Your Ultimate Guide to Sourcing Composite Shoes

Guide to Composite Shoes

- Introduction: Navigating the Global Market for composite shoes

- Understanding composite shoes Types and Variations

- Key Industrial Applications of composite shoes

- Strategic Material Selection Guide for composite shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for composite shoes

- Comprehensive Cost and Pricing Analysis for composite shoes Sourcing

- Spotlight on Potential composite shoes Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for composite shoes

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the composite shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of composite shoes

- Strategic Sourcing Conclusion and Outlook for composite shoes

Introduction: Navigating the Global Market for composite shoes

In today’s competitive global footwear industry, composite shoes have emerged as a vital innovation, offering a strategic edge for manufacturers, retailers, and importers alike. Their lightweight, durable, and cost-effective properties make them increasingly attractive across diverse markets—from Nigeria and Brazil to Middle Eastern and European economies—where consumer demand for quality and affordability continues to rise. For B2B buyers operating internationally, understanding the nuances of composite shoe sourcing is crucial to capitalize on emerging opportunities and mitigate risks.

This comprehensive guide provides an in-depth exploration of the entire supply chain—covering product types, materials, manufacturing processes, quality control standards, and leading suppliers. It also offers actionable insights into cost considerations, market trends, and common FAQs, empowering buyers to make informed, strategic decisions. Whether you are seeking reliable partners in Asia, exploring innovative materials, or navigating import regulations, this resource is designed to streamline your sourcing process.

By equipping you with industry expertise and market intelligence, this guide aims to enhance your competitiveness in the global marketplace. It is tailored specifically for international B2B buyers from Africa, South America, the Middle East, and Europe, ensuring you are well-positioned to identify quality suppliers, optimize costs, and meet evolving consumer demands with confidence.

Understanding composite shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Carbon Fiber Composite Shoes | High strength-to-weight ratio, rigid, lightweight, often customizable | Aerospace, automotive, high-performance sports | Very durable and lightweight, but higher initial cost and limited flexibility |

| Resin-Impregnated Composite Shoes | Molded with resin matrix, good impact resistance, customizable shapes | Footwear manufacturing, protective gear | Cost-effective and versatile, but may have lower fatigue resistance over time |

| Hybrid Composite Shoes | Combination of different composite materials for tailored properties | Specialty footwear, orthopedics, industrial safety | Offers balanced strength and flexibility, but complex to produce and costlier |

| Thermoplastic Composite Shoes | Recyclable, easy to mold, good for rapid prototyping | Fashion footwear, custom designs | Cost-efficient with fast turnaround, but less durable under heavy use |

| Structural Composite Shoes | Heavy-duty, designed for high load-bearing applications | Industrial safety footwear, military gear | Excellent strength and durability, but heavier and less comfortable for daily wear |

Carbon Fiber Composite Shoes

Carbon fiber composite shoes are renowned for their exceptional strength-to-weight ratio and rigidity. They are predominantly used in high-performance applications such as aerospace, automotive, and specialized sports footwear. For B2B buyers, these shoes are ideal when durability and lightweight characteristics are priorities, especially for products requiring high precision and strength. However, the high manufacturing costs and limited flexibility should be considered, making them suitable for niche markets rather than mass consumer segments.

Resin-Impregnated Composite Shoes

This type involves molding composite materials with resin matrices, offering excellent impact resistance and customizable shapes. They are widely used in footwear manufacturing, protective gear, and industrial safety applications. For buyers, resin-impregnated shoes provide a cost-effective solution with good versatility for different designs. The primary considerations include their moderate fatigue resistance, which may affect long-term durability in demanding environments, and the importance of quality control during manufacturing to ensure consistent performance.

Hybrid Composite Shoes

Hybrid composite shoes combine multiple materials, such as carbon fiber with thermoplastics or resins, to optimize specific properties like flexibility, strength, and weight. These are particularly suited for specialty footwear, orthopedics, and industrial safety equipment. For B2B buyers, hybrid options offer a tailored approach to meet diverse customer needs, but they tend to involve more complex manufacturing processes, which can increase costs. Careful supplier evaluation is crucial to ensure quality and consistency.

Thermoplastic Composite Shoes

Thermoplastic composites are valued for their recyclability, ease of molding, and rapid prototyping capabilities. They are increasingly used in fashion footwear, custom-designed shoes, and quick-turnaround orders. Buyers benefit from lower costs and faster production cycles, making them suitable for dynamic markets and emerging brands. However, their lower durability under heavy or prolonged use should be weighed against the need for frequent replacements or upgrades.

Structural Composite Shoes

Designed for industrial and heavy-duty applications, structural composite shoes are built to withstand high loads and harsh environments. They are essential in industrial safety footwear, military gear, and other demanding sectors. For B2B buyers, these shoes offer unmatched strength and longevity, reducing replacement costs over time. The trade-off involves increased weight and potentially reduced comfort, so they are best suited for operational settings rather than casual or everyday wear.

Key Industrial Applications of composite shoes

| Industry/Sector | Specific Application of composite shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Heavy Industry | Safety footwear for construction workers and heavy machinery operators | Enhanced protection against impact, electrical hazards, and fatigue reduction | Certification standards (e.g., EN, ASTM), durability, supplier reliability |

| Oil & Gas | Anti-static, flame-resistant composite safety shoes | Reduced risk of fires/explosions, improved safety compliance, lightweight comfort | Material resistance to hydrocarbons, certification, supply chain stability |

| Mining | Heavy-duty, shock-absorbing composite boots | Superior impact absorption, high durability, lower weight for extended wear | Resistance to abrasion, water resistance, supplier experience in rugged environments |

| Logistics & Warehousing | Comfortable, slip-resistant composite safety shoes | Enhanced worker safety, reduced slip and fall incidents, comfort for long shifts | Slip resistance ratings, comfort features, availability of size ranges |

| Agriculture & Forestry | Durable, puncture-resistant composite footwear | Protection against sharp objects, lightweight for mobility, weather resistance | Puncture resistance levels, weatherproofing, local supplier support |

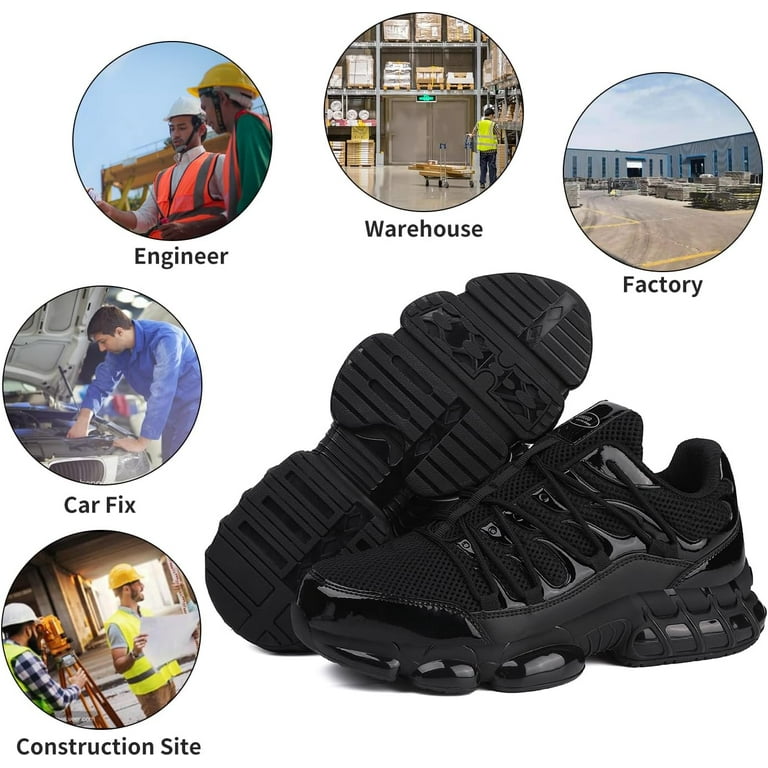

Construction & Heavy Industry

Composite shoes are essential in construction and heavy industry sectors, where workers face hazards like falling objects, electrical risks, and prolonged standing. These shoes combine impact resistance with electrical insulation, reducing injury risks and fatigue. For international buyers, especially from Africa and South America, sourcing certified, durable, and compliant footwear ensures worker safety and adherence to local safety standards. Reliability in supply and quality assurance are crucial for large-scale projects.

Oil & Gas

In the oil and gas industry, composite shoes are designed to meet stringent safety standards such as anti-static and flame-resistant properties. These shoes help prevent fires and explosions caused by static buildup or ignition of flammable media. For B2B buyers in the Middle East or Brazil, sourcing shoes with proven material resistance to hydrocarbons and certifications like ATEX or IECEx is vital. Ensuring consistent supply and quality compliance minimizes operational risks and enhances safety protocols.

Mining

Mining operations demand footwear that balances robustness with comfort. Composite shoes used in mining are engineered for impact absorption, abrasion resistance, and weather resilience. They are lighter than traditional steel-toe boots, reducing fatigue during long shifts. Buyers in Africa and South America should prioritize suppliers with experience in rugged environments, offering high durability, water resistance, and puncture protection to ensure safety and longevity in challenging conditions.

Logistics & Warehousing

In logistics and warehousing, workers require footwear that offers slip resistance, comfort, and durability to prevent accidents during long hours of standing and movement. Composite shoes provide lightweight protection, reducing fatigue while maintaining safety standards. B2B buyers should focus on sourcing shoes with high slip-resistance ratings, ergonomic features, and reliable supply chains to meet the needs of large workforce deployments across Europe, Nigeria, or Brazil.

Agriculture & Forestry

Agricultural and forestry workers face hazards like sharp tools, uneven terrain, and weather exposure. Composite footwear offers puncture resistance, weatherproofing, and lightweight mobility, essential for safety and productivity. For buyers in regions like Africa and South America, selecting suppliers that provide weather-resistant, puncture-proof, and durable shoes ensures worker safety, reduces downtime, and aligns with local environmental conditions.

Strategic Material Selection Guide for composite shoes

Material Analysis for Composite Shoes

Selecting the appropriate materials for composite shoes is critical to ensure product performance, durability, and compliance with international standards. For B2B buyers across diverse markets such as Africa, South America, the Middle East, and Europe, understanding the properties, advantages, and limitations of common materials is essential for making informed procurement decisions.

Carbon Fiber Reinforced Polymers (CFRP)

Key Properties:

Carbon fiber composites are renowned for their exceptional strength-to-weight ratio, high stiffness, and excellent fatigue resistance. They typically withstand temperatures up to 300°C and are resistant to corrosion and chemicals, making them suitable for demanding environments.

Pros & Cons:

The primary advantage of CFRPs is their lightweight yet durable nature, which enhances comfort and performance in high-performance footwear. However, manufacturing complexity and high raw material costs are significant barriers, especially for mass-market applications. The production process requires specialized equipment and expertise, which can extend lead times.

Impact on Application:

CFRPs excel in applications requiring high strength and low weight, such as sports or safety footwear. Their chemical resistance makes them suitable for shoes exposed to harsh media, including oils and solvents.

International Buyer Considerations:

Buyers from regions like Nigeria or Brazil should verify compliance with local standards such as ASTM or ISO for composite materials. The high cost may be mitigated by sourcing from regions with established CFRP manufacturing capabilities, but import tariffs and logistics should be carefully evaluated.

Glass Fiber Reinforced Polymers (GFRP)

Key Properties:

GFRPs are known for their good mechanical strength, moderate weight, and resistance to corrosion. They generally tolerate temperatures up to 150°C and are less expensive than carbon fiber composites.

Pros & Cons:

GFRPs offer a balanced mix of performance and affordability, making them suitable for a broad range of footwear applications. Manufacturing is less complex than CFRPs, enabling quicker production cycles. However, they are heavier and less stiff, which may impact comfort in certain designs.

Impact on Application:

Ideal for work or safety shoes where chemical and moisture resistance are priorities. GFRPs are also suitable for applications requiring moderate load-bearing capacity.

International Buyer Considerations:

European standards such as DIN and JIS often specify testing for fiber-reinforced plastics. Buyers should ensure suppliers provide certifications confirming compliance. Cost-effectiveness makes GFRPs attractive for markets with budget constraints, like parts of Africa and South America.

Thermoplastic Polyurethane (TPU)

Key Properties:

TPU is a versatile polymer with excellent elasticity, abrasion resistance, and good chemical resistance. It can withstand temperatures up to 80°C and is flexible and lightweight.

Pros & Cons:

TPU’s flexibility and durability make it popular for shoe components like midsoles and outsoles. Manufacturing processes such as injection molding are well-established, reducing complexity. However, TPU may degrade under prolonged UV exposure unless stabilized, and its mechanical strength is lower compared to fiber-reinforced composites.

Impact on Application:

Best suited for flexible shoe parts, especially in casual or athletic footwear. Its media compatibility includes oils, greases, and some solvents, but UV stability must be considered for outdoor use.

International Buyer Considerations:

Buyers should verify that TPU materials meet standards like REACH or RoHS, especially for markets with strict chemical regulations such as Europe. Cost varies depending on grade and formulation but generally remains moderate, making it accessible for diverse markets.

Aluminum Alloys

Key Properties:

Aluminum alloys are lightweight, corrosion-resistant, and possess good thermal conductivity. They typically withstand temperatures up to 200°C and are easy to machine and weld.

Pros & Cons:

Aluminum offers a good balance of strength and weight, with relatively straightforward manufacturing. However, it is less impact-resistant compared to composites and can be prone to fatigue over time. Cost varies depending on alloy grade, with high-grade alloys being more expensive.

Impact on Application:

Suitable for structural components within composite shoes, especially where weight reduction is critical. Aluminum’s corrosion resistance is advantageous in humid or saline environments common in coastal regions.

International Buyer Considerations:

European and Middle Eastern markets often specify standards like ASTM B209 or EN 573 for aluminum materials. Importers should ensure that alloys used are compliant and sourced from reputable suppliers to avoid counterfeit or substandard materials.

Summary Table

| Material | Typical Use Case for composite shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Fiber Reinforced Polymers | High-performance sports, safety, or aerospace-inspired footwear | Exceptional strength-to-weight ratio, high stiffness | High cost, complex manufacturing | High |

| Glass Fiber Reinforced Polymers | Work, safety, or casual footwear requiring durability | Cost-effective, corrosion resistant | Heavier, less stiff than CFRP | Med |

| Thermoplastic Polyurethane (TPU) | Shoe midsoles, outsoles, flexible components | Flexible, abrasion resistant, easy to process | UV degradation risk, lower mechanical strength | Med |

| Aluminum Alloys | Structural components, lightweight frames | Lightweight, corrosion resistant, easy to machine | Less impact resistant, potential fatigue | Varies |

This strategic material overview empowers international B2B buyers to select materials aligned with their specific application requirements, regional standards, and budget considerations. Proper material choice not only enhances product performance but also ensures compliance and market acceptance across diverse regions.

In-depth Look: Manufacturing Processes and Quality Assurance for composite shoes

Manufacturing Processes of Composite Shoes

The production of composite shoes involves a series of carefully orchestrated stages, each critical to ensuring product quality, durability, and compliance with international standards. Understanding these stages enables B2B buyers to assess supplier capabilities effectively.

Material Preparation

The manufacturing process begins with sourcing and preparing raw materials. Common materials include advanced composites such as carbon fiber, fiberglass, or thermoplastic resins, combined with traditional footwear components like EVA or PU foams. Suppliers typically undertake rigorous material testing to verify properties such as tensile strength, flexibility, and environmental resistance. For B2B buyers, requesting material certification reports (e.g., ISO 9001, REACH compliance) is essential to ensure supplier transparency and quality consistency.

Forming and Molding

The core of composite shoe manufacturing involves forming the composite structure through molding techniques. Common methods include:

- Compression Molding: Applying heat and pressure to shape composite layers within molds, suitable for high-volume production.

- Resin Transfer Molding (RTM): Injecting resin into fiber preforms within a closed mold, providing precise control over fiber alignment and resin content.

- 3D Printing/Additive Manufacturing: Emerging for rapid prototyping or small batch runs, offering complex geometries and custom designs.

During this stage, manufacturers focus on achieving optimal fiber orientation and resin impregnation to maximize structural integrity. Process parameters are closely monitored, with detailed process logs maintained for traceability.

Assembly

Post-forming, the composite components are assembled with other shoe parts, such as insoles, outsoles, and decorative elements. Adhesive bonding (e.g., industrial-grade epoxies or polyurethane adhesives) is common, often supplemented with mechanical fasteners or heat welding to enhance durability. Precision in assembly ensures proper fit, comfort, and aesthetic quality. B2B buyers should verify that assembly processes adhere to documented procedures, with traceability of all components.

Illustrative Image (Source: Google Search)

Finishing and Quality Control

The finishing stage involves surface treatments, painting, branding, and final inspection. Techniques like surface polishing, coating, or laser etching are used to meet design specifications.

Quality Assurance (QA) and Control in Composite Shoe Manufacturing

Robust quality assurance protocols are vital for international B2B transactions, especially when dealing with diverse regulatory environments such as Nigeria, Brazil, or Middle Eastern markets.

International and Industry-Specific Standards

- ISO 9001: The cornerstone of quality management, requiring systematic documentation, process control, and continuous improvement.

- CE Marking (Europe): Ensures compliance with European safety, health, and environmental requirements, including footwear safety standards.

- ASTM and ISO Testing Standards: For mechanical properties, abrasion resistance, and environmental durability.

- Additional Certifications: Such as REACH (chemical safety), UL, or local standards depending on the destination market.

Inspection Points in the Manufacturing Cycle

- Incoming Quality Control (IQC): Verifies raw materials upon receipt, checking for compliance with specifications, proper labeling, and absence of defects. Suppliers should provide material test reports, certificates of conformity, and batch traceability.

- In-Process Quality Control (IPQC): Conducted during each manufacturing stage, focusing on process parameters like temperature, pressure, fiber alignment, and resin impregnation. Regular sampling and testing ensure adherence to specifications.

- Final Quality Control (FQC): Performed on finished shoes, including visual inspection for surface defects, dimensional accuracy, and assembly integrity. Mechanical testing such as flexural strength, peel tests, and adhesion tests are common.

Testing Methods and Certification Verification

- Mechanical Testing: Includes tensile, compression, and shear tests to ensure structural robustness.

- Environmental Testing: Simulates conditions like humidity, UV exposure, and temperature cycling to assess durability.

- Dimensional Inspection: Uses 3D scanning or calipers to verify shape and size conformity.

- Chemical Analysis: Checks for residual chemicals, VOC emissions, and compliance with chemical safety standards.

B2B buyers should request detailed test reports and certificates from suppliers. Engaging third-party inspection agencies (e.g., SGS, Bureau Veritas) for pre-shipment audits provides additional assurance of quality compliance.

Verifying Supplier Quality for International B2B Buyers

Given the diversity of markets and regulatory landscapes, B2B buyers must implement rigorous supplier verification procedures:

- Supplier Audits: Conduct on-site inspections to evaluate manufacturing facilities, quality systems, and adherence to standards. For buyers from Nigeria, Brazil, or the Middle East, engaging local or third-party auditors familiar with regional regulations ensures comprehensive assessment.

- Documentation Review: Examine certifications, test reports, and process documentation. Suppliers should provide ISO 9001 certificates, material certificates, and compliance declarations.

- Sample Testing: Request product samples for independent testing, especially for critical performance parameters.

- Factory Visits: When feasible, visiting manufacturing sites offers insights into operational practices, workforce conditions, and quality management culture.

- Ongoing Monitoring: Establish regular review cycles, including periodic audits and review of quality metrics, to maintain supplier accountability.

Special Considerations for B2B Buyers from Africa, South America, the Middle East, and Europe

Buyers from diverse regions should be aware of specific nuances:

- Regulatory Compliance: Ensure suppliers understand and meet local standards (e.g., Brazilian INMETRO, Nigerian SONCAP, Middle Eastern Gulf standards). Clarify certification requirements early in negotiations.

- Customs and Import Controls: Verify that certifications align with customs documentation to prevent delays or rejections.

- Cultural and Language Barriers: Engage local consultants or partners to facilitate communication, audits, and compliance verification.

- Trade Agreements and Tariffs: Consider preferential trade agreements or tariffs that might influence procurement costs and timelines.

Final Recommendations

- Establish clear quality specifications and expectations before entering into contracts.

- Prioritize suppliers with proven track records and recognized certifications.

- Incorporate quality assurance clauses into procurement agreements, including penalties for non-compliance.

- Leverage third-party inspection agencies for unbiased verification.

- Maintain transparent documentation and audit trails to facilitate compliance audits and future supplier evaluations.

By understanding and rigorously implementing these manufacturing and quality assurance practices, B2B buyers can significantly reduce risks, ensure consistent product quality, and foster long-term, reliable supplier relationships across international markets.

Comprehensive Cost and Pricing Analysis for composite shoes Sourcing

Understanding the Cost Structure of Composite Shoes

For international B2B buyers sourcing composite shoes, understanding the detailed cost components is essential to negotiate effectively and optimize procurement budgets. The primary cost elements include:

-

Materials: The core of composite shoes involves high-strength composites, synthetic leathers, and specialized adhesives. Material costs can vary significantly based on quality, certifications (e.g., environmental standards), and sourcing regions. Premium materials or custom formulations will elevate costs.

-

Labor: Manufacturing labor costs differ widely across regions. Asian countries like China and Vietnam typically offer lower wages, whereas Eastern Europe or parts of South America may have higher labor expenses but potentially higher craftsmanship quality. For African and Middle Eastern suppliers, costs may be competitive but often require thorough quality checks.

-

Manufacturing Overhead: These include equipment depreciation, factory utilities, and operational expenses. Overheads tend to be higher in regions with stricter environmental or safety regulations, impacting overall costs.

-

Tooling and Equipment: Initial tooling costs are significant, especially for custom designs or molds. These are usually amortized over large production runs, making economies of scale crucial for cost-efficiency.

-

Quality Control (QC): Ensuring consistent quality, certifications, and compliance adds to costs but is critical for brand reputation and avoiding costly rejections or returns.

-

Logistics and Shipping: International shipping expenses depend on shipment volume, mode (air, sea, land), and logistics efficiency. Buyers from Africa and South America should consider longer lead times and higher freight costs, especially for bulky or fragile composite shoes.

-

Profit Margin: Suppliers incorporate margins based on market competition, order size, and relationship strength. Larger orders generally attract better pricing but require negotiation.

Factors Influencing Pricing

Several key factors influence the final price of composite shoes:

-

Order Volume & MOQ: Larger orders typically reduce unit costs due to economies of scale. Buyers should negotiate for favorable MOQs, especially when testing new suppliers or designs.

-

Specifications & Customization: Higher customization, intricate designs, or specific features (e.g., waterproofing, branding) increase manufacturing complexity and costs.

-

Material Choices: Premium or specialized materials, such as eco-friendly composites or certifications (e.g., ISO, REACH), tend to raise prices but may offer differentiation advantages.

-

Quality & Certifications: Suppliers with ISO or other industry certifications might charge a premium but can provide assurance of quality and compliance, critical for international markets.

-

Supplier Location & Capabilities: Suppliers in regions with advanced manufacturing infrastructure often offer better quality but at higher prices, whereas emerging markets might provide cost advantages but require rigorous quality assurance.

-

Incoterms & Logistics Terms: FOB (Free on Board) prices exclude shipping, whereas CIF (Cost, Insurance, Freight) include it, affecting the total landed cost. Buyers should clarify these terms upfront.

Strategic Tips for International Buyers

-

Negotiate Total Cost of Ownership (TCO): Focus not only on unit price but also on shipping, customs duties, taxes, and after-sales support. For example, sourcing from Brazil or Nigeria may involve higher import duties but could reduce freight costs due to proximity.

-

Leverage Volume & Long-term Relationships: Building trust and committing to larger, consistent orders can unlock better pricing and payment terms.

-

Evaluate Quality & Certifications: Prioritize suppliers with proven compliance to avoid costly rejections, especially in markets with strict standards like Europe.

-

Understand Pricing Nuances: Be aware of potential hidden costs such as tooling charges, sample fees, or incremental costs for special packaging.

-

Assess Lead Times & Flexibility: Longer lead times may reduce costs but impact time-to-market. Flexibility in production schedules can also influence pricing negotiations.

Price Range Estimates (Indicative)

While prices fluctuate based on specifications and supplier location, a rough estimate for composite shoes ranges from $15 to $40 per pair for bulk orders. Premium or highly customized models can exceed this range, especially with added certifications or eco-friendly materials. Buyers should always request detailed quotations and factor in additional costs like shipping, duties, and taxes to determine the true landed cost.

By thoroughly analyzing these cost components and influencing factors, international B2B buyers from Africa, South America, the Middle East, and Europe can make informed sourcing decisions. Strategic negotiation and clear understanding of the total cost landscape are key to achieving competitive pricing and ensuring product quality in the global composite shoes market.

Spotlight on Potential composite shoes Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for composite shoes.)*

Essential Technical Properties and Trade Terminology for composite shoes

Critical Technical Properties for Composite Shoes

Material Grade

Material grade defines the quality and performance level of the composite components used in shoe manufacturing. Higher-grade materials, such as aerospace-grade carbon fiber or advanced composites, offer superior strength-to-weight ratios, durability, and resistance to environmental factors. B2B buyers should specify and verify the material grade to ensure the product meets safety standards and performance expectations, especially for demanding applications like safety footwear or sports shoes.

Tensile and Impact Strength

These properties measure a composite shoe’s ability to withstand pulling forces and sudden impacts without failure. High tensile strength ensures the shoe maintains structural integrity under stress, while impact resistance is critical for protecting the wearer in industrial environments. Suppliers should provide test reports demonstrating compliance with industry standards, helping buyers assess durability and safety.

Tolerance and Dimensional Accuracy

Tolerance refers to the permissible deviation from specified dimensions during manufacturing. Precise tolerances are essential for proper fit, comfort, and compatibility with other shoe components. For B2B buyers, especially those involved in OEM (Original Equipment Manufacturer) production, understanding and verifying tolerances ensures consistent product quality and reduces rework costs.

Weight Specifications

Lightweight composites contribute to improved comfort and performance, particularly in athletic or safety footwear. Buyers should seek detailed weight specifications for the composite parts, aiming for materials that balance strength with minimal weight. Excessively heavy components can lead to user fatigue and reduced product appeal.

Environmental Resistance

This property encompasses resistance to moisture, UV exposure, chemicals, and temperature fluctuations. Given the varied climates across Africa, South America, the Middle East, and Europe, selecting composites with high environmental resistance ensures longevity and reliable performance in diverse conditions. Manufacturers should provide data on weathering tests and chemical resistance.

Trade Terms and Industry Jargon

OEM (Original Equipment Manufacturer)

Refers to manufacturers that produce shoes or components branded and sold by another company. Understanding OEM terms helps buyers negotiate production quantities, branding rights, and customization options. Clear communication about OEM agreements ensures alignment on quality standards and intellectual property rights.

MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to produce or sell in a single order. MOQs impact procurement planning and cash flow, especially for buyers from emerging markets. Negotiating flexible MOQs can enable smaller or more frequent orders, reducing inventory costs.

RFQ (Request for Quotation)

A formal process where buyers solicit price and delivery terms from multiple suppliers. An RFQ helps compare offers on technical specifications, lead times, and costs, facilitating informed purchasing decisions. Accurate RFQs should include detailed technical requirements to avoid misunderstandings.

Incoterms (International Commercial Terms)

Standardized trade terms published by the International Chamber of Commerce that define responsibilities for shipping, insurance, and tariffs. Common Incoterms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) clarify who bears costs and risks at each shipment stage. Familiarity with Incoterms ensures smoother logistics and cost management.

Certification and Compliance Terms

Terms such as CE, ISO, or ASTM indicate adherence to international safety, quality, or environmental standards. Buyers should verify that suppliers provide relevant certification documents, especially for export markets where compliance is mandatory. These certifications reduce risk and facilitate market access.

Conclusion

A thorough understanding of these technical properties and trade terms empowers B2B buyers to make informed decisions, negotiate effectively, and ensure the composite shoes meet their specific market needs. Clear technical specifications combined with industry-standard terminology foster transparency and streamline procurement processes across diverse international markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the composite shoes Sector

Market Overview & Key Trends

The global composite shoes market is experiencing significant growth driven by technological innovation, evolving consumer preferences, and supply chain diversification. Key drivers include increasing demand for lightweight, durable, and high-performance footwear across industries such as sports, safety, and fashion. Emerging markets, particularly in Africa, South America, the Middle East, and parts of Europe, present substantial opportunities for B2B buyers seeking to expand their footprint.

Technological advancements—such as the development of high-strength fiber composites, 3D printing, and automation—are transforming manufacturing processes, reducing lead times, and improving customization options. For international buyers, sourcing from regions with advanced manufacturing capabilities, like Europe, can ensure high quality and technological innovation. Conversely, emerging markets like Nigeria and Brazil offer cost-effective manufacturing options but may require careful vetting of quality standards and supply reliability.

Market dynamics are also shaped by fluctuating raw material costs, geopolitical factors, and trade policies. For instance, tariffs and import/export regulations can influence sourcing decisions, prompting buyers to explore local or regional suppliers to mitigate risks. Digital sourcing platforms and supply chain transparency tools are increasingly vital for managing these complexities, offering real-time insights and traceability.

For B2B buyers in these regions, understanding local manufacturing ecosystems, assessing supplier capacity, and establishing strong relationships are crucial. Leveraging trade associations and attending industry expos can facilitate connections with reliable suppliers. Additionally, staying attuned to emerging trends like customization, sustainable materials, and rapid prototyping can give buyers a competitive edge in sourcing composite shoes.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a central consideration in the composite shoes sector, driven by both consumer demand and regulatory pressures. Environmentally conscious buyers are prioritizing suppliers who demonstrate commitment to reducing carbon footprints, minimizing waste, and employing eco-friendly materials. The use of recycled fibers, bio-based resins, and biodegradable composites is gaining traction as manufacturers seek to lower environmental impact.

Ethical sourcing practices are equally important, especially for B2B buyers aiming to uphold corporate social responsibility standards. Ensuring supply chain transparency helps prevent issues such as labor exploitation, child labor, and unfair wages. Certification schemes like Fair Trade, SA8000, and ISO 14001 serve as benchmarks for ethical and environmental compliance, and sourcing from certified suppliers can enhance brand reputation and market acceptance.

In regions like Africa and South America, where regulatory frameworks may vary, due diligence is vital. Buyers should prioritize suppliers who provide transparent documentation and third-party audits. Additionally, engaging with suppliers committed to sustainable innovation—such as those investing in green manufacturing processes—can lead to long-term cost savings and brand differentiation. Incorporating sustainability criteria into procurement policies not only aligns with global trends but also mitigates risks associated with non-compliance or supply chain disruptions.

Evolution and Industry Context

The evolution of composite shoes has been marked by continuous innovation aimed at enhancing performance, comfort, and sustainability. Initially driven by the need for lightweight, durable footwear in sports and safety applications, the sector has expanded into fashion and luxury markets, emphasizing design and eco-conscious materials.

For B2B buyers, understanding this trajectory is essential for strategic sourcing. Companies that adapt early to trends such as bio-based composites, circular economy principles, and digital manufacturing will be better positioned to meet evolving customer expectations. Moreover, regional differences in technological adoption and regulatory environments influence sourcing strategies—European manufacturers often lead in sustainability standards, while emerging markets may offer cost advantages.

By staying informed about these industry shifts, international buyers can optimize their supply chains, foster innovation, and align procurement practices with global sustainability goals, ensuring long-term competitiveness in the composite shoes market.

Frequently Asked Questions (FAQs) for B2B Buyers of composite shoes

1. How can I effectively vet composite shoe suppliers to ensure quality and reliability?

Vetting suppliers begins with thorough due diligence. Request comprehensive company profiles, including manufacturing certifications (ISO, CE, etc.), quality control processes, and client references. Conduct virtual factory audits or on-site visits if feasible, especially in regions like China, Vietnam, or Brazil. Evaluate their production capacity, lead times, and compliance with safety standards relevant to your target markets. Additionally, review samples to assess material quality, craftsmanship, and durability. Partnering with suppliers with transparent operations and verified credentials minimizes risks and ensures consistent product quality aligned with your brand standards.

2. What are the key considerations for customizing composite shoes for different markets?

Customization should align with regional preferences, safety standards, and branding goals. Communicate clearly about material options, color schemes, branding placements, and design specifications. Ensure the supplier can accommodate small to large order quantities for customized features and understands local market trends. Be aware of regional regulations—such as labeling requirements or safety certifications—so that your customized shoes are compliant. Establish clear timelines for sample approval and production. Working with suppliers experienced in international markets can streamline customization and reduce delays, ensuring your product appeals to diverse customer bases.

3. What are typical MOQs, lead times, and payment terms for bulk composite shoe orders?

Minimum order quantities (MOQs) for composite shoes often range from 500 to 5,000 pairs, depending on the supplier’s capacity and customization complexity. Lead times typically vary from 4 to 12 weeks after order confirmation, influenced by order size, complexity, and destination logistics. Payment terms commonly include 30% upfront deposit with the balance payable before shipment or upon delivery, but this can be negotiated—especially for repeat buyers or large orders. Establish clear contractual terms, ensuring transparency on production milestones, penalties for delays, and currency considerations, to facilitate smooth transactions.

4. What certifications and quality assurance processes should I look for in composite shoe suppliers?

Key certifications include ISO 9001 for quality management, environmental standards like ISO 14001, and safety certifications relevant to footwear (e.g., CE marking for Europe). Suppliers should have robust QA processes, including raw material testing, in-process inspections, and final product audits. Request documentation of batch testing results, durability tests, and compliance certificates. For markets like Europe and Brazil, compliance with local safety and environmental standards is crucial. Verifying these certifications reduces risks of non-compliance, recalls, or reputational damage, and assures your customers of product safety and quality.

Illustrative Image (Source: Google Search)

5. How can I manage international logistics effectively when importing composite shoes?

Effective logistics begins with selecting reliable freight forwarders experienced in your target regions. Consider incoterms like FOB or CIF that suit your financial and risk preferences. For Africa, South America, and the Middle East, plan for potential customs clearance delays—partner with brokers familiar with local import regulations. Consolidate shipments when possible to reduce costs. Track shipments proactively and communicate regularly with logistics providers. Also, consider warehousing options near your key markets to facilitate faster delivery and inventory management. Proper logistics planning minimizes delays, reduces costs, and improves overall supply chain resilience.

6. What are common dispute resolution methods with international composite shoe suppliers?

Disputes often arise over quality, delivery delays, or payment issues. It’s advisable to include clear dispute resolution clauses in your contracts, favoring international arbitration under recognized rules (e.g., ICC, UNCITRAL). Mediation can be a first step to resolve issues amicably before arbitration. Maintaining detailed records of all communications, inspections, and transactions helps in dispute cases. Building strong relationships and clear communication channels with suppliers reduces misunderstandings. When selecting suppliers, prefer those with established dispute resolution procedures and positive reputations for resolving conflicts professionally, thus safeguarding your investments.

7. How do I ensure compliance with regional safety and environmental standards for composite shoes?

Understand the specific standards applicable to your target markets—such as REACH in Europe, INMETRO in Brazil, or local safety regulations in Nigeria and the Middle East. Work with suppliers who proactively test raw materials and finished products against these standards, providing relevant certifications. Incorporate compliance requirements into your purchase agreements and request copies of testing reports. Regular audits and third-party inspections can verify ongoing compliance. Staying updated on evolving regulations ensures your products remain market-ready, reduces the risk of penalties, and enhances your brand’s reputation for safety and environmental responsibility.

8. What steps should I take if I encounter quality issues or delays with my supplier?

Immediately document the issue with detailed photos, inspection reports, and correspondence records. Communicate promptly and clearly with your supplier, outlining the problem and referencing contractual obligations. Request corrective actions, such as rework, replacement, or compensation, depending on severity. If a resolution isn’t reached, consider engaging third-party inspectors or mediators. Maintaining flexibility and open communication helps resolve issues efficiently. For recurring problems, reassess your supplier relationship, and consider diversifying your supply chain or sourcing from multiple vendors to mitigate risks and ensure continuous supply.

Strategic Sourcing Conclusion and Outlook for composite shoes

Conclusion and Future Outlook

Effective strategic sourcing is pivotal for international B2B buyers seeking to capitalize on the growing market for composite shoes. By prioritizing supplier diversification, rigorous quality assessment, and cost optimization, buyers can enhance supply chain resilience while maintaining competitive advantages. Emphasizing transparency and fostering strong supplier relationships will further mitigate risks and ensure consistent product quality.

As the market evolves, emerging regions such as Africa, South America, the Middle East, and parts of Europe present significant opportunities for sourcing innovative composite footwear solutions. Leveraging local manufacturing capabilities and sustainable practices can lead to cost efficiencies and brand differentiation. Staying ahead of industry trends—such as eco-friendly materials and advanced manufacturing techniques—will be crucial for maintaining market relevance.

Illustrative Image (Source: Google Search)

Looking forward, international buyers should adopt a proactive, strategic approach to sourcing, emphasizing agility and innovation. Engaging with trusted suppliers and exploring new partnerships will be vital in navigating global supply chain dynamics. By doing so, buyers can unlock new growth avenues and ensure their competitive edge in the dynamic composite shoe industry.