Your Ultimate Guide to Sourcing Ken Griffey Shoes

Guide to Ken Griffey Shoes

- Introduction: Navigating the Global Market for ken griffey shoes

- Understanding ken griffey shoes Types and Variations

- Key Industrial Applications of ken griffey shoes

- Strategic Material Selection Guide for ken griffey shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for ken griffey shoes

- Comprehensive Cost and Pricing Analysis for ken griffey shoes Sourcing

- Spotlight on Potential ken griffey shoes Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for ken griffey shoes

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the ken griffey shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of ken griffey shoes

- Strategic Sourcing Conclusion and Outlook for ken griffey shoes

Introduction: Navigating the Global Market for ken griffey shoes

In today’s highly interconnected global marketplace, sourcing high-quality athletic footwear like Ken Griffey shoes requires strategic insight and a nuanced understanding of international supply chains. These iconic sneakers, celebrated for their performance and cultural significance, have become a sought-after product for retailers, distributors, and wholesalers across Africa, South America, the Middle East, and Europe. Effectively navigating this landscape can unlock substantial commercial opportunities, but it also demands a comprehensive approach to sourcing, quality assurance, and market trends.

This guide offers an in-depth exploration of key aspects crucial to successful procurement of Ken Griffey shoes. It covers the various product types—ranging from authentic retail-grade models to OEM and ODM options—along with insights into the materials used, manufacturing standards, and quality control protocols. Additionally, it provides practical advice on identifying reliable suppliers, understanding cost structures, and assessing market demand in diverse regions.

For B2B buyers aiming to expand their footwear offerings or strengthen their supply chains, this guide is an essential resource. It empowers you to make informed decisions, mitigate risks, and leverage competitive advantages in a dynamic global market. Whether sourcing from Asian manufacturing hubs like Vietnam and Indonesia or exploring regional import regulations, this comprehensive overview ensures you are equipped to succeed in the evolving landscape of Ken Griffey shoes.

Understanding ken griffey shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Retro Model | Timeless design inspired by original Griffey sneakers | Sports retail, collectibles | Pros: High brand recognition, appeal to nostalgic markets; Cons: Limited innovation, potentially higher MOQ |

| Performance Pro Model | Advanced cushioning, lightweight materials, enhanced support | Athletic footwear, specialty sports stores | Pros: Superior performance, appeals to serious athletes; Cons: Higher manufacturing costs, longer lead times |

| Limited Edition/Collaborations | Unique designs, special colorways, exclusive branding | High-end boutiques, collector markets | Pros: Creates exclusivity and premium pricing; Cons: Limited availability, higher procurement risk |

| Youth/Junior Variants | Smaller sizes, durable construction, vibrant colors | Youth sports shops, educational institutions | Pros: Expands market reach, high volume potential; Cons: Smaller margins, inventory complexity |

| Customizable/Personalized Models | Custom colorways, branding options for teams or organizations | Corporate gifting, team sponsorships | Pros: High customer engagement, premium pricing; Cons: Increased production complexity, longer turnaround |

Characteristics and Suitability of Each Type

Classic Retro Model

These shoes replicate the original design that made Ken Griffey Jr. iconic. They appeal primarily to collectors, nostalgic consumers, and casual fans. B2B buyers should focus on sourcing from authorized suppliers to ensure authenticity and brand integrity. These models are suitable for retail outlets emphasizing heritage products, with moderate to high retail margins. Consider MOQ requirements carefully, as limited editions may require higher initial investments.

Performance Pro Model

Designed with advanced materials, these shoes prioritize athletic performance, featuring enhanced cushioning, support, and lightweight construction. They are ideal for specialty sports stores, athletic retailers, and direct channels targeting serious players. B2B buyers should evaluate lead times and manufacturing costs, as these models often involve premium components. Bulk purchasing discounts and long-term supplier relationships can optimize margins.

Limited Edition/Collaborations

These variants are released in restricted quantities, often featuring unique colorways or designer collaborations. They target high-end boutiques, sneaker collectors, and premium sports outlets. B2B buyers should assess the risk of overstock and consider pre-orders or consignment models. Establishing partnerships with authorized distributors ensures authenticity and reduces counterfeiting risks.

Youth/Junior Variants

Smaller sizes and durable, vibrant designs make these shoes suitable for school sports programs and youth sports retailers. They often have higher turnover rates but lower margins per unit. B2B buyers should focus on volume purchasing and inventory management, especially in markets with high youth sports participation. Building relationships with schools and sports academies can open consistent sales channels.

Customizable/Personalized Models

Offering options for custom colors or branding, these shoes serve corporate clients, teams, and event organizers. They command higher price points and foster brand loyalty. B2B buyers should develop flexible manufacturing processes and reliable logistics to meet customization demands. Early engagement with clients can help forecast demand and optimize production schedules.

By understanding these variations, international B2B buyers can strategically select product types aligned with regional market preferences, supply chain capabilities, and consumer demand, ensuring profitable and sustainable sourcing of Ken Griffey shoes.

Key Industrial Applications of ken griffey shoes

| Industry/Sector | Specific Application of ken griffey shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Sportswear & Athletic Apparel | Custom branded athletic shoes for sports teams and retail distribution | Enhances brand visibility, boosts sales, and fosters brand loyalty | Quality assurance, OEM customization options, reliable supply chain |

| Footwear Manufacturing | Production of high-performance basketball shoes | Meets demand for durable, innovative sports footwear | Material compliance, manufacturing standards, cost competitiveness |

| Retail & E-commerce | Wholesale distribution to sports retailers and online platforms | Expands product portfolio, attracts diverse customer segments | Certification, packaging standards, flexible MOQ |

| Corporate & Promotional Gifting | Branded ken griffey shoes as corporate gifts or promotional items | Strengthens B2B partnerships, enhances corporate branding | Customization capabilities, timely delivery, branding options |

| Sports & Athletic Events | Sponsorship of sports tournaments and athlete endorsements | Increases brand exposure, drives global recognition | Authenticity verification, event-specific branding, logistics support |

Custom-branded Athletic Shoes for Sports Teams and Retail Distribution

Ken Griffey shoes are highly sought after in the sportswear industry, especially for branding and retail sales. B2B buyers from Africa, South America, the Middle East, and Europe can leverage these shoes to produce custom-branded athletic footwear tailored for local sports teams, schools, or retail outlets. These shoes enhance team identity and foster brand loyalty among consumers. For international buyers, sourcing high-quality, customizable options with reliable lead times and compliance with regional standards is essential. Establishing strong OEM partnerships ensures consistent quality and timely delivery, critical for maintaining brand reputation in competitive markets.

Production of High-Performance Basketball Shoes

Ken Griffey shoes are renowned for their durability and performance, making them ideal for manufacturing high-performance basketball footwear. B2B buyers in footwear manufacturing can incorporate these shoes into their product lines, catering to athletes seeking reliable and innovative sports footwear. For international suppliers, ensuring adherence to safety standards, material quality, and sustainable manufacturing practices is crucial. Building relationships with trusted suppliers who can provide consistent quality at competitive prices supports scalability and helps penetrate markets with increasing demand for premium sports shoes.

Wholesale Distribution to Retailers and Online Platforms

The global rise of e-commerce and retail outlets presents significant opportunities for distributing ken griffey shoes. B2B buyers can purchase in bulk for resale through sports stores, online marketplaces, and specialty retailers across Africa, South America, the Middle East, and Europe. Emphasizing packaging standards, certification, and flexible MOQ options is vital for success. Reliable logistics and customs clearance support seamless supply chains, enabling buyers to meet local consumer demands swiftly. Offering a variety of models and sizes further enhances market competitiveness and customer satisfaction.

Branded Shoes as Corporate Gifts or Promotional Items

Ken Griffey shoes serve as premium corporate gifts or promotional merchandise, enhancing brand visibility and corporate relationships. B2B buyers can customize these shoes with corporate logos, event branding, or special designs to suit marketing campaigns or partnership initiatives. For international buyers, sourcing options should include high-quality customization, prompt production, and reliable international shipping. These shoes can significantly elevate brand perception when used strategically in corporate gifting, sponsorships, or promotional events across diverse regions.

Sponsorship of Sports Tournaments and Athlete Endorsements

Leveraging ken griffey shoes in sports sponsorships and athlete endorsements provides substantial brand exposure. B2B buyers involved in event management or brand sponsorships can partner with sports organizations or athletes to elevate visibility in key markets. Authenticity verification, regional branding customization, and efficient logistics are critical for executing successful sponsorship campaigns. This application not only boosts brand recognition but also opens avenues for long-term B2B collaborations with sports entities across Africa, South America, the Middle East, and Europe, fostering sustained market growth.

Strategic Material Selection Guide for ken griffey shoes

Analysis of Common Materials for Ken Griffey Shoes from a B2B Perspective

Leather

Leather remains a primary material in athletic footwear, including Ken Griffey shoes, due to its superior durability, breathability, and aesthetic appeal. From a B2B standpoint, high-quality leather—such as full-grain or top-grain—offers excellent abrasion resistance and longevity, making it suitable for premium product lines. However, leather processing involves complex tannage procedures that can increase manufacturing costs and time, especially if sourcing from regions with less developed tannery infrastructure.

For international buyers, compliance with environmental standards such as the EU REACH regulation or California Proposition 65 is critical, especially in European markets. Leather sourced from regions with strict environmental controls (e.g., Europe, some parts of South America) may command higher prices but offer better compliance assurance. Conversely, buyers from Africa or Southeast Asia should verify supplier certifications to avoid legal or reputational risks related to environmental and labor standards.

Synthetic Materials (e.g., Mesh, PU, TPU)

Synthetic materials like mesh, polyurethane (PU), and thermoplastic polyurethane (TPU) are popular due to their lightweight nature, flexibility, and ease of manufacturing. Mesh is often used for uppers to enhance breathability, while TPU provides structural support and durability. These materials are generally less expensive than leather and can be produced with consistent quality at scale, making them attractive for mass production.

However, synthetic materials may have limitations in extreme conditions—such as high heat or moisture—potentially affecting product longevity. For international buyers, compatibility with local climate conditions is essential; for instance, buyers in humid regions like Indonesia or parts of Africa should prioritize moisture-resistant synthetics. Additionally, compliance with standards like ASTM or JIS for safety and environmental impact should be verified, especially when exporting to regions with strict regulations.

Rubber and EVA (Ethylene Vinyl Acetate)

Rubber and EVA are predominantly used in the outsole of Ken Griffey shoes, providing grip, shock absorption, and durability. Rubber offers excellent wear resistance and traction, suitable for various playing surfaces, while EVA provides lightweight cushioning, enhancing comfort during extended use.

Illustrative Image (Source: Google Search)

From a manufacturing perspective, rubber can be more complex to mold and bond but offers superior performance. EVA, being lighter and easier to mold, reduces production costs and time. For international buyers, sourcing high-quality rubber that meets standards like DIN or ASTM is vital, especially for markets demanding high safety and performance standards. Buyers should also consider regional availability—some regions may have limited access to specialized rubber compounds, impacting lead times and costs.

Considerations for International B2B Buyers

For buyers across Africa, South America, the Middle East, and Southeast Asia, material selection must align with regional standards and environmental regulations. European markets, for example, emphasize sustainability and strict chemical regulations, requiring transparent supply chains and eco-friendly materials. Buyers in emerging markets should prioritize suppliers with robust certifications (ISO, OEKO-TEX) to mitigate risks related to product recalls or regulatory non-compliance.

Cost sensitivity varies across regions; Southeast Asian buyers often benefit from lower manufacturing costs but should ensure quality consistency. African and Middle Eastern buyers may face logistical challenges, emphasizing the importance of reliable supply chains and local partnerships. Overall, understanding regional standards, environmental compliance, and climate considerations will enable international B2B buyers to select materials that optimize both performance and market acceptance.

Summary Table of Materials for Ken Griffey Shoes

| Material | Typical Use Case for Ken Griffey Shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather | Upper material providing durability and aesthetic appeal | Excellent durability, breathability, premium look | Higher manufacturing complexity and cost | High |

| Synthetic (Mesh, PU, TPU) | Upper support, breathability, structural support | Lightweight, cost-effective, easy to produce | Less durable under extreme conditions | Med |

| Rubber/EVA | Outsole for grip, shock absorption | High wear resistance (rubber), lightweight (EVA) | Rubber molding is complex; EVA less durable | Varies (Rubber: Med, EVA: Low) |

| N/A | N/A | N/A | N/A | N/A |

This table provides a clear overview for international B2B buyers to evaluate material choices based on application needs, cost considerations, and regional compliance requirements. Selecting the appropriate materials will ensure product performance aligns with market expectations while maintaining cost efficiency and regulatory adherence.

In-depth Look: Manufacturing Processes and Quality Assurance for ken griffey shoes

Manufacturing Processes of Ken Griffey Shoes

The manufacturing of Ken Griffey shoes involves a series of meticulously planned stages designed to ensure high quality, durability, and performance. For international B2B buyers, understanding these stages is crucial for assessing supplier capabilities and ensuring product consistency.

Material Preparation

The process begins with sourcing and preparing raw materials such as synthetic or genuine leather, mesh fabrics, rubber, and foam padding. Suppliers often source these materials from certified vendors who comply with international standards like ISO 9001 to guarantee quality. Material inspection at this stage involves checking for defects, consistency in thickness, colorfastness, and material integrity.

Forming and Cutting

Once materials are approved, they are cut into specific patterns using advanced cutting machines, such as CNC cutters or laser cutting technology, which provide precision and minimize waste. For high-performance basketball shoes like Ken Griffey models, attention is paid to pattern accuracy to ensure proper fit and support. This stage may also include pre-shaping components like insoles and midsoles.

Assembly

During assembly, components are stitched, glued, and assembled on automated or semi-automated production lines. Key techniques include ultrasonic welding for seamless bonding, especially for synthetic materials, and high-frequency stitching for durability. The assembly process also involves attaching components like the outsole, midsole, upper, and laces, with strict adherence to design specifications. This stage often incorporates robotic systems for consistency and efficiency.

Finishing

The final stage involves quality finishing touches such as cleaning, polishing, and applying branding elements (logos, labels). Quality control checks are integrated into this phase to identify any cosmetic or structural defects. The shoes are then packaged according to international standards, ensuring they are protected during transit.

Quality Assurance (QA) and Quality Control (QC) Practices

Ensuring consistent quality in Ken Griffey shoes requires robust QA and QC measures aligned with international standards. For B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, verifying these practices is critical to mitigate risks.

International Standards and Industry Certifications

- ISO 9001: Most reputable manufacturers operate under ISO 9001, focusing on quality management systems that promote continuous improvement, customer satisfaction, and defect prevention.

- CE Marking: For shoes intended for markets in Europe, CE certification indicates compliance with EU safety, health, and environmental requirements.

- Additional Certifications: Some manufacturers may hold certifications like OEKO-TEX for eco-friendly materials or ASTM standards for performance testing.

QC Checkpoints Throughout Manufacturing

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival for specifications such as color consistency, material strength, and defect presence.

- In-Process Quality Control (IPQC): Continuous inspections during each manufacturing stage monitor adherence to design specifications, stitching quality, bonding strength, and dimensional accuracy.

- Final Quality Control (FQC): Post-assembly inspections verify overall shoe quality, including visual appearance, structural integrity, and functional tests like sole adhesion and flexibility.

Testing Methods

- Visual Inspection: Checks for cosmetic defects, color mismatches, and surface blemishes.

- Mechanical Testing: Includes tensile strength, flex fatigue, and sole adhesion tests to ensure durability.

- Environmental Testing: Shoes are tested for resistance to humidity, temperature variations, and UV exposure to simulate real-world conditions.

- Performance Testing: For performance-oriented models, tests such as grip, shock absorption, and stability are conducted.

Illustrative Image (Source: Google Search)

Verifying Supplier QC for International B2B Buyers

For international buyers, verifying the authenticity and quality of supplier QC practices is paramount. Several approaches include:

- Third-Party Inspections: Engaging independent inspection agencies (e.g., SGS, Bureau Veritas) to conduct pre-shipment inspections, audits, and sample testing.

- Factory Audits: Conducting comprehensive audits focusing on quality management systems, production capabilities, and adherence to social and environmental standards.

- Review of Quality Reports: Request detailed QC reports, test certificates, and documentation of compliance with relevant standards.

- Sample Verification: Reviewing samples before large orders helps assess craftsmanship, materials, and adherence to specifications.

- On-site Visits: When feasible, visiting manufacturing facilities provides direct insight into QC practices, worker conditions, and operational transparency.

Nuances for International B2B Transactions

- Cultural and Regional Variations: Understanding local manufacturing practices and quality standards in regions like Vietnam, Indonesia, or Brazil helps tailor expectations and communication.

- Language and Documentation: Ensure clear communication and detailed documentation, including QC reports, test results, and compliance certificates, are available in accessible languages.

- Lead Times and Flexibility: Account for regional differences in production lead times and the potential need for additional QC checks or audits.

- Trade Regulations: Be aware of import regulations, tariffs, and certification requirements specific to your market, which may necessitate additional testing or documentation.

Actionable Insights for B2B Buyers

- Establish clear quality specifications and expectations upfront, including required certifications and testing standards.

- Incorporate third-party inspection and audit processes into procurement workflows to verify supplier claims and ensure compliance.

- Build strong relationships with suppliers who demonstrate transparency, consistent quality, and adherence to international standards.

- Regularly review and update quality control protocols to align with evolving industry standards and market requirements.

- Leverage regional expertise and local inspection services to navigate regional manufacturing nuances effectively.

By understanding and actively managing manufacturing and quality assurance processes, international B2B buyers from Africa, South America, the Middle East, and Europe can secure reliable supply chains, ensure product quality, and foster long-term partnerships in the Ken Griffey shoes market.

Comprehensive Cost and Pricing Analysis for ken griffey shoes Sourcing

Cost Structure Breakdown for Ken Griffey Shoes Sourcing

Understanding the comprehensive cost structure is vital for international B2B buyers aiming to optimize procurement strategies for Ken Griffey shoes. The primary cost components include:

-

Materials: The choice of upper fabrics (mesh, synthetic leather, or genuine leather) significantly impacts costs. Premium materials or custom designs increase expenses, whereas standard materials tend to be more economical. Sole components, including rubber compounds and cushioning systems, also vary in cost depending on quality and durability requirements.

-

Labor: Manufacturing costs differ by country, driven by wages, skill levels, and labor laws. Southeast Asian countries like Vietnam and Indonesia typically offer lower labor costs compared to European manufacturers, but quality standards and compliance certifications may influence pricing.

-

Manufacturing Overheads: These include factory utilities, equipment depreciation, and production line efficiencies. Larger or more automated facilities often have higher initial investments but can reduce per-unit costs over volume.

-

Tooling & Molds: Custom molds or tooling for specific designs, logos, or sizes involve upfront costs. These are amortized over the production volume, making high-volume orders more cost-effective.

-

Quality Control & Certifications: Ensuring compliance with international standards (ISO, CE, ASTM) can add to costs but is crucial for market access, especially in Europe and the Middle East.

-

Logistics & Shipping: Freight costs depend on order volume, destination port, and chosen Incoterms. Shipping by sea is cost-effective for large volumes, while air freight is faster but significantly more expensive. Duties, tariffs, and taxes vary by importing country.

-

Margins: Suppliers typically incorporate profit margins within their prices, which can range from 10% to 30%, depending on the supplier’s reputation, volume, and relationship dynamics.

Price Influencers and Their Impact

Several factors influence the final pricing of Ken Griffey shoes in the B2B context:

-

Order Volume & MOQ: Larger orders benefit from economies of scale, reducing per-unit costs. Many suppliers offer tiered pricing, with significant discounts for high-volume commitments.

-

Specifications & Customization: Tailored designs, branding, or special features elevate costs. Standard models are more economical, but customization can command premiums.

-

Materials & Quality Standards: Premium materials and higher-grade certifications (e.g., sustainable sourcing, organic components) increase costs but may open premium markets.

-

Supplier Location & Capabilities: Suppliers in regions with established footwear manufacturing ecosystems (Vietnam, Indonesia) often provide more competitive prices due to mature supply chains and infrastructure.

-

Incoterms & Delivery Terms: FOB (Free on Board) and CIF (Cost, Insurance, and Freight) are common. FOB prices are typically lower but transfer responsibility to the buyer after shipment, affecting total landed costs.

Strategic Tips for International B2B Buyers

-

Negotiate Effectively: Leverage order volume and long-term partnership potential to negotiate better pricing, discounts, or favorable payment terms.

-

Focus on Total Cost of Ownership (TCO): Beyond unit price, consider logistics, tariffs, customs clearance, and potential rework costs. For example, sourcing from Vietnam might reduce manufacturing costs but could incur higher logistics expenses if shipping to Europe.

-

Standardize & Optimize: Opt for standard models to benefit from existing tooling and economies of scale. Customization should be reserved for high-margin markets or flagship products.

-

Understand Pricing Nuances: Be aware of hidden costs such as certification fees, packaging, or special handling requirements. Clarify these during negotiations to avoid surprises.

-

Evaluate Supplier Reliability & Certifications: Ensure suppliers meet quality standards and have the capacity to scale, especially when dealing with markets requiring specific certifications (e.g., CE in Europe).

Disclaimer on Price Estimates

Indicative prices for Ken Griffey shoes in B2B transactions typically range from $10 to $25 per pair for standard models in bulk quantities. Premium or customized versions can exceed this range, reaching $30 to $50 or more per unit. These figures are approximate and vary based on factors such as order size, material choices, and supplier location. Always conduct detailed supplier negotiations and request formal quotations tailored to your specific requirements.

By thoroughly analyzing these cost components and influencing factors, international buyers from Africa, South America, the Middle East, and Europe can better strategize their sourcing, negotiate effectively, and optimize their total landed costs for Ken Griffey shoes.

Spotlight on Potential ken griffey shoes Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for ken griffey shoes.)*

Essential Technical Properties and Trade Terminology for ken griffey shoes

Key Technical Properties for Ken Griffey Shoes

1. Material Grade

The quality of materials used—such as synthetic leather, mesh, and rubber—directly impacts durability and comfort. High-grade materials ensure longer product life, resistance to wear, and consistent performance, which are critical for bulk orders and brand reputation. For international buyers, verifying material certifications (e.g., OEKO-TEX, ISO standards) is essential to meet local safety and quality regulations.

2. Manufacturing Tolerance

Tolerance refers to the permissible deviation in dimensions during production, typically measured in millimeters or percentages. Tight tolerances (e.g., ±0.5mm) indicate precise manufacturing, reducing defects and ensuring uniformity across batches. This consistency is vital for quality control, especially when scaling orders for multiple markets with different standards.

3. Weight Specifications

The weight of the shoe affects consumer perception and performance. Lighter shoes are preferred for athletic use, while heavier models may appeal for casual wear. Accurate weight specifications help B2B buyers assess suitability for target markets and price positioning, influencing logistics and shipping costs.

4. Sole Composition and Traction Properties

The outsole material—such as rubber or TPU—determines grip and durability. High-traction soles reduce slipping and are crucial for athletic shoes like Ken Griffey models. Understanding the composition helps buyers evaluate product longevity and safety standards across various climates and terrains.

5. Colorfastness and Finish Quality

Colorfastness ensures that the shoes retain their appearance after exposure to elements like sweat, water, and UV rays. Finish quality pertains to surface smoothness and branding details. Both properties impact consumer satisfaction and brand perception, which are key for retail success.

Essential Trade Terms for B2B Engagement

1. OEM (Original Equipment Manufacturer)

Refers to factories that produce shoes based on a brand’s design and specifications. B2B buyers should clarify OEM capabilities, including customization options, quality standards, and lead times, to ensure product consistency with their branding requirements.

2. MOQ (Minimum Order Quantity)

The smallest quantity a manufacturer requires to commence production. Understanding MOQ helps buyers plan inventory and negotiate pricing. Lower MOQs are advantageous for testing markets or limited launches, especially in regions with smaller retail outlets.

3. RFQ (Request for Quotation)

A formal process where buyers solicit detailed price quotes, lead times, and terms from suppliers. An RFQ is essential for comparing multiple suppliers and ensuring transparency in costs, especially when sourcing across diverse markets.

4. Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and delivery—such as FOB (Free on Board), CIF (Cost, Insurance, Freight), and DDP (Delivered Duty Paid). Familiarity with Incoterms ensures clarity on who bears costs and risks at each stage of transit, facilitating smoother international transactions.

5. Lead Time

The period from order placement to product delivery. Accurate knowledge of lead times helps B2B buyers coordinate inventory, marketing campaigns, and retail launches, especially when working with manufacturers in regions like Asia or South America.

6. Quality Inspection Standards

Agreements on inspection criteria—such as ISO standards or third-party audits—ensure product quality before shipment. Establishing clear standards minimizes the risk of receiving defective goods, which is critical for maintaining customer satisfaction in diverse markets.

By understanding these technical properties and trade terms, international buyers from Africa, South America, the Middle East, and Europe can make informed decisions, streamline procurement processes, and foster successful supplier relationships. Clear communication of specifications and terms ensures products meet market expectations and compliance standards, ultimately supporting sustainable growth and brand reputation globally.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the ken griffey shoes Sector

Market Overview & Key Trends

The global market for athletic footwear, including iconic models like Ken Griffey shoes, is driven by several converging factors. Consumer demand for performance, style, and brand heritage sustains steady growth, with particular emphasis on retro and limited-edition releases that appeal to collectors and enthusiasts worldwide. For international B2B buyers from Africa, South America, the Middle East, and emerging markets such as Vietnam and Indonesia, this offers opportunities to tap into a highly receptive customer base eager for authentic and innovative products.

Emerging sourcing trends are reshaping supply chain strategies. Digitalization of procurement platforms and data-driven demand forecasting enable buyers to access real-time inventory updates and streamline procurement processes. Additionally, increased adoption of advanced manufacturing technologies—such as 3D printing and automation—reduces lead times and costs, making it easier for international buyers to secure product batches tailored to regional preferences.

Market dynamics are also influenced by geopolitical factors, tariffs, and trade agreements, which can affect sourcing costs and timelines. Buyers should monitor regional trade policies to optimize import/export strategies. Furthermore, the rising influence of e-commerce platforms facilitates direct-to-consumer sales, prompting brands and suppliers to develop flexible, scalable distribution channels.

For buyers in regions like Africa, South America, and Southeast Asia, establishing strong relationships with regional distributors and local manufacturers can mitigate logistical hurdles. Embracing multi-channel sourcing—combining direct imports with local assembly or customization—can enhance market responsiveness and competitiveness.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a core consideration in sourcing Ken Griffey shoes, driven by increasing consumer awareness and regulatory pressures. Environmentally conscious buyers prioritize suppliers that adhere to sustainable practices, including the use of eco-friendly materials, water conservation, and waste reduction throughout the manufacturing process.

Certifications such as Global Organic Textile Standard (GOTS), Forest Stewardship Council (FSC), and Leather Working Group (LWG) are vital indicators of a supplier’s commitment to sustainability and ethical standards. B2B buyers should verify these credentials during supplier evaluations to ensure compliance with international environmental and social norms.

Ethical sourcing also encompasses fair labor practices, transparent supply chains, and social responsibility initiatives. Collaborating with suppliers who uphold these principles not only mitigates reputational risks but also aligns with the growing demand from end consumers for ethically produced products.

Innovations in sustainable materials—such as recycled polyester, plant-based dyes, and bio-based rubber—offer avenues for differentiation in the marketplace. Engaging with suppliers committed to green innovation can improve product appeal and help meet stringent environmental regulations across regions like Europe and the Middle East.

Brief Evolution/History (Optional)

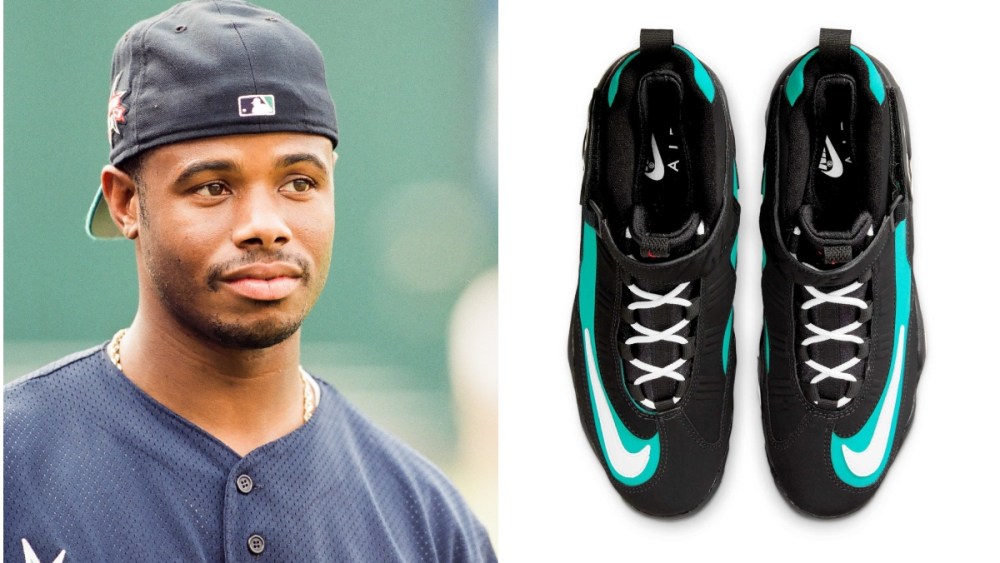

The evolution of Ken Griffey shoes reflects a broader trend in athletic footwear—moving from basic performance gear to iconic lifestyle and collectible items. Originally launched in the late 1980s, these shoes gained popularity through their association with the baseball legend Ken Griffey Jr. and their innovative design features. Over the decades, the model has seen multiple reissues and collaborations, making it a sought-after product in both athletic and sneakerhead communities.

For B2B buyers, understanding this history underscores the importance of authenticity, limited editions, and brand storytelling in product positioning. Leveraging these elements can create premium offerings that command higher margins and foster brand loyalty across diverse markets. Recognizing the brand’s legacy also informs sourcing strategies that emphasize quality, authenticity, and heritage—key factors in maintaining consumer trust and market relevance.

Illustrative Image (Source: Google Search)

Frequently Asked Questions (FAQs) for B2B Buyers of ken griffey shoes

1. How can I verify the legitimacy and reliability of a Ken Griffey shoes supplier?

Verifying supplier legitimacy is critical for secure transactions. Start by requesting official business licenses, export certificates, and third-party audit reports. Check their reputation through industry trade associations, online B2B marketplaces, and customer reviews. Request references from other international buyers, especially those from your region, to confirm their delivery consistency and product quality. Additionally, consider visiting supplier facilities or engaging third-party inspection services before placing large orders. Partnering with verified suppliers reduces risks related to counterfeit products, non-compliance, and unreliable delivery timelines.

2. What customization options are available for Ken Griffey shoes in B2B orders?

Many suppliers offer customization to meet branding or regional preferences. Common options include logo placement, color schemes, material choices, and packaging. For bulk orders, negotiate minimum order quantities (MOQs) that accommodate your customization needs without excessive costs. Clarify lead times for customization, as complex designs may require additional production time. Ensure detailed specifications are documented in contracts to prevent misunderstandings. Customization can significantly enhance your brand presence in local markets, but always verify supplier capability and ensure quality control standards are maintained throughout the process.

3. What are typical MOQs, lead times, and payment terms for bulk orders of Ken Griffey shoes?

MOQ requirements vary depending on the supplier and customization complexity, typically ranging from 500 to 2,000 pairs. Lead times generally span 4 to 12 weeks, influenced by order size and customization. For payments, suppliers often prefer a 30% deposit upfront, with the balance paid before shipment or upon delivery. Some may accept letters of credit or bank guarantees, especially for larger transactions. Negotiate flexible payment terms aligned with your cash flow, and establish clear timelines to synchronize with your distribution plans. Building strong relationships can facilitate better terms over time.

4. What quality assurance certifications and standards should I look for?

Ensure suppliers adhere to internationally recognized quality standards such as ISO 9001 or equivalent. Request detailed quality assurance (QA) reports, factory audit certificates, and test reports for materials and safety compliance. For footwear, compliance with regional standards like REACH (Europe), CPSIA (North America), or local certification bodies is essential. Verify whether the supplier conducts pre-shipment inspections and if third-party QA agencies are involved. These certifications and procedures help guarantee product safety, durability, and compliance with regional regulations, reducing the risk of product recalls or legal issues in your target markets.

5. How can I manage logistics and shipping efficiently from suppliers in Asia or other regions?

Start by selecting suppliers experienced in international shipping and familiar with your destination country’s import regulations. Choose reliable freight forwarders or logistics partners with track record in handling footwear shipments. Consider incoterms like FOB or CIF to clarify responsibilities and costs. Consolidate shipments when possible to reduce freight costs, and plan for customs clearance procedures, tariffs, and taxes specific to your region. Establish clear communication channels for real-time updates. Proactively managing logistics ensures timely delivery, minimizes delays, and controls costs, especially critical when operating across continents.

6. What should I do if I encounter disputes or product quality issues?

Establish clear contractual terms covering quality standards, inspection procedures, and dispute resolution mechanisms before placing orders. In case of disputes, gather evidence such as photos, inspection reports, and correspondence. Engage a third-party inspection service immediately upon receiving the shipment to verify claims. Negotiate directly with the supplier for corrective actions, replacements, or refunds. If unresolved, consider arbitration or legal avenues based on the jurisdiction specified in your contract. Building strong communication and documented evidence from the outset helps resolve issues efficiently and preserves long-term business relationships.

7. How can I ensure compliance with regional import regulations and tariffs?

Research import regulations, tariffs, and labeling requirements specific to your country or region, such as customs duties, product standards, and packaging laws. Collaborate with local customs brokers or trade consultants to navigate complex procedures. Ensure supplier provides all necessary documentation, including commercial invoices, certificates of origin, and compliance certificates. Proper documentation minimizes delays and prevents penalties. Staying updated on trade agreements and tariff changes helps optimize costs. Establishing compliance protocols ensures smooth entry into your market, safeguarding your investment and reputation.

8. What are the best practices for building long-term B2B relationships with suppliers?

Focus on transparent communication, timely payments, and consistent order volumes to build trust. Regularly visit supplier facilities or conduct virtual audits to maintain quality standards. Negotiate flexible terms as your partnership matures, including better MOQs, payment terms, and lead times. Share market insights and collaborate on product innovations to deepen the relationship. Providing feedback and resolving issues promptly fosters loyalty. Long-term partnerships reduce procurement risks, improve pricing, and enhance customization options, giving you a competitive edge in your target markets across Africa, South America, the Middle East, and Southeast Asia.

This set of FAQs offers comprehensive, actionable insights tailored to international B2B buyers sourcing Ken Griffey shoes, emphasizing due diligence, customization, logistics, and relationship management to succeed in global trade.

Strategic Sourcing Conclusion and Outlook for ken griffey shoes

Conclusion and Future Outlook

Effective strategic sourcing for Ken Griffey shoes offers B2B buyers the opportunity to optimize costs, enhance product quality, and strengthen supply chain resilience. By carefully evaluating suppliers across regions—such as Asia, Europe, and emerging markets—buyers can capitalize on diverse manufacturing capabilities and competitive pricing, while mitigating risks associated with geopolitical or logistical disruptions.

For international buyers from Africa, South America, the Middle East, and Southeast Asia, establishing robust supplier relationships and embracing innovative sourcing strategies are crucial for gaining a competitive edge. Leveraging local market insights, fostering partnerships, and prioritizing compliance with quality standards will enable sustainable growth and market differentiation.

Looking ahead, the evolving global trade landscape underscores the importance of agility and strategic diversification in sourcing approaches. B2B buyers should continuously monitor industry trends, technological advancements, and geopolitical developments to adapt proactively. By doing so, they can unlock new opportunities, ensure reliable supply chains, and meet the growing demand for Ken Griffey shoes in their respective markets.

Act now—embrace strategic sourcing as a vital tool to elevate your procurement practices and secure long-term success in the dynamic global footwear industry.