Your Ultimate Guide to Sourcing Dance Shoes For Women

Guide to Dance Shoes For Women

- Introduction: Navigating the Global Market for dance shoes for women

- Understanding dance shoes for women Types and Variations

- Key Industrial Applications of dance shoes for women

- Strategic Material Selection Guide for dance shoes for women

- In-depth Look: Manufacturing Processes and Quality Assurance for dance shoes for women

- Comprehensive Cost and Pricing Analysis for dance shoes for women Sourcing

- Spotlight on Potential dance shoes for women Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for dance shoes for women

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the dance shoes for women Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of dance shoes for women

- Strategic Sourcing Conclusion and Outlook for dance shoes for women

Introduction: Navigating the Global Market for dance shoes for women

In the dynamic landscape of global fashion and performance footwear, dance shoes for women represent a vital segment with expanding demand across diverse markets. For international B2B buyers—from Nigeria’s burgeoning dance communities and Thailand’s vibrant entertainment sectors to South American cultural festivals and European dance academies—access to high-quality, reliable suppliers is essential for competitive advantage. These specialized shoes are not merely apparel; they are integral to performers’ success, comfort, and safety, making sourcing decisions both strategic and impactful.

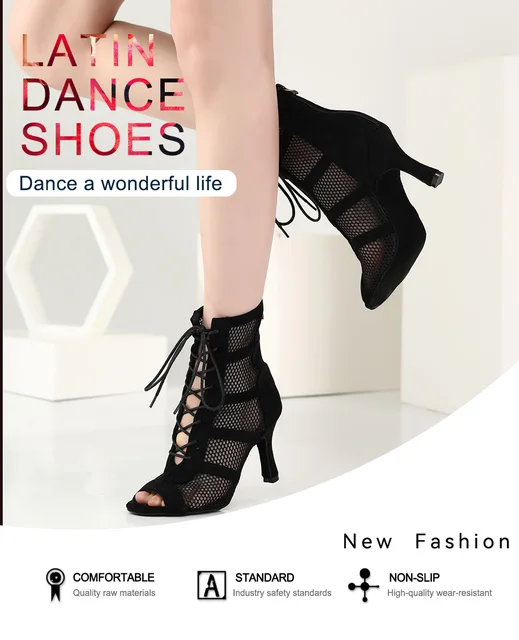

Illustrative Image (Source: Google Search)

This comprehensive guide is designed to empower you with the critical insights needed to navigate the complexities of the global dance shoe market. It covers a wide spectrum—from the various types and materials used, to manufacturing processes and quality control standards. You will find guidance on identifying reputable suppliers, understanding cost structures, and evaluating market trends that influence supply and demand across regions. Additionally, the guide addresses common questions, helping you mitigate risks and optimize your procurement strategies.

For B2B buyers in Africa, South America, the Middle East, and Europe, this resource offers actionable intelligence to facilitate informed, confident purchasing decisions. Whether you’re sourcing for retail, wholesale, or custom orders, understanding the nuances of the international supply chain—along with regional market dynamics—can significantly enhance your sourcing efficiency, product quality, and profitability. This guide aims to be your strategic partner in unlocking the full potential of the global dance shoe market.

Understanding dance shoes for women Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Ballroom Dance Shoes | Suede or leather sole, low heel, supportive structure | Dance studios, retail, wholesale distribution | Pros: Wide market appeal, durable; Cons: Higher manufacturing costs |

| Latin & Salsa Shoes | Open toe or heel, flexible sole, often with a heel (2-3 inches) | Specialty dance retailers, online marketplaces | Pros: High demand in niche markets; Cons: Limited versatility |

| Ballet & Contemporary Shoes | Soft, flexible, often with minimal sole, sometimes with split sole | Ballet schools, dance academies | Pros: Growing demand in educational sectors; Cons: Smaller niche |

| Jazz & Tap Shoes | Hard sole, reinforced toe, secure fit | Performing arts suppliers, wholesale vendors | Pros: Consistent demand in performance markets; Cons: Limited to specific genres |

| Character & Folk Shoes | Traditional design, sturdy construction, often with laces or buckles | Cultural dance groups, costume suppliers | Pros: Niche but steady demand; Cons: Seasonal or event-driven sales |

Characteristics and Suitability of Major Dance Shoe Types

Ballroom Dance Shoes:

Designed for stability and elegance, ballroom shoes feature a suede or leather sole that allows smooth turns and gliding. They typically have a low, broad heel for balance, making them suitable for competitive and social ballroom dancing. B2B buyers should prioritize sourcing high-quality materials and consistent sizing options to meet the demands of dance studios and retail outlets. Bulk purchasing of varied sizes and styles can ensure broad market coverage, but higher manufacturing costs require careful supplier vetting for quality assurance.

Latin & Salsa Shoes:

These shoes are characterized by their open toes, heels, and flexible soles, which facilitate quick movements and spins. They are often made with lightweight materials to enhance agility. Ideal for niche retailers focusing on Latin dance markets, these shoes command premium pricing but require precise craftsmanship. B2B buyers should consider supplier expertise in creating durable yet flexible footwear, as Latin dance shoes often experience high wear. Packaging and branding tailored to the Latin dance community can boost sales in targeted markets.

Ballet & Contemporary Shoes:

Featuring soft, minimal soles and flexible construction, ballet shoes are essential for training academies and dance schools. Contemporary shoes often resemble ballet slippers but may include additional support. These shoes are produced in a variety of sizes and widths to accommodate diverse student needs. For B2B buyers, establishing relationships with manufacturers that can deliver consistent quality at scale is vital, especially as demand grows in educational sectors across emerging markets.

Jazz & Tap Shoes:

With their hard soles and reinforced toes, jazz and tap shoes are designed for performance durability. They often feature buckles or laces for a secure fit, making them suitable for theatrical productions and dance schools. B2B buyers should focus on sourcing from suppliers capable of offering both standard and custom designs to meet the specific needs of performance venues. Volume discounts and reliable supply chains are critical given the seasonal and event-driven nature of demand.

Character & Folk Shoes:

Traditional in appearance, these shoes are crafted with sturdy materials to withstand cultural and folk dance routines. They often feature laces, buckles, or decorative elements. The niche market for these shoes is steady, driven by cultural festivals and dance groups. B2B buyers should explore suppliers experienced in traditional footwear to ensure authenticity and durability, and consider seasonal inventory planning aligned with cultural events to optimize sales.

Key Industrial Applications of dance shoes for women

| Industry/Sector | Specific Application of dance shoes for women | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Performing Arts & Entertainment | Costumes for ballet, jazz, and contemporary dance performances | Enhances visual appeal and authenticity, supporting brand reputation and audience engagement | Quality craftsmanship, reliable sizing, and adherence to safety standards |

| Fitness & Wellness | Dance-based fitness classes such as Zumba, aerobics, and dance therapy | Improves participant experience, reduces injury risk, and boosts class retention | Durability, non-slip soles, comfort, and availability of diverse sizes |

| Retail & Wholesale Distribution | Wholesale supply to dance academies, retail stores, and online platforms | Expanding market reach, brand visibility, and volume sales opportunities | Competitive pricing, consistent quality, and flexible MOQ (minimum order quantity) |

| Hospitality & Tourism | Dance performances and entertainment at hotels, resorts, and cruise ships | Elevates guest experience, supports themed events, and enhances venue prestige | Stylish designs, comfortable fit for prolonged wear, and compliance with safety standards |

| Cultural & Community Events | Traditional and cultural dance festivals requiring specialized footwear | Preserves cultural authenticity, attracts audiences, and promotes local artisans | Authentic designs, regional customization options, and reliable supply chain |

Performing Arts & Entertainment

Dance shoes for women are fundamental in the performing arts industry, especially for ballet, jazz, and contemporary dance companies. They are designed to provide optimal support, flexibility, and aesthetic appeal, which are crucial for professional performances. For international B2B buyers from regions like Nigeria or Thailand, sourcing high-quality dance shoes ensures that performers look authentic while minimizing injury risks due to inadequate footwear. Reliable supply chains and adherence to safety standards are essential to meet the rigorous demands of stage productions and uphold the reputation of dance academies and entertainment venues.

Fitness & Wellness

The booming global fitness industry, including dance-based classes such as Zumba and aerobics, relies heavily on specialized dance shoes for women. These shoes offer non-slip soles, cushioning, and support, enhancing safety and comfort during vigorous routines. For B2B buyers from emerging markets in Africa or South America, sourcing durable, comfortable, and affordable dance shoes can improve client satisfaction and class retention rates. Ensuring consistent quality and a wide range of sizes will help meet the diverse needs of fitness centers and wellness operators across different regions.

Retail & Wholesale Distribution

Wholesale distribution of dance shoes to retail outlets, dance academies, and online platforms presents significant growth opportunities. Buyers from Europe or Southeast Asia, such as Thailand, can capitalize on the increasing popularity of dance as a lifestyle and fashion statement. Sourcing from reliable manufacturers who offer competitive pricing, consistent quality, and flexible order quantities enables distributors to respond swiftly to market demands. Building strong supplier relationships ensures product authenticity and timely delivery, vital for maintaining competitive advantage in diverse markets.

Hospitality & Tourism

Hotels, resorts, and cruise ships frequently host dance performances and themed events that require stylish, comfortable dance shoes for women. These shoes contribute to the overall guest experience, adding a touch of elegance and authenticity to entertainment offerings. For international buyers in regions like the Middle East or Europe, sourcing fashionable yet functional dance footwear ensures guest satisfaction and supports high-profile events. Emphasizing design, comfort, and safety compliance is key to meeting the expectations of discerning hospitality clients.

Cultural & Community Events

Traditional and cultural dance festivals often demand specialized footwear that respects regional aesthetics and authenticity. For buyers from Africa or South America, sourcing culturally appropriate dance shoes helps promote local traditions and attract tourism. Ensuring regional customization, authentic designs, and reliable supply chains allows for successful participation in festivals and community events. These applications also open avenues for collaborations with local artisans, enhancing cultural preservation and economic development.

Strategic Material Selection Guide for dance shoes for women

Material Analysis for Dance Shoes for Women

Selecting the appropriate materials for dance shoes involves balancing performance, durability, cost, and compliance with international standards. For B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, understanding the properties and implications of different materials is crucial for making informed procurement decisions.

Leather

Leather remains the traditional choice for dance shoes due to its excellent breathability, flexibility, and aesthetic appeal. It offers high comfort levels, conforming well to foot shape over time, which enhances dancer performance. Leather’s natural properties provide good temperature regulation, making it suitable for various climates, from the hot Middle East to cooler European environments.

Pros & Cons:

Leather is highly durable and can last for years with proper maintenance, making it cost-effective over the long term. However, high-quality leather can be expensive, and the manufacturing process is labor-intensive, which can increase initial costs. Leather also requires specific care to prevent cracking or deterioration, especially in humid or salty environments common in coastal regions of Africa and South America.

Impact on Application:

Leather’s flexibility and aesthetic appeal make it ideal for performance shoes, especially those requiring a snug fit and elegant appearance. It also conforms well to foot contours, providing support during complex dance movements.

International Considerations:

Leather products must comply with regional import standards, such as the European Union’s REACH regulations or specific country-specific animal welfare standards. Buyers from Africa and South America should verify local import duties and certification requirements. Leather sourced from sustainable and ethically certified suppliers may also be preferred to meet increasing consumer and regulatory demands.

Synthetic Materials (e.g., Microfiber, PVC, PU)

Synthetic materials are increasingly popular due to their lower cost, consistent quality, and ease of manufacturing. Microfiber and polyurethane (PU) are common choices in dance shoe production, offering a range of properties tailored to different needs.

Pros & Cons:

Synthetic materials are generally more affordable than leather, reducing initial costs for manufacturers and importers. They are lightweight, water-resistant, and easy to clean, making them suitable for various environments, including humid regions in South America and tropical climates in Southeast Asia. However, synthetic materials tend to be less breathable, which can lead to discomfort during prolonged use and may cause sweating or odor issues.

Impact on Application:

Synthetic uppers can be engineered for specific flexibility and support levels, but they may lack the natural conformability of leather. They are often used in entry-level or mass-produced dance shoes, where cost efficiency is prioritized.

International Considerations:

Manufacturers should ensure synthetic materials meet safety and chemical compliance standards such as ASTM, DIN, or JIS. Buyers from regions with strict import regulations, like Europe, should verify that materials are free from harmful chemicals (e.g., phthalates, heavy metals). Additionally, synthetic materials’ environmental impact is under scrutiny; sourcing eco-friendly or recyclable synthetics can enhance market acceptance.

Rubber and EVA Soles

The sole material is critical for grip, shock absorption, and durability. Rubber and EVA (ethylene-vinyl acetate) are the most common options for dance shoe soles.

Pros & Cons:

Rubber soles provide excellent grip and durability, making them suitable for various dance styles and floor types. They are resistant to wear and tear, especially in high-traffic environments. EVA soles are lightweight, offering enhanced comfort and shock absorption, but they tend to wear out faster than rubber.

Impact on Application:

Rubber soles are ideal for studio and stage performances requiring reliable traction. EVA soles are better suited for practice shoes or those used on smooth surfaces where cushioning is prioritized.

International Considerations:

Manufacturers should ensure that sole materials comply with local safety standards, such as slip resistance certifications. For export markets, especially in Europe and the Middle East, adherence to standards like ASTM D2047 (slip resistance) can be advantageous. Environmental considerations, such as the recyclability of rubber or EVA, are increasingly relevant for eco-conscious buyers.

Summary Table

| Material | Typical Use Case for dance shoes for women | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather | Performance, stage, and premium dance shoes | Breathability, conformability, aesthetic appeal | High cost, requires maintenance, less suitable for humid environments | High |

| Synthetic (Microfiber, PU) | Entry-level, mass-produced, practice shoes | Cost-effective, water-resistant, lightweight | Less breathable, environmental concerns, chemical compliance | Low to Med |

| Rubber & EVA soles | Sole for grip and shock absorption | Durability (Rubber), lightweight (EVA) | EVA wears faster, rubber can be heavier | Low to Med |

This detailed understanding of materials allows B2B buyers to select the most suitable options based on regional climate, compliance standards, cost considerations, and end-user preferences. Tailoring material choices to specific markets ensures better product performance, regulatory adherence, and customer satisfaction across diverse international regions.

In-depth Look: Manufacturing Processes and Quality Assurance for dance shoes for women

Manufacturing Processes for Dance Shoes for Women

Manufacturing dance shoes for women involves a series of meticulously planned stages designed to ensure comfort, durability, and aesthetic appeal. Understanding these stages enables B2B buyers to evaluate supplier capabilities and ensure product quality.

1. Material Preparation

The process begins with sourcing and preparing high-quality raw materials. Typical materials include soft, flexible leathers (e.g., calfskin, suede), synthetic leathers, breathable fabrics, and specialized insoles. Suppliers often perform initial quality checks on incoming materials, assessing factors such as thickness, flexibility, and absence of defects. For international buyers, verifying that suppliers adhere to recognized material standards (e.g., OEKO-TEX for textiles) is crucial, especially when compliance with regional regulations like REACH in Europe is required.

2. Forming and Cutting

The prepared materials are then cut into pattern pieces using either manual or automated cutting machines, depending on the scale. Precision is critical here to ensure proper fit and symmetry. Advanced manufacturers may employ CAD/CAM systems for pattern design, enabling consistent reproduction across large batches. For B2B buyers, inspecting the cutting process and verifying that patterns align correctly can help prevent defects downstream.

3. Assembly and Stitching

Assembling involves stitching the various parts—upper, lining, and sole—together. Techniques such as lockstitch, overlock, or specialized decorative stitches are used based on design and durability requirements. Quality control during assembly often includes real-time inspection (IPQC) to catch issues like uneven stitching, loose threads, or misaligned parts. For higher-end dance shoes, double-stitching and reinforced seams enhance longevity, which should be verified through supplier documentation and sample inspections.

4. Lasting and Shaping

The shoe’s upper is shaped over a last (a mold that mimics foot anatomy) to ensure proper fit and form. This process may involve heat-setting or manual molding, depending on materials. Precision in this stage impacts comfort and performance, especially important for dance shoes requiring specific arch support and flexibility. B2B buyers should inquire about the types of lasts used and the consistency of shaping procedures.

5. Finishing and Quality Checks

Finishing includes attaching soles, adding decorative elements, and applying coatings or protective finishes. Final quality checks involve visual inspections for defects such as surface blemishes, glue residues, or uneven finishes. Some manufacturers also perform functional tests, such as slip resistance or flexibility assessments, depending on the shoe design. The finishing process is crucial for aesthetic appeal and safety standards compliance.

Quality Assurance Protocols and Standards

Effective quality assurance (QA) is fundamental for international B2B transactions, especially when sourcing from diverse regions such as Africa, South America, the Middle East, and Europe.

1. International Standards and Certifications

– ISO 9001: Most reputable manufacturers adhere to ISO 9001 standards, ensuring systematic quality management systems. B2B buyers should request certification proof and audit reports to verify ongoing compliance.

– CE Marking (European Market): For dance shoes intended for markets in the EU, CE certification confirms conformity with safety, health, and environmental protection standards.

– Other Industry-Specific Certifications: Depending on the target market, certifications like ASTM (for safety standards in the US) or API (for specific manufacturing processes) may be relevant.

2. In-Process Quality Control (IQC, IPQC, FQC)

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival for defects, dimensions, and compliance with specifications. B2B buyers should request detailed inspection reports and supplier audits.

– In-Process Quality Control (IPQC): Continuous checks during production identify deviations early, such as stitching quality, dimensional accuracy, or material integrity. Regular sampling and testing can prevent defective batches.

– Final Quality Control (FQC): Before shipment, a thorough inspection ensures the finished shoes meet all specifications. Visual inspections, functional tests (flexibility, slip resistance), and measurement verifications are common.

3. Testing Methods

– Durability Tests: Simulate long-term wear through flexing, abrasion, and tensile tests.

– Comfort and Fit Tests: Assess cushioning, arch support, and overall ergonomics, often via prototype fitting sessions.

– Safety Tests: Slip resistance tests (using standardized slip testers), as well as chemical safety assessments for adhesives and dyes, align with regional safety standards.

4. Verification for B2B Buyers

– Supplier Audits: Conduct on-site audits or hire third-party inspection agencies to evaluate manufacturing processes, quality systems, and compliance.

– Inspection Reports: Require detailed QC reports, including test results, defect rates, and corrective actions.

– Sample Approval: Insist on pre-production samples for approval before mass production begins.

– Ongoing Monitoring: Establish quality agreements that include periodic audits, batch testing, and continuous improvement clauses.

Nuances for International B2B Engagement

B2B buyers from Africa, South America, the Middle East, and Europe face specific challenges and considerations:

- Regional Compliance: Ensure suppliers understand regional requirements such as REACH (Europe), ASTM standards (North America), or local safety standards.

- Communication and Documentation: Clear, detailed specifications and documentation are vital, especially when language barriers exist. Engaging bilingual inspectors or agents can mitigate misunderstandings.

- Quality Certifications: Prioritize suppliers with recognized international certifications (ISO, CE, SGS, TUV) to reduce risk and streamline compliance.

- Supply Chain Transparency: Request transparency regarding sourcing of materials, manufacturing locations, and quality control practices to ensure ethical and consistent production.

In summary, a thorough understanding of manufacturing stages combined with rigorous quality assurance protocols enables B2B buyers to select reliable suppliers capable of delivering high-quality dance shoes for women. Emphasizing certification verification, process audits, and ongoing quality monitoring ensures products meet both regional standards and end-user expectations, fostering long-term international partnerships.

Comprehensive Cost and Pricing Analysis for dance shoes for women Sourcing

Cost Structure Breakdown for Dance Shoes for Women

Understanding the comprehensive cost components is crucial for international buyers aiming to negotiate effectively and optimize procurement strategies. The primary cost elements include:

- Materials: High-quality synthetic leathers, genuine leathers, mesh fabrics, and specialized soles. Material costs can vary significantly based on quality, source country, and customization requirements. For instance, premium leathers or eco-friendly fabrics typically command higher prices.

- Labor: Manufacturing labor costs differ widely across regions. Countries like Thailand and Turkey often offer competitive labor rates, whereas European factories may have higher wages but potentially superior craftsmanship. Consider the skill level needed for intricate designs, which influences labor costs.

- Manufacturing Overheads: Factory operational costs, including machinery depreciation, energy, and facility maintenance, contribute to the overall price. Efficient factories with modern equipment tend to have lower overheads, impacting final costs.

- Tooling & Development: Initial mold creation and design tooling are usually one-time investments but are factored into unit costs for small production runs or custom designs. Larger orders dilute these costs effectively.

- Quality Control & Certifications: Ensuring compliance with safety and quality standards (e.g., EN, ISO, or specific dance shoe certifications) can add to costs but is vital for market acceptance, especially in Europe and the Middle East.

- Logistics & Incoterms: Shipping costs depend on volume, destination, and chosen Incoterms. FOB (Free on Board) and CIF (Cost, Insurance, and Freight) are common options; CIF often simplifies cost management for buyers but may carry higher per-unit costs.

- Margins: Suppliers typically add markups ranging from 15% to 40%, depending on order size, customization, and the complexity of the product.

Key Price Influencers

Several factors significantly impact the final price of dance shoes:

- Order Volume & MOQ: Larger orders usually benefit from lower unit costs due to economies of scale. Many suppliers offer discounts beyond their minimum order quantities (MOQs), which can range from 100 to 500 pairs depending on the manufacturer.

- Customization & Specifications: Unique designs, branding, specialized materials, or custom sizing increase production complexity and costs. Standard models are more cost-effective, while bespoke options can add 20-50% to unit prices.

- Material Choices: Premium or eco-friendly materials are more expensive but may be necessary for high-end markets or certification compliance.

- Quality & Certifications: Meeting international standards, especially for export to Europe or the Middle East, often requires additional testing and certification, which can increase costs but enhance marketability.

- Supplier Factors: Established brands with reputation and certifications tend to charge premium prices but may offer better quality assurance and reliability.

- Incoterms & Shipping: FOB terms favor buyers by reducing initial costs, whereas CIF simplifies logistics but may increase the landed cost.

Actionable Tips for International B2B Buyers

- Negotiate Volume Discounts: Leverage larger orders to negotiate better unit prices, especially when sourcing from regions like Thailand or Turkey where production costs are competitive.

- Optimize Total Cost of Ownership (TCO): Consider not only the unit price but also shipping, customs, taxes, and post-sale service costs. For instance, sourcing from Europe might involve higher manufacturing costs but lower shipping times and more straightforward customs clearance.

- Assess Quality & Certification Needs: Invest in suppliers who meet necessary safety and quality standards to avoid costly rejections or recalls, especially crucial for markets with strict regulations like Europe.

- Understand Pricing Nuances: Be aware that suppliers may quote lower prices for standard designs but add charges for customization or expedited shipping. Clarify all costs upfront and request detailed quotations.

- Build Long-term Relationships: Consistent orders foster better negotiation leverage and priority production scheduling, which can lead to cost savings over time.

Disclaimer on Price Ranges

Indicative prices for women’s dance shoes can vary widely based on the factors outlined. As a rough guide, standard models manufactured in Southeast Asia may range from $8 to $15 per pair for bulk orders (e.g., 1,000+ units), whereas customized or premium-quality shoes produced in Europe or the Middle East could cost $20 to $35 per pair. Always obtain multiple quotes and consider total landed costs for accurate budgeting.

By understanding these cost components and influencing factors, B2B buyers from Africa, South America, the Middle East, and Europe can make informed sourcing decisions, negotiate effectively, and secure optimal value in their dance shoe procurement strategies.

Spotlight on Potential dance shoes for women Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for dance shoes for women.)*

Essential Technical Properties and Trade Terminology for dance shoes for women

Key Technical Properties for Dance Shoes for Women

Understanding the technical specifications of dance shoes is essential for international buyers to ensure product quality, compliance, and customer satisfaction. Here are the critical properties to evaluate:

1. Material Grade and Composition

The quality of materials used in dance shoes directly impacts durability, flexibility, and comfort. Common materials include genuine leather, synthetic leather, suede, and specialized fabrics. High-grade materials offer better longevity and performance, which is vital for retailers and distributors aiming to meet customer expectations and reduce return rates.

2. Sole Thickness and Flexibility

The sole’s thickness influences the shoe’s grip, shock absorption, and ease of movement. A flexible sole is crucial for styles like ballet or contemporary dance, while a non-slip, appropriately thick sole benefits ballroom or Latin shoes. Precise tolerances in sole manufacturing ensure consistent performance across batches, reducing customer complaints.

3. Tolerance and Manufacturing Precision

Tolerance refers to the permissible variance in dimensions such as length, width, and heel height. Tight tolerances (e.g., ±0.5mm) indicate high manufacturing precision, ensuring the shoes fit correctly and perform reliably. For international markets, consistent sizing and fitting are critical to reduce returns and exchanges.

4. Breathability and Ventilation Features

Effective ventilation, achieved through breathable materials or mesh panels, enhances comfort during extended wear. Buyers should verify the breathability specifications, especially for warmer climates like Nigeria or Southeast Asia, to meet local consumer preferences and prevent issues like odor or excessive sweating.

5. Weight and Balance

Lightweight shoes facilitate ease of movement and reduce fatigue, especially important for professional dancers. The weight should be balanced across the shoe to ensure stability and control, which are vital for safety and performance.

6. Colorfastness and Finish Quality

The durability of the shoe’s color and finish under repeated use and cleaning is crucial for maintaining a premium appearance. High-quality dyeing and finishing processes prevent fading or cracking, which is essential for brand reputation in competitive markets.

Industry and Trade Terminology for Dance Shoes

Familiarity with key industry terms enhances communication and negotiation efficiency in international B2B transactions:

1. OEM (Original Equipment Manufacturer)

Refers to factories producing dance shoes under a brand’s specifications and design. Understanding OEM capabilities allows buyers to customize products to meet regional preferences or branding requirements, facilitating private label opportunities.

2. MOQ (Minimum Order Quantity)

The smallest number of units a manufacturer is willing to produce per order. Recognizing MOQ helps buyers plan procurement volumes, negotiate better pricing, and avoid overstocking, especially when entering new markets.

3. RFQ (Request for Quotation)

A formal request issued by buyers to suppliers seeking detailed pricing, lead times, and terms for specific products. Mastery of RFQ processes ensures competitive quotes and clearer communication of product requirements.

4. Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities between buyer and seller for delivery, risk transfer, and costs (e.g., FOB, CIF). Understanding Incoterms helps in negotiating shipping terms, managing logistics costs, and minimizing misunderstandings across borders.

5. Lead Time

The period from order placement to product delivery. Accurate knowledge of lead times is vital for planning inventory, especially in markets with seasonal demand spikes or limited warehousing.

6. Quality Assurance (QA) and Certification

Standards and certifications (e.g., ISO, CE) ensure product safety and quality compliance. Buyers should verify these credentials to meet local regulations and assure end-users of product reliability.

Actionable Insights for International Buyers

- Prioritize suppliers with clear specifications on material quality and manufacturing tolerances to ensure product consistency.

- Leverage OEM capabilities for customization suited to regional preferences, enhancing market competitiveness.

- Clarify MOQ and lead times early in negotiations to align production schedules with market demand.

- Understand and incorporate relevant Incoterms in contracts to optimize logistics costs and responsibilities.

- Ensure suppliers provide comprehensive QA certifications to meet local safety standards and reduce compliance risks.

By mastering these technical properties and trade terms, international B2B buyers can make informed decisions, foster stronger supplier relationships, and successfully penetrate diverse markets with high-quality dance shoes for women.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the dance shoes for women Sector

Market Overview & Key Trends

The global dance shoes for women market is witnessing dynamic shifts driven by evolving consumer preferences, technological advancements, and supply chain innovations. Key drivers include increasing participation in dance-related activities worldwide, rising disposable incomes, and a growing emphasis on fashion-forward, performance-enhancing footwear. For international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, understanding these drivers is crucial for strategic sourcing and market positioning.

Emerging sourcing trends emphasize digital transformation, including the adoption of e-commerce platforms, virtual supplier audits, and AI-driven demand forecasting. These tools facilitate more transparent, efficient, and flexible procurement processes, reducing lead times and costs. Additionally, the integration of 3D printing and advanced manufacturing techniques allows for rapid prototyping and customized designs, appealing to niche markets and premium segments.

Market dynamics are also influenced by regional manufacturing hubs—such as China, Vietnam, and India—offering cost-effective production options, while European and North American brands focus on quality and innovation. For buyers from Nigeria, Thailand, or Latin American countries, establishing relationships with reliable manufacturers and leveraging trade agreements can optimize supply chains. Furthermore, the rise of private label and OEM partnerships presents opportunities for regional buyers to develop unique product lines.

Illustrative Image (Source: Google Search)

In terms of product trends, there is a noticeable shift toward lightweight, breathable, and ergonomically designed shoes that enhance dancer performance and comfort. Sustainability considerations are increasingly integrated into product development, driven by consumer demand and regulatory pressures. Staying abreast of these trends allows B2B buyers to better align their sourcing strategies with market expectations, ensuring competitive advantage and customer satisfaction.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a critical aspect of sourcing dance shoes for women, influencing purchasing decisions across all regions. Environmental impacts of footwear manufacturing—such as water consumption, chemical use, and waste generation—are under scrutiny, prompting brands and buyers to prioritize eco-friendly practices.

Ethical sourcing encompasses fair labor practices, safe working conditions, and transparent supply chains. Buyers from Africa, South America, the Middle East, and Europe are increasingly seeking suppliers with verified certifications such as Fair Trade, SA8000, or BSCI. These certifications ensure adherence to ethical standards and reduce reputational risks associated with labor exploitation or environmental violations.

Incorporating ‘green’ materials is a growing trend. Eco-conscious buyers prefer products made from recycled or biodegradable materials, such as natural rubber, organic cotton, and plant-based adhesives. Certifications like Global Organic Textile Standard (GOTS) and Forest Stewardship Council (FSC) add credibility and appeal to environmentally minded consumers.

Additionally, sustainable packaging, reduced carbon footprints in logistics, and waste reduction initiatives are gaining importance. Suppliers that can demonstrate a comprehensive sustainability strategy—integrating eco-design, responsible sourcing, and transparent reporting—are better positioned to meet the expectations of international buyers. Building partnerships with suppliers committed to sustainability not only aligns with regulatory trends but also enhances brand reputation and consumer trust.

Brief Evolution/History (Optional)

The evolution of the dance shoe market reflects broader shifts in fashion, performance technology, and sustainability consciousness. Initially, functional design and affordability dominated, with limited focus on aesthetics or environmental impact. Over time, innovations such as lightweight materials, advanced cushioning, and ergonomic designs emerged to improve dancer comfort and performance.

More recently, sustainability has gained prominence, driven by global environmental initiatives and consumer awareness. Manufacturers now incorporate eco-friendly materials and ethical practices as standard components of product development. For B2B buyers, understanding this evolution helps in sourcing high-quality, responsible products that meet modern standards and consumer expectations, ensuring long-term competitiveness in a rapidly changing marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of dance shoes for women

1. How can I effectively vet dance shoe suppliers to ensure quality and reliability?

To vet international suppliers effectively, start by requesting detailed company credentials, including business licenses, manufacturing certifications (e.g., ISO, CE), and quality assurance policies. Review their product samples for craftsmanship, materials, and comfort standards. Check references or client testimonials, especially from buyers in similar markets. Conduct virtual factory audits or third-party inspections if possible. Additionally, verify their compliance with relevant safety and environmental standards. Partnering with suppliers who are transparent about their processes and have a proven track record reduces risks and ensures consistent product quality.

2. What customization options are typically available for dance shoes, and how do they impact lead times and costs?

Most suppliers offer customization in areas such as color, material, sole type, heel height, and branding (e.g., logo placement). Some may also customize fit features or add specific embellishments. Customization usually increases lead times by 2-4 weeks, depending on complexity, and can add 10-30% to unit costs. To optimize costs and timelines, clearly define your specifications early and consider minimum order quantities for customized products. Establishing a strong communication channel with the supplier ensures alignment on designs and reduces the risk of delays or costly revisions.

3. What are typical MOQs, lead times, and payment terms for bulk dance shoe orders?

MOQ requirements vary widely but generally range from 200 to 1,000 pairs for new suppliers, with established manufacturers sometimes accepting smaller orders for trial runs. Lead times typically span 4-12 weeks, depending on order volume and customization complexity. Payment terms often include a 30% upfront deposit with the balance payable before shipment or upon arrival. Some suppliers may offer letters of credit or trade finance options for large orders. Negotiating flexible payment terms and clear delivery schedules upfront helps mitigate risks and aligns cash flow with your sales cycle.

4. How can I verify that suppliers meet international safety and quality standards?

Request certification documents such as ISO 9001, CE, or other relevant safety standards specific to footwear. Ask for detailed QA reports, including material safety, durability testing, and compliance with environmental regulations like REACH or CPSIA. Consider third-party testing or audits for confirmation. Additionally, review supplier warranties or after-sales support policies. Building relationships with suppliers who proactively provide certifications and testing results demonstrates their commitment to quality and compliance, reducing the risk of non-conformance in your target markets.

5. What are the best logistics strategies for importing dance shoes into different regions, such as Africa, South America, or Europe?

Partner with freight forwarders experienced in international trade, focusing on options like sea freight for cost efficiency or air freight for speed. Consolidate shipments to reduce costs and consider port-to-door delivery services for convenience. Understand customs procedures and import duties specific to each country—working with local customs brokers can streamline clearance. For regions with complex logistics, explore local warehousing or distribution centers to shorten delivery times. Establish clear communication channels with logistics providers to monitor shipments and address delays proactively.

6. How should I handle disputes or quality issues with international suppliers?

Establish clear contractual clauses covering quality standards, inspection rights, and dispute resolution processes before placing orders. If issues arise, document problems thoroughly with photos and detailed descriptions. Engage in direct communication with the supplier to seek a resolution, such as replacements or refunds. If informal resolution fails, consider arbitration or mediation through recognized trade organizations or local chambers of commerce. Building a relationship based on transparency and mutual respect can prevent conflicts. Having a solid legal framework and backup suppliers mitigates risks and ensures continuity.

7. How can I ensure consistent product quality across large or ongoing orders?

Implement a multi-tiered quality control process, including pre-production samples approval, in-process inspections, and final quality checks before shipment. Collaborate with third-party inspection agencies for unbiased assessments. Establish detailed quality specifications and communicate them clearly to suppliers. Consider periodic audits of manufacturing facilities, especially for long-term partnerships. Building a strong, transparent relationship with your supplier encourages adherence to quality standards. Additionally, maintaining open feedback loops and continuous improvement initiatives helps sustain consistent product excellence over time.

Illustrative Image (Source: Google Search)

8. What factors should I consider when selecting a supplier to ensure long-term partnership success?

Prioritize suppliers with proven experience in dance footwear, strong certifications, and positive international references. Assess their capacity to scale with your business, including production flexibility and lead time reliability. Consider their responsiveness, communication clarity, and willingness to customize. Evaluate their financial stability and commitment to compliance with safety standards. Long-term relationships are built on trust, consistent quality, and mutual growth; therefore, choose partners who demonstrate transparency, proactive problem-solving, and a collaborative mindset. Regular performance reviews and open dialogue foster sustainable partnerships that support your market expansion efforts.

Strategic Sourcing Conclusion and Outlook for dance shoes for women

Conclusion and Future Outlook

Effective strategic sourcing is crucial for international buyers seeking high-quality dance shoes for women, especially in dynamic markets across Africa, South America, the Middle East, and Europe. By diversifying sourcing channels, prioritizing supplier reliability, and emphasizing quality standards, buyers can mitigate risks and secure competitive pricing. Embracing local manufacturing opportunities and leveraging trade agreements can further optimize supply chain efficiencies and reduce lead times.

Looking ahead, the global dance footwear market is poised for continued growth driven by increasing demand for specialized, fashionable, and performance-oriented products. Buyers who adopt a proactive, data-driven approach to sourcing—focusing on innovation, sustainability, and supplier partnerships—will be better positioned to capitalize on emerging opportunities.

International B2B buyers from regions such as Nigeria, Thailand, and other emerging markets should prioritize building resilient supply chains that adapt to evolving consumer preferences and regulatory environments. By doing so, they can enhance their market competitiveness and foster long-term success in the vibrant dance footwear industry. Now is the time to refine sourcing strategies and forge strategic alliances that drive sustainable growth.