capacity, lead times, and responsiveness influence pricing. Established suppliers with reliable delivery often command higher but more predictable prices.

-

Incoterms and Shipping: The choice of Incoterm impacts total landed cost. Buyers should consider FOB terms for better control or CIF if they prefer suppliers to handle logistics, which might be slightly more expensive but reduces complexity.

Strategic Tips for B2B Buyers from Africa, South America, the Middle East, and Europe

-

Negotiate for Volume Discounts and Flexible MOQs: Building long-term relationships can unlock better pricing tiers, especially for large or repeat orders.

-

Focus on Total Cost of Ownership (TCO): Beyond unit price, consider shipping, customs duties, compliance costs, and after-sales support. Sometimes paying a premium upfront yields savings later through fewer quality issues or streamlined logistics.

-

Leverage Regional Sourcing: For buyers in Africa and South America, local sourcing options or nearshore manufacturing (e.g., Turkey or Eastern Europe) can significantly reduce shipping costs and lead times.

-

Understand Pricing Nuances: Prices are often indicative and subject to change based on raw material fluctuations, currency exchange rates, and geopolitical factors. Always seek detailed quotes and contractual clarity.

-

Factor in Customs and Import Regulations: Different regions have varying tariffs and import restrictions. For example, Brazil imposes high import taxes, which should be incorporated into cost estimates.

-

Engage in Strategic Negotiation: Use your market knowledge and order volume to negotiate better terms, including payment terms, discounts, and lead times.

Disclaimer

Prices for Capezio shoes can vary widely depending on specifications, order size, and supplier relationships. As a rough guide, FOB prices for standard models typically range from $5 to $15 per pair, with customized or premium models costing more. Always request detailed quotes and conduct due diligence to verify supplier capabilities and compliance standards.

Spotlight on Potential capezio shoes Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for capezio shoes.)*

Essential Technical Properties and Trade Terminology for capezio shoes

Key Technical Properties for Capezio Shoes

1. Material Grade and Composition

The quality of materials used in Capezio shoes directly influences durability, comfort, and performance. Common materials include genuine leather, synthetic fabrics, and specialized dance textiles. High-grade materials ensure longevity and meet industry standards, which is vital for maintaining brand reputation and reducing return rates.

2. Tolerance and Manufacturing Precision

Tolerance levels refer to the permissible deviation in shoe dimensions during manufacturing, typically measured in millimeters. Tight tolerances (e.g., ±0.5 mm) guarantee consistent fit across batches, which is crucial for dancers requiring precise sizing. For B2B buyers, specifying tolerance standards helps ensure product uniformity and reduces quality discrepancies.

3. Flexibility and Support Features

Dance shoes like Capezio’s often require a balance between flexibility and support. Technical specifications include the type of sole material (e.g., split-sole leather) and arch support design. These properties impact the dancer’s performance and safety, making them critical for B2B buyers to verify with manufacturers.

4. Weight and Breathability

Lightweight shoes facilitate ease of movement, while breathable materials prevent excessive sweating, reducing discomfort and odor. These properties are particularly important for performance footwear used in intense routines. B2B buyers should specify these features based on their target market needs.

5. Colorfastness and Finish Quality

Durability of color and finish is essential, especially for shoes exposed to frequent washing or intense use. High-quality dyes and finishing processes prevent fading and cracking, maintaining aesthetic appeal over time. Suppliers should provide certification or testing reports verifying these properties.

6. Compliance and Certification Standards

Depending on the destination market, shoes may need to meet specific safety or environmental standards (e.g., REACH in Europe, ASTM in the US). Ensuring compliance avoids legal barriers and facilitates smooth import processes, making this a key property to verify.

Common Trade Terms in Capezio Shoe Industry

1. OEM (Original Equipment Manufacturer)

Refers to manufacturers producing shoes under the buyer’s brand name. B2B buyers often engage OEM suppliers to customize designs, packaging, or branding, enabling market differentiation. Understanding OEM agreements helps secure exclusive product lines and control over branding.

2. MOQ (Minimum Order Quantity)

The smallest order size a manufacturer is willing to accept. MOQs vary depending on product complexity and supplier policies. For buyers, negotiating MOQs is essential for balancing inventory costs with market demand, especially when entering new regions.

3. RFQ (Request for Quotation)

A formal request sent to suppliers asking for price, lead times, and terms for specific products. B2B buyers should prepare detailed RFQs to compare offers effectively, ensuring transparency and competitive pricing before committing to large orders.

4. Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and tariffs between buyer and seller. Common Incoterms include FOB (Free on Board), CIF (Cost, Insurance, Freight), and DDP (Delivered Duty Paid). Clear understanding of Incoterms minimizes misunderstandings and clarifies cost responsibilities across borders.

5. Lead Time

The period from order placement to product delivery. Knowing a supplier’s lead time is vital for supply chain planning, especially when coordinating shipments across continents. B2B buyers should confirm lead times to align production schedules with market launches.

6. Certification and Testing Reports

Documents verifying that products meet safety, quality, and environmental standards. These are often required for customs clearance and regulatory compliance. Requesting and reviewing these reports helps mitigate risks of shipment delays or rejections.

Actionable Insights for International Buyers

- Prioritize Material and Manufacturing Standards: Confirm material grades and tolerance levels to ensure product consistency and quality, especially when dealing with international suppliers unfamiliar with your standards.

- Leverage Trade Terms Knowledge: Use Incoterms and certifications to negotiate better shipping arrangements and compliance, reducing unexpected costs or delays.

- Negotiate MOQs and Lead Times: Tailor order quantities and schedules to your market demand, avoiding excess inventory or shortages.

- Request Detailed Documentation: Always obtain certification and testing reports to verify product safety and environmental compliance, crucial for entry into regulated markets like Europe and Brazil.

- Build Strong Supplier Relationships: Understanding and clearly communicating trade terms and technical specifications will facilitate smoother negotiations and long-term partnerships across regions like Africa, South America, the Middle East, and Europe.

By mastering these technical properties and trade terminologies, B2B buyers can optimize procurement strategies, ensure product quality, and streamline international trade processes for Capezio shoes.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the capezio shoes Sector

Market Overview & Key Trends

The global market for dance footwear, including Capezio shoes, is experiencing significant shifts driven by technological advancements, evolving consumer preferences, and supply chain innovations. As a well-established brand, Capezio continues to adapt to these trends, making sourcing decisions increasingly complex yet promising for international B2B buyers.

Emerging trends include digitalization of supply chains, with blockchain and IoT technologies enhancing transparency and traceability—crucial for buyers in regions like Africa, South America, the Middle East, and Europe. These tools enable better verification of authenticity, ethical sourcing, and real-time inventory management, reducing risks associated with counterfeiting and supply disruptions.

Market dynamics are also influenced by geopolitical factors, tariffs, and trade agreements, which can impact pricing and lead times. Buyers in diverse regions such as Thailand or Brazil should consider local manufacturing capabilities, logistics infrastructure, and regional trade policies to optimize costs and delivery schedules. Additionally, there’s an increasing demand for customization and eco-conscious products, prompting brands like Capezio to incorporate sustainable materials and innovative designs.

The B2B landscape is further shaped by e-commerce platforms and direct-to-retailer models, facilitating faster procurement cycles and broader reach. For buyers, leveraging these digital channels can improve sourcing agility, reduce overheads, and expand market access. As sustainability becomes a decisive factor, sourcing strategies must align with environmental standards and social compliance to meet both consumer expectations and regulatory requirements across different regions.

In summary, international B2B buyers should prioritize technological integration, regional trade considerations, and sustainable sourcing practices to navigate the evolving Capezio shoes market effectively.

Sustainability & Ethical Sourcing in B2B

Sustainability and ethical sourcing are increasingly pivotal in the global footwear sector, especially for brands like Capezio that emphasize craftsmanship and social responsibility. For B2B buyers, integrating sustainable practices into procurement not only aligns with global environmental standards but also enhances brand reputation and consumer trust.

Illustrative Image (Source: Google Search)

Environmental impact considerations include reducing carbon footprints through optimized logistics, selecting eco-friendly materials, and adopting manufacturing processes that minimize waste and pollution. Capezio has begun incorporating sustainable materials such as recycled fabrics, organic cotton, and biodegradable components into its product lines, making it easier for buyers to meet their own sustainability commitments.

Ethical sourcing encompasses fair labor practices, safe working conditions, and transparent supply chains. Buyers should prioritize partnerships with suppliers that hold recognized certifications such as Fair Trade, WRAP (Worldwide Responsible Accredited Production), or SA8000. These certifications verify compliance with labor laws and ethical standards, reducing exposure to reputational risks.

Furthermore, sustainability certifications—like Global Organic Textile Standard (GOTS) or Forest Stewardship Council (FSC)—serve as reliable indicators of environmentally responsible sourcing. Incorporating these standards into procurement criteria can facilitate access to premium markets and meet the increasing demand from consumers for ethically produced products.

To strengthen supply chain integrity, buyers should engage in regular audits, foster long-term supplier relationships, and support capacity-building initiatives that promote sustainable practices. Embracing sustainability not only benefits the environment but also provides a competitive edge in regions where eco-conscious consumers and regulators are becoming more influential.

Brief Evolution/History (Optional)

Capezio’s origins date back to 1887, rooted in a commitment to quality dance footwear. Over the decades, the brand evolved from a small family business into a global leader in dance and performance shoes, renowned for craftsmanship and innovation. This history underscores a legacy of adapting to changing industry standards and consumer preferences.

For B2B buyers, understanding Capezio’s evolution highlights its emphasis on quality, innovation, and social responsibility—factors critical in sourcing decisions. The company’s shift towards sustainable materials and ethical manufacturing reflects broader industry trends, making it a reliable partner committed to responsible business practices.

This historical perspective also emphasizes the importance of partnering with brands that have a proven track record of adapting to market demands, ensuring long-term supply stability and alignment with regional sustainability initiatives. For regions like Africa, South America, the Middle East, and Europe, collaborating with an established, forward-thinking brand like Capezio can facilitate compliance with local regulations and consumer expectations while supporting sustainable development goals.

Frequently Asked Questions (FAQs) for B2B Buyers of capezio shoes

1. How can I verify the credibility and reliability of a Capezio shoe supplier?

Verifying supplier credibility is essential for secure international transactions. Start by requesting detailed company credentials, including business licenses, export licenses, and relevant certifications (e.g., ISO, social compliance). Review their track record through references, trade references, and online platforms like Alibaba or Global Sources. Conduct virtual or in-person audits if possible, focusing on manufacturing facilities, quality control processes, and compliance standards. Additionally, check for consistent communication, transparent pricing, and responsiveness. Engaging with suppliers who have a proven export history and positive reviews reduces risks associated with fraud or substandard products.

2. Can Capezio shoes be customized for my market, and what are the typical options?

Yes, Capezio offers customization options to meet specific market needs. Common customizations include branding (logo placement), color variations, sizing adjustments, and exclusive designs. Some suppliers may also offer material modifications or packaging customization to suit regional preferences. To initiate customization, communicate your specific requirements clearly and request sample prototypes before bulk production. Be aware that customization may influence minimum order quantities (MOQs) and lead times. Establish a detailed agreement upfront to ensure your branding and product specifications are accurately implemented, facilitating market differentiation.

3. What are the typical minimum order quantities, lead times, and payment terms for importing Capezio shoes?

MOQ and lead times vary depending on the supplier and order complexity. Generally, MOQs range from 300 to 1,000 pairs for standard models, with higher volumes often securing better pricing. Lead times typically range from 4 to 8 weeks after order confirmation, but complex customizations may extend this period. Payment terms often include a 30% deposit upfront with the balance payable before shipment or upon receipt of goods, with options for letters of credit or bank guarantees for larger orders. Negotiating flexible terms is crucial, especially for smaller buyers or urgent markets; building relationships can facilitate more favorable conditions.

4. What quality assurance measures and certifications should I look for when sourcing Capezio shoes?

Ensure your supplier adheres to strict quality assurance protocols, including ISO 9001 certification or equivalent standards. Request documentation of material testing, durability assessments, and compliance with international safety standards such as CE, ASTM, or REACH, depending on your region. Regular factory audits and third-party inspections during production help maintain quality consistency. Additionally, ask for product samples for testing upon arrival to verify material quality, comfort, and durability. Working with suppliers who provide comprehensive QA reports minimizes the risk of defective shipments and ensures your products meet your market’s regulatory requirements.

5. How can I manage logistics effectively when importing Capezio shoes to my country?

Efficient logistics require early planning and choosing reliable freight partners familiar with your destination country’s import regulations. Consider options such as sea freight for cost-effectiveness on large volumes or air freight for urgent deliveries. Collaborate with freight forwarders who can handle customs clearance, warehousing, and last-mile delivery. Clarify incoterms (e.g., FOB, CIF) with your supplier to define responsibilities and costs clearly. Maintain open communication to monitor shipment status, and prepare all necessary documentation—commercial invoices, packing lists, certificates of origin—to prevent delays. Building relationships with experienced logistics providers reduces transit risks and ensures timely delivery.

6. What should I do if there is a dispute or quality issue with my Capezio shoe order?

Address disputes promptly by documenting issues with detailed photos, samples, and communication records. Communicate directly with your supplier to seek a resolution, such as replacement, rework, or refund. Many reputable suppliers offer post-shipment support and quality guarantees; clarify these terms before ordering. If unresolved, escalate through trade platforms or involve third-party arbitration services specializing in international trade disputes. Establish clear contractual clauses on quality standards, inspection rights, and dispute resolution procedures beforehand. Proactive communication and well-documented evidence are key to resolving issues efficiently and protecting your business interests.

7. Are there any regional or import restrictions I should be aware of when sourcing Capezio shoes?

Yes, import restrictions vary by country and may include tariffs, import quotas, or specific certification requirements. Check your country’s customs regulations and import duties for footwear and apparel. Some regions, like the Middle East or South America, may have specific standards related to safety, labeling, or environmental compliance. Additionally, ensure that your supplier’s documentation (certificates of origin, compliance certificates) aligns with local regulations to facilitate smooth customs clearance. Consulting with local import/export experts or customs brokers can help you navigate regional restrictions, avoid delays, and optimize your landed costs.

8. How can I build a sustainable and long-term partnership with my Capezio shoes supplier?

Fostering trust and transparency is vital for long-term success. Start by establishing clear communication channels, sharing your forecasted volumes, and providing regular feedback. Pay on time and honor contractual commitments to build credibility. Consider visiting the supplier’s facility periodically to strengthen relationships and verify ongoing compliance with quality and social standards. Explore opportunities for joint product development or exclusive designs to deepen collaboration. Maintaining flexibility and understanding regional market nuances can also help adapt to changing demands. A mutually beneficial partnership reduces risks, enhances product innovation, and ensures consistent supply to meet your market needs effectively.

Strategic Sourcing Conclusion and Outlook for capezio shoes

Final Thoughts and Future Outlook for Strategic Sourcing of Capezio Shoes

Effective strategic sourcing is essential for international B2B buyers seeking to optimize quality, cost-efficiency, and supply chain resilience in the competitive dancewear and footwear market. For buyers in Africa, South America, the Middle East, and Europe, establishing strong supplier relationships with reputable manufacturers—particularly in regions like Asia—can unlock significant advantages, including access to innovative designs and scalable production capabilities.

Leveraging a diversified sourcing strategy minimizes risks associated with geopolitical uncertainties, currency fluctuations, and supply disruptions. Additionally, aligning sourcing decisions with sustainability and ethical standards enhances brand reputation and compliance across global markets.

Looking ahead, staying informed about evolving manufacturing trends, technological advancements, and trade policies will be crucial. Buyers should actively pursue partnerships that prioritize quality control, flexible logistics, and sustainable practices to maintain a competitive edge.

Now is the time for international B2B buyers to refine their sourcing strategies, foster strategic supplier collaborations, and adapt to global market shifts. Embracing proactive, data-driven approaches will ensure sustained growth and resilience in the dynamic landscape of Capezio shoe procurement.