Your Ultimate Guide to Sourcing Carbon Plated Running Shoes

Guide to Carbon Plated Running Shoes

- Introduction: Navigating the Global Market for carbon plated running shoes

- Understanding carbon plated running shoes Types and Variations

- Key Industrial Applications of carbon plated running shoes

- Strategic Material Selection Guide for carbon plated running shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for carbon plated running shoes

- Comprehensive Cost and Pricing Analysis for carbon plated running shoes Sourcing

- Spotlight on Potential carbon plated running shoes Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for carbon plated running shoes

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the carbon plated running shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of carbon plated running shoes

- Strategic Sourcing Conclusion and Outlook for carbon plated running shoes

Introduction: Navigating the Global Market for carbon plated running shoes

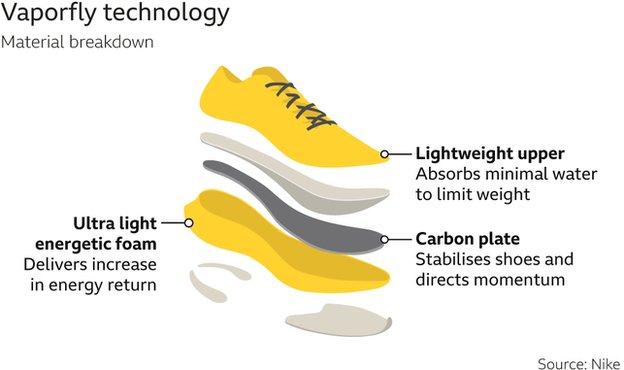

In today’s highly competitive athletic footwear industry, carbon plated running shoes have emerged as a game-changer, revolutionizing performance for athletes worldwide. Their advanced design, incorporating carbon fiber plates, offers significant benefits—enhanced speed, improved energy return, and superior durability—making them a sought-after product across global markets. For B2B buyers, understanding the nuances of this rapidly evolving segment is crucial to sourcing high-quality products that meet both consumer demand and competitive pricing.

This comprehensive guide aims to equip international buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Egypt and Australia—with the essential insights needed for effective sourcing. We will explore the various types of carbon plated shoes, the materials used, and the latest manufacturing and quality control standards. Additionally, the guide provides actionable intelligence on supplier landscapes, cost considerations, and market trends, along with answers to frequently asked questions.

By leveraging this knowledge, B2B buyers can make informed decisions that optimize supply chain efficiency, ensure product authenticity, and capitalize on the growing demand for high-performance athletic footwear. Whether you are establishing new supplier relationships or expanding existing ones, this guide empowers you to navigate the global market confidently and strategically.

Understanding carbon plated running shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Race-Optimized Carbon Plated Shoes | Ultra-lightweight materials, minimal cushioning, stiff carbon plate for maximum propulsion | Competitive racing, high-performance retail | Pros: High speed potential, appealing to elite athletes; Cons: Higher cost, limited durability for daily training |

| Daily Trainer Carbon Shoes | Slightly thicker midsole, enhanced durability, versatile cushioning | Commercial retail, sports stores, fitness centers | Pros: Versatile, longer lifespan, suitable for daily runs; Cons: Slightly heavier, less aggressive propulsion |

| Long-Distance Endurance Shoes | Moderate stiffness, enhanced support, optimized for sustained efforts | Specialized sports stores, endurance athletes | Pros: Comfort over extended periods, good support; Cons: May lack explosive speed features, higher manufacturing complexity |

| Budget-Friendly Carbon Shoes | Cost-effective materials, simplified design, moderate carbon plate integration | Emerging markets, value-focused retail chains | Pros: Accessible pricing, entry-level product; Cons: Lower performance, shorter lifespan, limited advanced features |

| Customizable Carbon Shoes | Modular components, adaptable plate stiffness, customizable fit | Niche markets, premium retail, corporate sports programs | Pros: Tailored fit and performance, high perceived value; Cons: Higher procurement cost, longer lead times |

Race-Optimized Carbon Plated Shoes

Race-optimized models are engineered for maximum lightweight efficiency and stiffness, often featuring minimal cushioning to reduce weight. They are ideal for elite athletes and racing teams aiming for top performance in competitions. For B2B buyers, these shoes appeal to high-end retail outlets and specialty sports stores targeting performance-conscious consumers. However, their higher price point and limited durability make them less suitable for everyday training or casual markets. Buyers should consider the target customer profile and durability requirements before stocking these models.

Daily Trainer Carbon Shoes

Designed for versatility, daily trainers combine moderate weight, durability, and comfort, making them suitable for a broad consumer base. They are well-suited for retail outlets looking to offer high-performance yet practical running shoes. These models often feature a balanced midsole and a supportive carbon plate that enhances propulsion without compromising comfort. For B2B buyers, these shoes provide a reliable product with broader market appeal, though they may be slightly heavier than racing models. Ensuring supply chain stability for consistent quality is key when sourcing these shoes.

Illustrative Image (Source: Google Search)

Long-Distance Endurance Shoes

Endurance models prioritize comfort, support, and stability over prolonged use, making them suitable for marathon runners and long-distance athletes. They typically feature a moderate stiffness level, a supportive midsole, and enhanced cushioning to reduce fatigue. These shoes are attractive to specialty sports stores and endurance-focused markets. B2B buyers should evaluate the manufacturing quality, as durability and comfort are critical for customer satisfaction. Pricing should reflect the specialized features, and bulk purchasing can leverage economies of scale.

Budget-Friendly Carbon Shoes

Targeting emerging markets and value-focused retail channels, these shoes incorporate simplified designs with affordable materials and moderate carbon plate integration. They serve as entry-level options for consumers seeking performance benefits without premium pricing. For B2B buyers, these shoes open access to new markets and customer segments, but they often come with trade-offs in performance and longevity. Maintaining consistent quality control and clear communication on product capabilities is essential to prevent customer dissatisfaction and brand reputation issues.

Customizable Carbon Shoes

These models offer modular components allowing buyers or end-users to tailor fit, stiffness, and performance features. They are often sold through premium retail channels or corporate sports programs, emphasizing personalized experiences. For B2B buyers, they present an opportunity to differentiate their offerings and cater to niche markets. However, higher procurement costs and longer lead times require careful planning. Establishing strong supplier relationships and inventory management strategies is vital to capitalize on the premium positioning of these shoes.

Key Industrial Applications of carbon plated running shoes

| Industry/Sector | Specific Application of carbon plated running shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Sports & Athletic Equipment Manufacturers | Incorporation into high-performance athletic footwear lines for elite markets | Differentiates products with advanced technology, boosting brand prestige and sales | Consistent quality control, reliable supply chain, and certification standards |

| Retail & Wholesale Distributors | Bulk procurement for sports stores, specialty outlets, and e-commerce platforms | Offers competitive edge through innovative products, increasing market share | Cost-effective sourcing, flexible MOQs, and compliance with regional safety standards |

| Custom & OEM Footwear Production | Development of bespoke running shoes tailored for regional athletes or corporate branding | Enables differentiation and premium pricing, catering to niche markets | Customization capabilities, lead times, and adherence to international manufacturing standards |

| Healthcare & Rehabilitation | Use in therapeutic footwear for patients with mobility issues | Supports injury recovery and mobility, creating new healthcare product lines | Material safety, biocompatibility, and adherence to medical device regulations |

| Military & Tactical Gear | Integration into specialized footwear for personnel in extreme environments | Enhances performance, endurance, and injury prevention in demanding conditions | Durability, high-performance standards, and compliance with military specifications |

Application in Sports & Athletic Equipment Manufacturing

Carbon plated running shoes are revolutionizing high-performance athletic footwear, especially for elite athletes and professional sports brands. Manufacturers incorporate this advanced technology to develop shoes that maximize energy return, reduce fatigue, and improve running economy. For international B2B buyers, especially from regions like Africa, South America, and the Middle East, sourcing reliable, high-quality carbon plates is crucial to meet global performance standards. Ensuring consistent quality, certification, and supply chain stability can significantly enhance product reputation and market competitiveness.

Retail & Wholesale Distributors

Distributors in diverse markets—ranging from European sports retailers to African specialty sports shops—capitalize on the growing demand for innovative running shoes. Bulk procurement of carbon plated shoes offers a strategic advantage by providing consumers with cutting-edge products, thereby increasing sales and brand loyalty. B2B buyers should prioritize sourcing from suppliers with scalable production capacities, competitive pricing, and adherence to regional safety and quality standards to ensure seamless distribution and customer satisfaction.

Custom & OEM Footwear Production

For regional brands and OEM manufacturers, integrating carbon plated running shoes into their product lines allows for customization tailored to specific athletic or cultural needs. This sector benefits from sourcing flexible, high-quality materials that support bespoke designs, branding, and regional preferences. International buyers from countries like Egypt or Australia should evaluate suppliers’ ability to deliver consistent quality, lead times, and compliance with international manufacturing standards to maintain brand integrity and meet market expectations.

Healthcare & Rehabilitation

The application of carbon plated technology in therapeutic footwear opens new avenues in healthcare, especially for patients with mobility impairments or recovering from injuries. These shoes support enhanced mobility, energy efficiency, and comfort, making them valuable in medical device markets. B2B buyers in healthcare sectors need to prioritize sourcing materials that meet safety and biocompatibility standards, ensuring regulatory compliance across different regions, including Europe and South America.

Military & Tactical Gear

In military and tactical footwear, carbon plates contribute to increased durability, energy efficiency, and injury prevention in extreme environments. Such shoes are critical for personnel operating in rugged terrains, deserts, or mountainous regions. International buyers from the Middle East or Australia should focus on sourcing highly durable, high-performance materials that meet military specifications, ensuring reliability, longevity, and operational effectiveness in demanding conditions.

Strategic Material Selection Guide for carbon plated running shoes

Material Analysis for Carbon Plated Running Shoes

Selecting the appropriate materials for the carbon plates in running shoes is critical for optimizing performance, durability, and manufacturing efficiency. For international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, understanding the properties and implications of each material is essential for making informed procurement decisions. Here, we analyze four common materials used in carbon plates: Carbon Fiber Reinforced Polymer (CFRP), Polyetheretherketone (PEEK), Thermoplastic Polyurethane (TPU), and Aluminum Alloys.

Carbon Fiber Reinforced Polymer (CFRP)

Key Properties:

CFRP is the most prevalent material for high-performance running shoe plates. It offers exceptional stiffness-to-weight ratio, high tensile strength, and excellent fatigue resistance. Its thermal stability allows it to withstand typical running conditions, while its corrosion resistance is inherently high due to the polymer matrix.

Pros & Cons:

CFRP provides superior energy return and durability, making it ideal for competitive and long-distance shoes. Manufacturing involves precise layup and curing processes, which can increase initial costs. Its lightweight nature benefits performance but may pose challenges in recycling and disposal.

Impact on Application:

CFRP plates are compatible with various media, including moisture and sweat, without degradation. They require careful handling during manufacturing to prevent delamination or fiber misalignment.

International Buyer Considerations:

Buyers from regions with strict import standards (e.g., Europe’s REACH, ASTM certifications in the US) should verify CFRP suppliers’ compliance with environmental and safety regulations. In emerging markets like Africa or South America, cost-effective CFRP variants are available but may vary in quality. Ensuring supplier transparency and quality certifications can mitigate risks.

Polyetheretherketone (PEEK)

Key Properties:

PEEK is a high-performance thermoplastic with excellent mechanical strength, chemical resistance, and thermal stability (up to 480°C). It exhibits good fatigue resistance and maintains properties over a wide temperature range, making it suitable for demanding environments.

Pros & Cons:

PEEK offers high durability and can be machined into complex shapes, facilitating design flexibility. However, its high raw material cost and more complex manufacturing process (e.g., injection molding or machining) increase overall production expenses. Its lighter weight compared to metals is advantageous, but it may not match CFRP’s stiffness.

Impact on Application:

PEEK’s chemical inertness makes it suitable for environments with exposure to sweat or cleaning agents. Its thermal stability ensures consistent performance across different climates, from the hot Middle East to cooler European regions.

International Buyer Considerations:

PEEK’s compliance with global standards (e.g., ISO, ASTM) is well-established, but buyers should confirm supplier certifications. For markets with import restrictions or tariffs, sourcing from regions with established PEEK manufacturing (e.g., Europe, Asia) can reduce costs and lead times.

Thermoplastic Polyurethane (TPU)

Key Properties:

TPU is a versatile thermoplastic elastomer known for its flexibility, abrasion resistance, and impact absorption. It is less stiff than CFRP or PEEK but provides excellent energy return and comfort.

Pros & Cons:

TPU is cost-effective, easy to process via extrusion or injection molding, and offers good environmental resistance. Its main limitation is lower stiffness, which may reduce the energy transfer efficiency in high-performance applications. It also tends to degrade faster under UV exposure unless stabilized.

Impact on Application:

TPU’s flexibility makes it suitable for midsole components or overlays rather than primary structural plates. It performs well in humid or wet conditions common in tropical regions like Africa or South America.

International Buyer Considerations:

TPU suppliers are widespread, especially in China and Europe, making it accessible for import. Buyers should ensure the TPU grade aligns with ASTM or ISO standards for footwear applications. In regions with strict environmental regulations, selecting bio-based or stabilized TPU grades can be advantageous.

Aluminum Alloys

Key Properties:

Aluminum alloys (e.g., 6061, 7075) are lightweight metals with good strength-to-weight ratios, corrosion resistance, and thermal conductivity. They are less stiff than CFRP but more rigid than TPU.

Pros & Cons:

Aluminum plates are easier and cheaper to manufacture, with well-established supply chains globally. They are less durable than CFRP and may deform under repeated stress, but they are highly recyclable. Their thermal conductivity can influence comfort in extreme climates.

Impact on Application:

Aluminum is suitable for entry-level or budget-friendly running shoes. Its corrosion resistance makes it suitable for humid environments, but it requires protective coatings to prevent oxidation.

International Buyer Considerations:

Aluminum alloys are globally standardized (e.g., ASTM, DIN). Buyers should specify alloy grades to ensure consistency. In regions like the Middle East, where high temperatures are common, aluminum’s thermal properties should be considered in design.

Summary Table

| Material | Typical Use Case for carbon plated running shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Fiber Reinforced Polymer (CFRP) | High-performance racing shoes, competitive models | Excellent stiffness-to-weight ratio, durability | Higher manufacturing complexity, cost | High |

| Polyetheretherketone (PEEK) | Premium endurance shoes, specialized applications | High thermal and chemical resistance, durability | Expensive raw material, complex processing | High |

| Thermoplastic Polyurethane (TPU) | Mid-tier shoes, cushioning overlays | Cost-effective, flexible, impact absorption | Lower stiffness, faster degradation if UV exposed | Low |

| Aluminum Alloys | Budget-friendly, entry-level shoes | Easy to manufacture, recyclable, cost-effective | Less stiff, potential for deformation | Med |

This comprehensive analysis equips international B2B buyers with the insights needed to select materials aligned with regional demands, regulatory standards, and performance expectations. Prioritizing compliance, cost, and environmental considerations will ensure sustainable and competitive product offerings across diverse markets.

In-depth Look: Manufacturing Processes and Quality Assurance for carbon plated running shoes

Manufacturing Processes for Carbon Plated Running Shoes

The manufacturing of carbon plated running shoes involves a series of highly specialized and precision-driven stages, each critical to ensuring performance, durability, and safety. Understanding these stages enables B2B buyers to better evaluate supplier capabilities and maintain quality consistency across international markets.

Material Preparation and Component Manufacturing

The process begins with sourcing and preparing high-quality materials. Key components include:

- Midsole with Carbon Plate: Typically made from thermoplastic or carbon fiber composites, these plates are cut into precise shapes and thicknesses, often via CNC machining or laser cutting to ensure consistency.

- Upper Materials: Usually engineered mesh, synthetic leather, or knit fabrics, selected for breathability and flexibility.

- Outsole: Made from durable rubber compounds with specific tread patterns for grip and wear resistance.

Suppliers often employ material testing at this stage, verifying tensile strength, flexibility, and chemical composition to meet industry standards.

Forming and Assembly

Once components are prepared, the assembly process involves:

- Molding and Bonding: The midsole components, including the carbon plate, are integrated into the foam core through precision molding techniques like injection or compression molding. Advanced adhesives or thermal bonding are used to secure the carbon plate firmly without compromising flexibility.

- Upper Construction: The upper is stitched, welded, or glued onto the midsole assembly, often using automated sewing or ultrasonic welding to ensure durability.

- Incorporation of Cushioning and Stability Features: Additional elements such as insoles, heel counters, and stabilization plates are assembled to enhance overall performance.

Automation and robotics are increasingly employed to ensure uniformity, especially in high-volume production, minimizing human error.

Finishing and Quality Control

Final steps include:

- Surface Finishing: Application of protective coatings, branding, and aesthetic details.

- Cleaning and Inspection: Shoes are cleaned of manufacturing residues and inspected for visual defects.

- Packaging: Ensuring each shoe is correctly labeled with batch information, size, and compliance marks.

Quality Assurance (QA) and Standards for Carbon Plated Shoes

Ensuring consistent quality in carbon plated running shoes demands adherence to international standards, rigorous testing, and thorough inspection protocols.

International and Industry Standards

- ISO 9001: The cornerstone for Quality Management Systems, ISO 9001 certification indicates a supplier’s commitment to process consistency, customer satisfaction, and continuous improvement.

- CE Marking (Europe): Signifies compliance with European safety, health, and environmental requirements, essential for EU markets.

- ASTM and ISO Testing Standards: For performance metrics like shock absorption, flexural strength, and durability.

- Additional Certifications: For specific markets, certifications such as the Australian Safety Standards or regional compliance marks (e.g., SABS in South Africa) may be required.

Quality Control Checkpoints

Effective QC involves multiple inspection stages:

- Incoming Quality Control (IQC): Raw materials are tested upon receipt for specifications, contamination, and defects.

- In-Process Quality Control (IPQC): Continuous monitoring during manufacturing—checking dimensions, bonding strength, and assembly precision.

- Final Quality Control (FQC): Complete shoes undergo thorough inspection for visual defects, weight, fit, and functional performance.

Testing Methods and Techniques

- Mechanical Testing: Tensile, compression, and flexural tests confirm the material’s performance under load.

- Environmental Testing: Accelerated aging, temperature, and humidity tests assess durability in diverse climates typical of markets in Africa, South America, and the Middle East.

- Performance Testing: Simulating running conditions with specialized treadmills and gait analysis equipment to verify the effectiveness of the carbon plate in enhancing propulsion.

- Chemical Testing: Ensuring no harmful substances (e.g., restricted phthalates or heavy metals) are present, complying with REACH or other regional regulations.

Verifying Supplier QC for International B2B Buyers

For international buyers, especially from regions with varying regulatory landscapes, verifying supplier quality assurance practices is crucial.

- Supplier Audits: Conduct on-site audits focusing on manufacturing processes, QC documentation, and workforce training. Audits can be performed by third-party inspectors or internal teams.

- Review of QC Reports and Certifications: Request detailed reports covering incoming raw materials, in-process inspections, and final testing results. Confirm validity and compliance with relevant standards.

- Third-Party Inspection Services: Engage independent inspection agencies (e.g., SGS, Bureau Veritas) to verify product quality before shipment.

- Sample Testing: Perform independent testing on samples from bulk shipments, focusing on critical performance and safety parameters.

Special Considerations for International B2B Buyers

Buyers from Africa, South America, the Middle East, and Europe face unique challenges and opportunities in quality assurance:

- Regulatory Alignment: Understand local regulatory requirements (e.g., EU’s REACH, Australia’s ACCC standards) and ensure suppliers provide compliant documentation.

- Cultural and Logistical Factors: Consider language barriers and logistical complexities; establishing clear communication channels and detailed QC documentation is vital.

- Building Long-term Relationships: Regular audits, quality reviews, and feedback loops foster trust and consistent quality over time.

- Capacity for Customization: Some markets demand specific features or certifications; select suppliers capable of adapting their QC processes accordingly.

Conclusion

For B2B buyers, a comprehensive understanding of manufacturing processes and quality assurance protocols is essential to mitigate risks and ensure product excellence. Prioritizing certified suppliers with transparent QC practices, leveraging third-party inspections, and aligning with international standards will help maintain high quality standards for carbon plated running shoes across diverse markets. Engaging with manufacturers who integrate advanced testing methods and adhere to rigorous QC checkpoints will ultimately support your brand’s reputation and customer satisfaction globally.

Comprehensive Cost and Pricing Analysis for carbon plated running shoes Sourcing

Cost Structure Breakdown for Carbon Plated Running Shoes

Understanding the detailed cost components is essential for international buyers aiming to negotiate effectively and optimize their procurement budgets. The primary cost elements include:

-

Materials: High-performance engineered fabrics, carbon fiber plates, midsole foams, and durable outsole compounds. Premium materials, especially those with specialized properties like lightweight strength or energy return, significantly influence costs. Sourcing from certified suppliers with quality assurance can add to material expenses but ensures product consistency.

-

Labor: Manufacturing labor costs vary widely depending on the sourcing country. For instance, Asian manufacturing hubs (e.g., Vietnam, China) often offer lower labor costs but may come with longer lead times, while facilities in Europe or the Middle East might charge higher wages but provide faster turnaround and higher quality standards.

-

Manufacturing Overhead: This includes factory utilities, machinery depreciation, and quality control processes. Advanced automation and lean manufacturing practices can reduce overheads, but initial investments in technology may increase upfront costs.

-

Tooling and Setup Costs: Custom molds and tooling for unique designs or specific specifications entail significant upfront investments. These costs are amortized over large production volumes, making economies of scale crucial for cost efficiency.

-

Quality Control (QC): Rigorous testing, including durability, safety certifications, and compliance with international standards (e.g., ISO, ASTM), adds to costs but is vital for market acceptance, especially in regulated markets.

-

Logistics & Shipping: International shipping costs depend on volume, destination, and shipping mode. Air freight offers speed but at a premium, while sea freight is more economical for bulk orders. Incoterms (e.g., FOB, CIF) significantly impact total landed costs and buyer responsibilities.

-

Margins: Manufacturers typically apply profit margins ranging from 10% to 30%, influenced by order volume, customization level, and supplier relationship strength.

Price Influencers and Variability

Several factors impact the final price of carbon plated running shoes:

-

Order Volume & MOQ: Larger orders reduce per-unit costs through economies of scale. Many suppliers offer discounts for bulk purchases, but minimum order quantities (MOQs) can be a barrier for smaller buyers.

-

Customization & Specifications: Custom designs, branding, or specific performance features increase costs due to additional tooling, longer lead times, and specialized materials.

-

Material Choices: Opting for premium or proprietary materials elevates costs but can differentiate products in competitive markets.

-

Quality Certifications & Standards: Certifications like ISO, ASTM, or country-specific standards (e.g., CE marking in Europe) may entail certification fees and testing, influencing overall pricing.

-

Supplier Factors: Supplier reputation, production capacity, and geopolitical stability can impact costs and lead times. Established suppliers with proven track records might charge premium but offer reliability.

-

Incoterms & Logistics: FOB (Free on Board) terms shift responsibility to the buyer for shipping, while CIF (Cost, Insurance, Freight) includes these costs, often simplifying procurement but potentially increasing total costs.

Buyer Tips for Cost-Effective Sourcing

-

Negotiate Bulk & Long-Term Agreements: Building relationships with suppliers can unlock better pricing, especially if you commit to consistent order volumes or long-term partnerships.

-

Leverage Total Cost of Ownership (TCO): Consider all costs—material, manufacturing, logistics, customs, and after-sales support—burchasing at the lowest unit price without factoring in logistics or quality standards can be misleading.

-

Understand Pricing Nuances: Be aware that prices can fluctuate based on raw material costs, currency exchange rates, and geopolitical factors. Regular market intelligence is vital.

-

Optimize Logistics & Incoterms: Negotiating favorable shipping terms, consolidating shipments, and choosing the right Incoterm can substantially reduce landed costs, especially for buyers in Africa, South America, the Middle East, or remote regions like Australia.

-

Customization & Certification Costs: Balance the need for product differentiation with the associated costs. Standard models may offer better margins and faster delivery.

Indicative Price Range (Disclaimer)

Based on current market data and supplier reports, the unit cost for a standard carbon plated running shoe (excluding branding and advanced customization) typically ranges from $50 to $100 for large-volume orders. Premium models with advanced materials or certifications can push prices upward of $120 to $150 per pair. Buyers should account for additional costs such as shipping, customs duties, and taxes, which vary by country.

By thoroughly analyzing these cost components and factors, international B2B buyers can better strategize their sourcing approach, negotiate effectively, and ensure competitive pricing in diverse markets.

Spotlight on Potential carbon plated running shoes Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for carbon plated running shoes.)*

Essential Technical Properties and Trade Terminology for carbon plated running shoes

Critical Technical Properties for Carbon Plated Running Shoes

1. Material Grade of Carbon Plate

The quality and type of carbon fiber used in the plate directly influence performance, durability, and cost. Higher-grade materials, such as T700 or T800 carbon fibers, offer increased stiffness and resilience, which can improve energy return and reduce fatigue during long runs. B2B buyers should specify desired grades based on performance needs and budget constraints, ensuring compatibility with manufacturing capabilities.

2. Plate Thickness and Flexural Stiffness

The thickness of the carbon plate (measured in millimeters) determines the shoe’s stiffness and energy transfer efficiency. Thicker plates (typically 0.8mm to 1.2mm) provide greater propulsion but may compromise flexibility and comfort. Understanding the optimal stiffness for target markets—whether for elite athletes or casual runners—is crucial for product positioning and consumer satisfaction.

3. Midsole Material and Density

The midsole’s foam material (e.g., EVA, Pebax, or TPU) and its density influence cushioning, weight, and responsiveness. Lightweight, high-rebound foams are preferred for competitive models, while more durable and cushioned options suit everyday training shoes. B2B buyers should verify compatibility between the midsole and the carbon plate to ensure optimal performance.

4. Tolerance and Manufacturing Precision

Tolerance levels refer to the allowable variance in dimensions and material properties during manufacturing. Tight tolerances (e.g., ±0.1mm) ensure consistent performance and fit, reducing returns or complaints. Suppliers that can maintain strict tolerances are more reliable for high-performance footwear, especially in markets demanding precise specifications.

5. Weight Specifications

The overall weight of the shoe impacts athlete performance and market competitiveness. Lighter shoes (generally under 200 grams for men’s size 9) are favored for racing, while slightly heavier models might cater to daily training. B2B buyers should specify weight targets aligned with their brand positioning and consumer expectations.

6. Durability and Wear Resistance

The carbon plate and midsole materials must withstand repetitive impacts without degradation. Durability affects product lifecycle, customer satisfaction, and brand reputation. Selecting high-quality materials and manufacturing processes ensures longevity, especially important for markets where consumers value long-term investment in footwear.

Common Trade Terms and Industry Jargon

1. OEM (Original Equipment Manufacturer)

Refers to factories that produce carbon plated running shoes based on a brand’s design and specifications. Understanding OEM capabilities helps buyers assess production quality, lead times, and customization options for different markets.

2. MOQ (Minimum Order Quantity)

The smallest quantity of shoes a manufacturer is willing to produce per order. Knowledge of MOQ is essential for planning inventory levels and managing costs, especially in regions with variable demand like Africa or South America.

3. RFQ (Request for Quotation)

A formal request from a buyer to a supplier seeking pricing, lead times, and technical details. Efficient RFQ processes enable buyers to compare suppliers quickly and negotiate favorable terms, critical for international procurement.

4. Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and customs clearance. Familiarity with Incoterms (e.g., FOB, CIF) ensures clarity on cost responsibilities and delivery obligations across different countries and logistics setups.

5. Lead Time

The duration from order placement to product delivery. Shorter lead times are advantageous for rapid market response, especially in competitive or emerging markets. B2B buyers should verify supplier lead times relative to their supply chain demands.

6. Certification & Compliance Standards

Includes industry standards like ISO certifications, and regional compliance such as REACH or CE marking. Ensuring products meet these standards reduces regulatory risks and facilitates smoother entry into target markets.

Strategic Insights for B2B Buyers

Understanding these technical properties and trade terms empowers buyers to make informed decisions, negotiate effectively, and ensure product quality aligns with market expectations. Tailoring specifications based on regional performance demands—such as durability for African markets or lightweight design for European racing—can enhance competitiveness. Clear communication of technical requirements and familiarity with trade terminology streamline procurement processes, reduce delays, and build stronger supplier relationships.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the carbon plated running shoes Sector

Market Overview & Key Trends

The global market for carbon plated running shoes has experienced significant growth driven by technological advancements, increasing consumer demand for high-performance footwear, and the expanding influence of professional athletics and recreational running cultures worldwide. For international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for strategic sourcing and market entry.

Emerging trends include the integration of lightweight, high-strength carbon fiber plates that enhance running efficiency and speed, alongside innovations in foam cushioning and breathable materials. These developments are partly driven by collaborations between brands and specialized materials suppliers, creating opportunities for vertical integration or direct sourcing. Additionally, regional markets are witnessing a surge in local manufacturing initiatives, often supported by government incentives aimed at boosting innovation and export capacity.

Illustrative Image (Source: Google Search)

From a sourcing perspective, key drivers include the increasing availability of sustainable raw materials, technological expertise in composite manufacturing, and the rising importance of supply chain resilience. Buyers are now prioritizing suppliers with proven capacity for scalable production, quality assurance, and compliance with international standards. For regions like Africa and South America, local sourcing options are expanding, although they may still require investment in quality control and technological transfer. Meanwhile, European and Middle Eastern markets are leaning towards premium, innovative products, emphasizing brand differentiation and performance.

Illustrative Image (Source: Google Search)

Market dynamics also reflect a shift towards shorter, more flexible supply chains to mitigate geopolitical risks and raw material shortages. Buyers are adopting just-in-time inventory strategies and exploring near-shoring options where feasible. Overall, understanding these trends enables B2B buyers to align their sourcing strategies with evolving technological, economic, and consumer demands.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a central concern for stakeholders across the supply chain of carbon plated running shoes. Environmental impacts associated with synthetic materials, carbon fiber production, and manufacturing processes underscore the necessity for eco-conscious sourcing strategies. Buyers from Africa, South America, the Middle East, and Europe should prioritize suppliers who demonstrate transparency and commitment to reducing their carbon footprint through sustainable practices.

The adoption of environmentally friendly materials—such as bio-based polymers, recycled carbon fibers, and biodegradable composites—can significantly enhance a brand’s sustainability credentials. Certifications like ISO 14001, OEKO-TEX, and Fair Trade are increasingly sought after, serving as indicators of compliance with environmental and social standards. Ethical sourcing extends beyond materials to encompass fair labor practices, safe working conditions, and supply chain transparency.

For B2B buyers, establishing partnerships with suppliers who hold ‘green’ certifications and adhere to ethical standards is essential for mitigating reputational risks and aligning with global sustainability trends. Incorporating sustainability clauses into contracts, investing in supplier audits, and supporting capacity-building initiatives can foster responsible sourcing. Moreover, embracing circular economy principles—such as designing for recyclability and facilitating product take-back programs—can further enhance environmental stewardship and brand loyalty.

Brief Evolution/History

The evolution of carbon plated running shoes from niche high-performance gear to mainstream sporting equipment reflects technological innovation and market demand. Initially, carbon fiber plates were used primarily in elite racing shoes to optimize energy return and reduce fatigue. Over the past decade, advancements in material science and manufacturing have enabled broader adoption across various consumer segments, including recreational runners.

For B2B buyers, understanding this progression highlights opportunities for sourcing innovative materials and partnering with manufacturers capable of scaling production while maintaining quality. As sustainability concerns grow, recent developments focus on eco-friendly materials and manufacturing processes, signaling a shift towards more responsible innovation. This historical context underscores the importance of staying abreast of technological advances and regulatory developments to remain competitive in this evolving sector.

Frequently Asked Questions (FAQs) for B2B Buyers of carbon plated running shoes

-

How can I verify the credibility and reliability of a carbon plated running shoe supplier?

To ensure supplier credibility, conduct thorough due diligence by requesting industry certifications (ISO, CE, etc.), reviewing client testimonials, and examining their export history. Ask for samples to assess product quality firsthand. Additionally, verify their business licenses, production capacity, and compliance with international trade standards. Engaging with verified trading platforms or industry associations can also help identify reputable suppliers. Establish clear communication channels and request references from previous international clients, especially from your region, to gauge their reliability and responsiveness. -

What customization options are typically available, and how do they impact lead times and costs?

Suppliers often offer customization in areas such as branding (logos, labels), colorways, material blends, and specific design features like sole thickness or upper mesh types. Customization can influence lead times, adding anywhere from 2 to 8 weeks depending on complexity, and may increase unit costs due to setup fees or minimum order quantities (MOQs). Clearly define your specifications upfront and negotiate terms that balance flexibility with cost efficiency. Working with suppliers experienced in international OEM/ODM projects can streamline the process and reduce delays. -

What are typical MOQs, lead times, and payment terms for bulk orders of carbon plated running shoes?

Most suppliers require MOQs ranging from 500 to 2,000 pairs, though premium or highly customized orders may necessitate higher quantities. Lead times generally span 4 to 12 weeks, depending on order complexity and production capacity. Payment terms often include a 30% deposit upfront with the balance payable before shipment, or letters of credit for larger transactions. Negotiating flexible payment options and planning production schedules well in advance is crucial for aligning with your distribution timelines, especially when importing to regions like Africa or South America. -

What quality assurance measures and certifications should I look for in suppliers?

Ensure suppliers adhere to internationally recognized quality standards such as ISO 9001, and verify compliance with safety and environmental certifications like REACH or OEKO-TEX. Request detailed QA procedures, including raw material testing, in-process inspections, and final product audits. Certifications demonstrate a commitment to quality, safety, and environmental responsibility, which are critical for market acceptance and regulatory compliance in regions like Europe or Australia. Consider engaging third-party inspection agencies for pre-shipment audits to mitigate risks. -

What are the key logistics considerations when importing carbon plated running shoes internationally?

Logistics planning should account for shipping mode (sea, air, or land), customs clearance, and warehousing. Sea freight is cost-effective for large volumes but slower, while air freight offers quicker delivery at higher costs. Ensure suppliers provide complete documentation such as commercial invoices, packing lists, and certificates of origin. Be aware of import duties, taxes, and regional compliance requirements—these vary significantly between Africa, South America, the Middle East, and Europe. Partnering with experienced freight forwarders familiar with your destination country can optimize transit times and reduce customs delays. -

How should I handle potential disputes or quality issues with international suppliers?

Establish clear contractual terms covering product specifications, inspection rights, and dispute resolution methods (preferably arbitration or mediation). Maintain detailed records of all communications, inspections, and quality reports. If issues arise, communicate promptly with evidence and seek resolution directly or through third-party mediators. Including clauses for corrective actions, refunds, or replacements can protect your interests. Building a strong relationship based on transparency and mutual understanding often facilitates quicker resolutions and long-term partnerships. -

What are the main challenges when sourcing carbon plated running shoes from emerging markets, and how can I mitigate them?

Common challenges include inconsistent quality, language barriers, logistical delays, and payment risks. To mitigate these, establish strict quality control protocols, work with local agents or consultants, and conduct virtual or on-site factory audits. Use secure payment methods like letters of credit or escrow services to minimize financial risks. Building relationships with trusted local partners and leveraging trade associations can also enhance reliability and streamline communication, especially in regions with less established export infrastructure. -

What are best practices for building sustainable and long-term B2B relationships with suppliers?

Focus on transparent communication, timely payments, and mutual respect. Regularly visit supplier facilities or arrange virtual tours to foster trust and better understand their capabilities. Offer feedback on product quality and delivery performance, and be open to collaborative development projects. Long-term relationships benefit from consistent volume orders, shared commitments to quality, and support for supplier capacity building. Staying updated on industry trends and maintaining open dialogue ensures adaptability and mutual growth in the competitive international market.

Strategic Sourcing Conclusion and Outlook for carbon plated running shoes

Strategic Sourcing Conclusion and Outlook for Carbon Plated Running Shoes

Effective strategic sourcing is pivotal for B2B buyers aiming to capitalize on the growing demand for carbon plated running shoes. By establishing strong relationships with reliable manufacturers, diversifying supply chains, and prioritizing quality assurance, buyers can mitigate risks and secure competitive pricing. Emphasizing transparency and sustainability in sourcing practices not only enhances brand credibility but also aligns with evolving consumer expectations globally.

Looking ahead, the rapid innovation within this segment presents significant opportunities for international buyers from Africa, South America, the Middle East, and Europe to gain a competitive edge. Embracing emerging manufacturing hubs and leveraging local market insights will be essential for optimizing costs and reducing lead times. Additionally, fostering strategic collaborations across regions can facilitate access to cutting-edge materials and design advancements.

Actionable Takeaways for B2B Buyers:

– Conduct thorough supplier evaluations focusing on quality, compliance, and sustainability.

– Explore regional manufacturing options to diversify supply sources and reduce logistical complexities.

– Invest in building long-term partnerships that support innovation and scalability.

– Stay informed on industry trends and technological advancements to anticipate market shifts.

By adopting a proactive, strategic approach to sourcing, international buyers can position themselves for sustained success in the dynamic landscape of carbon plated running shoes.