Your Ultimate Guide to Sourcing Red Designer Shoes

Guide to Red Designer Shoes

- Introduction: Navigating the Global Market for red designer shoes

- Understanding red designer shoes Types and Variations

- Key Industrial Applications of red designer shoes

- Strategic Material Selection Guide for red designer shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for red designer shoes

- Comprehensive Cost and Pricing Analysis for red designer shoes Sourcing

- Spotlight on Potential red designer shoes Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for red designer shoes

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the red designer shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of red designer shoes

- Strategic Sourcing Conclusion and Outlook for red designer shoes

Introduction: Navigating the Global Market for red designer shoes

In the highly competitive world of luxury footwear, red designer shoes symbolize boldness, exclusivity, and high fashion. For international B2B buyers, especially from regions such as Africa, South America, the Middle East, and Europe, sourcing these iconic products offers significant growth opportunities—if approached with strategic insight and industry knowledge. The demand for authentic, high-quality red designer footwear continues to rise as brands seek to expand their market footprint and capitalize on consumers’ desire for statement pieces that convey confidence and style.

This comprehensive guide equips you with essential insights into the complex landscape of sourcing red designer shoes. From understanding the various types—ranging from classic pumps to avant-garde sneakers— to evaluating materials like genuine leather, sustainable fabrics, and innovative synthetics, this resource ensures informed decision-making. It covers critical aspects such as manufacturing processes, quality control standards, and reliable supplier networks across key sourcing hubs like Italy, Thailand, and emerging markets in Africa and South America.

Moreover, the guide provides actionable advice on estimating costs, navigating import/export regulations, and identifying market trends that influence demand. Whether you are a distributor, retailer, or manufacturer, this resource empowers you to make strategic, cost-effective sourcing decisions that align with your brand’s positioning and growth objectives. Ultimately, it serves as an indispensable tool for international B2B buyers aiming to succeed in the dynamic global market for red designer shoes.

Understanding red designer shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Leather Pumps | Sleek, polished leather with a pointed or rounded toe; often with stiletto heels | Luxury retail, corporate gifting, boutique stores | Pros: High perceived value, timeless appeal. Cons: Higher manufacturing costs, limited flexibility for mass customization. |

| Sporty Sneakers | Bright red color, lightweight materials, often with branding or logo accents | Casualwear lines, promotional giveaways, sports collaborations | Pros: Popular among younger demographics, versatile for various markets. Cons: Shorter product lifecycle, potential oversaturation. |

| Elegant Ankle Boots | Red leather or suede, mid-heel height, often with decorative elements like buckles or zippers | Fashion boutiques, seasonal collections, luxury segments | Pros: High-margin potential, seasonal demand. Cons: Size and style variations increase inventory complexity. |

| Formal Oxfords & Brogues | Classic lace-up design, polished finish, often with brogue detailing | Business attire, formal events, corporate gifting | Pros: Appeal to professional markets, durable. Cons: Limited appeal outside formal sectors, higher production standards needed. |

| Statement Sandals | Bold red hues, decorative straps, platform or block heels | Resort wear, summer collections, high-end casual lines | Pros: Eye-catching, trend-driven. Cons: Seasonal demand, sensitive to fashion cycles. |

Classic Leather Pumps

Classic red leather pumps are a staple in luxury and formal footwear lines, characterized by their refined silhouette and often high stiletto heels. They are ideal for upscale retail outlets and corporate gifting programs targeting professionals and affluent consumers. For B2B buyers, these shoes offer high perceived value, making them suitable for premium markets. However, their production costs are higher due to quality materials and craftsmanship, and they may require careful inventory management to avoid obsolescence. When sourcing, consider suppliers with a reputation for quality and consistency to meet luxury standards.

Sporty Sneakers

Red sporty sneakers are increasingly popular across diverse markets, especially among younger consumers. Their lightweight construction, vibrant color, and branding elements make them suitable for casualwear, promotional campaigns, and collaborations with sports or lifestyle brands. B2B buyers should evaluate suppliers for their ability to produce at scale, maintain quality, and offer customization options. While sneakers tend to have shorter product cycles due to fashion trends, they can generate high turnover and volume sales, especially in emerging markets with growing middle classes.

Elegant Ankle Boots

Red ankle boots combine style and functionality, often crafted from leather or suede with decorative accents like buckles or zippers. They are well-suited for fashion boutiques, seasonal collections, and luxury segments targeting urban, fashion-conscious consumers. For B2B buyers, the key considerations include supplier flexibility in offering various sizes and styles, as well as quality assurance for durability. These shoes typically command higher margins but require careful inventory planning to align with seasonal demand and trend shifts.

Formal Oxfords & Brogues

This category features polished, lace-up shoes with classic detailing, often in a vibrant red finish for statement-making. They are primarily used in business attire, formal events, and corporate gifting, appealing to professional markets across different regions. B2B buyers should focus on sourcing from manufacturers with expertise in formal footwear and consistent quality standards. These shoes tend to have longer product lifecycles but may involve higher production costs and stricter quality controls to meet formalwear standards.

Statement Sandals

Red statement sandals are characterized by bold designs, decorative straps, and platform or block heels, making them popular in resort, summer, and high-end casual collections. They are ideal for seasonal promotions and luxury resort markets, offering high visual impact. For international buyers, especially in markets with seasonal climates, sourcing reliable suppliers who can produce trendy, high-quality sandals at scale is essential. Their trend-driven nature means inventory planning should be agile to adapt to changing fashion cycles.

Key Industrial Applications of red designer shoes

| Industry/Sector | Specific Application of red designer shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Luxury Retail | High-end retail displays and promotional events | Enhances brand image, attracts premium clientele, and boosts sales | Authenticity, brand reputation, and authenticity certifications |

| Entertainment & Events | Costume design for theatrical productions, concerts, or fashion shows | Creates visually striking appearances, reinforcing brand or event themes | Customization options, material quality, and compliance with safety standards |

| Corporate & Promotional | Branded corporate gifts or promotional giveaways | Elevates brand visibility, fosters client loyalty, and enhances corporate image | Custom branding options, bulk sourcing capabilities, and delivery timelines |

| Manufacturing & Custom Design | Custom-made footwear for niche markets or exclusive collections | Differentiates product offerings, appeals to luxury or niche markets | Flexibility in design, material sourcing, and adherence to quality standards |

| Hospitality & Tourism | Luxury hotel or resort staff uniforms with distinctive footwear | Reinforces brand identity, provides unique guest experiences | Durability, comfort, and consistency in color and style across large orders |

Fashion & Luxury Retail

Red designer shoes are a staple in high-end retail environments, often used as statement pieces to attract affluent clients and elevate brand prestige. Retailers and boutiques from regions like Europe or South America leverage these shoes during promotional campaigns or in flagship displays to create a luxurious ambiance. B2B buyers should prioritize sourcing authentic, certified products that reflect the brand’s exclusivity. Ensuring reliable supply chains and authentic provenance is crucial for maintaining brand integrity in international markets.

Entertainment & Events

In the entertainment industry, especially for theatrical productions, concerts, and fashion shows, red designer shoes serve as eye-catching costume elements that enhance visual storytelling. They help create memorable performances and align with thematic aesthetics. For international B2B buyers from regions like the Middle East or Africa, customization—such as specific shades or embellishments—is often required. Sourcing high-quality, compliant footwear ensures safety and durability on stage, while quick turnaround times support dynamic production schedules.

Corporate & Promotional

Red designer shoes are increasingly used as branded corporate gifts or promotional items, especially in markets like Europe or Thailand. They serve as memorable tokens that reinforce brand identity and foster customer loyalty. For B2B buyers, the focus should be on bulk sourcing, customization options (logos, colors), and reliable delivery. High-quality manufacturing guarantees that promotional footwear withstands repeated use, maintaining a positive brand impression across diverse international markets.

Manufacturing & Custom Design

Some industries, especially niche luxury markets or bespoke fashion houses, commission custom-made red designer shoes to differentiate their collections. These applications demand flexibility in design, high-quality materials, and strict adherence to standards. Buyers from regions like South America or Africa seeking exclusivity should evaluate suppliers’ craftsmanship, material sourcing transparency, and capacity for bespoke production. This approach allows brands to offer unique products that command premium pricing.

Hospitality & Tourism

Luxury hotels and resorts often incorporate distinctive footwear, such as red designer shoes, into staff uniforms to reinforce their brand identity and create memorable guest experiences. These shoes must combine durability, comfort, and aesthetic appeal, often tailored to regional climate and cultural preferences. International B2B buyers should prioritize sourcing from manufacturers with proven quality assurance, scalable production, and consistent color matching to ensure a cohesive brand presentation across multiple properties.

Strategic Material Selection Guide for red designer shoes

Material Analysis for Red Designer Shoes

Selecting the appropriate materials for red designer shoes is critical to ensuring product quality, durability, and compliance with international standards. Different markets have varying preferences and regulatory requirements, making it essential for B2B buyers to understand the properties and implications of each material choice.

Leather (Full-Grain, Patent, or Suede)

Key Properties:

Leather remains the most traditional and luxurious material for high-end designer shoes. Full-grain leather offers excellent durability, breathability, and develops a unique patina over time. Patent leather provides a glossy, eye-catching finish suitable for statement footwear, while suede offers a softer, textured appearance.

Pros & Cons:

– Pros: High aesthetic appeal, excellent durability, natural breathability, and ease of dyeing in vibrant colors like red.

– Cons: Requires regular maintenance, sensitive to water and humidity, and can be costly depending on quality. Manufacturing complexity varies with finish type; patent leather involves additional coating processes.

Impact on Application:

Leather’s flexibility and natural properties make it suitable for various shoe styles, from formal to casual. However, for regions with high humidity or frequent rain (e.g., parts of South America and Southeast Asia), leather shoes may require additional waterproofing treatments.

International B2B Considerations:

Leather sourcing must comply with environmental and ethical standards such as the Leather Working Group (LWG) certifications. Buyers from regions like Europe often prioritize sustainably sourced leather, while markets like Argentina and Thailand may have more flexible standards but still require compliance with local import regulations. Leather’s natural origin generally aligns with high-end consumer preferences globally.

Synthetic Materials (Polyurethane, PVC)

Key Properties:

Synthetic materials are engineered for consistency and cost-effectiveness. Polyurethane (PU) can mimic leather’s appearance and texture, offering good flexibility and lightweight properties. PVC is more rigid but highly resistant to water and chemicals.

Pros & Cons:

– Pros: Lower cost, consistent quality, excellent water resistance, and ease of manufacturing. Suitable for mass production and quick turnaround.

– Cons: Generally less breathable, can crack over time (especially PVC), and may lack the luxury feel of genuine leather. Environmental concerns due to non-biodegradability and chemical content.

Impact on Application:

Synthetic materials are ideal for fashion-forward, trend-driven designs, especially where affordability is a priority. They perform well in humid or wet climates but may not meet the durability standards expected for long-term luxury use.

International B2B Considerations:

Synthetic materials often meet various international standards like ASTM D4236 (for safety and toxicity). Buyers from Africa, South America, and the Middle East should verify compliance with local import regulations concerning chemical content and environmental standards. Additionally, eco-conscious markets in Europe increasingly favor bio-based or recyclable synthetics, influencing material choice.

Thermoplastic Elastomers (TPE) and Rubber

Key Properties:

TPE and rubber are flexible, elastic, and impact-absorbing materials. They are often used for shoe soles, especially for sporty or casual styles, providing excellent grip and shock absorption.

Pros & Cons:

– Pros: High flexibility, durability, excellent slip resistance, and weather resistance.

– Cons: Limited aesthetic appeal for high-fashion shoes, potential for degradation over time under UV exposure, and sometimes heavier than other options.

Impact on Application:

Ideal for soles and accents on designer shoes that require durability and grip. For the upper parts, these materials are less common unless used for specific design elements.

International B2B Considerations:

Rubber and TPE materials must meet safety standards such as REACH (Europe) or ISO certifications for chemical safety. Buyers should consider sourcing from suppliers with transparent compliance documentation, especially when exporting to regions with strict chemical regulations like the EU or Middle East.

Summary Table

| Material | Typical Use Case for red designer shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather | Formal, luxury, high-end fashion footwear | Natural, durable, luxurious appearance | High cost, maintenance required, sensitive to moisture | High |

| Synthetic (PU, PVC) | Trendy, casual, mass-market footwear | Cost-effective, water-resistant, consistent quality | Less breathable, environmental concerns | Low to Med |

| Thermoplastic Elastomers (TPE) / Rubber | Soles, shock absorption, grip-focused designs | Durable, flexible, slip-resistant | Less aesthetic for upper parts, heavier | Med |

This comprehensive understanding of material properties and market considerations enables B2B buyers from diverse regions to make informed decisions aligned with their target markets, compliance standards, and brand positioning.

In-depth Look: Manufacturing Processes and Quality Assurance for red designer shoes

Manufacturing Processes for Red Designer Shoes

The production of high-end red designer shoes involves a series of meticulously controlled stages, each critical to ensuring the final product meets luxury standards and international compliance. For B2B buyers, understanding these processes facilitates better supplier evaluation and quality assurance.

1. Material Preparation

The journey begins with sourcing premium raw materials, predominantly high-quality leather, suede, or innovative synthetic fabrics tailored for luxury footwear. For red shoes, pigment application during the dyeing process is crucial to achieve an even, vibrant hue. Suppliers often use vegetable-tanned or chrome-tanned leather, depending on environmental standards and client preferences. Material inspection at this stage ensures consistency in color, texture, and absence of defects.

2. Forming and Cutting

The cut components—uppers, insoles, outsoles—are precisely shaped using advanced CAD/CAM technology, allowing for intricate designs and consistency across batches. Laser cutting and die-cutting are common techniques that enhance precision while reducing waste. For red designer shoes, particular attention is paid to color matching and avoiding dye bleeding during cutting.

3. Assembly and Stitching

Assembling involves stitching, bonding, and attaching components, often using both hand and machine techniques. High-quality footwear employs reinforced stitching for durability, with some brands favoring hand-stitched details to enhance luxury appeal. Adhesives used are typically solvent-free and conform to environmental standards. Special attention is given to the alignment of the red color, ensuring seamless visual appeal.

4. Finishing and Detailing

The finishing phase includes polishing, dyeing touch-ups, and adding decorative elements like embellishments or logos. For red shoes, surface treatments such as gloss or matte finishes are applied, often with multiple coats to ensure color vibrancy and durability. Sole attachment, heel setting, and final surface smoothing are conducted meticulously, with a focus on achieving a flawless appearance.

Quality Assurance Standards and Protocols

B2B buyers must verify that suppliers adhere to rigorous quality standards throughout the manufacturing process. International standards such as ISO 9001 serve as the foundational quality management framework, ensuring systematic process control and continuous improvement.

1. International and Industry-Specific Certifications

– ISO 9001: Demonstrates compliance with quality management systems, covering process consistency, documentation, and corrective actions.

– CE Marking: For shoes sold within the European Economic Area, ensuring safety, health, and environmental standards.

– API (American Petroleum Institute): Less common but relevant if synthetic or alternative materials are involved, particularly in eco-friendly or innovative materials.

2. Quality Control Checkpoints

– Incoming Quality Control (IQC): Inspection of raw materials upon arrival, verifying color consistency, material integrity, and dye stability for red hues.

– In-Process Quality Control (IPQC): Continuous monitoring during manufacturing, including stitch strength tests, color fastness, dimensional accuracy, and bonding strength.

– Final Quality Control (FQC): Comprehensive inspection of finished shoes, assessing visual defects, color uniformity, finishing quality, and adherence to specifications.

3. Testing Methods

– Color Fastness Testing: Using standardized methods (e.g., ISO 105) to ensure the red dye remains stable under light, rubbing, and moisture exposure.

– Durability Tests: Flexing, abrasion, and adhesion tests to confirm longevity, especially for high-wear areas like soles and heels.

– Environmental Compliance: Testing for VOC emissions and toxic substances, aligning with REACH or CPSIA standards relevant in Europe and the Americas.

Verifying Supplier Quality for International B2B Engagement

For international buyers, especially from Africa, South America, the Middle East, and Europe, supplier verification is essential to mitigate risks and ensure consistent product quality.

1. Factory Audits and Inspections

Engage third-party inspection agencies (e.g., SGS, Bureau Veritas, Intertek) to conduct comprehensive audits. These audits evaluate the manufacturing environment, adherence to standards, and capacity to produce at scale while maintaining quality. For red designer shoes, audits should include specific checks on dyeing processes, finishing techniques, and QC documentation.

2. Quality Reports and Documentation

Require detailed Quality Inspection Reports (QIR) and Certificates of Conformance for each batch. These documents should include test results, defect rates, and compliance certifications. Transparent record-keeping allows buyers to track quality trends and identify potential issues proactively.

3. Third-Party Inspections and Sample Testing

Periodic random sampling and testing by independent labs help verify ongoing quality. For example, testing for color fastness, sole adhesion, and overall finish can confirm supplier claims. B2B buyers can also consider engaging local inspection firms or regional representatives familiar with the manufacturing standards prevalent in countries like Thailand or Argentina.

Nuances for International B2B Buyers

Different regions may have specific expectations and standards influencing quality assurance practices:

-

Africa & South America: Suppliers might have varying levels of infrastructure; thus, buyers should emphasize detailed audits and insist on international certifications. Local agents or inspectors can facilitate communication and ensure standards are met.

-

Middle East: Buyers should verify compliance with environmental and safety standards, especially for luxury products with high aesthetic value. Certifications like ISO 14001 (environmental management) can be an added assurance.

-

Europe: Strict adherence to REACH, CE, and other EU standards is expected. Buyers should request comprehensive documentation and ensure suppliers are familiar with European testing protocols.

Conclusion

A thorough understanding of manufacturing processes and stringent quality assurance protocols are vital for B2B buyers sourcing red designer shoes internationally. By emphasizing transparency, certification, and independent verification, buyers can mitigate risks, ensure product consistency, and build long-term supplier relationships that uphold the luxury standards expected in this segment.

Comprehensive Cost and Pricing Analysis for red designer shoes Sourcing

Cost Components in Red Designer Shoes Sourcing

Understanding the detailed cost structure is crucial for B2B buyers aiming to optimize procurement strategies for red designer shoes. The primary cost components include:

-

Materials: High-quality leather, synthetic fabrics, or specialized textiles used for the upper and lining. For designer shoes, premium materials significantly influence price, especially if sourced from renowned tanneries or suppliers with certifications. Custom colors like vibrant reds may require specific dyes, adding to material costs.

-

Labor: Skilled craftsmanship is essential for designer footwear, often involving artisanal techniques or meticulous hand-finishing. Labor costs vary widely by country—manufacturers in Southeast Asia (e.g., Thailand) may offer competitive rates, while European artisans may command premium wages.

-

Manufacturing Overhead: Includes factory utilities, machinery maintenance, and administrative expenses. Overhead costs are typically embedded within unit prices but can fluctuate based on factory location and operational efficiency.

-

Tooling & Development: Initial mold creation and design adjustments are significant upfront investments, especially for bespoke or customized designs. These costs are amortized over the production volume.

-

Quality Control & Certifications: Ensuring consistency, durability, and compliance with international standards (e.g., ISO, ethical certifications) adds to the overall cost but is vital for premium branding.

-

Logistics & Shipping: Freight costs depend on shipment volume, destination, and chosen incoterms. Air freight offers speed but is more expensive; sea freight is cost-effective for bulk orders. Additional costs include customs duties, taxes, and warehousing.

-

Profit Margin: Suppliers incorporate their margin, which varies based on brand reputation, order volume, and negotiation outcomes. Higher margins are typical for luxury or bespoke designer shoes.

Factors Influencing Pricing Beyond Basic Costs

Several variables can significantly impact the final price:

-

Order Volume & MOQ: Larger orders typically reduce per-unit costs due to economies of scale. Many manufacturers offer discounts for high-volume purchases or long-term partnerships.

-

Customization & Specifications: Custom colors, unique embellishments, or specific design features elevate costs. Standardized models are more economical.

-

Materials & Quality Certifications: Using genuine leather or sourcing eco-friendly, certified materials increases expenses but enhances brand value and consumer appeal.

-

Supplier Location & Capabilities: Asian manufacturers, especially in Thailand and China, often provide competitive pricing and efficient production cycles. European suppliers may charge premiums due to higher labor costs but offer superior craftsmanship and certifications.

-

Incoterms & Delivery Terms: FOB (Free on Board) terms shift shipping responsibility to the buyer, often reducing initial costs. DDP (Delivered Duty Paid) includes all logistics and duties, simplifying the process but increasing upfront costs.

Strategic Tips for International B2B Buyers

-

Negotiate with Suppliers: Leverage order volume and long-term potential to secure better prices. Clarify all cost components upfront, including hidden fees.

-

Focus on Total Cost of Ownership (TCO): Beyond unit price, consider logistics, customs, potential rework, and warranty costs. A slightly higher initial price might reduce total expenses if it ensures better quality and faster delivery.

-

Understand Pricing Nuances by Region: Buyers from Africa, South America, the Middle East, and Europe should recognize regional differences in supplier pricing, taxes, and import duties. For example, Argentine import tariffs or Middle Eastern VAT can significantly influence landed costs.

-

Sample and Quality Assurance: Always request samples before large orders. Ensuring color accuracy, material authenticity, and craftsmanship helps avoid costly rejections or returns.

-

Pricing Disclaimers: Given fluctuations in raw material costs, currency exchange rates, and geopolitical factors, prices are indicative and subject to change. Maintain open communication with suppliers for updated quotes.

Final Thoughts

Effective sourcing of red designer shoes demands a comprehensive understanding of the cost structure and influencing factors. By meticulously analyzing each component and leveraging negotiation strategies, international buyers can optimize their procurement costs, ensuring both quality and profitability. Tailoring sourcing approaches to regional supplier landscapes and maintaining flexibility in specifications can further enhance cost-efficiency and supply chain resilience.

Spotlight on Potential red designer shoes Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for red designer shoes.)*

Essential Technical Properties and Trade Terminology for red designer shoes

Key Technical Properties for Red Designer Shoes

1. Material Grade and Composition

The quality of materials used significantly impacts the shoe’s durability, aesthetic appeal, and brand positioning. High-grade leathers, such as full-grain or top-grain leather, are preferred for luxury designer shoes due to their superior appearance and longevity. Synthetic alternatives should be specified by type and grade to ensure consistency across batches. For B2B transactions, clear material specifications help prevent quality discrepancies and facilitate sourcing from reputable suppliers.

2. Color Fastness and Finish

Given the distinctive red color, ensuring color fastness is critical. This property indicates how well the dye resists fading or bleeding during wear and cleaning. A high color fastness rating (typically rated on a scale of 1-8) assures the buyer of long-lasting vibrancy. The finish—matte, glossy, or satin—also influences aesthetic appeal and must be clearly specified to match brand standards.

3. Tolerance and Fit Specifications

Manufacturers must adhere to strict dimensional tolerances to ensure the shoes fit correctly across different markets. Tolerance levels define the acceptable variation in measurements such as length, width, and heel height. Precise tolerances reduce returns and complaints, especially important for international shipments where sizing standards may differ.

4. Sole and Heel Composition

The sole and heel materials affect comfort, slip resistance, and wear. Common options include rubber, thermoplastic rubber (TPR), or leather. For high-end shoes, a combination of materials may be used to balance durability and aesthetics. Clear specifications on sole thickness and heel height are essential for consistent product delivery across regions.

5. Stitching and Finishing Quality

High-quality stitching ensures durability and a premium appearance. Specifications should include stitch type, thread material, and stitch density (stitches per inch). Precise finishing details—like edge trimming and decorative elements—are vital for brand reputation and should meet industry standards for luxury footwear.

6. Packaging and Labeling Standards

Proper packaging protects the shoes during transit and enhances brand presentation. Specifications include box dimensions, materials, and labeling language. Clear labeling standards, including size, country of origin, and care instructions, are crucial for compliance with import regulations in diverse markets.

Essential Trade Terms in the Red Designer Shoe Industry

1. OEM (Original Equipment Manufacturer)

OEM refers to manufacturers producing shoes based on a buyer’s design and specifications. For international buyers, understanding OEM arrangements ensures clarity on intellectual property rights, design control, and quality standards. OEM partnerships often offer cost advantages but require detailed agreements to protect brand integrity.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity a supplier is willing to produce per order. It helps manage production costs and inventory levels. Buyers from regions like Africa or South America should negotiate MOQs that balance cost efficiency with market demand, especially when testing new markets or launching limited editions.

3. RFQ (Request for Quotation)

An RFQ is a formal request sent to suppliers asking for detailed price proposals based on specific product requirements. A well-structured RFQ includes technical specs, packaging, delivery timelines, and payment terms. It is essential for comparing supplier offers and ensuring transparency in pricing.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers for shipping, insurance, and tariffs. Common terms like FOB (Free on Board), CIF (Cost, Insurance, Freight), and DDP (Delivered Duty Paid) specify who bears costs and risks at each stage of transportation. Understanding Incoterms helps buyers optimize logistics and control costs across borders.

5. Lead Time

Lead time refers to the duration from order placement to shipment readiness. For international markets, accurate knowledge of lead times helps in planning inventory, marketing campaigns, and sales cycles. Longer lead times may require strategic inventory buffers, especially in regions with less frequent shipments.

6. Quality Assurance (QA) Standards

QA standards encompass inspections and testing procedures to verify product quality before shipment. International buyers should specify QA protocols, including sample approval processes, compliance certifications, and defect tolerances. Strong QA standards reduce the risk of receiving non-conforming products and enhance brand reputation.

This comprehensive understanding of technical properties and trade terminology enables international B2B buyers to make informed decisions, negotiate effectively, and establish reliable supply chains for red designer shoes across diverse markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the red designer shoes Sector

Market Overview & Key Trends

The global market for red designer shoes is driven by a confluence of fashion trends, consumer demand for luxury and statement footwear, and technological innovations in manufacturing and sourcing. As an iconic color symbolizing passion, power, and elegance, red shoes hold a premium appeal across multiple regions, including Europe, North America, and emerging markets in Africa, South America, and the Middle East.

For B2B buyers, understanding regional dynamics is crucial. In Europe, there is a strong shift toward sustainable luxury, with brands and consumers increasingly valuing ethically sourced and environmentally friendly products. Meanwhile, in regions like Argentina and Thailand, local craftsmanship and artisanal techniques continue to influence sourcing decisions, offering unique value propositions for international buyers.

Emerging trends include the integration of digital sourcing platforms, which facilitate real-time communication and transparency, and the adoption of AI-driven demand forecasting tools to optimize inventory. Additionally, sustainable materials such as recycled plastics, plant-based dyes, and eco-certified leathers are gaining prominence, aligning with global environmental commitments.

Market dynamics are also shaped by supply chain disruptions and geopolitical factors. Buyers from Africa and South America should leverage diversified sourcing networks to mitigate risks, while those from the Middle East and Europe can benefit from established trade agreements and technological infrastructure. Overall, the sector is witnessing a shift towards more agile, transparent, and sustainable sourcing practices, demanding that B2B buyers stay informed and adaptable.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a central pillar in the red designer shoes sector, driven by both consumer expectations and regulatory pressures. For B2B buyers, sourcing from suppliers with strong environmental credentials not only enhances brand reputation but also ensures compliance with increasingly strict standards in key markets like the EU, Middle East, and North America.

Environmental impacts of shoe production—such as water use, chemical runoff, and carbon emissions—are under scrutiny. Ethical sourcing involves ensuring that raw materials, like leather and dyes, are obtained responsibly, with suppliers adhering to Fair Trade and environmental certification standards such as GOTS (Global Organic Textile Standard) or Leather Working Group (LWG) certifications. Utilizing eco-friendly materials, such as vegetable-tanned leather, recycled textiles, and bio-based dyes, can significantly reduce environmental footprints.

Transparency in the supply chain is vital; B2B buyers should prioritize partnerships with suppliers who provide verifiable sustainability credentials. Developing long-term relationships with certified manufacturers not only mitigates compliance risks but also aligns with growing consumer demand for ethically produced luxury goods. Incorporating sustainability clauses into contracts, investing in supplier audits, and fostering capacity-building initiatives are actionable steps that can elevate supply chain integrity.

Furthermore, adopting a circular economy approach—such as designing for disassembly, promoting recycling programs, and encouraging resale—can position brands as leaders in eco-conscious luxury footwear. By integrating sustainability deeply into sourcing strategies, B2B buyers can differentiate their offerings and contribute positively to environmental and social well-being.

Brief Evolution/History (Optional)

Historically, the production of luxury footwear, including red designer shoes, was rooted in artisanal craftsmanship and limited mass production. Over recent decades, the sector has evolved with globalization, technological advances, and a heightened focus on sustainability. The shift from purely luxury craftsmanship to incorporating sustainable practices reflects broader societal values and market expectations.

For B2B buyers, understanding this evolution highlights the importance of sourcing from innovative suppliers who blend traditional techniques with modern eco-friendly practices. As consumers increasingly demand transparency and ethical integrity, the industry’s trajectory points toward greater adoption of sustainable materials, digital transparency tools, and ethical certifications. Recognizing these trends enables buyers to make informed decisions that align with both market demands and corporate responsibility commitments.

Frequently Asked Questions (FAQs) for B2B Buyers of red designer shoes

1. How can I effectively vet suppliers of red designer shoes to ensure quality and reliability?

Thorough vetting begins with requesting comprehensive company credentials, including business licenses, manufacturing permits, and industry certifications (e.g., ISO, CE). Review their portfolio for similar products, and ask for references from other international buyers. Conduct virtual factory audits or request detailed videos and photos of production facilities to verify capacity and quality control processes. Additionally, evaluate their compliance with safety standards and sustainability practices, especially if branding or intellectual property rights are involved. Engaging third-party inspection agencies before shipment can further mitigate risks and ensure the supplier meets your quality expectations.

2. What customization options are typically available for red designer shoes, and how do they impact lead times and costs?

Most suppliers offer customization in areas such as color shades, materials, embellishments, branding (logos, tags), and packaging. Advanced customizations like unique patterns or exclusive designs may require longer lead times—often 4-8 weeks—due to design approval and production adjustments. Custom orders usually entail higher MOQ requirements and setup costs, but they can significantly enhance product differentiation in your market. To optimize costs, plan ahead and communicate your specifications early, allowing suppliers to allocate resources efficiently. Confirm all customization details upfront to avoid misunderstandings that could delay delivery or increase expenses.

3. What are typical MOQs, lead times, and payment terms for bulk orders of red designer shoes?

MOQs for designer shoes generally range from 200 to 1,000 pairs, depending on the supplier’s production capacity and the level of customization. Lead times usually vary between 4 to 12 weeks, influenced by order complexity and quantity. Common payment terms include a 30% upfront deposit with the balance paid before shipment or upon delivery, often via bank transfer or letter of credit for larger orders. Negotiate flexible terms that align with your cash flow, especially when ordering in smaller batches or during initial partnerships. Establish clear timelines and payment schedules to avoid delays or disputes.

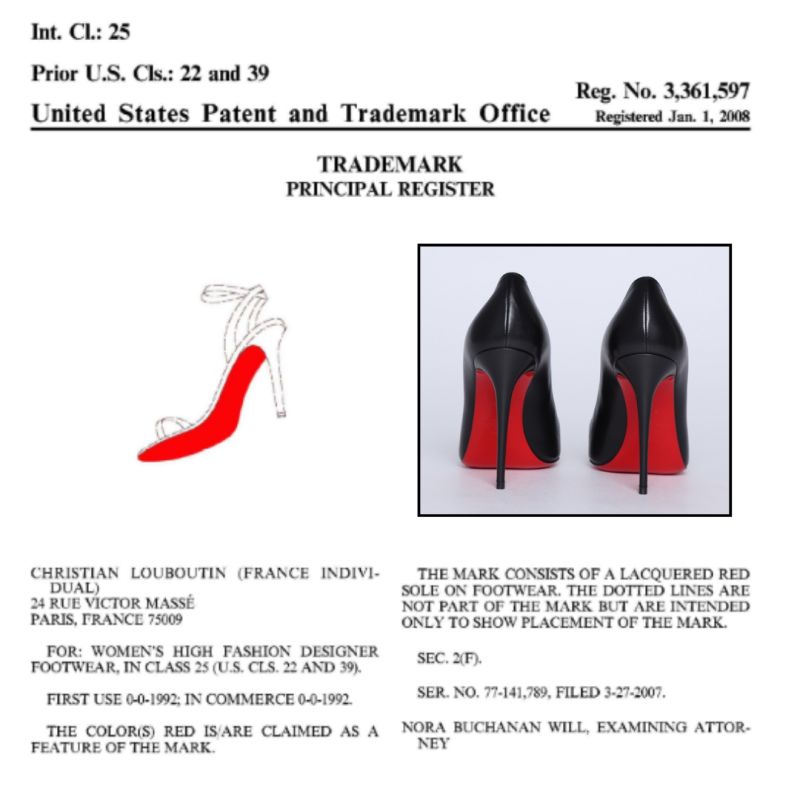

Illustrative Image (Source: Google Search)

4. What certifications or quality assurance documents should I request from suppliers?

Request relevant certifications such as ISO 9001 (quality management), environmental compliance (e.g., REACH, ROHS), and safety standards applicable to footwear. For designer shoes, intellectual property rights documentation is critical to prevent counterfeit issues. Ask for factory audit reports, sample testing results, and material safety data sheets (MSDS). Suppliers should also provide a detailed quality control plan, including inspection procedures at various production stages. Verifying these documents helps ensure product safety, compliance with international standards, and protection of your brand integrity.

Illustrative Image (Source: Google Search)

5. How should I manage logistics, shipping, and customs clearance for international orders of red designer shoes?

Coordinate with suppliers experienced in international shipping, preferably those offering FOB or CIF terms to simplify your logistics. Choose reliable freight forwarders with expertise in handling footwear and luxury goods, ensuring proper packaging to prevent damage. Provide clear shipping instructions and accurate documentation, including commercial invoices, packing lists, and certificates of origin. Be aware of import tariffs, VAT, and customs procedures in your country—these can significantly affect costs and delivery times. Establish a strong communication line with your logistics partners to monitor shipments and address issues proactively.

6. What are common dispute resolution mechanisms in international B2B transactions for designer shoes?

Disputes often arise over quality, delivery delays, or payment issues. To mitigate this, include clear contractual clauses specifying dispute resolution methods—preferably arbitration under internationally recognized rules (e.g., ICC, UNCITRAL). Specify jurisdiction and language in the contract to avoid ambiguity. Maintain detailed records of communications, purchase orders, and inspection reports to support your claims. Engaging a local legal advisor familiar with international trade laws can expedite resolution. Building strong supplier relationships and conducting regular audits also help prevent conflicts before they escalate.

Illustrative Image (Source: Google Search)

7. How can I ensure the authenticity of designer branding and prevent counterfeit issues?

Work exclusively with suppliers who can provide proof of authorized licensing or brand ownership rights. Request detailed documentation, including licensing agreements, official brand authorization letters, and certificates of authenticity. Conduct due diligence on supplier reputation and history in luxury footwear markets. Incorporate brand-specific quality standards and trademarks into contracts, and consider using secure packaging and tamper-evident labels. Regularly audit suppliers and inspect shipments to verify branding accuracy. Protecting your brand integrity is vital for long-term success and customer trust in the luxury segment.

8. What strategies can I use to build long-term, reliable partnerships with suppliers of red designer shoes?

Start by establishing transparent communication and clearly defined expectations regarding quality, lead times, and pricing. Prioritize suppliers with proven track records in international markets and those who demonstrate flexibility and responsiveness. Consider smaller initial orders to build trust before scaling up. Maintain consistent payment practices and provide constructive feedback to foster mutual growth. Visiting suppliers’ facilities when possible can deepen relationships and ensure alignment. Regularly review performance metrics and update contractual terms to adapt to market changes, ensuring a sustainable and mutually beneficial partnership over time.

Strategic Sourcing Conclusion and Outlook for red designer shoes

Final Insights and Future Outlook

Effective strategic sourcing of red designer shoes offers international B2B buyers a competitive edge by balancing quality, exclusivity, and cost efficiency. Leveraging diversified supply chains, fostering strong supplier relationships, and staying attuned to emerging trends will ensure access to authentic, high-end products that meet discerning market demands.

For buyers across Africa, South America, the Middle East, and Europe—such as Argentina and Thailand—prioritizing transparency, ethical sourcing, and sustainable practices can enhance brand reputation and consumer trust. Establishing clear quality standards and negotiating favorable terms early in the sourcing process will mitigate risks and secure reliable supply channels.

Looking ahead, the dynamic landscape of luxury footwear demands agility and innovation. Embracing digital tools for supplier vetting and market analysis will streamline procurement and open new opportunities for collaboration. By adopting a strategic, forward-thinking approach, international buyers can position themselves as leaders in the competitive market for red designer shoes, ensuring sustained growth and differentiation in the global luxury segment.