Your Ultimate Guide to Sourcing Eminem Shoes

Guide to Eminem Shoes

- Introduction: Navigating the Global Market for eminem shoes

- Understanding eminem shoes Types and Variations

- Key Industrial Applications of eminem shoes

- Strategic Material Selection Guide for eminem shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for eminem shoes

- Comprehensive Cost and Pricing Analysis for eminem shoes Sourcing

- Spotlight on Potential eminem shoes Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for eminem shoes

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the eminem shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of eminem shoes

- Strategic Sourcing Conclusion and Outlook for eminem shoes

Introduction: Navigating the Global Market for eminem shoes

In today’s competitive global marketplace, securing authentic and high-quality Eminem shoes presents a significant opportunity for B2B buyers across Africa, South America, the Middle East, and Europe. These shoes, driven by the artist’s influence and brand appeal, have become a sought-after commodity, offering lucrative margins and strong consumer demand. However, navigating the complexities of sourcing—ranging from authentic product identification to supplier reliability—requires strategic insight and thorough market knowledge.

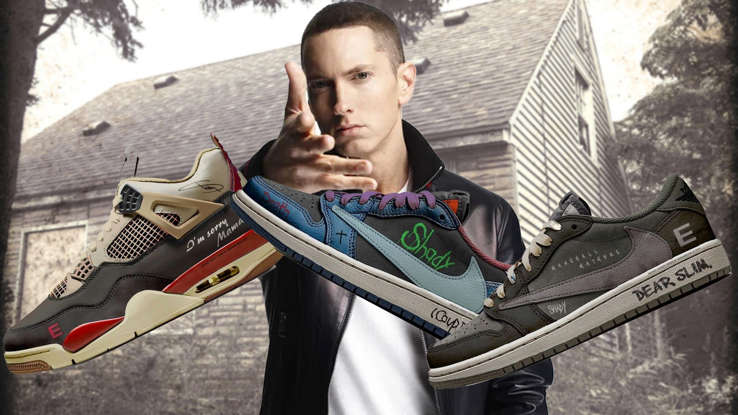

Illustrative Image (Source: Google Search)

This comprehensive guide is designed to empower international buyers with actionable intelligence, covering critical aspects such as product varieties, materials, manufacturing processes, quality control standards, and sourcing channels. It provides clarity on cost structures, potential suppliers, and market trends, enabling you to make informed, risk-mitigated procurement decisions. Whether you are exploring wholesale partnerships in Thailand, sourcing from Argentina, or establishing direct manufacturing contacts in Europe or the Middle East, understanding the nuances of the Eminem shoes market is essential for success.

By leveraging this guide, B2B buyers will gain the confidence to identify legitimate suppliers, negotiate effectively, and capitalize on emerging market opportunities. It aims to streamline your sourcing process, reduce risks associated with counterfeit products, and position your business for sustainable growth in the global footwear industry. In a rapidly evolving landscape, being well-informed is your most valuable asset for strategic international expansion.

Understanding eminem shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Low-Top Sneakers | Traditional design with minimal ankle support, lightweight | Retail, wholesale distribution, sports stores | Pros: High demand, versatile; Cons: Competitive market, price sensitivity |

| High-Top Performance Shoes | Elevated ankle support, specialized cushioning, durable materials | Athletic footwear suppliers, specialty sports retailers | Pros: Niche market, higher margins; Cons: Higher production costs, limited target audience |

| Limited Edition Collaborations | Unique designs, exclusive releases, premium materials | Collector-focused distributors, premium boutiques | Pros: High resale value, brand prestige; Cons: Limited stock, high procurement costs |

| Customizable Models | Modular components, customizable colors/materials | Custom footwear manufacturers, corporate gifting | Pros: Differentiation, higher customer engagement; Cons: Complex inventory management, longer lead times |

| Eco-Friendly Variants | Sustainable materials, eco-conscious manufacturing processes | Green retailers, eco-focused distributors | Pros: Growing consumer demand, brand differentiation; Cons: Higher raw material costs, supply chain complexity |

Classic Low-Top Sneakers

This type features a timeless silhouette with minimal ankle coverage, making it highly versatile and widely appealing. They are ideal for mass-market retail, wholesale distribution, and sports outlets due to their broad consumer base. B2B buyers should consider bulk procurement for cost efficiency and assess demand trends across regions like Africa and South America, where casual and athletic footwear are popular. While these shoes benefit from high turnover, intense market competition and price sensitivity require careful margin management.

High-Top Performance Shoes

Designed with added ankle support and advanced cushioning, these shoes cater to athletes and sports enthusiasts. They are suitable for specialty sports retailers and premium distributors targeting niche markets that demand durability and performance. B2B buyers should evaluate quality standards and supplier reliability, especially when importing to regions with varying import regulations like the Middle East or Europe. Although they command higher margins, production costs are elevated, and market size may be limited compared to low-tops.

Illustrative Image (Source: Google Search)

Limited Edition Collaborations

These shoes feature exclusive designs developed through partnerships with artists, designers, or brands. They are highly sought after by collectors and premium boutiques, offering opportunities for high resale margins. For B2B buyers, securing authentic stock from reputable sources is crucial, as counterfeit risks are prevalent. Limited availability can drive exclusivity and brand prestige but also necessitates careful inventory planning and higher procurement costs, especially when catering to high-end markets in Europe or emerging luxury segments in Africa.

Customizable Models

Offering modular components and personalized options, these shoes appeal to consumers seeking unique products. They are suitable for custom footwear manufacturers and corporate gifting solutions, where personalization enhances customer loyalty. B2B buyers should focus on establishing reliable supply chains for customizable parts and managing longer lead times. The flexibility of these models can provide a competitive edge in markets like South America and the Middle East, where personalized products are increasingly valued.

Eco-Friendly Variants

Made from sustainable materials and produced through eco-conscious processes, these shoes align with the growing global demand for environmentally responsible products. They are ideal for green retailers and distributors targeting eco-aware consumers in Europe, Thailand, or Argentina. B2B buyers should assess supply chain transparency, raw material sourcing, and certification standards. While raw material costs may be higher, marketing eco-friendly credentials can significantly boost brand differentiation and appeal to environmentally conscious markets.

Key Industrial Applications of eminem shoes

| Industry/Sector | Specific Application of eminem shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing & Heavy Industry | Protective footwear for workers in hazardous environments | Enhances worker safety, reduces injury-related costs, and ensures compliance with safety standards | Certification for industrial safety, durability, supply chain reliability |

| Logistics & Warehousing | Slip-resistant, durable shoes for warehouse staff | Improves worker safety, reduces accident-related downtime, boosts productivity | Slip resistance ratings, comfort for long shifts, consistent supply |

| Sports & Recreation | Custom-branded footwear for sports teams or events | Builds brand recognition, enhances team identity, potential revenue stream | Customization options, branding quality, lead times, MOQ requirements |

| Retail & Wholesale Distribution | Bulk supply of trendy, affordable shoes for retail chains | Expands product portfolio, attracts diverse customer segments, increases margins | Competitive pricing, quality assurance, flexible MOQ policies |

| Medical & Healthcare | Specialized shoes for healthcare professionals | Ensures hygiene, comfort, and safety in clinical environments | Compliance with medical standards, antimicrobial features, hygiene certifications |

Manufacturing & Heavy Industry

Eminem shoes serve as essential protective footwear for workers in manufacturing plants, construction sites, and other heavy industries. These shoes are designed to withstand harsh conditions, providing impact resistance, puncture protection, and slip resistance. For international B2B buyers from regions like Africa, South America, or the Middle East, sourcing durable, certified safety shoes ensures compliance with local occupational safety standards, reducing legal liabilities. Reliable supply chains and certifications such as ASTM or EN standards are critical to meet industry requirements and maintain operational continuity.

Logistics & Warehousing

In logistics hubs and warehouses, slip-resistant and durable eminem shoes help minimize workplace accidents, which are common in environments with spilled liquids or uneven surfaces. For European or Asian buyers, investing in high-quality, safety-certified footwear can significantly decrease downtime caused by injuries, thereby improving overall productivity. When sourcing, buyers should prioritize shoes with proven slip resistance ratings, comfort features for extended wear, and consistent inventory availability to ensure seamless supply for large-scale operations.

Sports & Recreation

Eminem shoes are increasingly used as promotional or team-branded footwear in sports and recreational activities. For B2B buyers in regions like South America or Europe, offering customizable shoes with team logos or event branding can boost brand visibility and create additional revenue streams. Key considerations include high-quality branding options, rapid turnaround times, and MOQ flexibility. These shoes can serve as merchandise, sponsorship giveaways, or team apparel, enhancing engagement and loyalty.

Retail & Wholesale Distribution

Bulk sourcing of trendy, affordable eminem shoes allows retail chains across Africa, the Middle East, or Latin America to diversify their product offerings. These shoes appeal to a broad customer base seeking fashionable yet cost-effective footwear. For wholesale distributors, maintaining consistent quality, competitive pricing, and reliable delivery schedules is vital. Establishing strong relationships with manufacturers ensures access to a wide product range, enabling retailers to respond swiftly to market trends and consumer demand.

Medical & Healthcare

Specialized eminem shoes designed for healthcare professionals are vital for clinical environments where hygiene and comfort are paramount. These shoes typically feature antimicrobial properties, slip resistance, and ergonomic support. For B2B buyers in regions like Europe or the Middle East, sourcing shoes that meet medical standards (e.g., EN 20347) ensures compliance and enhances staff safety. Reliable supply, customization options for hospital branding, and certifications are critical factors for procurement decisions in this sector.

Strategic Material Selection Guide for eminem shoes

Material Analysis for Eminem Shoes

When selecting materials for Eminem shoes, B2B buyers must consider not only the performance characteristics but also regional standards, manufacturing complexities, and cost implications. Below is an in-depth analysis of four common materials used in shoe manufacturing, tailored for international markets including Africa, South America, the Middle East, and Europe.

Illustrative Image (Source: Google Search)

Leather (Full-Grain and Synthetic Variants)

Key Properties:

Leather offers excellent durability, breathability, and a premium aesthetic. Full-grain leather is highly resistant to wear and aging, while synthetic leather provides a more affordable alternative with easier maintenance.

Pros & Cons:

– Pros: High durability, natural look and feel, good flexibility, and excellent aging characteristics.

– Cons: Higher manufacturing complexity, significant environmental impact if not sourced sustainably, and cost variability depending on grade and source.

Impact on Application:

Leather performs well in various climates but may require treatment for water resistance, especially in humid regions. Synthetic variants are often preferred in markets with strict import regulations or environmental concerns.

International Buyer Considerations:

Buyers should verify compliance with regional standards such as REACH in Europe or environmental certifications in South America and Africa. Sustainable sourcing and traceability are increasingly demanded, influencing procurement decisions.

EVA (Ethylene Vinyl Acetate)

Key Properties:

EVA is a lightweight, flexible foam material widely used in midsoles for cushioning. It exhibits good shock absorption, chemical resistance, and weatherability.

Pros & Cons:

– Pros: Cost-effective, easy to mold, lightweight, and provides excellent cushioning.

– Cons: Less durable under high wear conditions, susceptible to UV degradation over time, and can compress with prolonged use.

Impact on Application:

Ideal for casual or sports shoes where comfort is prioritized. Its lightweight nature benefits markets with transportation or shipping cost constraints.

International Buyer Considerations:

EVA’s compliance with safety standards (such as ASTM F963 in the US or EN71 in Europe) is essential. Buyers should also consider the availability of raw materials locally or regionally to reduce costs and lead times.

Rubber (Natural and Synthetic)

Key Properties:

Rubber offers excellent elasticity, abrasion resistance, and waterproof qualities. Natural rubber is derived from latex, while synthetic variants like SBR (styrene-butadiene rubber) are engineered for specific performance traits.

Pros & Cons:

– Pros: High resilience, weather resistance, and good grip.

– Cons: Natural rubber can have supply chain issues due to environmental concerns, and synthetic rubber may involve complex manufacturing processes.

Impact on Application:

Rubber is crucial for outsoles, providing durability and slip resistance. Its performance varies with formulation; for example, vulcanized rubber enhances longevity.

International Buyer Considerations:

Buyers should assess regional standards for chemical safety (e.g., REACH, JIS). Sourcing from regions with sustainable rubber plantations can align with corporate social responsibility goals.

Mesh and Textile Fabrics

Key Properties:

Textile materials like mesh are lightweight, breathable, and flexible, making them suitable for uppers and linings.

Pros & Cons:

– Pros: Cost-effective, easy to manufacture, and comfortable for the wearer.

– Cons: Less resistant to water and abrasion, can degrade quickly in harsh environments.

Impact on Application:

Best suited for sports and casual shoes, especially in warmer climates. For regions with high humidity or dust, additional treatments or reinforcements may be necessary.

International Buyer Considerations:

Compliance with standards such as OEKO-TEX or ISO 9001 can be critical. Buyers should also consider regional preferences for aesthetics and environmental sustainability.

Summary Table

| Material | Typical Use Case for Eminem Shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather (Full-Grain/Synthetic) | Uppers, overlays | Durable, premium look | Costly, environmental concerns | High |

| EVA | Midsoles, insoles | Lightweight, cushioning | Less durable under heavy wear | Low |

| Rubber (Natural/Synthetic) | Outsoles | Resilient, slip-resistant | Supply chain variability | Med |

| Mesh/Textile Fabrics | Uppers, linings | Breathable, flexible | Water and abrasion susceptible | Low |

This comprehensive analysis provides B2B buyers with a strategic understanding of material choices, enabling informed procurement decisions aligned with regional standards, cost considerations, and end-use performance. Tailoring material selection to specific markets will optimize product quality, compliance, and customer satisfaction across diverse global regions.

In-depth Look: Manufacturing Processes and Quality Assurance for eminem shoes

Manufacturing Processes of Eminem Shoes

The production of Eminem shoes involves a series of meticulously managed stages designed to ensure high-quality output aligned with international standards. For B2B buyers, understanding these stages can facilitate better collaboration, quality control, and compliance verification.

1. Material Preparation

The process begins with sourcing and preparing raw materials, including high-grade leathers, synthetics, textiles, adhesives, and specialized components like insoles and outsole materials. Suppliers often utilize environmentally sustainable sources, especially for European and Middle Eastern markets, where eco-labeling is increasingly mandated. Material testing at this stage includes checking for durability, colorfastness, and compliance with relevant certifications such as REACH or OEKO-TEX.

Key B2B Insight: Verify suppliers’ material certifications and request detailed material test reports to ensure compliance with regional regulations, especially for markets like the EU, where chemical safety standards are strict.

2. Forming and Cutting

In this stage, materials are cut into precise patterns using automated cutting machines that ensure consistency and minimize waste. Computer-Aided Design (CAD) systems are standard for accuracy. Foam padding and lining are also prepared here. Advanced manufacturers employ laser cutting or CNC machines for enhanced precision, which directly impacts the fit and comfort of the final product.

B2B Action Point: Ensure your supplier employs modern cutting technologies and maintains calibration records. This helps in assessing their capability to produce consistent, high-quality components.

3. Assembly and Stitching

Assembled components—upper, lining, and insoles—are stitched using industrial sewing machines. For durability, high-frequency stitching and reinforced seams are common. Some manufacturers incorporate automation, such as robotic sewing for repetitive tasks, improving consistency and reducing defect rates. Adhesives are applied carefully to prevent issues like delamination.

Industry Standard: Use of double-stitched seams and high-quality adhesives aligned with ASTM or ISO standards enhances product durability. For markets demanding water resistance, seam sealing is critical.

4. Finishing and Quality Checks

Finishing involves attaching outsoles, adding decorative elements, branding, and final polishing. Automated and manual inspections are performed to ensure aesthetic standards and structural integrity. Embellishments like embroidery or prints undergo specific quality checks for alignment and color consistency.

B2B Tip: Confirm if finishing lines incorporate automated inspection systems, which can detect minute defects invisible to the naked eye.

Quality Assurance (QA) and Control Protocols

Maintaining consistent quality in Eminem shoes requires rigorous QA measures, aligned with international standards and tailored to regional market requirements.

1. International Standards and Certifications

- ISO 9001: Most reputable manufacturers operate under ISO 9001, ensuring a systematic approach to quality management, process control, and continuous improvement.

- CE Marking: For European markets, CE certification signifies compliance with safety, health, and environmental directives.

- API & Other Industry Certifications: For specific markets, certifications like ASTM for safety standards or regional chemical compliance certificates are essential.

Action for B2B Buyers: Request copies of these certifications and verify their validity through certification bodies. Ensure the supplier’s quality management system is regularly audited.

2. Inspection Points and Testing Methods

Quality control is embedded at multiple stages:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival, including tests for chemical composition, tensile strength, and colorfastness.

- In-Process Quality Control (IPQC): Monitoring during manufacturing involves dimensional checks, seam strength tests, and adhesion tests. Automated inspection systems, such as vision-based defect detection, are increasingly adopted for consistency.

- Final Quality Control (FQC): Completed shoes undergo comprehensive inspections, including visual checks, weight measurements, and functional tests (e.g., flexibility, slip resistance).

Testing Methods Include:

- Tensile and Adhesion Testing: To ensure durability of glued or stitched components.

- Flex Testing: Simulating wear conditions to verify product longevity.

- Colorfastness & Aesthetic Checks: Ensuring no color bleeding or surface defects.

- Environmental Testing: Resistance to humidity, temperature fluctuations, and UV exposure, particularly relevant for outdoor or sports shoes.

3. Third-Party Inspections and Audits

To mitigate risks, B2B buyers should commission third-party inspection agencies (e.g., SGS, Bureau Veritas, Intertek) to conduct pre-shipment inspections. These agencies verify compliance with contractual specifications, quality standards, and regulatory requirements.

Audit Focus Areas:

- Factory quality management systems

- Raw material traceability

- Production consistency

- Final product conformity

Tip: Regular audits, especially for suppliers in regions like Thailand, Argentina, or Middle Eastern countries, can uncover hidden issues and foster continuous improvement.

Nuances for International B2B Buyers

From Africa and South America

Buyers should emphasize transparency in sourcing and testing, given regional concerns about counterfeit or substandard products. Establish clear quality benchmarks and request detailed inspection reports. Engaging with suppliers who have ISO 9001 or similar certifications can help mitigate risks.

From the Middle East and Europe

Market-specific standards such as REACH, RoHS, and CE require suppliers to demonstrate chemical safety and environmental compliance. B2B buyers must verify these through official certification documents and independent lab reports. For European markets, adherence to EN standards for footwear durability and safety is crucial.

For Buyers in Thailand and Argentina

Manufacturers often operate under local certifications and may have varying levels of compliance. Conduct regular audits, request third-party inspection reports, and consider establishing long-term relationships to ensure consistent quality. Additionally, understanding regional customs and import regulations can streamline verification processes.

Final Recommendations for B2B Buyers

- Establish Clear Quality Specifications: Document detailed quality requirements and communicate them explicitly during sourcing.

- Request Comprehensive Documentation: Material certificates, test reports, and certification copies should be obtained before shipment.

- Implement Regular Audits: Use third-party inspectors and conduct periodic factory visits to ensure ongoing compliance.

- Leverage Technology: Utilize digital platforms for real-time inspection reports and certification verification.

- Build Long-Term Relationships: Collaborate with suppliers committed to continuous improvement and quality excellence, especially in emerging markets.

By understanding the detailed manufacturing processes and implementing rigorous quality assurance protocols, B2B buyers can significantly reduce risks, ensure product consistency, and foster sustainable supplier relationships across diverse international markets.

Comprehensive Cost and Pricing Analysis for eminem shoes Sourcing

Cost Structure Breakdown

Understanding the comprehensive cost structure of Eminem shoes is vital for effective sourcing. The primary components include:

-

Materials: The choice of materials—synthetic leathers, textiles, rubber soles—significantly impacts cost. High-quality or specialized materials for premium variants can increase expenses, while standard materials keep costs lower. Regional price variations for raw materials also influence overall costs.

-

Labor: Manufacturing costs vary by country, with Asian countries (e.g., China, Vietnam) typically offering lower labor rates, whereas European or Middle Eastern factories might charge higher wages but offer superior craftsmanship or faster turnaround times.

-

Manufacturing Overhead: This includes factory utilities, machinery depreciation, and indirect labor. Overheads tend to be higher in regions with stricter labor or environmental regulations, influencing total production costs.

-

Tooling & Setup: Initial molds, dies, and tooling can be a significant upfront expense, especially if custom designs or limited editions are involved. These costs are amortized over production runs, so larger volumes reduce per-unit costs.

-

Quality Control & Certifications: Ensuring consistent quality and obtaining necessary certifications (e.g., ISO, environmental standards) add to costs but are crucial for market acceptance, especially in Europe and the Middle East.

-

Logistics & Shipping: International freight, customs duties, tariffs, and inland transportation form a substantial part of the total cost. Incoterms (e.g., FOB, CIF) directly influence who bears these costs and when.

-

Profit Margin: Distributors and manufacturers typically add a markup to cover risks and ensure profitability, often ranging from 10% to 30%, depending on the relationship and market dynamics.

Price Influencers

Several factors directly impact the final price of Eminem shoes in the B2B context:

-

Order Volume & MOQ: Larger orders generally secure better unit prices due to economies of scale. Buyers from Africa, South America, or smaller markets should negotiate for volume discounts or flexible MOQs.

-

Specifications & Customization: Customized designs, unique materials, or branding (e.g., special packaging, labels) increase costs. Standard models are more cost-effective but may limit differentiation.

-

Material Choices: Premium or imported materials elevate costs, whereas locally sourced or alternative materials can reduce expenses, especially in regions with domestic manufacturing capabilities.

-

Quality & Certifications: Higher quality standards and certifications (e.g., compliance with European safety standards) often command premium pricing but can open lucrative markets.

-

Supplier Factors: Factory reputation, lead times, payment terms, and reliability influence prices. Established suppliers may charge more but offer better quality assurance and consistency.

-

Incoterms & Logistics: Choosing FOB can shift logistics responsibilities to the buyer, potentially reducing costs for the supplier but increasing complexity for the buyer. CIF terms include shipping costs but may carry higher per-unit prices.

Buyer Tips for Cost Optimization

-

Negotiate for Volume & Flexibility: Larger orders usually attract discounts, but also consider flexible MOQs to avoid excess inventory costs, especially in markets like Argentina or Thailand.

-

Leverage Total Cost of Ownership (TCO): Consider not only unit price but also shipping, customs, taxes, and potential rework costs. A slightly higher unit price might be offset by lower logistics expenses or faster delivery.

-

Build Long-term Relationships: Reliable partnerships can lead to better pricing, priority production slots, and customized terms. Transparent communication about quality expectations minimizes costly rework.

-

Understand Pricing Nuances: Be aware of hidden costs such as currency fluctuations, import tariffs, or certification fees. For example, European buyers might face higher tariffs but benefit from premium quality and compliance.

-

Regional Sourcing & Local Production: Explore regional manufacturing options to reduce lead times and logistics costs. For instance, Middle Eastern buyers might leverage nearby suppliers in Turkey or Egypt for cost efficiency.

Price Range & Indicative Costs

While prices vary widely depending on specifications and quantity, typical FOB unit costs for standard Eminem shoes can range from $15 to $30 for bulk orders. Premium or customized models may range from $30 to $50 or higher. Importantly, these figures are indicative; actual prices depend heavily on negotiations, specifications, and regional factors.

Final Note

For international B2B buyers, especially from Africa, South America, the Middle East, and Europe, understanding the detailed cost breakdown and influencing factors is essential to optimize procurement strategies. Prioritize building strong supplier relationships, negotiate effectively, and consider total landed costs to ensure competitive pricing and sustainable sourcing.

Spotlight on Potential eminem shoes Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for eminem shoes.)*

Essential Technical Properties and Trade Terminology for eminem shoes

Critical Technical Properties for Eminem Shoes

1. Material Grade and Composition

The quality of materials used—such as genuine leather, synthetic fabrics, or rubber compounds—directly impacts durability and consumer satisfaction. For B2B buyers, specifying the grade (e.g., full-grain leather versus bonded leather) ensures consistent product quality. High-grade materials often command higher prices but offer better longevity, which is crucial for brand reputation and retail success.

2. Tolerance Levels

Tolerance refers to the allowable deviation in dimensions during manufacturing, typically measured in millimeters. Precise tolerances (e.g., ±0.5mm) are essential for ensuring uniformity across batches, reducing returns, and maintaining brand standards. Buyers should specify tolerances for key components such as sole thickness and upper dimensions to facilitate quality control.

3. Sole and Midsole Specifications

The composition and flexibility of the sole influence comfort and performance. Specifications include durometer hardness (a measure of material firmness), sole thickness, and slip resistance ratings. These properties are vital for ensuring the shoes meet safety standards and customer expectations in different markets.

4. Stitching and Finish Quality

Consistent, reinforced stitching and high-quality finishing reflect manufacturing precision. These aspects affect product durability and aesthetics. B2B buyers should look for standardized quality metrics or certifications that confirm adherence to industry standards, especially when sourcing for large volume distribution.

5. Weight and Breathability

Lightweight shoes enhance comfort, especially for active wear, while breathable materials improve user experience in warmer climates. Knowing the specific weight per shoe and fabric breathability ratings helps buyers predict product performance in targeted markets like Africa, South America, or the Middle East.

6. Compliance with Regional Standards

Eminem shoes must adhere to regional safety and environmental standards, such as REACH in Europe or ASTM standards in the US. Ensuring compliance mitigates legal risks and facilitates smoother import processes, especially for international buyers operating under strict regulatory environments.

Essential Trade Terms for Eminem Shoes

1. OEM (Original Equipment Manufacturer)

Refers to the factory or company producing the shoes based on the buyer’s specifications. Understanding OEM relationships helps buyers assess manufacturing capacity, quality control practices, and potential for customization.

2. MOQ (Minimum Order Quantity)

The smallest quantity of shoes that a manufacturer will accept per order. Knowledge of MOQ is vital for planning inventory and cash flow, especially when entering new markets or testing demand in regions like Europe or South America.

3. RFQ (Request for Quotation)

A formal request sent to suppliers asking for detailed price proposals, lead times, and terms. An RFQ process enables buyers to compare offers efficiently and negotiate better terms, critical for cost-sensitive markets.

4. Incoterms (International Commercial Terms)

Standardized trade definitions that specify responsibilities for shipping, insurance, and customs clearance. Common Incoterms include FOB (Free on Board), CIF (Cost, Insurance, and Freight), and DDP (Delivered Duty Paid). Clear understanding of Incoterms ensures smooth logistics and cost management across diverse markets.

5. Lead Time

The period from order placement to product delivery. Accurate knowledge of lead times helps buyers plan inventory and meet seasonal demand peaks, particularly important in regions with longer customs clearance procedures.

6. Quality Certifications

Documents or standards such as ISO, CE, or regional safety approvals that verify compliance with industry norms. Acquiring and verifying these certifications reassure buyers of product safety and quality, facilitating easier market entry.

Summary:

Understanding these technical properties and trade terms empowers B2B buyers from Africa, South America, the Middle East, and Europe to make informed sourcing decisions. Clear specifications on material quality, manufacturing tolerances, and compliance ensure product consistency and meet regional standards. Simultaneously, mastering trade terminology like OEM, MOQ, RFQ, and Incoterms streamlines negotiations, logistics, and risk management, fostering successful international partnerships.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the eminem shoes Sector

Market Overview & Key Trends

The global eminem shoes market is driven by evolving consumer preferences, technological advancements, and shifting sourcing landscapes. Increasing demand for customized and limited-edition footwear is prompting brands to innovate in design and manufacturing processes. For international B2B buyers from Africa, South America, the Middle East, and Europe, understanding these trends is crucial for strategic sourcing and distribution.

Emerging B2B tech trends, such as digital supply chain management, blockchain for provenance verification, and AI-driven demand forecasting, are enhancing transparency and efficiency. These innovations allow buyers to better track raw material origins, streamline inventory management, and reduce lead times. Additionally, the rise of direct-to-consumer (DTC) models influences sourcing strategies, encouraging closer collaboration with manufacturers and suppliers.

Market dynamics are also influenced by geopolitical factors, tariffs, and regional trade agreements, which can impact costs and lead times. For example, European buyers benefit from established trade frameworks within the EU, while African and South American buyers need to navigate tariffs and import regulations. Sourcing from regions like Southeast Asia (e.g., Thailand) remains popular due to established manufacturing hubs, but diversification into emerging markets offers resilience against disruptions.

Sustainability concerns are increasingly shaping B2B decisions. Buyers are seeking suppliers with eco-friendly practices, certifications, and transparent supply chains. The demand for innovative, sustainable materials—such as recycled plastics, organic textiles, and biodegradable components—is rising. Staying ahead in this market requires leveraging technological tools for sourcing, understanding regional trade nuances, and aligning with sustainability goals to meet consumer expectations globally.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a critical factor influencing B2B procurement in the eminem shoes sector. Environmental impacts from raw material extraction, manufacturing emissions, and waste generation are under scrutiny, prompting buyers to prioritize suppliers with robust eco-credentials. Ethical sourcing practices not only mitigate reputational risks but also align with global consumer trends favoring responsible brands.

For international buyers, establishing supply chains that adhere to recognized environmental standards—such as ISO 14001, Fair Trade, and LEED certifications—is essential. These certifications verify sustainable practices across raw material sourcing, manufacturing processes, and waste management. For instance, sourcing from suppliers that utilize recycled or organic materials reduces environmental footprints and appeals to eco-conscious markets.

In addition, the adoption of ‘green’ materials—such as plant-based leathers, recycled textiles, and biodegradable soles—can differentiate products and meet regulatory requirements in regions like Europe and the Middle East. Transparency is key; leveraging blockchain and traceability tools allows buyers to authenticate supply chain claims and ensure compliance with labor laws and environmental standards.

Furthermore, engaging with suppliers committed to fair labor practices and community development fosters ethical supply chains. B2B buyers should prioritize partnerships with vendors who demonstrate social responsibility, including fair wages, safe working conditions, and environmental stewardship. This approach not only mitigates risks but also aligns with the growing demand for ethically produced footwear in global markets.

Brief Evolution/History (Optional)

The eminem shoes sector has evolved from basic athletic footwear to a highly innovative and fashion-forward industry. Initially driven by performance and durability, the market now emphasizes design, sustainability, and technological integration. For B2B buyers, understanding this evolution highlights the importance of sourcing from manufacturers who have adapted to these shifts—particularly those investing in sustainable R&D and advanced manufacturing techniques. This historical perspective underscores the sector’s trajectory towards more responsible and technologically sophisticated production, essential for aligning supply chain strategies with future market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of eminem shoes

-

How can I verify the credibility and reliability of Eminem shoe suppliers?

To ensure supplier credibility, conduct thorough due diligence by reviewing their business licenses, certifications, and third-party audit reports. Request references from other international buyers and examine their production capacity, past export records, and client testimonials. It’s also advisable to visit their manufacturing facilities if feasible or hire local inspection services. Engaging with suppliers who participate in recognized trade associations or who have established compliance with international standards (e.g., ISO, CE) can significantly reduce risks. A reliable supplier will be transparent about their operations and willing to provide detailed documentation. -

What customization options are available for Eminem shoes, and how do they impact lead times and costs?

Many suppliers offer customization such as branding, packaging, colors, and limited design modifications. Customization typically involves additional setup costs and may extend lead times by 2-4 weeks depending on complexity. For large orders, negotiate volume discounts and clear timelines upfront. Ensure your specifications are detailed and confirmed in writing to avoid miscommunication. For quick turnaround, consider suppliers with in-house design teams and flexible manufacturing processes. Always factor in the time for approvals and samples to avoid delays in your supply chain. -

What are typical minimum order quantities (MOQs), lead times, and payment terms for international bulk purchases?

MOQs for Eminem shoes generally range from 500 to 5,000 pairs, depending on the supplier and customization level. Lead times usually span 4 to 12 weeks, influenced by order size, complexity, and production capacity. Common payment terms include 30% upfront via wire transfer or letter of credit, with the balance payable before shipment or upon delivery. Negotiate flexible terms, especially for first-time orders, and consider using trade finance tools or escrow services to mitigate payment risks. Clear communication on these terms is essential to avoid misunderstandings. -

What quality assurance procedures and certifications should I expect from reputable Eminem shoe suppliers?

Reputable suppliers should provide comprehensive QA protocols, including raw material inspection, in-process testing, and final product audits. Look for certifications such as ISO 9001 for quality management, CE marking for safety compliance, and environmental standards like RoHS or REACH. Request sample testing reports and factory inspection certificates. Consider third-party testing for durability, sole adhesion, and colorfastness, especially for large orders. Establish quality benchmarks in your contract and conduct pre-shipment inspections or hire inspection agencies to verify compliance before shipment. -

How can I optimize logistics and shipping to minimize costs and delivery times?

Choose suppliers with established logistics networks and experience shipping to your region. Consolidate shipments where possible to reduce freight costs. Consider multiple shipping options such as sea freight for large volumes, air freight for urgent orders, or multimodal solutions. Work with freight forwarders who specialize in your target markets for better rates and customs handling. Always clarify Incoterms (e.g., FOB, CIF) to understand responsibilities and costs. Maintaining good communication with suppliers and logistics providers ensures timely updates and smooth customs clearance, reducing delays and unexpected expenses. -

What are common dispute resolution methods in international B2B transactions for Eminem shoes?

Disputes often arise over quality, delivery delays, or payment issues. To mitigate risks, specify dispute resolution clauses in your contract, preferably favoring arbitration under recognized rules (e.g., ICC or LCIA) in neutral jurisdictions. Maintaining detailed documentation, including contracts, inspection reports, and communication logs, supports claims. Engage local legal counsel familiar with international trade laws in your region. Building strong supplier relationships and clear communication channels also help prevent disputes. When conflicts occur, aim for amicable resolution but be prepared to escalate through arbitration if necessary. -

How do I ensure compliance with import regulations, taxes, and tariffs in my country?

Research your country’s import regulations, tariffs, and trade agreements affecting footwear. Many countries classify shoes under HS codes that determine applicable duties and taxes. Consult with customs brokers or trade consultants to ensure proper classification and documentation. Keep updated on changes in trade policies or tariffs that could impact costs. Properly prepare import documentation such as invoices, certificates of origin, and compliance certificates to facilitate smooth clearance. Pre-arranging customs clearance and understanding duty exemptions or incentives can reduce delays and costs. -

What strategies can I use to build long-term relationships with Eminem shoe suppliers?

Establish trust through transparent communication, timely payments, and consistent order volumes. Provide constructive feedback and collaborate on product development or customization to foster loyalty. Invest in understanding their production processes and constraints, and share forecasts to aid planning. Consider volume discounts, early payment incentives, or joint marketing efforts to strengthen partnerships. Regular visits or virtual audits help maintain quality standards. Building a mutually beneficial relationship can lead to better pricing, priority production, and access to exclusive products or customizations, ensuring a competitive advantage in your target markets.

Strategic Sourcing Conclusion and Outlook for eminem shoes

Strategic Sourcing Outlook for Eminem Shoes

Effective strategic sourcing is critical for international B2B buyers aiming to capitalize on the growing demand for Eminem shoes. By prioritizing supplier diversification, quality assurance, and cost optimization, buyers can mitigate risks and ensure a reliable supply chain. Leveraging local manufacturing capabilities and establishing strong supplier relationships can further enhance competitiveness and responsiveness to market fluctuations.

For buyers in Africa, South America, the Middle East, and Europe—particularly regions like Thailand and Argentina—adopting a strategic sourcing approach offers tangible benefits. It enables access to innovative product designs, competitive pricing, and faster delivery times, all while maintaining high quality standards. As the market for branded footwear continues to evolve, proactive sourcing will be essential to securing a sustainable advantage.

Looking ahead, international B2B buyers should remain vigilant to emerging trends such as sustainable materials and ethical manufacturing practices, integrating these factors into their sourcing strategies. By fostering strategic partnerships and continuously optimizing their supply chains, buyers can position themselves for long-term success in the dynamic Eminem shoes market. Act now to build resilient, cost-effective sourcing frameworks that unlock growth opportunities across global markets.