Your Ultimate Guide to Sourcing New Travis Scott Shoes

Guide to New Travis Scott Shoes

- Introduction: Navigating the Global Market for new travis scott shoes

- Understanding new travis scott shoes Types and Variations

- Key Industrial Applications of new travis scott shoes

- Strategic Material Selection Guide for new travis scott shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for new travis scott shoes

- Comprehensive Cost and Pricing Analysis for new travis scott shoes Sourcing

- Spotlight on Potential new travis scott shoes Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for new travis scott shoes

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the new travis scott shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of new travis scott shoes

- Strategic Sourcing Conclusion and Outlook for new travis scott shoes

Introduction: Navigating the Global Market for new travis scott shoes

In today’s dynamic global footwear market, new Travis Scott shoes have emerged as a highly sought-after product, blending innovative design with cultural influence. For B2B buyers across Africa, South America, the Middle East, and Europe—such as Spain and Mexico—understanding the nuances of this niche is essential to capitalize on emerging opportunities. These sneakers not only represent a significant consumer demand but also offer lucrative margins when sourced strategically.

This comprehensive guide is designed to equip international buyers with critical insights into the entire supply chain—from the different types and materials used to manufacturing processes and quality control standards. It also highlights key supplier networks, cost considerations, and market trends that influence purchasing decisions. Additionally, we address frequently asked questions to help mitigate risks and streamline procurement.

By leveraging this knowledge, B2B buyers can make informed sourcing decisions that optimize quality, cost-efficiency, and market competitiveness. Whether you are establishing new distribution channels or expanding your existing product portfolio, understanding the intricacies of new Travis Scott shoes is vital for success in a rapidly evolving marketplace. This guide aims to empower you with actionable insights to navigate complexities, identify reliable partners, and capitalize on the global demand for this iconic sneaker line.

Understanding new travis scott shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Collaboration Model | Limited-edition releases with unique design elements, often featuring Travis Scott’s branding | Retail boutiques, online sneaker stores, exclusive distribution channels | Pros: High demand, strong brand association. Cons: Limited inventory, high resale risk |

| General Release Sneakers | Standardized models with consistent design, mass-produced for broad availability | Large-scale distributors, sportswear chains | Pros: Easier procurement, predictable supply. Cons: Lower exclusivity, price competition |

| Custom/Exclusive Editions | Customized versions for specific markets or clients, often with bespoke features | Premium B2B clients, boutique retailers | Pros: High margins, brand differentiation. Cons: Higher MOQ, longer lead times |

| Regional Variants | Variations tailored for specific geographic markets, considering local preferences and regulations | Regional distributors, importers | Pros: Market-specific appeal, regulatory compliance. Cons: Increased complexity in inventory management |

| Limited-Edition Collaborations | Special releases with other brands or artists, often highly sought after | High-end retailers, collectors | Pros: High resale value, brand prestige. Cons: Scarcity can limit volume, logistical challenges |

Classic Collaboration Model

This variation includes highly curated, limited-edition Travis Scott shoes often released through exclusive collaborations with brands like Nike. These shoes feature unique design elements such as special materials, colorways, or branding, making them highly desirable. For B2B buyers, especially those targeting premium markets or sneaker collectors, these models offer high resale potential and brand prestige. However, their limited production runs pose risks related to inventory shortages and fluctuating demand. Strategic partnerships with trusted suppliers are essential for securing authentic stock and managing supply chain uncertainties.

General Release Sneakers

Mass-produced Travis Scott shoes designed for broad market penetration, these models are typically available through major retail channels and online platforms. They are characterized by consistent design, reliable quality, and scalable manufacturing. For B2B buyers, these sneakers provide predictable procurement options, lower wholesale costs, and easier inventory management. However, due to high competition and widespread availability, margins may be thinner, and brand exclusivity is limited. Buyers should focus on establishing strong relationships with authorized distributors to ensure authenticity and timely supply.

Custom/Exclusive Editions

These variants are tailored for specific markets or high-profile clients, often featuring bespoke design elements or localized branding. They are ideal for B2B buyers seeking to differentiate their offerings in niche markets or luxury segments. Custom editions typically command higher margins and can reinforce brand positioning. The main considerations include higher minimum order quantities (MOQs), longer lead times for production, and the need for close collaboration with designers or manufacturers. These editions are best suited for buyers targeting premium consumers or collectors willing to pay a premium for exclusivity.

Regional Variants

Regional variants are adapted to meet local tastes, cultural preferences, or regulatory requirements. For instance, color schemes, sizing standards, or materials might differ based on geographic markets such as Europe, Latin America, or Africa. B2B buyers should leverage regional variants to enhance market penetration and compliance, but must also manage increased inventory complexity and potential logistical challenges. Establishing local partnerships or distribution hubs can mitigate these issues and improve responsiveness to regional demand fluctuations.

Limited-Edition Collaborations

These are highly exclusive Travis Scott shoes created in partnership with other brands, artists, or designers. They often generate significant hype and command premium resale prices. For B2B buyers, especially in high-end retail or collector markets, these collaborations offer opportunities for brand elevation and profit maximization. However, their scarcity can limit sales volume, and logistical complexities around authentic sourcing and distribution need careful management. Strategic planning and early procurement are vital to capitalize on the high demand for these collectible items.

Key Industrial Applications of new travis scott shoes

| Industry/Sector | Specific Application of new travis scott shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Apparel | Wholesale distribution to retail outlets for sneaker and streetwear brands | Enhances product portfolio with trending, high-demand footwear, attracting youth and urban markets | Ensuring reliable supply chains, authenticity verification, and compliance with regional import regulations |

| Sports & Leisure | Custom branded athletic and lifestyle footwear for sports teams and events | Boosts brand visibility and engagement through collaborations and limited editions | Sourcing original designs, managing intellectual property rights, and meeting regional safety standards |

| Entertainment & Media | Licensing for promotional campaigns, music tours, and celebrity collaborations | Increases market buzz and consumer interest, leveraging Travis Scott’s brand influence | Negotiating licensing agreements, ensuring consistent quality, and managing regional distribution rights |

| E-commerce & Retail | Direct-to-consumer sales via online platforms targeting international markets | Expands reach into emerging markets like Africa, South America, and Europe, driving sales growth | Establishing reliable logistics, localized payment options, and regional customer support infrastructure |

| Manufacturing & Customization | OEM production for bespoke footwear brands and custom collaborations | Provides innovative design options, reducing time-to-market for limited editions | Securing OEM partnerships, maintaining quality control, and aligning with regional import/export policies |

Fashion & Apparel

New Travis Scott shoes are increasingly popular among youth and streetwear markets worldwide. B2B buyers in fashion and apparel sectors can leverage these shoes for wholesale distribution to retail outlets, boutiques, and online stores. The key advantage is adding trending, high-demand footwear to existing product lines, which can significantly boost sales and brand appeal. For international buyers, especially from Africa and Latin America, establishing strong relationships with authentic suppliers and verifying product origin is crucial to avoid counterfeit issues. Additionally, compliance with regional import regulations and tariffs must be considered to ensure smooth market entry.

Sports & Leisure

Sports brands and leisurewear companies can incorporate Travis Scott shoes into their product offerings, either through licensing or collaborative branding. These shoes appeal to both athletes and lifestyle consumers, providing a crossover product that enhances brand visibility. For B2B buyers, sourcing original designs and maintaining intellectual property rights are essential to prevent counterfeit infiltration. Moreover, understanding regional safety standards, especially in markets like Europe and the Middle East, ensures the footwear meets necessary certifications, fostering consumer trust and regulatory compliance.

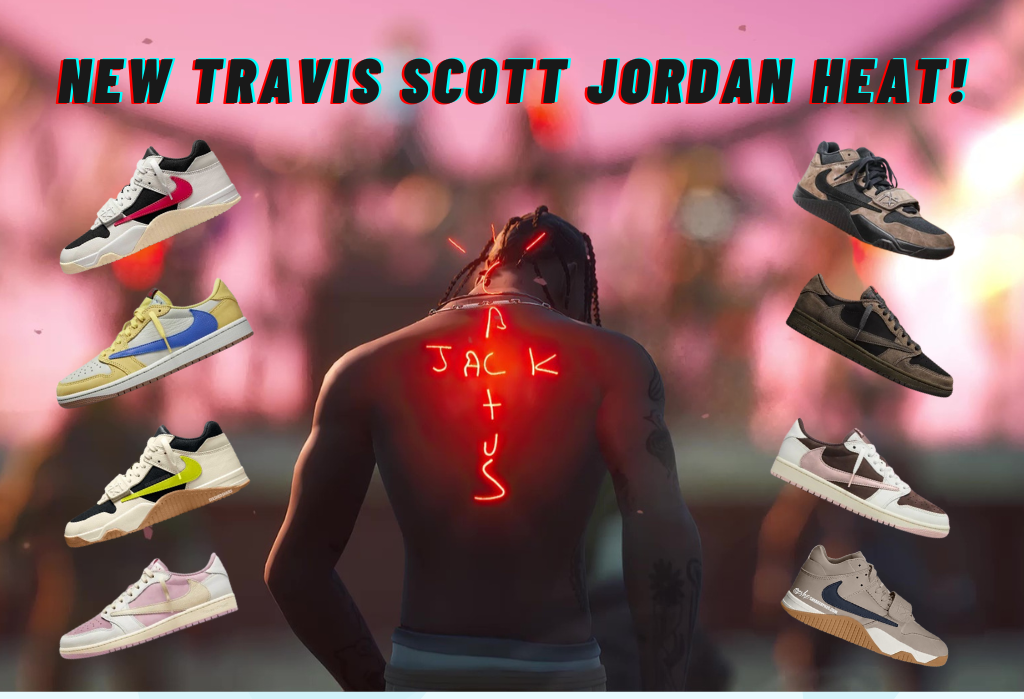

Illustrative Image (Source: Google Search)

Entertainment & Media

The dynamic nature of Travis Scott’s brand makes these shoes highly suitable for licensing in promotional campaigns, music tours, and celebrity collaborations. Entertainment companies and media agencies can use these shoes to generate hype and consumer interest, especially during high-profile events. For international B2B buyers, negotiating licensing agreements that protect regional rights is vital. Ensuring consistent product quality and managing distribution rights across different territories—such as Spain or Mexico—are key to maximizing brand impact and avoiding legal complications.

E-commerce & Retail

With the rise of online shopping, direct-to-consumer sales of Travis Scott shoes open significant opportunities in emerging markets like Africa, South America, and Europe. B2B buyers can partner with e-commerce platforms to expand reach and capitalize on regional demand. Critical considerations include establishing reliable logistics networks, offering localized payment options, and providing regional customer support. These factors are vital to ensure a seamless buying experience, foster brand loyalty, and mitigate supply chain disruptions in diverse markets.

Manufacturing & Customization

OEM manufacturing for bespoke or limited-edition Travis Scott shoes allows brands and custom footwear companies to innovate and differentiate themselves. These shoes appeal to collectors and fans seeking exclusive designs, creating a niche market. For international B2B buyers, securing OEM partnerships that adhere to quality standards and regional import/export regulations is essential. Maintaining strict quality control and aligning production with regional safety and environmental standards ensures product integrity and customer satisfaction across markets like Europe and Latin America.

Strategic Material Selection Guide for new travis scott shoes

Analysis of Common Materials for New Travis Scott Shoes

When selecting materials for new Travis Scott shoes, B2B buyers must consider performance, durability, cost, and compliance with international standards. Below is an in-depth analysis of three prevalent materials—leather, synthetic textiles, and rubber—highlighting their properties, advantages, limitations, and implications for global markets.

Leather

Key Properties:

Leather, especially full-grain or top-grain varieties, offers excellent durability, breathability, and a premium aesthetic. It provides natural flexibility and molds to the wearer over time, enhancing comfort. Leather also exhibits good resistance to abrasion but is sensitive to moisture and temperature fluctuations.

Pros & Cons:

Leather’s durability makes it suitable for high-wear areas, and its premium look appeals to consumers worldwide. However, it tends to be costly, and the manufacturing process involves significant resource use, including water and chemicals, raising sustainability concerns. Additionally, leather requires specialized tanning and finishing, which can complicate supply chains.

Impact on Application:

Leather’s breathability and aesthetic appeal make it ideal for uppers and decorative elements. Nonetheless, it is less suitable for parts exposed to excessive moisture unless treated, which could impact product longevity.

International Buyer Considerations:

Buyers from Africa, South America, the Middle East, and Europe should prioritize suppliers compliant with environmental standards such as the Leather Working Group (LWG) certifications. For markets with strict import regulations (e.g., the EU’s REACH standards), sourcing tanned leather with low chemical residues is essential. Moreover, leather’s weight and cost might influence shipping logistics and retail pricing strategies.

Synthetic Textiles

Key Properties:

Synthetic textiles, such as nylon, polyester, and mesh, are lightweight, flexible, and resistant to environmental factors like moisture and UV radiation. They can be engineered for specific performance traits, including breathability, water resistance, and stretchability.

Pros & Cons:

These materials generally offer lower production costs and simplified manufacturing processes, enabling rapid scalability. They are also easier to customize in terms of color and texture. However, synthetic textiles may lack the natural durability of leather and can degrade under prolonged UV exposure or high temperatures, potentially affecting the shoe’s lifespan.

Impact on Application:

Synthetic textiles are ideal for uppers, linings, and decorative overlays. Their moisture-wicking properties benefit performance-oriented designs, especially in humid or hot climates common in Africa and South America. However, their environmental footprint is a concern, and buyers should seek suppliers with sustainable manufacturing practices or recyclable options.

International Buyer Considerations:

Buyers should verify compliance with local environmental regulations, such as the EU’s REACH or South American standards. For regions with high humidity, moisture-resistant textiles can improve product performance and customer satisfaction. Additionally, sourcing from manufacturers with ISO 9001 or ISO 14001 certifications can ensure quality and sustainability.

Rubber

Key Properties:

Rubber, especially vulcanized rubber, provides excellent elasticity, shock absorption, and grip. It is highly resistant to wear, water, and many chemicals, making it suitable for outsoles and other structural components.

Pros & Cons:

Rubber’s durability and traction properties are unmatched for outsole applications, and it can withstand diverse environmental conditions. The downsides include its weight and potential environmental concerns if sourced from non-sustainable suppliers. Manufacturing rubber components involves vulcanization, which requires specialized equipment and expertise.

Impact on Application:

Rubber is predominantly used for outsoles, heel caps, and protective bumpers. Its chemical resistance makes it suitable for shoes intended for outdoor or rugged use. For regions with high temperatures or exposure to oils and chemicals, rubber’s resilience enhances product lifespan.

International Buyer Considerations:

Buyers should prioritize suppliers adhering to environmental standards such as the Global Rubber Sustainability Framework. Import regulations in Europe and other markets increasingly scrutinize rubber sourcing, emphasizing eco-friendly and ethically produced materials. Cost considerations are also vital, as high-quality vulcanized rubber can be more expensive but offers better longevity.

Summary Table

| Material | Typical Use Case for new Travis Scott shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather | Uppers, decorative overlays | Premium aesthetic, durability | High cost, environmental concerns | High |

| Synthetic Textiles | Uppers, linings, overlays | Lightweight, customizable, cost-effective | Less durable, environmental impact | Med |

| Rubber | Outsoles, heel caps, protective bumpers | Excellent grip, shock absorption | Heavyweight, environmental concerns | Med-High |

This comprehensive understanding of material properties enables international B2B buyers to make informed sourcing decisions aligned with regional standards, environmental commitments, and market preferences. Prioritizing compliant, sustainable, and performance-optimized materials will ensure the successful launch and longevity of Travis Scott shoes across diverse markets.

In-depth Look: Manufacturing Processes and Quality Assurance for new travis scott shoes

Manufacturing Processes for Travis Scott Shoes

The production of Travis Scott shoes involves a series of meticulously coordinated stages, each critical to ensuring product quality, consistency, and brand integrity. For international B2B buyers, understanding these stages can help in assessing supplier capabilities and establishing robust supply chain partnerships.

1. Material Preparation

The process begins with sourcing high-quality raw materials, including premium leathers, textiles, synthetics, and specialized soles. Suppliers often partner with certified vendors to ensure materials meet specified standards. Key considerations include material durability, aesthetic appeal, and compliance with international safety standards. For buyers, verifying supplier certifications (e.g., OEKO-TEX, REACH compliance) is essential to mitigate risks associated with substandard or non-compliant inputs.

2. Forming and Component Manufacturing

This stage involves cutting, molding, and shaping raw materials into components such as uppers, insoles, and outsoles. Techniques like CNC cutting, injection molding, and thermoforming are common. Advanced machinery ensures precision, reducing waste and ensuring uniformity across batches. For B2B buyers, evaluating the technological sophistication and capacity of manufacturing facilities can predict their ability to meet large-volume demands with consistent quality.

3. Assembly

Components are assembled through stitching, gluing, and bonding processes. Skilled labor combined with automated systems ensures tight tolerances and strong adhesion. Particular attention is paid to details like logo placement, stitching quality, and structural integrity. Suppliers often employ lean manufacturing principles to optimize efficiency while maintaining quality. Buyers should consider inspecting production lines or requesting detailed process documentation to verify assembly standards.

4. Finishing and Quality Control

Final touches include surface treatments, polishing, and packaging. This phase also involves rigorous quality inspections to ensure each shoe meets design specifications and safety standards. Finishing processes can incorporate branding elements, special coatings, or decorative features aligned with Travis Scott’s unique aesthetic.

Quality Assurance Protocols in Manufacturing

Implementing comprehensive quality control (QC) is vital for maintaining brand reputation and product consistency, especially for international markets with diverse regulatory landscapes.

1. International Standards and Certifications

Most reputable manufacturers adopt ISO 9001 standards, emphasizing a quality management system that promotes continuous improvement and customer satisfaction. Additional certifications relevant for specific regions include:

- CE Marking (Europe): Ensures conformity with health, safety, and environmental protection standards.

- API Certification (for certain materials or components): Validates material quality for durability and performance.

- REACH Compliance (Europe and others): Ensures chemical safety of materials used in manufacturing.

For buyers in Africa, South America, the Middle East, and Europe, verifying that suppliers hold relevant certifications can reduce compliance risks and facilitate smoother customs clearance.

2. Quality Control Checkpoints

Manufacturing involves multiple QC stages:

- Incoming Quality Control (IQC): Inspection of raw materials upon receipt to verify specifications and detect contamination or defects.

- In-Process Quality Control (IPQC): Continuous monitoring during production—checking stitching tightness, dimensional accuracy, and assembly integrity.

- Final Quality Control (FQC): Inspection of finished shoes for visual defects, structural issues, and adherence to design specs before packaging and shipment.

3. Testing Methods

Standardized testing ensures product durability and safety:

- Mechanical Testing: Tensile strength, flexural endurance, and abrasion resistance.

- Chemical Testing: Ensuring materials are free from harmful substances, complying with REACH or similar regulations.

- Environmental Testing: Resistance to water, UV exposure, and temperature fluctuations.

For high-end collaborations like Travis Scott shoes, suppliers often go beyond industry minimums to include additional aesthetic and performance tests.

4. Verification for B2B Buyers

Buyers should adopt proactive verification strategies:

- Audits and Inspections: Conduct on-site audits or hire third-party inspection agencies to assess manufacturing facilities, quality management systems, and production processes.

- Quality Reports and Documentation: Request detailed QC reports, test certificates, and compliance documentation for each batch.

- Sample Testing: Perform independent testing on samples to verify adherence to specifications before large-scale orders.

Nuances for International B2B Engagement

When sourcing Travis Scott shoes globally, B2B buyers from Africa, South America, the Middle East, and Europe must navigate regional regulatory requirements and logistical considerations.

- Regional Certification Alignment: Ensure suppliers understand regional standards such as CE for Europe, NOM for Mexico, or local safety and environmental regulations.

- Supply Chain Transparency: Favor suppliers with transparent quality documentation and traceability to mitigate risks associated with counterfeit or substandard products.

- Third-Party Inspection & Certification: Engage reputable inspection agencies (e.g., SGS, Bureau Veritas) to validate supplier claims, especially when dealing with new or less-established manufacturers.

- Cultural and Logistical Factors: Recognize regional differences in communication, language, and compliance norms. Establish clear contractual quality clauses and inspection protocols to ensure consistent quality across borders.

Final Recommendations for B2B Buyers

- Assess Supplier Capabilities: Prioritize manufacturers with proven experience in high-end sneaker production and adherence to international quality standards.

- Establish Clear Quality Expectations: Define detailed quality requirements, inspection procedures, and acceptance criteria in purchase agreements.

- Implement Continuous Monitoring: Regular audits and quality reviews help maintain standards, especially when scaling production or working with new suppliers.

- Leverage Local Expertise: Collaborate with regional quality assurance firms or consultants familiar with local manufacturing landscapes and regulatory environments.

By understanding and rigorously managing manufacturing and quality assurance processes, international B2B buyers can ensure they source authentic, high-quality Travis Scott shoes that meet regional standards and consumer expectations.

Comprehensive Cost and Pricing Analysis for new travis scott shoes Sourcing

Cost Structure Breakdown for Travis Scott Shoes

Understanding the detailed cost components involved in sourcing Travis Scott shoes is essential for international B2B buyers. The primary cost elements include:

-

Materials: Premium materials such as high-quality leather, synthetic fabrics, and specialized soles significantly influence costs. Customizations, unique design elements, or limited editions tend to elevate material expenses.

-

Labor: Manufacturing costs vary based on the country of production. For example, shoes produced in Southeast Asia typically have lower labor costs compared to European or North American factories, but quality standards and certifications can affect wages and compliance costs.

-

Manufacturing Overhead: This encompasses factory expenses, machinery depreciation, and energy costs. Factories with advanced automation or higher standards for quality control often incur higher overheads, which are passed on to the buyer.

-

Tooling and Setup: Initial tooling costs for molds and production setup can be substantial, especially for limited editions or customized designs. These costs are amortized over the order volume.

-

Quality Control (QC): Strict QC procedures, certifications (like ISO or Fair Trade), and testing for durability and safety add to the overall cost but are crucial for brand reputation and compliance in different markets.

-

Logistics & Shipping: Freight costs depend on the shipment volume, destination country, and chosen incoterms. Air freight is faster but more expensive, while sea freight offers cost-efficiency for bulk orders. Customs duties and tariffs also significantly impact landed costs.

-

Margin & Markup: Suppliers typically add a margin to cover their operational costs and profit. Markups vary based on order size, exclusivity, and buyer-supplier relationships.

Price Influencers & Factors

Several factors can influence the final price of Travis Scott shoes in international markets:

-

Order Volume & MOQ: Larger orders generally attract lower unit prices due to economies of scale. Many suppliers offer discounts beyond their minimum order quantities (MOQs), especially for bulk purchases.

-

Specifications & Customization: Custom features, special materials, or branding requirements increase costs. Limited editions or collaborations often command premium pricing.

-

Material Choices: Premium or exotic materials (e.g., genuine leather, sustainable fabrics) elevate costs. Material sourcing from different regions (e.g., Italy vs. China) can also affect prices.

-

Quality Certifications & Standards: Meeting international standards (ISO, CE, etc.) or obtaining specific certifications can add to costs but are often necessary for market access, especially in Europe and the Middle East.

-

Supplier Factors: Supplier reputation, production capacity, and location influence pricing. Well-established manufacturers with a track record of quality and compliance may charge higher premiums but reduce risks.

-

Incoterms & Delivery Terms: The choice of Incoterms (e.g., FOB, CIF, DDP) impacts who bears shipping, insurance, and customs costs. DDP (Delivered Duty Paid) simplifies the process but often increases the price.

Buyer Tips for Cost Optimization and Negotiation

-

Negotiate for Volume Discounts: Emphasize long-term partnerships and consistent order volumes to secure better pricing and flexible MOQ terms.

-

Focus on Total Cost of Ownership (TCO): Consider all costs—materials, shipping, tariffs, customs clearance, and after-sales support—beyond just the unit price. This holistic view can reveal more cost-effective sourcing options.

-

Leverage Multiple Suppliers: Diversify sourcing to compare costs, reduce risks, and improve bargaining power. Consider suppliers from regions like Southeast Asia, which often balance cost and quality.

-

Understand Pricing Nuances: Be aware that initial quotes may exclude additional costs like customs duties, taxes, or certification fees. Clarify these upfront to avoid surprises.

-

Stay Informed on Tariffs & Trade Policies: For markets like Europe or Mexico, stay updated on tariffs, trade agreements, and import restrictions that can influence landed costs.

-

Build Strong Relationships: Long-term partnerships can lead to better pricing, priority production slots, and flexible terms, especially important when dealing with limited editions or high-demand collaborations.

Indicative Price Range (Disclaimer)

While actual costs vary widely based on specifications, order size, and supplier location, typical FOB manufacturing prices for Travis Scott shoes range from $50 to $150 per pair for bulk orders. Landed costs in target markets like Spain, Mexico, or Middle Eastern countries can range from $80 to $250 per pair, factoring in duties, taxes, and logistics. Always conduct thorough due diligence and obtain multiple quotes to ensure competitive pricing aligned with quality standards.

By carefully analyzing these cost components and influencing factors, international B2B buyers can strategically negotiate and optimize their sourcing processes, ensuring they acquire authentic Travis Scott shoes at the best possible total cost.

Spotlight on Potential new travis scott shoes Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for new travis scott shoes.)*

Essential Technical Properties and Trade Terminology for new travis scott shoes

Critical Technical Properties for Travis Scott Shoes

1. Material Grade and Composition

The quality and specifications of materials used—such as leather, mesh, rubber, and foam—directly influence durability, comfort, and aesthetic appeal. High-grade materials ensure longevity and reduce defect rates, which is vital for brand reputation and customer satisfaction. For international buyers, verifying material certifications (e.g., REACH compliance in Europe) can facilitate smoother customs clearance.

2. Tolerance and Precision Standards

Tolerance refers to the permissible variation in dimensions and manufacturing specifications. Tight tolerances (e.g., ±0.5 mm) are essential for consistent fit and performance across batches. For B2B transactions, clear tolerance standards reduce returns and rework, ensuring uniform product quality suitable for premium branding like Travis Scott collaborations.

3. Sole and Midsole Specifications

The sole material, tread pattern, and cushioning technology (e.g., Nike Air or Zoom units) impact grip, comfort, and performance. Precise specifications are crucial for meeting safety standards and consumer expectations. Suppliers should provide detailed technical sheets outlining these properties for validation.

4. Weight and Flexibility

Lightweight and flexible shoes appeal to consumers seeking performance and comfort. Accurate weight measurements (per shoe) and flexibility ratings help buyers assess suitability for different markets, such as activewear or lifestyle segments. These properties influence logistics planning, especially for large shipments.

5. Colorfastness and Finish Quality

Colorfastness ensures that the shoes maintain their appearance after exposure to wear, sweat, and environmental factors. Finish quality, including stitching and surface smoothness, affects the overall premium feel associated with Travis Scott collaborations. Testing reports and compliance certificates are valuable for quality assurance.

6. Packaging and Labeling Standards

Proper packaging protects products during international transit, reducing damages and returns. Labeling must meet local regulatory requirements—such as country of origin marks, size labels, and safety warnings—facilitating customs clearance and consumer trust.

Industry and Trade Terminology for B2B Engagement

1. OEM (Original Equipment Manufacturer)

An OEM produces shoes based on specifications provided by the brand or buyer. Understanding OEM capabilities helps buyers assess the manufacturer’s ability to meet design and quality standards, especially for limited-edition Travis Scott releases.

2. MOQ (Minimum Order Quantity)

This is the smallest quantity a supplier is willing to produce per order. Negotiating MOQ is critical for emerging markets or smaller retailers looking to test demand without excessive inventory risks.

3. RFQ (Request for Quotation)

An RFQ is a formal request sent to suppliers detailing product specifications, quantities, and delivery timelines. Effective RFQs help secure competitive pricing and ensure supplier clarity on technical requirements.

4. Incoterms (International Commercial Terms)

Standardized trade terms (e.g., FOB, CIF, DDP) define responsibilities for shipping, insurance, and customs clearance. Familiarity with Incoterms enables buyers from diverse regions—such as Africa, South America, the Middle East, and Europe—to optimize logistics and cost management.

5. Lead Time

The period from order placement to product delivery. Understanding lead times is essential for planning inventory and marketing campaigns, especially when coordinating international shipments with customs and freight delays.

6. Quality Assurance (QA) and Compliance

QA processes ensure products meet specified standards, including safety, durability, and environmental regulations. Compliance documentation—such as CE marking in Europe or ISO certifications—can streamline customs clearance and reduce import barriers.

Summary

For international B2B buyers exploring new Travis Scott shoes, understanding these technical properties ensures product quality aligns with market expectations. Familiarity with trade terminology facilitates efficient negotiations, logistics planning, and compliance adherence across diverse regions. Prioritizing precise specifications and clear communication reduces risks and enhances the overall procurement process.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the new travis scott shoes Sector

Market Overview & Key Trends

The global market for new Travis Scott shoes is experiencing rapid growth driven by consumer demand for exclusive collaborations and limited-edition releases. As a culturally influential artist, Travis Scott’s footwear collaborations attract a broad audience, fueling resale markets and increasing international trade opportunities. For B2B buyers in Africa, South America, the Middle East, and Europe—particularly Spain and Mexico—this trend opens avenues for sourcing high-demand products with strong resale potential.

Emerging sourcing trends include increased reliance on digital platforms, such as brand-authorized marketplaces and B2B e-commerce portals, which facilitate transparent and efficient procurement processes. Advanced analytics and AI-driven demand forecasting are becoming vital for identifying trending models and optimizing inventory. Additionally, supply chain resilience is a key focus, with buyers seeking diversified sourcing options to mitigate disruptions caused by geopolitical tensions or logistical bottlenecks.

Market dynamics are also shaped by the rise of regional manufacturing hubs, especially in Asia and Eastern Europe, which offer competitive pricing and faster lead times. Importantly, the growing influence of direct-to-consumer (DTC) channels and limited-edition drops means B2B buyers must stay agile, leveraging real-time market data to capitalize on fleeting opportunities. For buyers in emerging markets like Africa and South America, establishing strong relationships with authorized distributors and leveraging import-export trade agreements can facilitate smoother access to these high-demand products.

Furthermore, sustainability and ethical sourcing are increasingly influencing purchasing decisions. Buyers should monitor shifts toward eco-conscious manufacturing, which not only aligns with global consumer values but can also provide a competitive edge in markets with stringent regulations, such as Europe and parts of the Middle East.

Sustainability & Ethical Sourcing in B2B

Sustainability in the new Travis Scott shoes sector is gaining critical importance among international B2B buyers, driven by evolving consumer expectations and regulatory pressures. Environmentally conscious sourcing involves prioritizing materials and manufacturing processes that reduce carbon footprints, minimize waste, and promote circular economy principles.

Eco-friendly materials such as recycled plastics, organic cotton, and sustainable leather alternatives are increasingly being integrated into footwear production. Certifications like Global Organic Textile Standard (GOTS), Forest Stewardship Council (FSC), and Leather Working Group (LWG) are vital indicators of environmentally responsible practices. B2B buyers should prioritize suppliers with these certifications to ensure compliance with international standards and appeal to eco-conscious markets in Europe and the Middle East.

Ethical sourcing also encompasses fair labor practices, transparent supply chains, and adherence to human rights standards. Establishing partnerships with suppliers who demonstrate compliance with International Labour Organization (ILO) standards and who provide traceability documentation can mitigate reputational and legal risks. For regions such as Africa and South America, where supply chain transparency can be challenging, engaging with verified suppliers or third-party auditors is crucial.

Investing in sustainability not only aligns with global environmental goals but can also provide a competitive advantage by appealing to consumers and retailers demanding greener products. Additionally, leveraging ‘green’ certifications and adopting eco-labeling strategies can open doors to premium markets and enhance brand reputation across borders.

Brief Evolution/History (Optional)

The evolution of Travis Scott’s footwear collaborations reflects a broader trend in the sneaker industry toward limited editions and artist partnerships. Initially rooted in streetwear culture, these collaborations have transformed into significant commercial ventures, influencing global sourcing and manufacturing strategies. For B2B buyers, understanding this trajectory underscores the importance of agility and trend awareness in procurement practices.

Over time, brands have shifted from traditional wholesale models to more dynamic, exclusive release strategies, often involving complex supply chains that emphasize scarcity and brand prestige. This evolution highlights the need for buyers to establish direct relationships with authorized distributors and leverage digital platforms for real-time inventory updates.

Recognizing this history can aid international buyers in navigating the complex landscape of licensed collaborations, ensuring authenticity and compliance while capitalizing on consumer enthusiasm for limited-edition products. As the sector continues to evolve, integrating historical insights into sourcing strategies will be essential for maintaining competitiveness and meeting market demands efficiently.

Frequently Asked Questions (FAQs) for B2B Buyers of new travis scott shoes

1. How can I verify the credibility and reliability of Travis Scott shoe suppliers?

To ensure supplier credibility, prioritize those with established industry reputations and verifiable track records. Request comprehensive company documentation, including business licenses, export licenses, and references from previous clients. Conduct due diligence through third-party verification platforms or trade associations. Additionally, review supplier certifications such as ISO or quality assurance standards. Engaging with suppliers that have transparent communication channels and positive reviews reduces risks related to counterfeit products or non-compliance, safeguarding your investment and brand integrity.

2. What customization options are available for international B2B buyers, and how does this affect lead times?

Many suppliers offer customization options such as branding, packaging, and limited design modifications, which are often negotiable based on order volume. Customization typically involves additional setup costs and may extend lead times by 2–4 weeks, depending on complexity. To optimize timelines, clearly specify your requirements upfront and select suppliers experienced in international customization. Establish detailed agreements on design approvals, production schedules, and sample approvals to avoid delays and ensure your branding aligns with local market preferences.

3. What are typical minimum order quantities (MOQs), and how do they impact pricing and logistics?

MOQs for Travis Scott shoes generally range from 100 to 500 pairs, depending on the supplier and customization level. Higher MOQs often result in lower unit prices due to economies of scale, but may pose risks if demand fluctuates. For buyers with limited market size, negotiating flexible MOQs or trial orders is advisable. Consider logistics costs associated with bulk shipments—larger orders often reduce per-unit freight costs but require careful inventory planning. Establish clear communication with suppliers about MOQs to balance cost savings with market demand.

4. What are the standard payment terms for international B2B transactions in this segment?

Common payment terms include 30% upfront deposit with the remaining 70% before shipment, or full payment upon delivery, depending on supplier trustworthiness and order size. Some suppliers may offer Letter of Credit (L/C) or Documentary Collections, providing additional security. Always negotiate terms that align with your cash flow and risk appetite. Using secure payment platforms and requiring formal contracts help prevent disputes. For high-value orders, consider escrow services or trade finance options to mitigate international payment risks.

5. How can I ensure product quality and compliance with international standards?

Request detailed product specifications, quality assurance processes, and third-party inspection reports before finalizing orders. Suppliers should provide certificates of authenticity, safety standards (e.g., CE, ISO), and compliance documentation relevant to your target markets. Conduct pre-shipment inspections through trusted third-party agencies to verify product quality, packaging, and labeling. Establish clear quality benchmarks in your contract, and include provisions for rework or refunds if standards are not met. Regular audits and maintaining open communication channels help sustain consistent quality.

Illustrative Image (Source: Google Search)

6. What are the typical logistics options and challenges for importing Travis Scott shoes to my country?

International shipping options include air freight for faster delivery or sea freight for cost efficiency on large volumes. Consider customs clearance procedures, import duties, and taxes specific to your country—these can significantly affect total landed costs. Engage experienced freight forwarders with expertise in your region to navigate complex customs regulations and documentation requirements. Be prepared for potential delays at borders or customs inspections, and ensure your supplier provides accurate shipping documentation. Proper logistics planning minimizes disruptions and ensures timely market entry.

7. How should I handle disputes or quality issues with international suppliers?

Establish clear contractual clauses covering dispute resolution, including preferred arbitration venues and applicable legal jurisdictions. Maintain detailed records of communications, purchase orders, and inspection reports to support your claims. In case of quality disputes, leverage third-party inspection reports and negotiate corrective actions directly with the supplier. Building long-term relationships based on transparency and mutual trust can prevent conflicts. If unresolved, consider legal channels or trade mediation services familiar with international commerce to protect your interests effectively.

8. What are key considerations for ensuring a smooth import process from supplier to my market?

Thoroughly understand import regulations, tariffs, and labeling requirements in your country to prevent customs delays. Coordinate closely with your supplier on shipping schedules, documentation, and preferred carriers. Implement a robust supply chain management system to track shipments and anticipate potential bottlenecks. Establish strong relationships with local customs brokers and logistics providers to facilitate smooth clearance. Regular communication, detailed planning, and contingency strategies are vital to manage risks, reduce costs, and ensure your Travis Scott shoes reach your customers promptly and in optimal condition.

Illustrative Image (Source: Google Search)

Strategic Sourcing Conclusion and Outlook for new travis scott shoes

Conclusion and Future Outlook

Effective strategic sourcing is crucial for international B2B buyers seeking to capitalize on the growing demand for Travis Scott shoes. By establishing strong supplier relationships, leveraging regional manufacturing advantages, and ensuring quality assurance, buyers can optimize costs while maintaining product integrity. Diversifying sourcing channels and engaging with trusted partners across Africa, South America, the Middle East, and Europe will mitigate risks and enhance supply chain resilience.

Looking ahead, the market for Travis Scott sneakers is poised for continued growth, driven by brand loyalty and global streetwear trends. Buyers should prioritize building agile procurement strategies that adapt to fluctuating demand and supply dynamics. Staying informed about emerging suppliers, sustainable practices, and regional trade policies will be vital for maintaining competitive advantage.

Actionable tip: Invest in comprehensive supplier due diligence and develop collaborative partnerships to ensure consistent quality and timely delivery. Embrace innovation in sourcing approaches to unlock new opportunities in these dynamic markets. By doing so, international B2B buyers from regions like Spain, Mexico, and beyond will be well-positioned to meet market demands and capitalize on future growth in this lucrative segment.