Your Ultimate Guide to Sourcing Daniel Green Shoes

Guide to Daniel Green Shoes

- Introduction: Navigating the Global Market for daniel green shoes

- Understanding daniel green shoes Types and Variations

- Key Industrial Applications of daniel green shoes

- Strategic Material Selection Guide for daniel green shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for daniel green shoes

- Comprehensive Cost and Pricing Analysis for daniel green shoes Sourcing

- Spotlight on Potential daniel green shoes Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for daniel green shoes

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the daniel green shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of daniel green shoes

- Strategic Sourcing Conclusion and Outlook for daniel green shoes

Introduction: Navigating the Global Market for daniel green shoes

In today’s highly interconnected global marketplace, sourcing high-quality footwear such as Daniel Green shoes requires strategic insight and precise decision-making. For international B2B buyers from regions like Africa, South America, the Middle East, and Europe—particularly countries such as Germany and Colombia—understanding the nuances of this niche brand is essential to competitive success. Daniel Green’s reputation for comfort, craftsmanship, and style makes it a sought-after product category, but navigating its supply chain, quality standards, and market dynamics can be complex.

This comprehensive guide is designed to empower you with critical knowledge—covering product varieties, materials, manufacturing processes, quality control measures, and supplier landscapes. By understanding these key factors, you can optimize sourcing strategies, negotiate better terms, and mitigate risks associated with cross-border procurement. Additionally, the guide explores cost considerations, market demand trends, and frequently asked questions, providing a holistic view that supports informed decision-making.

Whether you are expanding your product portfolio or entering new markets, mastering the intricacies of Daniel Green shoes will position you for sustainable growth. This resource aims to equip B2B buyers with actionable insights, ensuring they can confidently navigate the complexities of global sourcing and establish reliable, cost-effective partnerships across continents.

Understanding daniel green shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Leather Dress Shoes | Elegant, high-quality leather construction with minimal embellishments | Formal business attire, luxury retail outlets | Pros: High-end appeal, durable, suitable for premium markets. Cons: Higher procurement cost, limited casual versatility. |

| Casual Sneakers | Comfort-focused, lightweight materials, often with flexible soles | Casual wear, promotional merchandise, retail chains | Pros: Broad consumer appeal, high turnover. Cons: Less formal, may require frequent replacement in high-use scenarios. |

| Work & Safety Shoes | Reinforced toe caps, slip-resistant soles, durable materials | Industrial, construction, logistics sectors | Pros: Safety compliance, durability. Cons: Heavier, higher initial investment, may require specialized certifications. |

| Sustainable & Eco-friendly Shoes | Made with recycled or organic materials, eco-conscious design | Niche markets, eco-brands, corporate social responsibility initiatives | Pros: Growing demand, aligns with sustainability goals. Cons: Potentially higher costs, limited supply chain options. |

| Fashion-forward & Trendy Shoes | Innovative designs, limited editions, seasonal collections | Boutique retailers, fashion events, online boutiques | Pros: High margins, brand prestige. Cons: Fast fashion cycle, inventory risk, requires agile supply chain management. |

Characteristics, Suitability, and B2B Purchasing Considerations

Classic Leather Dress Shoes are the cornerstone of formal footwear, characterized by premium leather, refined craftsmanship, and timeless designs. They are highly suitable for B2B buyers targeting luxury retailers, corporate uniform suppliers, or government procurement programs. When sourcing, buyers should prioritize quality certifications, reliable supply chains, and consistency in craftsmanship to meet high-end standards. Bulk purchasing can reduce unit costs, but careful quality control is essential to uphold brand reputation.

Casual Sneakers emphasize comfort and versatility, often featuring lightweight, flexible materials such as mesh or synthetic fabrics. These are ideal for mass-market retail chains, promotional campaigns, or sportswear distributors. B2B buyers should evaluate supplier capabilities for large volume production, delivery lead times, and the ability to customize designs or branding. Given their popularity, maintaining a steady supply chain is critical to meet high consumer demand and avoid stockouts.

Work & Safety Shoes are designed with durability, safety features, and compliance in mind, including reinforced toes and slip-resistant soles. They are primarily suited for industrial sectors, construction companies, and logistics providers. When sourcing, buyers must verify safety certifications, material durability, and supplier compliance with regional safety standards. Volume discounts and long-term supply agreements can improve margins, but quality consistency and timely delivery are paramount.

Sustainable & Eco-friendly Shoes cater to the rising demand for environmentally responsible products. Made from recycled, organic, or biodegradable materials, they appeal to eco-conscious brands and corporate social responsibility initiatives. B2B buyers should assess suppliers’ sustainability credentials, material sourcing transparency, and ability to meet eco-certifications. While costs may be higher, positioning as a sustainable supplier can open new market segments and enhance brand reputation.

Fashion-forward & Trendy Shoes are characterized by innovative designs, seasonal collections, and limited editions. They are suitable for boutique retailers, online fashion platforms, and brands aiming to capture trend-conscious consumers. Buyers should focus on agility in production, quick turnaround times, and maintaining strong relationships with designers or trend forecasters. Managing inventory risk and ensuring rapid supply chain responsiveness are key to capitalizing on fashion cycles.

By understanding these variations, B2B buyers across Africa, South America, the Middle East, and Europe can make informed decisions aligned with their market needs, procurement strategies, and customer preferences.

Key Industrial Applications of daniel green shoes

| Industry/Sector | Specific Application of daniel green shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive & Manufacturing | Protective footwear for assembly line workers | Ensures safety compliance, reduces workplace injuries, boosts productivity | Certification standards (EN, ASTM), durability, comfort, supply chain reliability |

| Construction & Infrastructure | Heavy-duty safety shoes for construction sites | Protects against impacts, punctures, and slips; enhances worker safety | Material quality, slip resistance, compliance with regional safety standards |

| Agriculture & Forestry | Durable footwear for fieldwork and equipment handling | Provides waterproofing, stability, and abrasion resistance; supports long shifts | Weather resistance, comfort for extended wear, sourcing from sustainable suppliers |

| Logistics & Warehousing | Slip-resistant shoes for warehouse staff | Minimizes fall risks, enhances operational efficiency, reduces liability | Anti-slip sole technology, ergonomic design, consistent supply availability |

| Healthcare & Cleanroom | Antistatic and hygienic footwear | Prevents static buildup, maintains hygiene standards, reduces contamination risk | Antistatic properties, ease of cleaning, compliance with health safety standards |

Automotive & Manufacturing

In the automotive and manufacturing sectors, daniel green shoes are widely used as protective footwear for assembly line workers and technicians. These shoes are designed to meet strict safety standards, offering impact protection and slip resistance, which are essential in environments with heavy machinery and moving parts. For international B2B buyers from regions like Europe and South America, sourcing shoes that comply with regional safety certifications (such as EN or ASTM standards) ensures legal compliance and workforce safety. Durable, comfortable shoes also help reduce worker fatigue, boosting productivity and lowering injury-related costs.

Construction & Infrastructure

Construction sites demand footwear that can withstand harsh conditions, including rough terrains, heavy debris, and exposure to weather elements. daniel green shoes tailored for construction provide puncture resistance, slip resistance, and impact absorption, critical for worker safety. For buyers in Africa, the Middle East, and Europe, sourcing construction shoes with high-quality materials and regional safety certifications ensures compliance with local regulations and enhances worker safety. The durability and comfort of these shoes support long shifts and demanding environments, reducing replacement costs and downtime.

Agriculture & Forestry

Agricultural and forestry operations require footwear capable of handling rugged outdoor conditions, including mud, water, and uneven terrain. daniel green shoes used in these sectors are designed with waterproofing, abrasion resistance, and ergonomic support, enabling workers to perform effectively over extended periods. For B2B buyers in South America and Africa, sourcing sustainable, weather-resistant shoes that meet regional safety standards ensures operational efficiency and worker well-being. Reliable supply chains and quality assurance are critical to avoid disruptions during peak seasons.

Logistics & Warehousing

In logistics and warehousing, slip-resistant footwear is vital to prevent workplace accidents and ensure smooth operations. daniel green shoes with advanced anti-slip soles help minimize fall risks, which are common in environments with spills or uneven surfaces. For European and Middle Eastern buyers, selecting shoes that combine safety, comfort, and ergonomic design can reduce injury-related costs and improve worker morale. Consistent availability and compliance with regional safety standards are key sourcing considerations for maintaining operational continuity.

Healthcare & Cleanroom

Healthcare and cleanroom environments require footwear that prevents static buildup, maintains hygiene, and reduces contamination risks. daniel green shoes designed for these sectors incorporate antistatic properties and are easy to clean, aligning with stringent health and safety regulations in Europe and Latin America. For international B2B buyers, sourcing certified hygienic footwear that meets local standards ensures compliance and protects staff and patients. Reliable supply and quality assurance are essential to support ongoing health safety protocols.

This comprehensive overview highlights how daniel green shoes serve critical roles across diverse industries, emphasizing the importance of regional standards, material quality, and supply chain reliability for international B2B buyers.

Strategic Material Selection Guide for daniel green shoes

Analysis of Common Materials for Daniel Green Shoes

Selecting the appropriate materials for Daniel Green shoes is crucial for ensuring product quality, durability, and compliance with international standards. Different markets—particularly Africa, South America, the Middle East, and Europe—have specific requirements and preferences that influence material choice. Here, we analyze four common materials used in shoe manufacturing, focusing on their properties, advantages, limitations, and considerations for international B2B buyers.

Leather (Full-Grain, Top-Grain, and Corrected)

Key Properties:

Leather remains a traditional and highly valued material in high-quality footwear. It offers excellent breathability, flexibility, and aesthetic appeal. Depending on the grade, it can also provide good resistance to wear and environmental factors.

Pros & Cons:

– Pros: Durable, breathable, develops a desirable patina over time, aligns with luxury branding, and meets many international standards such as ASTM and DIN.

– Cons: Costly, labor-intensive manufacturing process, susceptible to water damage if untreated, and requires maintenance. Variability in quality depending on sourcing.

Impact on Application:

Leather’s permeability makes it suitable for indoor and moderate outdoor environments but less ideal for extremely wet or humid conditions unless treated. It is favored in markets like Europe and parts of South America where premium quality is preferred.

International Buyer Considerations:

Buyers from Africa and the Middle East should ensure leather is properly tanned and treated for moisture resistance. Compliance with environmental standards (e.g., REACH in Europe, local regulations in Colombia) is critical. Sourcing from certified tanneries can enhance product credibility.

Synthetic Materials (Polyurethane and PVC)

Key Properties:

Synthetic materials are engineered to mimic leather or other natural materials. They are lightweight, water-resistant, and can be produced with consistent quality.

Pros & Cons:

– Pros: Cost-effective, easy to manufacture, resistant to water and environmental damage, and available in a wide variety of colors and finishes.

– Cons: Less breathable, may degrade faster under UV exposure, and can feel less premium. Environmental concerns related to non-biodegradable waste.

Impact on Application:

Ideal for casual, outdoor, or workwear shoes, especially in regions with high humidity or frequent exposure to water. Their resistance to environmental factors makes them suitable for markets like Africa and the Middle East.

International Buyer Considerations:

Buyers should verify compliance with local environmental regulations, such as European REACH or South American standards. Preference for eco-friendly or recyclable synthetics can be a selling point. Cost considerations are significant, especially for large-volume orders.

Rubber and EVA (Ethylene Vinyl Acetate)

Key Properties:

Rubber and EVA are primarily used for soles and midsoles due to their shock absorption, flexibility, and waterproof qualities.

Pros & Cons:

– Pros: Excellent durability, slip resistance, and impact absorption. EVA is lightweight and comfortable.

– Cons: Rubber can be heavy and less flexible; EVA may degrade over time with exposure to UV and extreme temperatures.

Impact on Application:

Crucial for outsole construction, impacting safety and comfort. Rubber soles are preferred in outdoor and rugged environments, while EVA is common in casual or indoor shoes.

International Buyer Considerations:

Buyers should ensure material certifications for slip resistance and environmental safety. Compatibility with regional climate conditions is vital; for example, rubber soles perform well in hot climates, but EVA may soften in high temperatures.

Textile and Mesh Fabrics

Key Properties:

Textile materials are used for uppers, linings, and decorative elements. They offer breathability and flexibility.

Pros & Cons:

– Pros: Lightweight, breathable, and versatile in design. Can incorporate moisture-wicking properties.

– Cons: Less durable than leather or synthetics, susceptible to tearing, and may require additional treatments for water resistance.

Impact on Application:

Ideal for sports, casual, and summer footwear, especially in warmer climates. They are increasingly popular in European and South American markets due to comfort and style.

International Buyer Considerations:

Buyers should check for compliance with textile safety standards, such as OEKO-TEX or local certifications. Durability and maintenance instructions should be clear to end-users, especially in regions with high humidity or rough terrain.

Summary Table

| Material | Typical Use Case for Daniel Green Shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather (Full/Top/Corr.) | Formal, luxury, or premium casual footwear | Durable, breathable, premium appearance | High cost, maintenance required, environmental concerns | High |

| Synthetic (PU, PVC) | Casual, outdoor, or water-resistant shoes | Cost-effective, water-resistant, consistent quality | Less breathable, environmental impact, lower perceived value | Med |

| Rubber/EVA | Outsoles and midsoles for impact absorption and slip resistance | Excellent durability, shock absorption, lightweight | Rubber can be heavy, EVA degrades over time | Low to Med |

| Textile and Mesh | Uppers, linings, decorative elements | Lightweight, breathable, versatile | Less durable, water susceptibility | Low |

This strategic material analysis enables B2B buyers from diverse regions to make informed decisions aligned with their target markets, environmental standards, and cost structures. Prioritizing certified, environmentally compliant materials can also enhance brand reputation and ensure smoother international trade operations.

In-depth Look: Manufacturing Processes and Quality Assurance for daniel green shoes

Manufacturing Processes in the Production of Daniel Green Shoes

The manufacturing of Daniel Green shoes follows a structured, multi-stage process designed to ensure durability, comfort, and aesthetic appeal, aligned with international standards. For B2B buyers, understanding these stages helps in assessing supplier capabilities and quality consistency.

Material Preparation

The process begins with sourcing high-quality raw materials such as genuine leather, synthetic fabrics, and specialized insoles. Suppliers typically source these materials from reputable vendors who adhere to environmental and safety standards, especially when targeting European or Middle Eastern markets. Material inspection at this stage involves checking for defects, consistency in thickness, and compliance with standards like REACH or OEKO-TEX, which are critical for European buyers.

Forming and Cutting

Next, the raw materials are cut into various components using computer-controlled cutting machines. This precision ensures minimal waste and consistent sizing, which is vital for quality control. Techniques such as laser cutting or die-cutting are common, offering high accuracy and repeatability. For B2B buyers, verifying the calibration and maintenance records of these machines can be indicative of consistent quality.

Assembly and Stitching

The cut components are then assembled, often through a combination of manual stitching and automated sewing lines. Skilled artisans may be involved in intricate detailing, especially for premium lines. Key assembly techniques include welt construction, cementing, and sometimes vulcanization for specific sole attachments. Suppliers adhering to ISO 9001 standards typically implement standardized work procedures to ensure uniformity across batches.

Finishing and Quality Control

The final stages involve polishing, dyeing, applying protective coatings, and attaching hardware such as buckles or zippers. Finishing touches are crucial for aesthetic appeal and product longevity. At this stage, quality assurance checks are intensified, focusing on surface defects, color consistency, and proper attachment of components.

Quality Assurance (QA) and Control in Shoe Manufacturing

Effective QA is fundamental to delivering reliable, compliant products. Daniel Green shoes manufacturers often adopt internationally recognized standards, complemented by industry-specific certifications, to meet diverse market requirements.

International and Industry Standards

- ISO 9001: Most reputable manufacturers hold ISO 9001 certification, demonstrating a commitment to quality management systems. This includes documented procedures for production, inspection, and corrective actions.

- European CE Marking: For shoes sold within the European Economic Area, compliance with CE standards ensures safety, chemical safety, and environmental considerations.

- Other Certifications: Depending on the market, certifications like API (American Petroleum Institute) for specific manufacturing aspects or environmental certifications such as ISO 14001 may be relevant.

Quality Control Checkpoints

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival for defects, compliance with specifications, and safety standards. B2B buyers should request detailed IQC reports and supplier quality certifications.

- In-Process Quality Control (IPQC): Throughout manufacturing, checkpoints ensure each stage maintains quality standards. Techniques include visual inspections, dimensional checks, and mechanical testing.

- Final Quality Control (FQC): Before packaging, finished shoes undergo comprehensive inspections for defects, color matching, and structural integrity. Random sampling and statistical process control (SPC) are common methods.

Testing and Inspection Methods

- Visual and Dimensional Inspection: Ensures visual appeal, uniformity, and correct sizing.

- Durability Tests: Includes flex testing, abrasion testing, and adhesion tests for soles and overlays.

- Chemical Safety Testing: Verifies absence of harmful substances, aligning with REACH, CPSIA, or other chemical safety standards.

- Comfort and Fit Testing: Some manufacturers perform ergonomic assessments or wearer trials to ensure comfort standards.

How B2B Buyers Can Verify and Ensure Quality

For international buyers, especially from Africa, South America, the Middle East, and Europe, verifying supplier quality involves multiple strategies:

- Supplier Audits: Conduct on-site audits or hire third-party inspection firms to evaluate manufacturing practices, equipment maintenance, cleanliness, and worker conditions. Audits should include review of quality management systems and documentation.

- Inspection Reports: Request detailed inspection reports, including test results, defect rates, and compliance certificates. These reports should be recent and verifiable.

- Third-party Inspection Services: Utilize certified inspection agencies (e.g., SGS, Bureau Veritas, Intertek) to conduct pre-shipment inspections, ensuring the product matches specifications and quality standards.

- Sample Verification: Before large orders, request product samples for independent testing and assessment against contractual quality parameters.

- Factory Certifications: Confirm the authenticity and validity of certifications like ISO 9001, CE, and other relevant standards through certification bodies.

Special Considerations for International B2B Buyers

Buyers from different regions should account for specific nuances:

- European Buyers: Emphasize chemical safety (REACH compliance), environmental sustainability, and adherence to strict CE marking requirements. Transparency in chemical testing and environmental policies enhances trust.

- African and South American Buyers: Focus on durability and suitability for local climates (e.g., heat, humidity). Verify that manufacturing facilities adhere to fair labor practices and export compliance, which can influence customs clearance.

- Middle Eastern Buyers: Prioritize heat-resistant and water-resistant features, and ensure that certifications meet regional standards. Close attention to packaging and labeling requirements is also critical.

Conclusion

For B2B buyers, understanding the manufacturing and quality assurance processes of Daniel Green shoes provides a foundation for assessing supplier reliability and product consistency. Emphasizing rigorous supplier audits, documentation review, and third-party testing can mitigate risks and ensure compliance across diverse international markets. Tailoring verification strategies to regional requirements further enhances trust and fosters long-term supplier relationships.

Comprehensive Cost and Pricing Analysis for daniel green shoes Sourcing

Cost Structure Breakdown for Daniel Green Shoes

Understanding the comprehensive cost structure is essential for international B2B buyers aiming to optimize procurement strategies. The primary cost components include:

-

Materials: The quality of upper fabrics, insoles, outsoles, and linings significantly influences costs. High-performance or eco-friendly materials typically command premium prices. For Daniel Green shoes, mid-range to premium materials are common, impacting the overall material expenditure.

-

Labor: Manufacturing costs vary based on the country of production. Countries like China, Vietnam, and Indonesia tend to offer lower labor costs, whereas sourcing from suppliers in Eastern Europe or North Africa may involve higher wages but potentially better quality control.

-

Manufacturing Overhead: This includes factory utilities, machinery depreciation, and workforce management. Efficient factories with high automation levels can reduce overhead costs, translating to more competitive pricing.

-

Tooling & Development: Initial tooling and design customization involve upfront costs. For standard models, these are amortized over large production runs, reducing per-unit costs. Customized or limited-edition shoes will incur higher tooling expenses.

-

Quality Control & Certifications: Ensuring product consistency and compliance with international standards (e.g., REACH, ISO) can add to costs but are vital for market access, especially in Europe and the Middle East.

-

Logistics & Shipping: Shipping costs depend on order volume, destination, and chosen Incoterms. Larger orders benefit from economies of scale, reducing per-unit logistics expenses. Air freight offers speed but at higher costs, while sea freight is more economical for bulk shipments.

-

Profit Margin: Suppliers typically target a gross margin of 20-30%, but this varies based on order size, relationship, and market conditions.

Price Influencers and Their Impact

Several factors influence the final price, which B2B buyers must consider:

-

Order Volume & MOQ: Higher volumes and larger MOQs usually lead to lower unit prices due to economies of scale. Buyers from Africa and South America should negotiate for favorable MOQ terms to balance costs and inventory risks.

-

Specifications & Customization: Custom colors, designs, or branding increase costs due to additional tooling and setup. Standard models are more cost-effective for bulk purchases.

-

Material Selection: Premium or sustainable materials increase costs but can justify higher retail pricing and appeal to niche markets.

-

Quality & Certifications: Higher quality standards and certifications (e.g., eco-labels, safety standards) may add to costs but can open premium market segments.

-

Supplier Factors: Supplier reputation, reliability, and proximity influence pricing. Well-established suppliers may charge higher but offer better quality assurance and consistency.

-

Incoterms & Delivery Terms: FOB (Free on Board) or CIF (Cost, Insurance, Freight) terms impact total landed costs. Buyers should evaluate shipping options and insurance costs when comparing quotes.

Strategic Tips for International Buyers

-

Negotiate for Better Terms: Leverage large orders or long-term relationships to negotiate discounts, reduced MOQs, or flexible payment terms. Transparent communication about your projected order volume can unlock better pricing.

-

Focus on Total Cost of Ownership (TCO): Consider not just unit price but also shipping, customs duties, taxes, and potential rework costs. For example, sourcing from Europe may entail higher product costs but lower logistics expenses and faster delivery, reducing inventory holding costs.

-

Pricing Nuances: Be aware of hidden costs such as currency fluctuations, import duties, and compliance costs. Establish clear agreements on pricing and delivery schedules upfront.

-

Market-Specific Adjustments: Buyers from Africa and South America should factor in regional import tariffs and local taxes that can significantly affect landed costs. European and Middle Eastern buyers should verify compliance with local standards to avoid costly rejections.

Indicative Price Ranges (Disclaimers Apply)

While actual prices vary widely depending on specifications, order size, and supplier negotiations, approximate FOB prices for Daniel Green shoes range from $15 to $30 per pair for standard models produced in Asia. Customization and higher-end materials can push costs above $35 per pair. European or North African suppliers might charge slightly higher due to labor and overhead costs but can offer advantages in lead times and quality control.

In summary, successful sourcing of Daniel Green shoes requires a detailed understanding of the cost components, proactive negotiation, and strategic consideration of total landed costs. Tailoring your approach based on regional specifics and market demands will position your business for competitive advantage in the global footwear landscape.

Spotlight on Potential daniel green shoes Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for daniel green shoes.)*

Essential Technical Properties and Trade Terminology for daniel green shoes

Critical Technical Properties of Daniel Green Shoes

1. Material Grade and Composition

The quality of raw materials used in manufacturing Daniel Green shoes significantly impacts durability, comfort, and perceived value. Common upper materials include genuine leather, synthetic leather, or fabric blends, each with varying grades. High-grade materials typically meet industry standards for flexibility, breathability, and resistance to wear. For B2B buyers, verifying material certifications (e.g., leather grades or eco-labels) ensures product consistency and aligns with regional preferences or regulations.

2. Sole Composition and Flexibility

The outsole material, often rubber or thermoplastic polyurethane (TPU), determines slip resistance, shock absorption, and longevity. Precise specifications regarding sole thickness and tread pattern are vital for performance expectations. Flexible soles enhance comfort, especially for dress shoes, while rigid soles may be preferred for formal settings. Understanding these technical details helps buyers select products suited to their target markets.

3. Tolerance and Size Precision

Manufacturing tolerances refer to acceptable deviations in dimensions such as length, width, and heel height. Tight tolerances (e.g., ±1 mm) are essential for ensuring consistent fit, reducing returns, and enhancing customer satisfaction across diverse markets. Buyers should specify tolerances aligned with regional sizing standards and customer expectations.

4. Stitching and Finish Quality

The stitch density and finishing details reflect manufacturing quality and influence durability. High stitch counts prevent seam splitting, especially in high-stress areas. Precise finishing, such as polished edges and clean seams, not only improve aesthetics but also extend product lifespan. Inspection standards should be clearly communicated to ensure supplier adherence.

5. Color Fastness and Material Treatments

Color fastness—resistance to fading or bleeding—is crucial for maintaining aesthetic appeal over time. Additionally, treatments like water-repellent coatings or anti-odor finishes can add value in specific climates. These technical properties impact product longevity and customer satisfaction, especially in regions with varying weather conditions.

6. Compliance with Regional Standards

Manufacturers should meet regional safety and environmental standards, such as REACH (Europe), ASTM (North America), or local certifications in Africa and South America. Compliance ensures market access and reduces legal risks, making it a critical consideration for international B2B transactions.

Essential Industry and Trade Terms

1. OEM (Original Equipment Manufacturer)

Refers to companies that produce shoes based on the buyer’s specifications and branding. Understanding OEM relationships helps buyers negotiate customization, private labeling, and branding rights, which are common in international markets.

2. MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to produce per order. Recognizing MOQ helps buyers plan inventory levels and negotiate better terms, especially when entering new markets or testing product acceptance.

3. RFQ (Request for Quotation)

A formal document sent by buyers to suppliers requesting price, lead times, and technical details for specific products. An RFQ is essential for comparing suppliers and ensuring transparency in pricing and specifications across different regions.

4. Incoterms (International Commercial Terms)

Standardized trade terms published by the International Chamber of Commerce that define responsibilities for shipping, insurance, and customs clearance. Familiarity with Incoterms (e.g., FOB, CIF) helps international buyers clarify costs and risk allocation, ensuring smoother logistics.

5. Lead Time

The duration from order placement to product shipment. Accurate knowledge of lead times is vital for planning inventory and aligning production schedules, especially when managing supply chains across continents.

6. Quality Assurance (QA) and Inspection

Refers to the processes and standards used to verify product quality before shipment. Implementing QA protocols reduces the risk of receiving defective goods, a critical factor for maintaining brand reputation in diverse markets.

By mastering these technical properties and trade terms, international B2B buyers from Africa, South America, the Middle East, and Europe can make informed purchasing decisions, negotiate effectively, and establish reliable supply chains for Daniel Green shoes.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the daniel green shoes Sector

Market Overview & Key Trends

The global footwear industry is experiencing dynamic shifts driven by technological innovation, changing consumer preferences, and sustainability imperatives. For B2B buyers sourcing from Daniel Green Shoes, understanding these drivers is essential to capitalize on emerging opportunities and mitigate risks.

A significant trend is the digital transformation within supply chains, including the adoption of advanced manufacturing technologies like 3D printing, automation, and AI-driven inventory management. These innovations enhance production efficiency and enable more agile response to market demands, which is crucial for international buyers aiming for shorter lead times and customized offerings.

Emerging sourcing trends include increased reliance on nearshoring and regional supply hubs, especially in Europe and South America, to reduce logistics costs and environmental impact. For African and Middle Eastern buyers, leveraging local or regional manufacturing partnerships can offer cost advantages and faster turnaround times, while also aligning with regional economic development goals.

Market dynamics are influenced by fluctuating raw material costs, especially for eco-friendly leathers, recycled materials, and sustainable synthetics. Buyers from Germany and Colombia are increasingly prioritizing suppliers who demonstrate transparency and innovation in sourcing sustainable materials. Additionally, a shift toward omnichannel retailing and direct-to-consumer models impacts B2B sourcing strategies, requiring suppliers to be flexible and tech-savvy.

Global trade policies, tariffs, and geopolitical factors also shape sourcing decisions, especially for European buyers navigating post-Brexit trade complexities or Latin American buyers seeking preferential trade agreements. Staying informed about these dynamics ensures strategic positioning and risk mitigation in sourcing partnerships.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a cornerstone of strategic sourcing in the footwear sector, including Daniel Green Shoes. B2B buyers are increasingly scrutinizing suppliers for their environmental impact, ethical labor practices, and adherence to international standards. Incorporating sustainability not only aligns with corporate social responsibility goals but also appeals to increasingly eco-conscious consumers.

Environmental impact reduction involves sourcing renewable or recycled materials, minimizing water and energy consumption during manufacturing, and implementing waste reduction practices. Certified sustainable leather, such as those bearing the Leather Working Group (LWG) certification, is gaining prominence, ensuring traceability and environmentally responsible tanning processes. Additionally, innovative materials like plant-based leathers and bio-based synthetics are gaining traction as greener alternatives.

Ethical sourcing extends beyond environmental concerns to labor practices and fair wages. B2B buyers should prioritize partnerships with suppliers that demonstrate compliance with international labor standards, such as SA8000 or Fair Trade certifications. Transparency in supply chains is critical; blockchain and digital traceability tools are increasingly used to verify sourcing integrity.

Adopting ‘green’ certifications and standards can serve as a competitive advantage. For European buyers, certification schemes such as GOTS (Global Organic Textile Standard) or B Corp certification can bolster credibility. For buyers in Africa, South America, and the Middle East, establishing relationships with suppliers committed to continuous sustainability improvements can foster long-term resilience and brand reputation.

Brief Evolution/History

The footwear sector, including brands like Daniel Green Shoes, has evolved from traditional craftsmanship to a highly innovative and sustainability-driven industry. Historically reliant on labor-intensive processes, the sector has shifted toward automation, digital design, and sustainable materials over the past two decades.

This evolution is driven by consumer demand for ethically produced and environmentally friendly products, prompting brands and suppliers to innovate supply chains and manufacturing practices. For B2B buyers, understanding this history highlights the importance of partnering with suppliers committed to continuous improvement and adaptability in a rapidly changing landscape.

By integrating technological advancements and sustainability principles, the industry is moving toward a more resilient and responsible future. This context is vital for international buyers seeking reliable, forward-looking partners who can meet both current market demands and future regulatory standards.

Frequently Asked Questions (FAQs) for B2B Buyers of daniel green shoes

1. How can I verify the credibility and reliability of a Daniel Green Shoes supplier?

To ensure supplier credibility, conduct thorough due diligence by reviewing their business licenses, certifications, and industry reputation. Request references from other international buyers, and examine their experience in exporting to your region. Utilize third-party verification services or trade associations for background checks. Additionally, assess their online presence, website professionalism, and responsiveness. Visiting supplier facilities or engaging in video audits can further confirm operational capabilities. Reliable suppliers will willingly provide documentation such as ISO certifications, quality assurance reports, and export licenses, reducing the risk of fraud or substandard products.

2. What are the options for customizing Daniel Green Shoes for my market, and how do I initiate the process?

Daniel Green Shoes often offer customization options including branding (logos), color schemes, materials, and packaging. To start, communicate your specific needs clearly and request samples or prototypes. Discuss minimum order quantities (MOQs) associated with customization, lead times, and costs upfront. Work closely with the supplier’s design and production teams to ensure your specifications are feasible. Establish clear timelines and quality standards in your contract. Many suppliers are flexible with customization if you meet their MOQ requirements, enabling you to differentiate your offerings in local markets.

3. What are typical minimum order quantities, lead times, and payment terms for international bulk purchases?

MOQ and lead times vary depending on the supplier and product complexity but generally range from 500 to 2,000 pairs for standard styles. Lead times typically span 4 to 8 weeks from order confirmation to shipment, depending on production capacity and customization requirements. Payment terms often include a 30% deposit upfront with the balance paid before shipment, or letters of credit for larger orders. Negotiate flexible terms that align with your cash flow, and consider establishing a trusted payment process to mitigate risks. Early planning and clear communication are key to meeting your market deadlines.

4. What quality assurance measures and certifications should I expect from Daniel Green Shoes suppliers?

Reputable suppliers should adhere to international quality standards such as ISO 9001, ensuring consistent product quality. Ask for certificates of compliance, safety standards, and environmental certifications (e.g., REACH, OEKO-TEX). Request samples for pre-shipment testing or third-party inspection reports to verify material quality, durability, and finish. Establish quality control procedures in your contract, including inspection at various production stages. Regular audits and third-party inspections can help maintain standards and prevent defects, safeguarding your brand reputation in target markets.

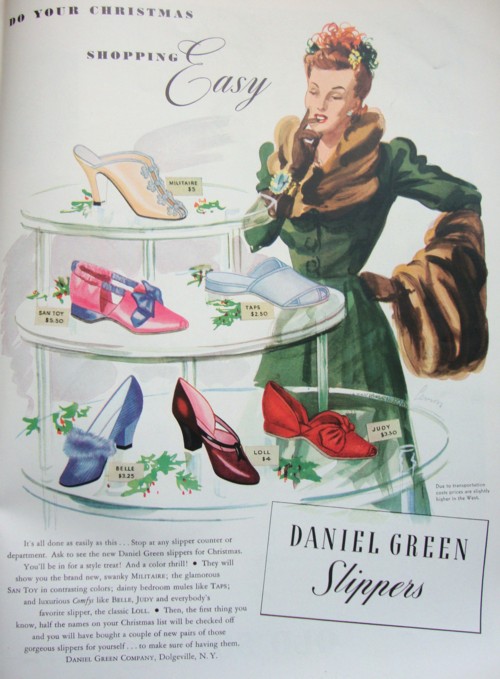

Illustrative Image (Source: Google Search)

5. How do I manage international logistics and customs clearance for shipping Daniel Green Shoes?

Coordinate with experienced freight forwarders familiar with your target markets to optimize shipping routes and costs. Choose reliable carriers offering tracking, insurance, and timely delivery options. Prepare all necessary documentation, including commercial invoices, packing lists, certificates of origin, and any specific certifications required by your country’s customs. Be aware of import duties, VAT, and local regulations to avoid delays or additional costs. Establish clear communication channels with your supplier and logistics partners to handle potential customs issues swiftly, ensuring a smooth supply chain flow.

Illustrative Image (Source: Google Search)

6. What steps should I take if I encounter disputes or quality issues with my order?

Immediately document the issue with detailed photos, descriptions, and inspection reports. Communicate directly with your supplier to seek a resolution, such as replacement, repair, or refund, based on your contractual terms. If negotiations stall, involve third-party mediators or arbitration bodies specializing in international trade disputes. Maintain records of all correspondence, agreements, and inspections to support your case. Building a relationship of transparency and professionalism can facilitate amicable solutions. Establishing clear dispute resolution clauses in your contracts beforehand can streamline future conflict management.

7. How can I ensure compliance with local regulations and standards in my country when importing Daniel Green Shoes?

Familiarize yourself with your country’s import regulations, labeling requirements, and safety standards relevant to footwear. Work with customs brokers or legal advisors experienced in your region’s trade policies. Request compliance documentation from your supplier, such as safety certifications and test reports. Ensure products meet local standards for materials, labeling, and packaging. Regularly monitor regulatory updates to prevent non-compliance issues that could lead to delays or penalties. Proactively aligning your import process with local legal requirements safeguards your investment and maintains smooth market entry.

8. What strategies can I use to build strong, long-term relationships with Daniel Green Shoes suppliers?

Develop clear, transparent communication channels and foster mutual trust through consistent, timely payments and feedback. Start with smaller orders to build confidence and gradually increase volume as the relationship solidifies. Be specific about your quality expectations, delivery schedules, and market needs, and encourage open dialogue. Consider visiting supplier facilities periodically to strengthen rapport and verify operations. Offering long-term commitments or exclusive arrangements can incentivize suppliers to prioritize your business. Maintaining professionalism, cultural sensitivity, and reliability will position you as a preferred partner, ensuring sustained supply and favorable terms.

Strategic Sourcing Conclusion and Outlook for daniel green shoes

Conclusion and Future Outlook

Effective strategic sourcing is essential for international B2B buyers seeking to optimize their supply chains with daniel green shoes. By prioritizing supplier diversity, quality assurance, and cost efficiency, buyers from Africa, South America, the Middle East, and Europe can unlock competitive advantages while mitigating risks. Emphasizing strong supplier relationships and leveraging global sourcing networks will further enhance flexibility and resilience in dynamic markets.

Looking ahead, the footwear industry is poised for continued innovation, sustainability advancements, and digital transformation. B2B buyers should capitalize on emerging trends such as eco-friendly materials and supply chain transparency to meet evolving consumer demands and regulatory standards. Building strategic partnerships with reliable suppliers like daniel green shoes will be crucial in maintaining a competitive edge.

Illustrative Image (Source: Google Search)

Actionable takeaway: Regularly review and adapt your sourcing strategies to align with industry developments and regional market conditions. Proactively engaging with suppliers and leveraging data-driven insights will enable smarter procurement decisions. As global markets evolve, a forward-thinking approach to sourcing will position your business for sustained growth and success.