Your Ultimate Guide to Sourcing Nike Valentine’S Day Shoes

Guide to Nike Valentine’S Day Shoes 2025

- Introduction: Navigating the Global Market for nike valentine’s day shoes 2025

- Understanding nike valentine’s day shoes 2025 Types and Variations

- Key Industrial Applications of nike valentine’s day shoes 2025

- Strategic Material Selection Guide for nike valentine’s day shoes 2025

- In-depth Look: Manufacturing Processes and Quality Assurance for nike valentine’s day shoes 2025

- Comprehensive Cost and Pricing Analysis for nike valentine’s day shoes 2025 Sourcing

- Spotlight on Potential nike valentine’s day shoes 2025 Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for nike valentine’s day shoes 2025

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the nike valentine’s day shoes 2025 Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of nike valentine’s day shoes 2025

- Strategic Sourcing Conclusion and Outlook for nike valentine’s day shoes 2025

Introduction: Navigating the Global Market for nike valentine’s day shoes 2025

In the highly competitive landscape of seasonal footwear, Nike’s Valentine’s Day shoes for 2025 represent a strategic opportunity for international B2B buyers aiming to capture consumer interest during this key gifting period. As demand for themed and innovative designs rises globally, sourcing the right products from reliable suppliers becomes critical to maximize margins and brand reputation. This guide offers an in-depth overview of Nike Valentine’s Day shoes for 2025, covering essential aspects such as product varieties, materials, manufacturing quality, supplier options, and cost considerations.

Understanding the nuances of product types—ranging from limited-edition sneakers to customized offerings—enables buyers to align their inventory with local market preferences. Insights into manufacturing standards and quality control processes ensure that imported products meet both global and regional expectations, reducing risks of defects or delays. Additionally, this guide highlights sourcing strategies tailored for markets across Africa, South America, the Middle East, and Europe, including Germany and Australia, empowering buyers to navigate complex import regulations, identify trustworthy suppliers, and negotiate favorable terms.

By synthesizing market trends, supplier landscapes, and logistical considerations, this resource equips B2B buyers with actionable insights to make informed sourcing decisions. Whether expanding product lines or entering new markets, understanding the dynamics of Nike’s Valentine’s Day footwear in 2025 positions buyers to capitalize on seasonal opportunities while maintaining competitive advantage in their respective regions.

Understanding nike valentine’s day shoes 2025 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Romantic Sneakers | Red or pink accents, heart motifs, limited-edition packaging | Retail, boutique collaborations, gift sets | Pros: High visual appeal, strong seasonal demand. Cons: Limited stock, higher price point. |

| Customizable Valentine’s Models | Modular design allowing personalization, interchangeable accessories | Promotional campaigns, corporate gifting | Pros: High customization potential, enhances brand engagement. Cons: Longer lead times, higher MOQ. |

| Eco-Friendly Valentine’s Line | Made from sustainable materials, eco-conscious branding | Green retail channels, eco-focused markets | Pros: Appeals to environmentally conscious buyers, aligns with CSR initiatives. Cons: Costlier materials, limited availability. |

| Unisex Themed Shoes | Gender-neutral designs with subtle Valentine’s motifs | Mass-market retail, online marketplaces | Pros: Broader audience appeal, simplified inventory. Cons: Less exclusivity, potential market saturation. |

| Premium Limited-Edition Shoes | High-end materials, exclusive designs, numbered editions | Luxury boutiques, collector markets | Pros: High margins, brand prestige. Cons: Limited scalability, niche market focus. |

Classic Romantic Sneakers

These shoes are characterized by iconic Valentine’s Day motifs such as hearts, roses, and romantic color schemes like red, pink, and white. They often come in limited-edition packaging to enhance their gift appeal. Suitable for retail outlets, boutique collaborations, and gift sets, these sneakers leverage seasonal demand for special occasions. B2B buyers should consider the limited stock availability and potentially higher retail prices, which can impact margins but boost exclusivity and consumer interest. They are ideal for tapping into holiday-specific marketing campaigns and seasonal retail spikes.

Customizable Valentine’s Models

Designed with modular components, these shoes enable end-users or retailers to personalize through interchangeable accessories like charms, patches, or color accents. They are perfect for promotional campaigns, corporate gifting, or brand collaborations aiming to engage consumers with interactive and personalized products. The primary consideration for buyers is longer lead times due to customization processes and higher minimum order quantities (MOQs). However, their flexibility can significantly enhance brand differentiation and customer loyalty, especially in markets emphasizing personalization trends.

Eco-Friendly Valentine’s Line

This variation emphasizes sustainability, utilizing recycled or organic materials, and eco-conscious manufacturing processes. Its appeal lies in aligning with global sustainability trends, making it attractive for green retail channels and environmentally aware markets like Europe and parts of Africa and South America. While these shoes often command a premium price, they can open access to niche markets and CSR-focused buyers. Limited availability and higher production costs are key considerations, but the growing demand for eco-conscious products can offset these challenges.

Unisex Themed Shoes

Featuring gender-neutral designs with subtle Valentine’s motifs such as hearts or minimal romantic symbols, these shoes are aimed at mass-market retail and online marketplaces. They simplify inventory management by reducing the need for gender-specific stock and appeal to broad demographics. The main advantage is market versatility; however, their less exclusive nature may limit premium positioning. B2B buyers should evaluate market saturation levels and consumer preferences for gender-neutral products in their regions.

Premium Limited-Edition Shoes

Crafted from high-end materials like leather or premium synthetics, these shoes are released in numbered editions to create scarcity and exclusivity. They are targeted at luxury boutiques and collector markets, offering high margins and brand prestige. The key purchasing considerations include scalability, as production volumes are limited, and the niche market focus may require targeted marketing efforts. They are ideal for establishing high-end brand positioning during seasonal peaks and special campaigns.

This segmentation allows B2B buyers across diverse markets to tailor their inventory strategies, aligning product types with regional preferences, consumer behaviors, and retail channels to maximize sales potential during Valentine’s Day 2025.

Key Industrial Applications of nike valentine’s day shoes 2025

| Industry/Sector | Specific Application of Nike Valentine’s Day Shoes 2025 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & E-commerce | Limited-edition promotional product bundles for Valentine’s Day campaigns | Enhances brand visibility, drives sales, and creates consumer engagement | Reliable supply chain, authentic product sourcing, and regional distribution channels |

| Fashion & Lifestyle | Custom collaborations with designers for seasonal collections | Differentiates brands in competitive markets, boosts exclusivity | Quality assurance, licensing agreements, and regional fashion preferences |

| Corporate Gifts & Incentives | Branded shoes as corporate gifting for employee/client appreciation | Strengthens corporate relationships, enhances brand loyalty | Customization options, bulk procurement capabilities, and import/export compliance |

| Tourism & Hospitality | Souvenir items for hotels, resorts, and travel agencies during Valentine’s period | Increases ancillary revenue, enhances guest experience | Certification for quality standards, regional distribution logistics |

| Event & Experience Management | Promotional merchandise for Valentine’s Day events and campaigns | Amplifies event branding, increases attendee engagement | Customization flexibility, quick turnaround, and regional event logistics |

Retail & E-commerce

Nike Valentine’s Day shoes serve as limited-edition promotional products for retail and online stores during the holiday season. B2B buyers can leverage these shoes to create exclusive product bundles that attract consumers seeking unique gifts. This application boosts brand visibility, increases sales, and fosters consumer loyalty, especially in markets like Europe and Australia where premium branding is valued. International buyers should prioritize sourcing from authorized suppliers to ensure authenticity and establish reliable distribution channels tailored to regional demand patterns.

Fashion & Lifestyle

In the fashion industry, Nike Valentine’s Day shoes are ideal for collaborations with designers or influencers to develop seasonal collections. These collaborations can generate buzz and differentiate brands in crowded markets, particularly in regions like Germany, South Africa, and South America. For B2B buyers, securing high-quality, authentic products with clear licensing agreements is crucial to maintain brand integrity. Regional fashion trends and consumer preferences should guide sourcing decisions to ensure market relevance and success.

Corporate Gifts & Incentives

Many corporations opt for Nike Valentine’s Day shoes as part of their employee or client appreciation programs. Custom-branded shoes serve as memorable gifts that enhance corporate relationships and foster loyalty. International B2B buyers should focus on bulk procurement options, customizable branding, and compliance with import/export regulations across different regions. Ensuring timely delivery and quality consistency is vital to meet corporate standards and avoid logistical issues, especially in diverse markets like the Middle East and South America.

Tourism & Hospitality

Hotels, resorts, and travel agencies utilize Nike Valentine’s Day shoes as souvenirs or promotional items during the holiday period. Offering branded shoes adds value to guest experiences and creates additional revenue streams. Sourcing considerations include certification for quality standards, regional distribution logistics, and customization options to match local branding or themes. For international buyers, establishing partnerships with regional suppliers ensures timely delivery and adherence to quality expectations.

Event & Experience Management

Event organizers and marketing agencies incorporate Nike Valentine’s Day shoes into campaigns, giveaways, or branded merchandise for Valentine’s events. These shoes serve as tangible promotional items that increase brand visibility and engagement among attendees. B2B buyers should focus on flexible customization, quick turnaround times, and regional logistics to meet event schedules. Establishing relationships with regional distributors or manufacturers can streamline procurement and ensure product availability for large-scale campaigns across diverse markets.

Strategic Material Selection Guide for nike valentine’s day shoes 2025

Analysis of Common Materials for Nike Valentine’s Day Shoes 2025

Leather (Genuine and Synthetic)

Leather remains a primary material in premium footwear, especially for special editions like Valentine’s Day shoes. Genuine leather offers excellent durability, breathability, and a premium aesthetic, making it highly desirable for consumers seeking luxury and longevity. Synthetic leather, on the other hand, provides a more cost-effective alternative with similar visual appeal but often at the expense of breathability and aging gracefully.

Key Properties:

Genuine leather is highly durable, flexible, and breathable, with good resistance to wear when properly maintained. It performs well across a range of temperatures but can be sensitive to moisture and extreme weather conditions. Synthetic leather varies in quality but generally offers water resistance and ease of cleaning, though it may degrade faster over time.

Pros & Cons:

Genuine leather’s durability and premium feel justify higher costs, but it involves complex manufacturing processes and higher raw material costs. Synthetic leather reduces manufacturing complexity and cost but can be less durable and environmentally problematic due to plastic content. Both materials require specific finishing processes to meet aesthetic standards.

Impact on Application:

Leather’s compatibility with dyes and finishes makes it suitable for detailed design work, embossing, and color customization—key for themed Valentine’s Day shoes. However, moisture sensitivity requires protective treatments, particularly in humid or rainy climates.

International Considerations:

For buyers in Africa, South America, the Middle East, and Europe, compliance with environmental and animal welfare standards (e.g., REACH in Europe, local regulations) is critical. Synthetic options may be preferred where animal welfare or import restrictions are strict. Leather sourced from sustainable suppliers aligned with certifications like LWG (Leather Working Group) can enhance market acceptance.

Mesh and Textile Fabrics

Mesh and textiles are favored for their lightweight, breathable, and flexible properties, ideal for casual and athletic footwear. They enable vibrant designs and are easier to manufacture at scale, making them suitable for limited-edition seasonal releases like Valentine’s Day shoes.

Key Properties:

Mesh fabrics are highly breathable, facilitating airflow and moisture management. Textiles can be engineered for specific performance attributes like stretch, water resistance, or insulation. Both materials are generally lightweight and adaptable to various shoe designs.

Pros & Cons:

The main advantage is breathability and comfort, with lower production costs and flexibility in design. However, textiles can be less durable, especially in high-wear areas, and may require reinforcement or additional coatings to improve longevity. They can also be susceptible to staining and moisture damage if not properly treated.

Impact on Application:

Textile materials are compatible with various dyes and printing techniques, allowing for intricate Valentine’s Day motifs. They also support eco-friendly manufacturing if recycled or organic fibers are used, aligning with sustainability trends.

International Considerations:

Buyers should consider local standards for textile safety (e.g., OEKO-TEX certification) and environmental regulations. In regions with high humidity or pollution, selecting moisture-resistant or treated fabrics is advisable. Additionally, compliance with import tariffs on textiles varies globally, influencing cost structures.

Thermoplastic Polyurethane (TPU)

TPU is a versatile polymer widely used in footwear for components like overlays, straps, and protective elements. Its elasticity, abrasion resistance, and transparency make it ideal for decorative accents and structural reinforcements in Valentine’s Day shoes.

Key Properties:

TPU offers excellent flexibility, high abrasion and tear resistance, and good weatherability. It performs well across a wide temperature range and resists oils and greases, making it suitable for various shoe parts exposed to stress.

Pros & Cons:

TPU’s durability and aesthetic versatility are significant advantages, especially for decorative elements. Manufacturing complexity is moderate, requiring specific molding and extrusion processes. Cost varies depending on grade and application complexity but tends to be higher than standard plastics.

Impact on Application:

Its compatibility with injection molding allows for detailed design features, which are crucial for themed shoes. TPU’s transparency and colorability support vibrant Valentine’s Day motifs, enhancing visual appeal.

International Considerations:

Regulatory compliance (e.g., REACH, FDA standards for contact materials) is essential for global markets. Buyers should verify supplier certifications and ensure material formulations meet regional safety standards. Additionally, sourcing from regions with established TPU manufacturing can reduce lead times and costs.

Summary Table

| Material | Typical Use Case for nike valentine’s day shoes 2025 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather (Genuine/Synthetic) | Upper material, overlays, premium accents | Durability, aesthetic appeal, breathability | Costly, complex manufacturing, environmental concerns | High |

| Mesh and Textile Fabrics | Breathable uppers, decorative panels | Lightweight, customizable, eco-friendly options | Less durable, staining, moisture sensitivity | Low to Med |

| Thermoplastic Polyurethane (TPU) | Overlays, decorative accents, structural reinforcements | Flexible, abrasion-resistant, visually versatile | Higher cost, requires specific processing | Med |

This comprehensive analysis aims to guide international B2B buyers in selecting materials that balance performance, cost, and compliance considerations, ensuring successful product launches for Valentine’s Day 2025 shoes across diverse markets.

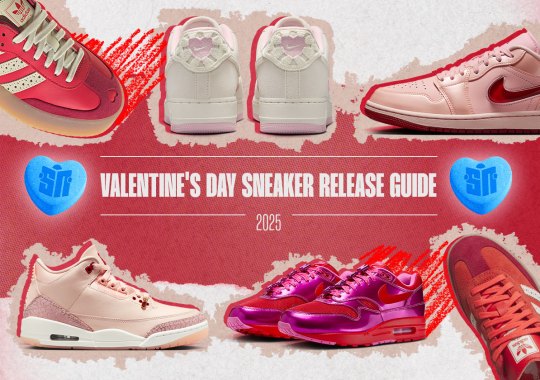

Illustrative Image (Source: Google Search)

In-depth Look: Manufacturing Processes and Quality Assurance for nike valentine’s day shoes 2025

Manufacturing Processes for Nike Valentine’s Day Shoes 2025

The production of Nike Valentine’s Day shoes 2025 involves a meticulously structured manufacturing process designed to ensure high quality, durability, and aesthetic appeal. For B2B buyers, understanding these stages is critical for effective supplier selection and quality assurance.

1. Material Preparation

The process begins with sourcing premium raw materials, including synthetic leathers, mesh fabrics, rubber compounds, and specialized foam insoles. Suppliers typically pre-verify material certifications (e.g., OEKO-TEX, REACH compliance) to ensure safety standards. Material preparation involves cutting, dyeing, and treating fabrics to meet Nike’s specific colorways and texture requirements. For international buyers, verifying supplier adherence to environmental and safety standards (like ISO 14001) is essential.

2. Forming and Molding

Next, components undergo shaping through molding techniques such as injection molding for midsoles and outsoles or thermoforming for upper parts. Advanced molds and CAD/CAM technology facilitate precise replication of Nike’s design specifications. This stage requires strict control over temperature and pressure parameters to ensure uniformity and prevent defects like warping or incomplete molding.

3. Assembly

The assembly stage integrates various components—upper, midsole, outsole, laces, and decorative elements—using industrial sewing, adhesive bonding, and ultrasonic welding. Automated and semi-automated assembly lines enhance efficiency, while manual quality checks at critical points ensure seams, attachments, and alignments meet standards. For international B2B buyers, assessing a supplier’s assembly capabilities and capacity is vital to meet volume demands.

4. Finishing

The final steps include surface finishing, such as polishing, branding (logos, tags), and packaging. Quality control at this stage ensures color consistency, branding accuracy, and absence of surface defects like scratches or glue marks. Packaging must also meet export requirements, including appropriate labeling and compliance with destination country standards.

Illustrative Image (Source: Google Search)

Quality Control (QC) Framework for Nike Valentine’s Day Shoes 2025

Quality assurance in the manufacturing of Nike shoes adheres to rigorous international standards and industry-specific benchmarks, ensuring product safety, performance, and aesthetic quality.

1. International Standards Compliance

Most manufacturers follow ISO 9001 standards for Quality Management Systems, emphasizing process consistency, customer satisfaction, and continuous improvement. Additionally, compliance with regional standards such as CE marking (for Europe), Australian Standards (AS/NZS), and ASTM specifications (for North America) is often required. These standards influence materials, safety testing, and environmental considerations.

2. Industry-Specific Certifications

For footwear, certifications like the Consumer Product Safety Improvement Act (CPSIA) in the U.S. or REACH in Europe guarantee chemical safety. Some suppliers also pursue certifications like OEKO-TEX Standard 100 for textiles, ensuring non-toxic materials. B2B buyers should verify these certifications through supplier documentation or third-party audits.

3. QC Checkpoints and Methodologies

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival for defects, dimensional accuracy, and compliance with specifications. Techniques include visual inspection, dimensional measurement, and chemical testing.

- In-Process Quality Control (IPQC): During manufacturing, checkpoints monitor parameters such as mold temperature, adhesive application, seam strength, and assembly precision. Statistical process control (SPC) tools help identify deviations early.

- Final Quality Control (FQC): Finished shoes undergo comprehensive testing, including visual inspection, functional tests (flexibility, adhesion), and durability assessments. Random sampling and 100% inspection are common depending on batch size and customer requirements.

4. Testing Methods

Standardized tests include:

- Mechanical Testing: Tensile, shear, and peel tests for adhesives and seams.

- Environmental Testing: Resistance to UV, water, and temperature cycling.

- Chemical Testing: Ensuring no harmful substances exceed permissible limits.

- Performance Testing: Wear trials simulating real-world use, including flexibility, shock absorption, and grip.

Verifying Supplier Quality and Navigating International QC Nuances

For B2B buyers across diverse regions, verifying supplier quality involves multiple layers:

- Audits and Inspections: Conduct on-site audits focusing on manufacturing processes, cleanliness, safety protocols, and documentation. Engage third-party inspection firms (e.g., SGS, Bureau Veritas) for impartial assessments.

- Quality Reports and Certifications: Request detailed QC reports, test certificates, and compliance documentation. Cross-reference these with internationally recognized standards.

- Sample Testing: Obtain samples for independent testing aligned with your market’s regulations. This is especially critical for European buyers due to strict chemical and safety standards.

- Supplier Capacity and Flexibility: Evaluate the supplier’s ability to scale production, implement rapid quality corrections, and adapt to custom specifications.

Regional Considerations:

- Africa and South America: Focus on verifying supplier adherence to local environmental regulations and capacity for large-volume production. Establish clear communication channels to address language and logistical barriers.

- Middle East: Prioritize compliance with regional safety standards and customs requirements. Inspect for certifications like GSO or SASO.

- Europe (e.g., Germany): Emphasize chemical safety, environmental sustainability, and adherence to EU directives like REACH and RoHS. Conduct audits with a focus on chemical management and supply chain transparency.

- Australia: Ensure compliance with AS/NZS standards and environmental regulations, with particular attention to chemical safety and sustainable sourcing.

Actionable Insights for B2B Buyers

- Develop a Robust Supplier Qualification Program: Incorporate comprehensive audits, sample testing, and certification verification tailored to regional standards.

- Leverage Third-Party Inspection Services: Employ reputable firms for consistent, impartial QC assessments, especially for remote suppliers.

- Establish Clear Quality Expectations: Clearly communicate quality benchmarks, testing procedures, and documentation requirements upfront.

- Monitor Continuous Improvement: Encourage suppliers to implement ISO 9001-based management systems and pursue relevant industry certifications.

- Stay Informed on Regional Regulations: Regularly update compliance requirements to avoid delays, penalties, or product recalls.

By understanding the detailed manufacturing processes and implementing rigorous QC practices, international B2B buyers can confidently source Nike Valentine’s Day shoes 2025 that meet global standards and regional market demands.

Comprehensive Cost and Pricing Analysis for nike valentine’s day shoes 2025 Sourcing

Cost Structure Analysis for Nike Valentine’s Day Shoes 2025

Understanding the comprehensive cost components involved in sourcing Nike Valentine’s Day shoes for 2025 is vital for international B2B buyers. The primary cost drivers include raw materials, manufacturing labor, overheads, tooling, quality control, logistics, and profit margins.

Illustrative Image (Source: Google Search)

Materials: High-quality synthetic leathers, textiles, and specialty embellishments for themed designs significantly influence cost. Suppliers sourcing from regions with lower raw material costs—such as certain Asian countries—may offer more competitive pricing but could face longer lead times or quality variances.

Labor: Manufacturing costs vary considerably based on the sourcing country. For instance, Asian factories (e.g., Vietnam, China) typically offer lower wages, whereas European or Middle Eastern facilities may have higher labor costs but better compliance with certain quality standards and certifications.

Manufacturing Overheads & Tooling: Investment in specialized tooling for limited-edition or custom Valentine’s Day designs can elevate initial setup costs but reduce per-unit expenses with higher volumes. Overheads also include factory maintenance, energy, and compliance costs, which differ by region.

Quality Control & Certifications: Premium quality assurance, sustainable sourcing certifications (e.g., ISO, Fair Trade), and compliance with international standards add to costs but are crucial for brand reputation and market acceptance, especially in Europe and Australia.

Logistics & Shipping: Costs depend on the sourcing country, destination, and chosen Incoterms. Shipping from Asia to Europe or Africa can range from $2 to $5 per pair for bulk sea freight, while air freight is faster but significantly more expensive. Customs duties and taxes further impact total landed costs.

Margins & Pricing: Markup margins vary based on buyer’s negotiation power, order volume, and market positioning. Typical margins range from 15% to 40%, but premium collaborations or limited editions may command higher markups.

Key Price Influencers & Sourcing Considerations

- Volume & MOQ: Larger order quantities usually unlock better unit prices. Buyers should negotiate Minimum Order Quantities (MOQs) aligned with their market size to optimize cost-efficiency without overstocking.

- Customization & Specs: Unique designs, special packaging, or bespoke materials increase costs. Clear communication of specifications upfront helps prevent costly revisions.

- Materials & Quality: Premium materials and certifications (e.g., eco-labels, safety standards) add to costs but are essential for competitive positioning, especially in Europe and Australia where consumers value sustainability.

- Supplier Factors: Supplier reputation, production capacity, lead times, and compliance track record influence pricing and reliability. Engaging with established suppliers or those with local representatives can mitigate risks.

- Incoterms & Logistics: Choosing appropriate Incoterms (e.g., FOB, CIF) impacts cost transparency and risk distribution. Buyers should evaluate shipping options carefully to balance cost, speed, and reliability.

Strategic Tips for International B2B Buyers

- Negotiate for Better Terms: Leverage order volume and long-term partnerships to negotiate lower unit prices and favorable payment terms. Consider bundled orders or repeat business discounts.

- Optimize Total Cost of Ownership (TCO): Beyond unit price, factor in logistics, customs, storage, and potential rework costs. A lower upfront price might incur higher TCO if shipping is slow or quality issues arise.

- Leverage Regional Advantages: Buyers from Africa and South America should explore sourcing from nearby regions (e.g., North Africa, South American manufacturing hubs) to reduce lead times and shipping costs. European and Middle Eastern buyers might benefit from sourcing within their regions to meet fast-turnaround needs.

- Pricing Nuances: Be aware of currency fluctuations, import tariffs, and local market conditions that can influence final landed costs. Regular market intelligence and supplier audits can help maintain competitive pricing.

Disclaimer

Prices for Nike Valentine’s Day shoes in 2025 are highly variable and depend on multiple factors including order volume, specifications, supplier relationships, and geopolitical conditions. As a guideline, unit costs for bulk orders from Asian manufacturers typically range between $20 and $40 per pair, excluding logistics and duties. European and Middle Eastern sourced products may cost 10-30% more due to higher labor and overhead costs. Buyers should conduct detailed negotiations and supplier assessments to obtain precise quotes tailored to their specific requirements.

Spotlight on Potential nike valentine’s day shoes 2025 Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for nike valentine’s day shoes 2025.)*

Essential Technical Properties and Trade Terminology for nike valentine’s day shoes 2025

Critical Technical Specifications for Nike Valentine’s Day Shoes 2025

1. Material Grade and Composition

The choice of materials—such as synthetic leather, mesh, or rubber—directly impacts product quality, durability, and comfort. For B2B buyers, understanding the specific grade of materials (e.g., premium PU leather vs. standard PU) ensures consistency across batches and aligns with target market expectations. High-grade materials typically command higher prices but offer better wear resistance and brand perception, crucial for seasonal releases like Valentine’s Day shoes.

2. Tolerance Levels

Tolerance specifications define acceptable variances in dimensions during manufacturing, such as sole thickness or upper panel width. Precise tolerance levels (e.g., ±0.2mm) are essential for ensuring product uniformity, especially when coordinating with retail displays or packaging. Strict tolerance adherence minimizes returns and enhances customer satisfaction, which is vital for limited-edition designs.

3. Weight Specifications

Lightweight shoes enhance comfort and are often a selling point for athletic or casual footwear. For seasonal collections, specifying maximum weight thresholds (e.g., grams per pair) helps maintain product appeal. B2B buyers should verify that manufacturing partners meet these specs to avoid costly rework or dissatisfaction at retail.

4. Color Consistency and Finish

Color matching (Pantone references) and surface finish quality are critical for seasonal, themed products like Valentine’s Day shoes. Consistent coloration across batches ensures brand integrity and customer trust. Suppliers should provide detailed color tolerance standards and finish quality reports to guarantee visual appeal and brand consistency.

5. Durability and Wear Resistance

Specifications for abrasion resistance, flex testing, and sole adhesion determine product longevity. For B2B buyers, insisting on test reports (e.g., ASTM or ISO standards) ensures the shoes withstand daily wear. This is especially important for seasonal products that aim to boost brand loyalty and repeat purchases.

Essential Industry and Trade Terminology

1. OEM (Original Equipment Manufacturer)

Refers to companies that produce footwear based on the design and specifications provided by the buyer. Understanding OEM relationships helps B2B buyers evaluate manufacturing reliability, quality control processes, and intellectual property protections.

2. MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to produce per order. Knowledge of MOQ helps buyers plan inventory and manage costs, especially for limited-edition seasonal products like Valentine’s Day shoes. Negotiating MOQs can also impact pricing and production timelines.

3. RFQ (Request for Quotation)

A formal process where buyers solicit price quotes, lead times, and terms from multiple suppliers. Efficient RFQ processes enable buyers to compare options systematically and select partners that offer the best balance of quality, cost, and delivery.

4. Incoterms (International Commercial Terms)

Standardized trade terms (e.g., FOB, CIF, DDP) define responsibility for shipping, insurance, and customs duties. For international B2B transactions, clarity on Incoterms ensures smooth logistics, cost management, and compliance, especially when importing shoes to diverse markets like Africa, South America, or Europe.

5. Lead Time

The duration from order placement to product shipment. Accurate understanding of lead times allows buyers to plan marketing campaigns and coordinate seasonal launches effectively. For Valentine’s Day shoes, aligning production schedules with retail timelines is critical for maximizing sales impact.

6. Quality Control (QC) Standards

Refers to the set procedures and benchmarks used to ensure products meet specified requirements. B2B buyers should specify QC standards (e.g., ISO 9001 compliance) and request inspection reports to reduce defects, returns, and reputational risks.

In summary, a clear grasp of these technical properties and trade terms enables international B2B buyers to communicate effectively with manufacturers, ensure product quality, manage costs, and streamline logistics. This knowledge is particularly vital for seasonal, high-visibility launches like Nike’s Valentine’s Day shoes 2025, where timing, consistency, and quality directly influence market success.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the nike valentine’s day shoes 2025 Sector

Market Overview & Key Trends

The 2025 Valentine’s Day shoe segment by Nike is shaped by evolving global consumer preferences, technological advancements, and supply chain innovations. For international B2B buyers from Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial to optimize sourcing strategies and meet market demands.

Global Drivers: Increasing consumer demand for limited-edition, themed footwear for special occasions like Valentine’s Day drives seasonal product cycles. Markets such as Europe and Australia exhibit a strong affinity for premium, innovative designs, while emerging markets in Africa and South America show growth in affordable, stylish options. Economic recovery post-pandemic, coupled with rising disposable incomes in these regions, is amplifying demand for Nike’s seasonal offerings.

Emerging Sourcing & Tech Trends: Digitalization is transforming supply chain management, with B2B platforms offering real-time tracking, virtual sampling, and AI-driven demand forecasting. Nike’s adoption of sustainable manufacturing practices and automation enhances efficiency, reduces lead times, and minimizes waste. Blockchain is increasingly used for transparent provenance, assuring authenticity and ethical sourcing—a vital factor for international buyers concerned with brand integrity.

Market Dynamics: Currency fluctuations, tariffs, and regional trade policies significantly impact sourcing costs. Buyers in Europe and Australia benefit from established logistics networks, ensuring timely delivery, whereas African and South American markets may face logistical challenges, emphasizing the need for strategic partnerships and local warehousing options. Consumer preferences for eco-friendly and ethically produced products are influencing procurement decisions, prompting buyers to prioritize suppliers with robust sustainability credentials.

Sustainability & Ethical Sourcing in B2B

Sustainability is no longer optional but a core criterion in sourcing Nike Valentine’s Day shoes for 2025. Consumers globally are increasingly conscious of environmental and social impacts, prompting brands to adopt greener practices. For B2B buyers, integrating sustainability into procurement strategies offers competitive advantages, including brand differentiation and compliance with international standards.

Environmental Impact: Nike’s commitment to reducing carbon footprints through renewable energy use, waste reduction, and water conservation is pivotal. Sourcing from suppliers with verified eco-friendly practices, such as those certified under LEED or ISO 14001, ensures alignment with Nike’s sustainability goals. Use of recycled materials—like Nike’s Flyleather or recycled polyester—is a key trend, appealing to environmentally conscious consumers and meeting regulatory requirements across regions.

Ethical Sourcing: Ethical labor practices and fair trade certifications are essential for maintaining brand integrity. Buyers should prioritize suppliers with verifiable compliance with labor standards, including fair wages, safe working conditions, and no child labor. Transparency in supply chains, supported by blockchain or third-party audits, enhances trust and mitigates risks associated with unethical practices.

Green Certifications & Materials: For Nike Valentine’s Day shoes, sourcing ‘green’ certified materials such as organic cotton, recycled rubber, and biodegradable adhesives can significantly enhance product appeal. Engaging with suppliers committed to sustainability not only aligns with Nike’s corporate ethos but also ensures resilience against future regulatory changes and consumer expectations.

Brief Evolution/History (Optional)

Nike’s journey toward sustainable and innovative product offerings began in the early 2000s, with a strategic focus on eco-friendly materials and ethical manufacturing. Over time, the brand’s emphasis on transparency and corporate responsibility has grown, leading to the development of eco-conscious product lines like Flyleather and recycled uppers. For B2B buyers, understanding this evolution highlights the importance of partnering with suppliers aligned with Nike’s sustainability trajectory, ensuring long-term viability and market relevance in the Valentine’s Day sector.

Frequently Asked Questions (FAQs) for B2B Buyers of nike valentine’s day shoes 2025

1. How can I verify the credibility and reliability of Nike footwear suppliers for Valentine’s Day 2025 orders?

To ensure supplier credibility, prioritize those with established international trade experience, verified business licenses, and transparent supply chain practices. Request references from previous B2B clients, review third-party audit reports, and check for compliance with recognized standards such as ISO or SA8000. Additionally, prioritize suppliers with a strong track record of timely delivery, quality assurance, and positive reviews from international buyers. Engaging with suppliers who participate in trade fairs or industry certifications can further reduce risks. Conduct virtual or in-person audits if feasible, and always establish clear contractual terms before committing.

2. What customization options are available for Nike Valentine’s Day shoes, and how does this impact lead times?

Nike offers various customization options, including color schemes, logos, packaging, and limited edition designs tailored for B2B partners. Customization typically requires additional lead time—ranging from 4 to 8 weeks—depending on complexity and order volume. Early planning is crucial, especially for seasonal campaigns like Valentine’s Day 2025. Confirm with suppliers about their capacity to handle specific customization requests and request detailed timelines upfront. To avoid delays, finalize designs well in advance and incorporate buffer periods for approval processes or unforeseen adjustments.

3. What are typical minimum order quantities (MOQs), lead times, and payment terms for bulk Nike Valentine’s Day shoes?

MOQs for Nike Valentine’s Day shoes generally range from 500 to 2,000 pairs per style, though this varies by supplier and customization level. Lead times from order confirmation to delivery typically span 8 to 16 weeks, factoring in production, quality checks, and logistics. Payment terms often include a 30% deposit upfront, with the balance payable before shipment or upon delivery. Negotiating flexible payment options, such as letter of credit or installments, can improve cash flow. Early engagement and clear communication about these terms are vital for smooth procurement.

4. What quality assurance processes and certifications should I verify when sourcing Nike Valentine’s Day shoes?

Ensure suppliers adhere to strict quality control procedures, including in-line inspections, final product audits, and compliance with international standards such as ISO 9001. Request documentation of factory certifications, social compliance (e.g., SA8000, BSCI), and environmental standards (e.g., ISO 14001). Conduct or commission third-party quality inspections before shipment to verify adherence to agreed specifications, particularly regarding materials, craftsmanship, and packaging. These measures help mitigate risks of defective products, customs delays, or reputational damage, especially when importing into diverse markets like Africa, South America, the Middle East, or Europe.

5. How do I manage logistics and customs clearance for international shipments of Nike Valentine’s Day shoes?

Collaborate with experienced freight forwarders familiar with your target markets to streamline logistics. Choose reliable shipping methods—air freight for faster delivery or sea freight for cost efficiency—based on order size and urgency. Provide complete and accurate documentation, including commercial invoices, packing lists, certificates of origin, and any required import permits. Be aware of local customs duties, taxes, and regulations in your destination country; pre-arranging clearance can prevent delays. Establish clear communication channels with logistics providers and customs brokers to track shipments and resolve issues promptly.

6. What steps should I take to handle disputes or quality issues with Nike Valentine’s Day shoe suppliers?

Establish clear contractual clauses covering product specifications, quality standards, delivery timelines, and dispute resolution mechanisms before placing orders. Maintain detailed records of communications, inspections, and acceptance reports. In case of disputes, initiate prompt negotiation, referencing contractual terms and documented evidence. If unresolved, consider arbitration or legal channels in line with the contract. Building strong supplier relationships and conducting regular performance reviews can prevent disputes. For critical markets, partnering with suppliers offering after-sales support and warranty services adds an extra layer of assurance.

7. How can I ensure compliance with local regulations and consumer standards when importing Nike Valentine’s Day shoes?

Stay informed about import regulations, safety standards, and labeling requirements specific to your country—whether in Africa, South America, the Middle East, or Europe. Verify that products meet local certification standards (e.g., CE marking in Europe, SABS in South Africa). Ensure proper labeling, including size, materials, and country of origin. Collaborate with local customs brokers to facilitate smooth clearance. Regularly review updates to trade policies, tariffs, and standards, and maintain compliance documentation. This proactive approach reduces the risk of customs delays, fines, or product recalls.

8. What are key considerations for building long-term B2B relationships with Nike shoe suppliers for seasonal campaigns like Valentine’s Day?

Focus on establishing transparent communication, mutual trust, and consistent quality delivery. Start with smaller pilot orders to assess supplier performance, then scale up based on reliability and responsiveness. Negotiate flexible terms, including MOQ adjustments, lead times, and payment options, to accommodate market fluctuations. Regularly review supplier performance through audits and feedback sessions. Building strategic partnerships may also include collaborative marketing, joint branding, or exclusive designs for upcoming seasons. Long-term relationships can lead to better pricing, priority production slots, and shared insights into market trends, all critical for seasonal campaigns like Valentine’s Day 2025.

Strategic Sourcing Conclusion and Outlook for nike valentine’s day shoes 2025

Strategic Sourcing Outlook for Nike Valentine’s Day Shoes 2025

Effective strategic sourcing remains pivotal for international B2B buyers aiming to capitalize on the 2025 Nike Valentine’s Day shoes market. Key considerations include diversifying supplier bases to mitigate geopolitical and supply chain risks, leveraging data-driven procurement strategies, and fostering strong partnerships with manufacturers in regions such as Southeast Asia, Europe, and South America. These approaches ensure consistent quality, competitive pricing, and timely delivery—critical factors during peak seasonal demands.

For buyers in Africa, the Middle East, Europe, and South America, establishing transparent communication channels and engaging in collaborative planning can significantly enhance sourcing resilience. Embracing sustainable and ethical sourcing practices not only aligns with global consumer expectations but also adds long-term value to your supply chain.

Looking ahead, the evolving landscape of global trade and consumer preferences underscores the importance of agility and innovation in sourcing strategies. By proactively building diverse supplier relationships and integrating advanced supply chain technologies, B2B buyers can better navigate uncertainties and seize opportunities presented by the Valentine’s Day 2025 market.

Take action now: evaluate your current sourcing frameworks, explore new regional partnerships, and prioritize sustainability to gain a competitive edge in this seasonal niche.