Your Ultimate Guide to Sourcing Marathon Running Shoes

Guide to Marathon Running Shoes

- Introduction: Navigating the Global Market for marathon running shoes

- Understanding marathon running shoes Types and Variations

- Key Industrial Applications of marathon running shoes

- Strategic Material Selection Guide for marathon running shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for marathon running shoes

- Comprehensive Cost and Pricing Analysis for marathon running shoes Sourcing

- Spotlight on Potential marathon running shoes Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for marathon running shoes

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the marathon running shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of marathon running shoes

- Strategic Sourcing Conclusion and Outlook for marathon running shoes

Introduction: Navigating the Global Market for marathon running shoes

In the highly competitive and rapidly evolving world of marathon running, the significance of high-performance shoes cannot be overstated. For B2B buyers across Africa, South America, the Middle East, and Europe—including key markets like Australia and Italy—sourcing the right marathon running shoes is crucial to gaining a competitive edge, meeting consumer demands, and ensuring brand reputation. This guide provides a comprehensive overview of the global marketplace, equipping buyers with the insights needed to make informed sourcing decisions.

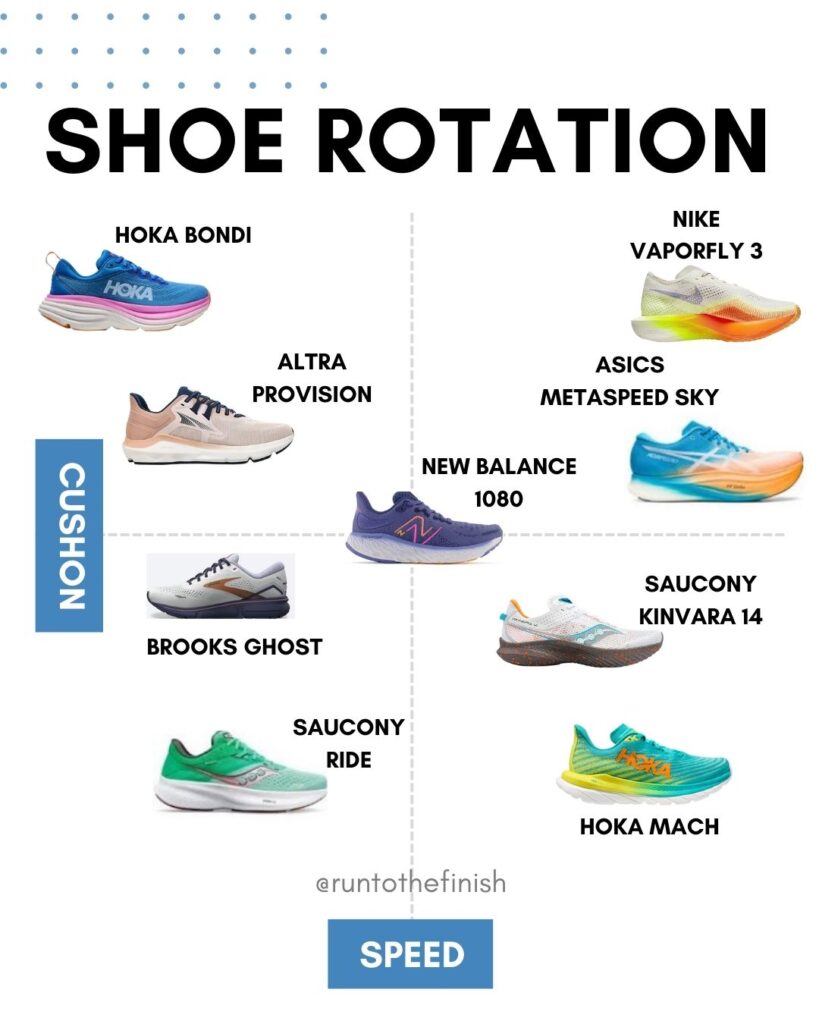

From understanding the diverse range of product types—such as lightweight racing shoes, cushioned training models, and specialized custom designs—to evaluating the latest innovations in materials and manufacturing techniques, this resource covers all critical aspects. It also delves into quality control standards, supplier landscapes, cost considerations, and market trends, enabling buyers to optimize their procurement strategies.

Furthermore, the guide addresses common challenges faced by international buyers, including navigating regional supply chains, assessing supplier reliability, and balancing quality with cost-efficiency. Whether you’re sourcing from established manufacturing hubs in Asia or exploring emerging suppliers in South America and Africa, this guide empowers you to identify trustworthy partners and secure products that meet your specific market needs.

By leveraging these insights, B2B buyers can confidently navigate the complexities of the global marathon running shoe market, ensuring they select partners and products that enhance performance, satisfy customer expectations, and drive sustainable growth.

Illustrative Image (Source: Google Search)

Understanding marathon running shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cushioning-Focused Shoes | Maximalist midsole cushioning, soft materials, plush feel | Retail, specialty running stores, sports brands | Pros: High consumer appeal, reduces injury risk. Cons: Higher production costs, bulkier packaging. |

| Lightweight Racing Shoes | Minimalist design, ultra-lightweight materials, responsive sole | Competitive racing, premium segments | Pros: Attracts performance-oriented buyers, premium pricing. Cons: Less durable, limited versatility. |

| Stability Shoes | Support features like medial posts, structured midsole | Market segments with overpronators, clinics | Pros: Broader customer base, perceived as supportive. Cons: Slightly higher manufacturing complexity, heavier. |

| Trail Marathon Shoes | Rugged outsole, reinforced toe caps, enhanced grip | Specialty outdoor and trail markets | Pros: Expands product range, appeals to niche segments. Cons: Higher R&D costs, limited indoor use. |

| Eco-Friendly Shoes | Sustainable materials, biodegradable components | Eco-conscious brands, health-focused markets | Pros: Growing demand, differentiation. Cons: Higher raw material costs, supply chain complexity. |

Cushioning-Focused Shoes

Cushioning-focused marathon shoes are designed with maximalist midsoles, often utilizing EVA or proprietary foam compounds to absorb impact. They are ideal for runners seeking comfort and injury prevention, making them popular among retail outlets targeting casual and mid-tier runners. For B2B buyers, sourcing these requires ensuring consistent foam quality and supply chain reliability, as consumer expectations for cushioning are high. Packaging and branding should emphasize comfort and health benefits to attract end-users.

Lightweight Racing Shoes

These shoes prioritize minimal weight and responsiveness, often featuring thin uppers and carbon plates or responsive foams. They appeal to performance-focused runners and elite athletes, making them suitable for premium retail segments. B2B buyers should evaluate supplier expertise in lightweight materials and ensure quality control to maintain performance standards. They are less durable and versatile, so bulk procurement should consider product lifecycle and return policies to mitigate unsold inventory risks.

Stability Shoes

Stability marathon shoes incorporate support features like medial posts and structured midsoles to assist overpronators. They cater to a broad demographic, including older athletes or those with specific biomechanical needs. For B2B buyers, understanding the technical specifications and ensuring consistent support features across batches is vital. They often command higher manufacturing costs but can expand market reach, especially in regions with high prevalence of biomechanical issues.

Trail Marathon Shoes

Designed for off-road conditions, trail marathon shoes feature rugged outsoles with aggressive lugs, reinforced toe caps, and water-resistant uppers. They open avenues in outdoor sports markets, particularly in regions with varied terrains like Africa or South America. B2B buyers should assess durability and R&D investments, as these shoes often require specialized manufacturing processes. They are less suitable for indoor or road use, so inventory segmentation is crucial.

Eco-Friendly Shoes

With sustainability gaining momentum globally, eco-friendly marathon shoes utilize recycled or biodegradable materials. They appeal to eco-conscious consumers and brands looking to differentiate in competitive markets like Europe or Australia. B2B buyers should evaluate raw material sourcing, supply chain transparency, and certification standards. While they often command premium prices, careful sourcing and consistent quality assurance are essential to meet consumer expectations and brand promises.

This segmentation provides B2B buyers with a strategic overview to tailor their procurement, marketing, and distribution efforts across diverse geographic markets, aligning product offerings with regional preferences and consumer trends.

Key Industrial Applications of marathon running shoes

| Industry/Sector | Specific Application of marathon running shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Sports & Athletic Equipment Manufacturers | Development of high-performance, durable running shoes for athletes | Enhances product portfolio with innovative, proven technology, boosting market competitiveness | Material quality, technological innovation, brand reputation, compliance with international standards |

| Healthcare & Rehabilitation | Custom orthotic and therapeutic footwear inspired by marathon shoe ergonomics | Provides effective solutions for injury prevention and recovery, expanding medical product offerings | Biocompatibility, comfort, customization capabilities, regulatory approvals |

| Footwear & Apparel Retailers | Premium athletic footwear for retail sale targeting sports enthusiasts | Differentiates product lines, attracts niche markets, and increases margins | Brand partnerships, supply chain reliability, adherence to regional market preferences |

| Manufacturing & R&D | Material testing and development for performance footwear | Supports innovation, accelerates product development cycles, reduces R&D costs | Material sourcing, testing standards, scalability, and supplier certifications |

| Military & Tactical Gear | Tactical footwear inspired by marathon shoe designs for durability and comfort | Improves soldier mobility and endurance, enhances product durability in rugged environments | Ruggedness, durability, compliance with military standards, supply chain robustness |

Sports & Athletic Equipment Manufacturers

Marathon running shoes are central to the development of high-performance athletic footwear. Manufacturers leverage advanced cushioning, energy return, and lightweight materials to create products that meet elite athlete standards. For B2B buyers, especially in Africa and South America, sourcing innovative marathon shoe components can differentiate their offerings in competitive markets. Ensuring high-quality materials, technological integration, and compliance with international standards like ISO or ASTM is critical to maintain product credibility and consumer trust.

Illustrative Image (Source: Google Search)

Healthcare & Rehabilitation

In the healthcare sector, marathon shoes inspire ergonomic and orthotic footwear designed for injury prevention and rehabilitation. These shoes address specific biomechanical needs, offering superior shock absorption and support. For international buyers, particularly in Europe and the Middle East, sourcing from brands with proven ergonomic designs and regulatory approvals ensures safety and efficacy. Customization options and biocompatible materials are vital to meet diverse patient needs and expand medical product portfolios.

Footwear & Apparel Retailers

Retailers targeting sports and fitness markets can capitalize on premium marathon shoes to attract niche segments such as endurance athletes and serious runners. These shoes often feature cutting-edge technology, appealing to consumers seeking performance and durability. For B2B buyers, establishing reliable supply chains with reputable manufacturers ensures consistent product quality. Additionally, understanding regional preferences and branding opportunities can maximize market penetration, especially in markets like Italy and Australia.

Manufacturing & R&D

R&D entities and manufacturing firms utilize marathon shoes as a benchmark for material testing and innovation. They explore new composites, sole designs, and ergonomic features to enhance performance and comfort. For international buyers, sourcing from trusted suppliers with advanced testing facilities and scalable production capabilities reduces time-to-market and R&D costs. Ensuring compliance with industry standards accelerates product approval and adoption in global markets.

Military & Tactical Gear

Marathon-inspired footwear is increasingly adapted for tactical and military applications, emphasizing durability, comfort, and endurance. These shoes support prolonged physical activity in rugged environments, improving soldier mobility and reducing injury risks. B2B buyers in defense sectors should prioritize sourcing from suppliers with proven ruggedness, compliance with military standards, and robust supply chains to ensure reliability in critical operations across diverse geographies including Africa and the Middle East.

Strategic Material Selection Guide for marathon running shoes

Material Analysis for Marathon Running Shoes

Selecting the appropriate materials for marathon running shoes is critical for ensuring product performance, durability, and compliance across diverse markets. For international B2B buyers, understanding the properties, advantages, and limitations of common materials enables informed sourcing decisions aligned with regional standards and consumer preferences.

Synthetic Mesh Fabrics (e.g., Polyester, Nylon)

Key Properties:

Synthetic mesh fabrics are widely used for uppers due to their lightweight, breathability, and flexibility. They typically withstand moderate temperature ranges (around -20°C to 60°C) and are resistant to moisture and environmental exposure. Their open structures facilitate airflow, enhancing comfort during long-distance runs.

Pros & Cons:

Advantages include low manufacturing costs, ease of customization, and good weight-to-strength ratio. However, synthetic meshes can be prone to tearing under high stress and may degrade over time with UV exposure. They are less resistant to abrasion compared to natural fibers, which can impact longevity.

Impact on Application:

Synthetic meshes are compatible with various adhesives and coatings, allowing for seamless integration with other shoe components. They also facilitate branding and aesthetic customization, which appeals to diverse regional markets.

International Considerations:

Buyers from Africa, South America, the Middle East, and Europe should verify compliance with regional standards such as REACH (Europe), ASTM (North America), or JIS (Japan). Synthetic fabrics often meet these standards but require documentation. Additionally, sourcing from suppliers with environmentally sustainable practices (e.g., recycled polyester) aligns with growing eco-conscious consumer preferences.

Thermoplastic Polyurethane (TPU)

Key Properties:

TPU is a versatile polymer known for its excellent abrasion resistance, elasticity, and chemical stability. It withstands a wide temperature range (-40°C to 80°C) and offers high tensile strength, making it suitable for midsole reinforcement, heel counters, and outsole components.

Pros & Cons:

TPU provides durability and flexibility, reducing the likelihood of cracking or tearing during intense use. Its manufacturing process is more complex and costly than simpler plastics, which can elevate product costs. Additionally, some grades of TPU may be sensitive to certain solvents or oils, affecting compatibility with specific adhesives.

Impact on Application:

TPU’s chemical resistance makes it compatible with various adhesives and coatings, facilitating manufacturing processes across different regions. Its high performance in outsole applications enhances longevity, especially in regions with rough terrains or variable climates.

International Considerations:

Regulatory compliance is crucial; buyers should ensure TPU materials meet regional standards such as REACH (Europe) or EPA regulations (U.S.). For markets like Africa and South America, sourcing from suppliers adhering to environmental and safety standards reduces regulatory hurdles and enhances product credibility.

Ethylene Vinyl Acetate (EVA)

Key Properties:

EVA is a foam material characterized by its excellent cushioning, flexibility, and lightweight nature. It performs well within temperature ranges from -30°C to 70°C and offers good shock absorption, critical for marathon running.

Pros & Cons:

EVA is cost-effective, easy to mold, and provides consistent cushioning. However, it is less durable than rubber or TPU, prone to compression set over time, which can diminish shock absorption. Its susceptibility to UV degradation necessitates protective coatings for outdoor use.

Impact on Application:

EVA’s compatibility with adhesives and ease of molding make it ideal for midsoles. Its lightweight properties are highly valued in performance footwear, especially in markets where consumer demand emphasizes comfort and affordability.

International Considerations:

Buyers should verify that EVA materials comply with regional safety standards, including VOC emissions and chemical content. Suppliers with certifications such as ISO 9001 or environmental management standards (ISO 14001) are preferable, especially for environmentally conscious markets like Europe and Australia.

Summary Table

| Material | Typical Use Case for marathon running shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Synthetic Mesh Fabrics | Uppers, breathability, lightweight | Breathability, low cost | Prone to tearing, UV degradation | Low |

| Thermoplastic Polyurethane (TPU) | Outsoles, reinforcements, heel counters | Durability, chemical stability | Higher manufacturing cost, complex processing | High |

| Ethylene Vinyl Acetate (EVA) | Midsoles, cushioning | Cost-effective, lightweight | Less durable, UV sensitive | Low |

This detailed understanding of material properties and regional considerations empowers international B2B buyers to optimize sourcing strategies, ensuring that their marathon running shoes meet both performance standards and consumer expectations across diverse markets.

In-depth Look: Manufacturing Processes and Quality Assurance for marathon running shoes

Manufacturing Processes for Marathon Running Shoes

The production of marathon running shoes involves a series of meticulously planned stages, each critical to ensuring product performance, durability, and comfort. For international B2B buyers, understanding these processes helps in assessing supplier capabilities and aligning quality expectations.

1. Material Preparation and Procurement

The manufacturing journey begins with sourcing high-performance materials such as lightweight mesh fabrics, engineered foams, rubber compounds, and thermoplastics. Suppliers often work with global or regional raw material providers, emphasizing certifications like ISO 9001 or ISO 14001 for quality and environmental management. Buyers should verify the authenticity of certifications and request detailed material test reports to ensure compliance with international standards.

2. Cutting and Forming

In this stage, digital CAD/CAM systems are employed to design precise patterns that optimize material usage and fit. Automated cutting machines, including laser or ultrasonic cutters, enhance precision and reduce waste. For B2B buyers, ensuring the supplier’s equipment is calibrated regularly and their processes are documented is vital for consistency across batches.

3. Assembly and Bonding

The assembled components—upper, midsole, outsole, and insoles—are bonded using advanced techniques such as heat welding, adhesive bonding, or stitching. For marathon shoes, particular attention is paid to the midsole’s foam density and the outsole’s durability. Suppliers should utilize industry-leading adhesives compliant with health and safety standards (e.g., REACH, RoHS) and employ automated or semi-automated stitching for uniformity.

4. Finishing and Quality Checks

The final phase involves finishing touches like trimming excess material, applying logos, and performing surface treatments. Automated inspection systems or manual checks are used to ensure aesthetic standards and dimensional accuracy. Suppliers may also perform specific tests like flexing or compression to simulate wear conditions.

Quality Assurance (QA) and Industry Standards

For B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, understanding the QA landscape is essential to mitigate risks and ensure product reliability.

1. International Standards Compliance

Most reputable manufacturers adhere to ISO 9001, which emphasizes a quality management system focusing on continuous improvement and customer satisfaction. Additionally, compliance with regional standards such as the European CE marking, ASTM standards, or ASTM F2413 (for safety footwear) enhances credibility. Buyers should request certification documentation and audit reports confirming adherence.

2. Industry-Specific Certifications and Testing

Given the high-performance demands of marathon shoes, specific testing protocols are standard:

– Durability Testing: Abrasion resistance, flex testing, and wear simulations using equipment like the Taber Abraser or Dynatup testers.

– Cushioning and Shock Absorption: Impact attenuation tests, often performed on custom test rigs, to verify midsole performance.

– Environmental Testing: Resistance to moisture, UV exposure, and temperature variations to ensure longevity across diverse climates.

3. Quality Control Checkpoints

Effective QC integrates multiple stages:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival for defects, certifications, and compliance.

– In-Process Quality Control (IPQC): During manufacturing, continuous inspections ensure process adherence, including dimensional checks, bonding strength tests, and visual inspections.

– Final Quality Control (FQC): The finished shoes undergo comprehensive testing—visual inspection, functional testing (flexibility, weight), and packaging verification—before shipment.

4. Testing Methods and Equipment

Standardized testing methods include:

– Mechanical Tests: Tensile, shear, and peel tests for adhesives.

– Physical Tests: Drop tests, compression tests, and fatigue testing.

– Environmental Tests: Humidity chambers, UV exposure, and temperature cycling.

Investing in advanced testing equipment and maintaining rigorous documentation is crucial for suppliers aiming to serve international markets.

Verifying Supplier Quality for International Buyers

For B2B buyers from diverse regions, establishing trust in supplier QC processes is paramount. The following strategies are recommended:

- Third-Party Inspections: Engage accredited inspection agencies like SGS, Bureau Veritas, or Intertek to perform pre-shipment audits, verifying compliance with agreed standards and specifications.

- Factory Audits: Conduct comprehensive audits focusing on manufacturing capabilities, QC procedures, employee safety, and environmental practices. This is especially relevant for buyers from regions with strict import regulations, such as Europe and Australia.

- Quality Documentation and Reports: Require detailed test reports, material certificates (e.g., OEKO-TEX, REACH compliance), and batch records to validate quality claims.

- Sample Verification: Request production samples for independent testing or third-party lab analysis to confirm lab reports’ authenticity and product performance.

Nuances for Different Regional Buyers

Africa & South America:

Buyers often face logistical challenges and varied regulatory environments. Emphasize suppliers with robust QC documentation, flexible testing options, and experience exporting to similar markets. Verify compliance with local import regulations and standards, and consider establishing long-term partnerships with manufacturers demonstrating consistent quality.

Middle East:

Climate resilience is vital; ensure suppliers test for heat and humidity resistance. Certifications like ISO 14001 and REACH compliance are critical, as environmental standards are increasingly enforced. On-site audits can confirm factory adherence to safety and quality practices.

Europe & Australia:

Regulatory strictness necessitates comprehensive certification—CE marking, EN standards, and environmental certifications. B2B buyers should prioritize suppliers with proven track records of compliance, transparent quality documentation, and participation in industry quality initiatives.

Conclusion

A thorough understanding of manufacturing processes and quality assurance practices enables B2B buyers to make informed sourcing decisions for marathon running shoes. Emphasizing supplier certifications, rigorous testing, and transparent QC protocols reduces risks and ensures product performance across diverse markets. Engaging with suppliers who demonstrate consistent adherence to international standards and proactive quality management is essential for building reliable supply chains in the competitive global sports footwear industry.

Comprehensive Cost and Pricing Analysis for marathon running shoes Sourcing

Cost Structure Breakdown

Understanding the detailed cost components involved in sourcing marathon running shoes is essential for effective negotiation and pricing strategy. The primary cost elements include:

-

Materials: High-performance synthetics, engineered mesh, rubber outsoles, and specialized foam insoles are standard. Material costs can vary significantly based on quality, sourcing country, and whether eco-friendly or certified materials are used. Premium materials like carbon fiber plates or antimicrobial fabrics elevate costs but can add value.

-

Labor: Manufacturing labor costs depend heavily on the country of production. For instance, Asian manufacturers (China, Vietnam, Indonesia) often offer lower labor costs but may have longer lead times or different quality standards. European or Middle Eastern factories might command higher wages but often provide quicker turnaround and higher quality assurance.

-

Manufacturing Overhead: Includes equipment depreciation, factory utilities, and indirect labor. These costs are generally embedded within the unit price but can vary with factory size and efficiency.

-

Tooling and Prototyping: Initial mold creation for outsole, midsole, and upper designs involves significant upfront costs, which are amortized over large production runs. Customization or complex designs will increase tooling expenses.

-

Quality Control (QC): Rigorous QC processes are vital, especially for international markets demanding certifications (ISO, CE, etc.). Higher QC standards can marginally increase costs but reduce return rates and warranty claims.

-

Logistics and Shipping: Freight costs fluctuate with global fuel prices, shipping method (air vs. sea), and destination port congestion. Incoterms (e.g., FOB, CIF) influence who bears transportation costs and risks.

-

Profit Margin: Manufacturers typically aim for a 10-30% profit margin, but this varies depending on order volume, relationship strength, and market competitiveness.

Price Influencers

Several factors influence the final unit price beyond raw costs:

-

Order Volume & MOQ: Larger orders significantly reduce per-unit costs due to economies of scale. Many suppliers offer discounts for bulk purchases, with MOQs ranging from 500 to 10,000 pairs depending on the manufacturer.

-

Specifications & Customization: Advanced features like lightweight materials, custom branding, unique colorways, or specialized insoles increase costs. Standard models are more cost-effective but less differentiated.

-

Material Choice: Premium or eco-certified materials come at a premium, but they can justify higher retail prices and meet specific market demands, particularly in Europe and Australia.

-

Quality Certifications: Buyers from Europe, Australia, or the Middle East often require compliance with strict standards. Certification costs (e.g., testing, documentation) can add to the price but are essential for market entry.

-

Supplier Factors: Established brands or suppliers with strong reputations may command higher prices due to reliability and quality assurance. Conversely, emerging manufacturers might offer competitive rates but require rigorous vetting.

-

Incoterms & Shipping Terms: FOB (Free On Board) terms shift transportation responsibility to the buyer, allowing control over logistics and costs. DDP (Delivered Duty Paid) simplifies the process but often comes at a premium.

Buyer Tips for Cost-Effective Sourcing

-

Negotiate Volume Discounts: Leverage large orders or repeat business to negotiate better unit prices. Even small incremental increases in order size can yield significant savings.

-

Focus on Total Cost of Ownership (TCO): Consider not just the unit price but also shipping, customs, duties, quality assurance, and after-sales support. For buyers in Africa, South America, or remote regions, logistics costs can substantially impact TCO.

-

Assess Pricing Nuances: Prices vary across regions due to labor costs, material availability, and supplier competition. European buyers might pay more upfront but benefit from shorter lead times and higher quality standards, while African or South American buyers should prioritize suppliers with experience in their markets and flexible payment terms.

-

Build Strong Supplier Relationships: Long-term partnerships often lead to better pricing, priority production, and improved quality.

-

Understand Certification and Compliance Costs: Ensuring compliance with local standards may involve additional testing and certification expenses. Factor these into your initial budget.

-

Stay Informed on Market Trends: Fluctuations in raw material prices, shipping rates, and currency exchange rates can impact costs. Regularly review your sourcing strategy to adapt accordingly.

Indicative Pricing (Disclaimer)

While prices vary widely based on specifications, order volume, and sourcing country, typical FOB prices for standard marathon shoes range from $20 to $40 per pair. Premium or customized models can range from $45 to $70+ per pair. For large orders (10,000+ pairs), per-unit costs often decrease by 10-20%. Always engage in detailed negotiations and request samples to validate quality before committing to large orders.

This comprehensive analysis aims to equip international B2B buyers with actionable insights to optimize sourcing strategies, negotiate effectively, and manage total costs efficiently across diverse markets.

Spotlight on Potential marathon running shoes Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for marathon running shoes.)*

Essential Technical Properties and Trade Terminology for marathon running shoes

Critical Technical Properties for Marathon Running Shoes

1. Material Grade and Composition

The quality of materials used directly impacts durability, weight, and performance. High-grade synthetic uppers, lightweight foams, and responsive midsoles ensure comfort and efficiency over long distances. For B2B procurement, specifying material grades—such as EVA foam density or TPU upper strength—helps maintain consistent product quality across batches.

2. Weight and Volume Tolerance

Lightweight shoes are crucial for marathon runners aiming to conserve energy. Tolerance levels define acceptable variances in weight and size during manufacturing, ensuring uniformity. Buyers should specify tolerances—e.g., ±5 grams for weight—to ensure product consistency, which is vital for brand reputation and athlete satisfaction.

3. Cushioning and Midsole Technology

Advanced cushioning systems (e.g., gel inserts, air pockets, or foam layers) reduce impact stress and improve comfort. Understanding the technical specifications of these systems, such as rebound energy return and compression set, allows buyers to select shoes tailored for specific running styles and terrains, enhancing athlete performance.

4. Outsole Durability and Traction

The outsole’s material composition influences grip and longevity. Rubber compounds with high abrasion resistance are preferred for marathon shoes, especially for varied surfaces. Tolerance specifications for outsole thickness and tread pattern consistency ensure durability and optimal grip, reducing injury risk.

5. Flexibility and Fit Specifications

Proper flexibility in the forefoot and a precise fit are essential for efficient running mechanics. Technical parameters like flex point location and upper stretchability should meet industry standards. These specifications impact comfort, preventing blisters and chafing during long runs.

Industry and Trade Terms for B2B Engagement

1. OEM (Original Equipment Manufacturer)

Refers to companies that produce marathon shoes under another brand’s specifications. Understanding OEM relationships enables buyers to source custom-designed shoes, ensuring product differentiation and meeting specific market needs.

2. MOQ (Minimum Order Quantity)

The smallest quantity a manufacturer is willing to produce per order. Clarifying MOQ helps buyers plan procurement volumes efficiently, manage inventory costs, and negotiate better terms, especially when entering new markets.

3. RFQ (Request for Quotation)

A formal request sent to suppliers asking for detailed pricing, lead times, and terms. Using RFQs allows buyers to compare offers objectively, ensuring competitive pricing and aligning production schedules with market demands.

4. Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities, costs, and risks during shipping (e.g., FOB, CIF). A clear understanding of Incoterms helps B2B buyers manage logistics, control costs, and mitigate risks during international transportation.

5. Lead Time

The period from order placement to product delivery. Accurate knowledge of lead times allows buyers to synchronize production schedules, plan inventory, and meet market deadlines efficiently.

6. Certification and Compliance Standards

Certifications such as ISO, REACH, or regional safety standards ensure products meet legal and safety requirements. Buyers should verify these certifications to ensure market acceptance and avoid regulatory issues in target regions.

By mastering these technical properties and trade terms, international B2B buyers from Africa, South America, the Middle East, and Europe can make informed decisions, streamline procurement processes, and establish reliable supply chains for high-quality marathon running shoes.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the marathon running shoes Sector

Market Overview & Key Trends

The global marathon running shoes sector is experiencing robust growth driven by increasing participation in endurance sports, rising health consciousness, and expanding sports infrastructure worldwide. Key markets such as North America, Europe, and parts of Asia continue to dominate, but emerging regions—Africa, South America, and the Middle East—are gaining traction due to rising disposable incomes and a growing sports culture.

For international B2B buyers, especially from Africa and South America, sourcing strategies are increasingly focused on agile, localized supply chains that can accommodate fluctuating demand and regional preferences. Digital platforms and advanced supply chain management tools are transforming procurement processes, enabling real-time inventory tracking and streamlined logistics.

Emerging trends include the adoption of innovative materials like carbon-fiber plates for enhanced propulsion and advanced cushioning technologies that improve performance and reduce injury risk. Sustainability-driven innovations, such as biodegradable midsoles and recycled uppers, are also gaining prominence, aligning with consumer and regulatory demands for eco-friendly products.

Furthermore, technological integration—such as 3D printing for custom-fit shoes and data-driven design—offers B2B buyers the chance to differentiate their offerings and meet the specific needs of diverse markets. As the sector evolves, brands are emphasizing product differentiation through performance, durability, and sustainability, which are critical factors influencing procurement decisions across regions.

For buyers from Europe and Australia, staying ahead involves monitoring these trends and establishing partnerships with manufacturers who invest in R&D and sustainable practices. In regions like the Middle East, where climate considerations are vital, sourcing lightweight, breathable, and heat-resistant materials is essential for product relevance.

Illustrative Image (Source: Google Search)

Sustainability & Ethical Sourcing in B2B

Sustainability has become a cornerstone in the marathon running shoe industry, driven by increasing consumer awareness and stricter regulations globally. For B2B buyers, integrating environmentally responsible practices into sourcing strategies is no longer optional but essential for long-term competitiveness.

Eco-conscious sourcing involves prioritizing suppliers who adhere to rigorous environmental standards, such as ISO 14001, and who utilize sustainable materials like recycled polyester, organic cotton, and plant-based rubber. Certifications such as Global Organic Textile Standard (GOTS) and Leather Working Group (LWG) are valuable indicators of ethical and sustainable practices within supply chains.

From an environmental perspective, the industry is shifting toward reducing carbon footprints through optimized manufacturing processes, energy-efficient facilities, and the use of renewable energy sources. The reduction of waste—both during production and in packaging—is also a critical focus, with many brands adopting circular economy principles.

Ethical sourcing extends beyond environmental concerns to encompass fair labor practices, transparency, and traceability. For B2B buyers, working with suppliers who demonstrate compliance with international labor standards (e.g., SA8000) and who provide traceability data ensures that products are produced ethically, mitigating risks associated with supply chain violations.

Investing in ‘green’ certifications and sustainable materials not only enhances brand reputation but also aligns with global market trends favoring eco-friendly products. For regions like Africa and South America, where local sourcing can reduce logistical emissions and support regional economies, establishing sustainable supply chains offers both environmental and socio-economic benefits.

Brief Evolution/History (Optional)

The evolution of marathon running shoes from basic cushioning designs to technologically advanced, performance-oriented footwear reflects broader industry shifts towards innovation and sustainability. Initially driven by simple comfort and durability, the sector has seen rapid technological advancements, including the integration of lightweight materials, energy-return systems, and data-driven design processes.

This evolution has significantly impacted B2B sourcing, as manufacturers now prioritize R&D investments to develop cutting-edge products that meet the high-performance expectations of global markets. Sustainability has also become integral, with early efforts focusing on recycled materials and eco-friendly manufacturing, setting the stage for more comprehensive sustainable practices today.

For international buyers, understanding this evolution provides insight into the importance of partnering with innovative, forward-thinking suppliers capable of delivering high-quality, sustainable products that meet the evolving demands of global consumers.

Frequently Asked Questions (FAQs) for B2B Buyers of marathon running shoes

1. How can I effectively vet marathon shoe suppliers to ensure product quality and reliability?

Vetting suppliers begins with thorough research and verification of their credentials. Request industry certifications such as ISO, CE, or specific footwear quality standards relevant to your target markets. Review their production facilities, ideally through virtual tours or third-party audits, to assess manufacturing processes and quality control systems. Ask for detailed samples and conduct independent testing for durability, comfort, and safety. Check references and seek feedback from other B2B clients, especially those in your region, to gauge reliability and after-sales support. Establish clear communication channels and set expectations early to foster a trustworthy partnership.

2. What customization options are typically available for marathon running shoes, and how can I incorporate branding or specific features?

Most manufacturers offer customization including branding (logos, color schemes), material selection, sole design, and performance features like enhanced cushioning or breathability. Collaborate closely with the supplier to specify your desired specifications, ensuring they can meet your quality standards. Request detailed prototypes or samples before large orders to verify the customization quality. For branding, ensure branding rights and intellectual property protections are clarified in your agreement. Advanced customization such as eco-friendly materials or specialized insoles can also be negotiated, especially if aligned with your market’s sustainability trends.

3. What are typical MOQs, lead times, and payment terms for bulk marathon shoe orders?

MOQ requirements vary widely but generally range from 500 to 5,000 pairs, depending on the manufacturer’s capacity and customization level. Lead times typically span 4 to 12 weeks from order confirmation to delivery, influenced by order complexity and logistics. Payment terms commonly include a 30% deposit upfront with the balance payable before shipment or upon delivery. Some suppliers may offer flexible terms for trusted partners or larger orders, such as letters of credit or open accounts. Establish clear agreements upfront to avoid delays, and consider building inventory buffers to mitigate supply chain disruptions.

4. What quality assurance certifications and testing should I require from suppliers?

Ensure your supplier complies with international safety and quality standards relevant to footwear, such as ISO 9001, ISO 14001, and compliance with regional standards like the European CE or the US ASTM. Request documentation of factory audits and third-party testing reports for durability, slip resistance, and non-toxicity of materials. Lab tests for sole adhesion, water resistance, and breathability can prevent future product failures. Additionally, request batch sampling and ongoing quality checks during production. Reliable suppliers will readily provide certification documentation and testing results to demonstrate adherence to these standards.

5. How do I manage international logistics and shipping for large orders to ensure timely delivery?

Coordinate with suppliers experienced in international shipping, preferably with established logistics partners. Clarify Incoterms (e.g., FOB, CIF) to define responsibilities and costs. Use reputable freight forwarders with tracking capabilities and customs clearance expertise in your region. Consider consolidating shipments to reduce costs and minimize delays. Factor in potential customs duties, import taxes, and local regulations specific to your country. Establish clear communication channels for real-time updates and contingency plans for delays caused by customs, port congestion, or transportation disruptions.

6. What should I include in dispute resolution clauses to protect my business interests?

Dispute resolution clauses should specify the preferred method (e.g., arbitration, mediation) and jurisdiction (preferably neutral or aligned with your country’s legal system). Clearly define what constitutes a breach, remedies available, and timelines for resolution. Incorporate clauses for quality disputes, delivery delays, or payment issues, ensuring they are enforceable internationally. It’s advisable to include provisions for third-party arbitration and specify applicable international trade laws. Consulting legal experts familiar with cross-border trade can help tailor these clauses to your specific markets and mitigate risks effectively.

7. How can I ensure compliance with regional import/export regulations and product standards?

Stay informed about import restrictions, tariffs, and product standards in your country and target markets. Engage with customs brokers and trade consultants to navigate complex regulations efficiently. Verify that your shoes meet regional standards, such as EU CE marking or Middle Eastern safety certifications, before shipment. Maintain comprehensive documentation including invoices, certificates of origin, and testing reports to streamline customs clearance. Regularly update your knowledge base through trade associations and government trade agencies, and ensure your supplier provides necessary compliance documentation for each shipment.

8. What are best practices for building long-term relationships with reliable marathon shoe suppliers?

Focus on transparent communication, timely payments, and mutual respect to foster trust. Regularly review supplier performance against agreed KPIs such as quality, delivery times, and responsiveness. Offer feedback and collaborate on product development to meet evolving market demands. Consider establishing strategic partnerships or exclusivity agreements for better pricing and priority service. Maintaining a diverse supplier base can mitigate risks, but investing in key reliable partners can lead to better terms and innovation. Continuous engagement and clear contractual terms ensure stability and growth in your supply chain over time.

Strategic Sourcing Conclusion and Outlook for marathon running shoes

Conclusion and Future Outlook

Effective strategic sourcing is essential for international buyers seeking to optimize quality, cost-efficiency, and supply chain resilience in the marathon running shoe market. By forging strong relationships with reputable manufacturers, leveraging regional manufacturing advantages, and staying attuned to innovation trends, buyers can secure competitive advantages in this dynamic industry.

As global demand for high-performance athletic footwear continues to grow, particularly in regions like Africa, South America, the Middle East, and Europe, proactive sourcing strategies will be key to meeting market expectations and expanding market share. Emphasizing transparency, sustainability, and technological innovation in sourcing practices will further enhance brand reputation and consumer loyalty.

Looking ahead, buyers should prioritize diversified supplier networks and stay informed of emerging manufacturing hubs and materials. Collaborating closely with suppliers and investing in long-term partnerships will mitigate risks and unlock new opportunities for growth. Embrace these strategic approaches to stay ahead in the evolving marathon shoe landscape and drive sustainable success in your international markets.