Your Ultimate Guide to Sourcing Rocker Bottom Shoes

Guide to Rocker Bottom Shoes

- Introduction: Navigating the Global Market for rocker bottom shoes

- Understanding rocker bottom shoes Types and Variations

- Key Industrial Applications of rocker bottom shoes

- Strategic Material Selection Guide for rocker bottom shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for rocker bottom shoes

- Comprehensive Cost and Pricing Analysis for rocker bottom shoes Sourcing

- Spotlight on Potential rocker bottom shoes Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for rocker bottom shoes

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the rocker bottom shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of rocker bottom shoes

- Strategic Sourcing Conclusion and Outlook for rocker bottom shoes

Introduction: Navigating the Global Market for rocker bottom shoes

In today’s dynamic global footwear landscape, rocker bottom shoes have emerged as a vital segment, offering innovative solutions for diverse consumer needs—from comfort and mobility to orthotic support. For international B2B buyers in regions such as Africa, South America, the Middle East, and Europe (including Turkey and Colombia), understanding the nuances of this niche is crucial for competitive sourcing and market expansion. As demand for ergonomic and health-conscious footwear grows, securing reliable suppliers and high-quality products becomes more than a strategic advantage—it’s a necessity.

This comprehensive guide equips you with essential insights to navigate the complex global market for rocker bottom shoes. It covers a broad spectrum of topics: different types and materials, manufacturing processes, quality control standards, sourcing strategies, cost considerations, and market trends. Additionally, it addresses frequently asked questions and highlights key factors influencing supplier selection and product differentiation.

By leveraging this knowledge, B2B buyers can make informed sourcing decisions that optimize quality, cost-efficiency, and supply chain reliability. Whether you’re seeking innovative manufacturers in Turkey, established suppliers in Colombia, or emerging markets across Africa and the Middle East, this guide provides the actionable intelligence needed to succeed in this specialized footwear segment. Empower your procurement strategy with expert insights and gain a competitive edge in the global rocker bottom shoes market.

Understanding rocker bottom shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Rocker Bottom Shoes | Curved sole with a smooth, continuous rocker profile | Footwear manufacturing, orthopedic supplies, retail | Pros: Widely accepted, versatile, easy to source. Cons: Limited customization options. |

| Therapeutic/Medical Grade | Specialized design with enhanced cushioning and biomechanical support | Medical institutions, rehabilitation centers, orthopedics | Pros: High demand in healthcare sectors, premium pricing. Cons: Higher cost, strict quality standards. |

| Fashion/Trend-Driven | Innovative designs with varied materials, colors, and aesthetics | Fashion brands, boutique retailers, online marketplaces | Pros: High margins, attractive to niche markets. Cons: Shorter product lifecycle, rapid trend changes. |

| Customizable/Modular Shoes | Modular components allowing tailored fit and function | Specialty orthopedics, custom footwear providers | Pros: High value for clients needing personalized solutions. Cons: More complex manufacturing and logistics. |

| Eco-Friendly/Sustainable | Made from recycled or biodegradable materials, eco-conscious design | Green retailers, eco-focused brands, NGOs | Pros: Growing consumer demand, strong brand differentiation. Cons: Potentially higher raw material costs, limited supplier options. |

Standard Rocker Bottom Shoes

This category includes the classic, mass-produced models with a uniformly curved sole designed to facilitate natural gait and reduce joint stress. They are suitable for general footwear manufacturing and orthopedic supplies, offering a broad market appeal. For B2B buyers, sourcing these shoes involves evaluating supplier reliability, material quality, and compliance with safety standards. The main advantage is their versatility and wide availability, but buyers should be cautious of quality inconsistencies and limited scope for customization.

Therapeutic/Medical Grade

Engineered for clinical and rehabilitative purposes, these shoes feature enhanced cushioning, stability, and biomechanical support. They are highly sought after by healthcare providers, orthopedists, and rehabilitation centers. B2B buyers should prioritize suppliers with proven quality certifications and consistent product standards. While these shoes command premium prices and open lucrative markets, they also require rigorous quality assurance and adherence to medical device regulations, especially important for export to regions with strict health standards like Europe and the Middle East.

Fashion/Trend-Driven

These shoes emphasize aesthetics, often incorporating innovative materials, vibrant colors, and contemporary designs. They appeal to fashion-forward consumers and boutique retailers, especially in markets with a strong emphasis on style, such as Europe and South America. For B2B buyers, the key considerations include staying ahead of trends, managing inventory turnover, and establishing partnerships with trendsetting brands. While offering high margins, these shoes tend to have shorter product lifecycles, demanding agile supply chains.

Customizable/Modular Shoes

This variation allows for personalized adjustments, such as interchangeable soles or adjustable fits, catering to clients with specific orthopedic needs or preferences. They are often used by specialty orthopedics and custom footwear providers. B2B buyers should evaluate manufacturing complexity, lead times, and logistics management, as these shoes typically require closer collaboration with manufacturers. Their high customization value makes them ideal for niche markets but may involve higher upfront costs and longer delivery cycles.

Eco-Friendly/Sustainable

Made from recycled, biodegradable, or sustainably sourced materials, these shoes appeal to environmentally conscious consumers and brands. They are gaining traction in markets like Europe and parts of Africa and South America where sustainability is a priority. B2B buyers should assess supplier sustainability credentials, raw material availability, and compliance with environmental standards. While they often command premium prices and enhance brand reputation, sourcing can be limited by the availability of eco-friendly materials, and costs may be higher than conventional options.

Key Industrial Applications of rocker bottom shoes

| Industry/Sector | Specific Application of rocker bottom shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare & Orthopedics | Custom orthotic footwear for patients with gait abnormalities | Improved patient outcomes, reduced recovery times, and enhanced mobility | Material durability, compliance with medical standards, customization capabilities |

| Sports & Rehabilitation | Rehabilitation shoes for post-injury recovery or athletic training | Accelerated recovery, injury prevention, and enhanced athletic performance | Shock absorption, lightweight design, adaptability to different foot shapes |

| Industrial Safety & Workwear | Anti-fatigue footwear for long hours of standing or manual labor | Increased worker comfort, reduced fatigue, and lower injury risk | Slip resistance, durability under harsh conditions, comfort for extended wear |

| Tourism & Hospitality | Comfort footwear for travel and hospitality staff | Improved employee comfort, reduced fatigue, and enhanced customer service | Cost-effectiveness, ease of cleaning, availability in bulk quantities |

| Retail & Fashion | Trend-driven casual and lifestyle shoes with ergonomic benefits | Market differentiation, customer satisfaction, and brand loyalty | Aesthetic appeal, variety of designs, consistent quality and supply chain reliability |

Healthcare & Orthopedics

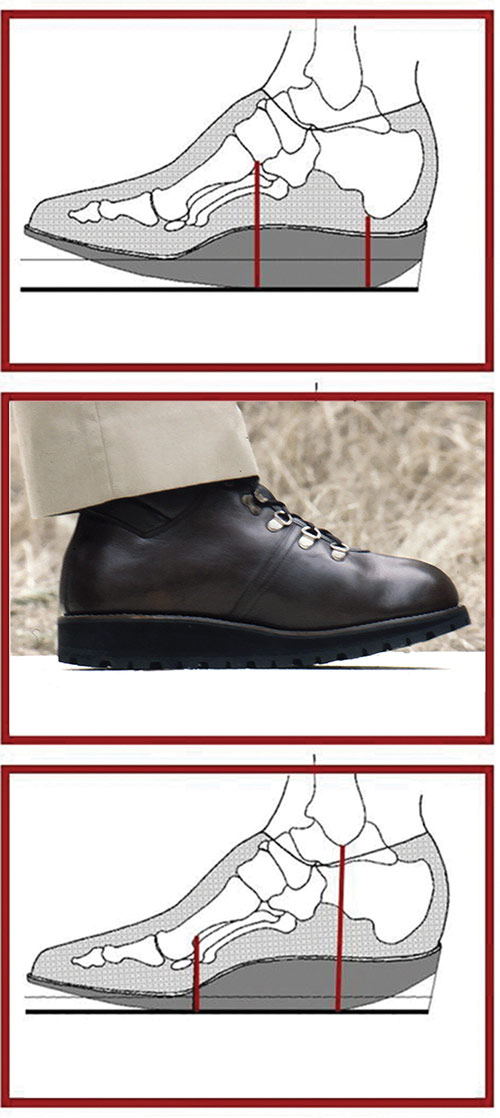

Rocker bottom shoes are extensively used in orthopedics to address gait abnormalities, plantar fasciitis, and other foot conditions. These shoes facilitate smoother heel-to-toe transitions, reducing stress on joints and muscles. For international B2B buyers in regions like Africa or South America, sourcing high-quality, customizable options that meet medical standards is crucial. Reliable suppliers must offer materials that are both durable and biocompatible, ensuring consistent performance and compliance with health regulations. This application provides a significant value proposition by improving patient mobility and reducing long-term healthcare costs.

Sports & Rehabilitation

In the sports and rehabilitation sectors, rocker bottom shoes are designed to support recovery from injuries such as Achilles tendinitis or ankle sprains. They promote proper gait mechanics and absorb shock during movement, which accelerates healing. For buyers across the Middle East or Europe, sourcing lightweight, shock-absorbent shoes with adaptable fits is essential. These shoes must also withstand frequent use and maintain their structural integrity over time, offering athletes and patients a reliable recovery tool that minimizes re-injury risks.

Industrial Safety & Workwear

Workers engaged in manual labor or those required to stand for prolonged periods benefit from rocker bottom shoes that reduce fatigue and prevent musculoskeletal strain. Industries such as manufacturing, construction, and logistics in regions like Turkey or Colombia require footwear that combines comfort with durability. Key sourcing considerations include slip resistance, robustness under harsh conditions, and ease of maintenance. Providing high-quality rocker sole shoes can lead to fewer workplace injuries, improved productivity, and lower insurance costs for businesses.

Tourism & Hospitality

Employees in the tourism and hospitality sectors often stand for long hours, making comfort footwear a priority. Rocker bottom shoes offer ergonomic benefits that reduce fatigue and discomfort, enhancing employee well-being and customer service quality. For B2B buyers, especially those sourcing in bulk from regions like Africa or South America, affordability, ease of cleaning, and a variety of styles are critical factors. Offering a range of comfortable, stylish options can help brands differentiate themselves in competitive markets.

Retail & Fashion

The fashion industry increasingly incorporates ergonomic footwear, with rocker bottom shoes gaining popularity for their comfort and trendy appeal. Retailers and brands targeting health-conscious consumers or those seeking stylish yet supportive footwear can leverage this application. Sourcing high-quality, aesthetically appealing shoes that meet both design and ergonomic standards allows manufacturers to tap into a growing market segment. Consistent supply chain reliability and customization options are vital for maintaining brand reputation and meeting diverse consumer preferences worldwide.

Strategic Material Selection Guide for rocker bottom shoes

Material Analysis for Rocker Bottom Shoes

Selecting the appropriate materials for rocker bottom shoes is critical for ensuring product performance, durability, and compliance with international standards. Different markets—such as Africa, South America, the Middle East, and Europe—have unique requirements based on environmental conditions, regulatory standards, and manufacturing capabilities. Here, we analyze four common materials used in the construction of rocker bottom shoes, focusing on their properties, advantages, limitations, and strategic considerations for international B2B buyers.

1. Thermoplastic Polyurethane (TPU)

Key Properties:

TPU is a versatile elastomer known for excellent flexibility, abrasion resistance, and good energy absorption. It performs well across a broad temperature range (-40°C to 80°C) and exhibits high impact resistance. Its chemical resistance makes it suitable for various media, including oils and greases.

Pros & Cons:

– Pros: Durable, lightweight, excellent shock absorption, and easy to mold into complex shapes. It also offers good UV stability, making it suitable for outdoor applications.

– Cons: Slightly higher cost compared to standard plastics and requires precise processing conditions. Over time, exposure to extreme UV or ozone can cause degradation if not stabilized.

Impact on Application:

TPU’s flexibility and durability make it ideal for the rocker sole, providing comfort and longevity. Its chemical resistance ensures compatibility with different environmental media, especially in regions with high humidity or exposure to pollutants.

International B2B Considerations:

TPU complies with many international standards such as ASTM D4236 and REACH regulations, facilitating market entry in Europe and other regions. Buyers should verify supplier certifications for environmental compliance. Its relatively higher cost might be offset by longer product lifespan, appealing to premium markets in Europe and the Middle East.

2. Rubber (Natural and Synthetic)

Key Properties:

Rubber, whether natural or synthetic (e.g., SBR, NBR), offers excellent elasticity, resilience, and slip resistance. It withstands significant pressure and deformation without permanent damage, making it suitable for high-wear areas.

Pros & Cons:

– Pros: Cost-effective, readily available, and easy to process. Natural rubber provides superior elasticity, while synthetic variants can be tailored for specific environmental resistances.

– Cons: Natural rubber can degrade under prolonged UV exposure and ozone, limiting outdoor durability. Synthetic rubbers vary in chemical resistance and may require additives for enhanced stability.

Impact on Application:

Rubber’s high resilience makes it suitable for the outsole of rocker shoes, especially where slip resistance and shock absorption are priorities. Its adaptability to different formulations allows customization for regional environmental conditions.

International B2B Considerations:

Rubber materials must meet standards like ASTM D2000 or DIN 53507 for quality assurance. Buyers in Africa and South America should consider local availability and supply chain stability. In regions with high UV exposure, synthetic rubbers with UV stabilizers are recommended to extend product life.

3. Ethylene Vinyl Acetate (EVA)

Key Properties:

EVA is a lightweight, flexible foam material with excellent cushioning and shock absorption properties. It performs well at temperatures from -30°C to 70°C and resists cracking and UV degradation.

Pros & Cons:

– Pros: Cost-effective, easy to mold, and provides superior comfort. It is also resistant to water and many chemicals.

– Cons: Less durable under heavy or abrasive use; prone to compression set over time, which can reduce cushioning effectiveness.

Impact on Application:

EVA is widely used in the midsole of rocker shoes to enhance comfort and reduce fatigue. Its lightweight nature is advantageous for markets where comfort is a priority, such as in Europe and Middle Eastern regions.

International B2B Considerations:

EVA complies with many safety standards, including REACH and ASTM F963. Buyers should consider the grade of EVA used, as lower-quality foam may degrade faster in hot climates like the Middle East. Sourcing from reputable suppliers ensures consistent quality and performance.

4. Polypropylene (PP)

Key Properties:

Polypropylene is a thermoplastic polymer known for its rigidity, chemical resistance, and low cost. It offers moderate impact resistance and can withstand temperatures up to 100°C.

Pros & Cons:

– Pros: Cost-effective, easy to process, and resistant to moisture and many chemicals.

– Cons: Less flexible than TPU or rubber, which can limit comfort and shock absorption. Its rigidity may lead to cracking under repeated stress.

Impact on Application:

PP is suitable for structural components of rocker shoes, such as support frames or stiffening elements. Its rigidity can be advantageous in applications requiring shape retention but less so for cushioning.

International B2B Considerations:

Polypropylene’s compliance with standards like ASTM D4101 and ISO 1872 makes it suitable for global markets. Buyers should consider regional environmental conditions—such as high temperatures or UV exposure—when selecting PP grades, as additives may be necessary to enhance durability.

Summary Table

| Material | Typical Use Case for rocker bottom shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Thermoplastic Polyurethane (TPU) | Outsole, shock absorption components | Excellent flexibility and durability | Higher cost, UV/Ozone sensitivity without stabilization | High |

| Rubber (Natural & Synthetic) | Outsole, slip-resistant tread | Resilience, slip resistance, cost-effective | UV/Ozone degradation (natural rubber), formulation variability | Med |

| Ethylene Vinyl Acetate (EVA) | Midsole, cushioning layer | Lightweight, superior cushioning | Less durable under heavy use, compression set | Low |

| Polypropylene (PP) | Structural support, stiff components | Cost-effective, chemical resistance | Rigid, limited flexibility | Low |

Final Notes for B2B Buyers

When selecting materials for rocker bottom shoes, consider regional environmental factors, regulatory standards, and manufacturing capabilities. For instance, buyers in Africa and South America should prioritize materials with proven UV and ozone resistance, such as stabilized TPU or synthetic rubber formulations. European markets may demand higher compliance with environmental standards like REACH, influencing material choice. Middle Eastern buyers should focus on materials that withstand high temperatures and intense sunlight, ensuring longevity and safety. Collaborating with suppliers who can provide certification and consistent quality will facilitate smoother market entry and customer satisfaction across diverse regions.

In-depth Look: Manufacturing Processes and Quality Assurance for rocker bottom shoes

Manufacturing Processes of Rocker Bottom Shoes

The production of rocker bottom shoes involves a series of meticulously coordinated stages designed to ensure durability, comfort, and compliance with international standards. For B2B buyers, understanding these processes is essential for evaluating supplier capabilities and product consistency.

Material Preparation and Selection

The process begins with selecting high-quality raw materials tailored to the specific design and functional requirements. Common materials include EVA foam, thermoplastic elastomers, rubber compounds, and durable synthetics for the sole, combined with leather, mesh, or synthetic uppers. Suppliers often source materials from certified vendors adhering to ISO 9001 standards to guarantee consistency.

Illustrative Image (Source: Google Search)

Material preparation involves precise cutting, molding, and blending. For thermoplastics and foams, extrusion and injection molding are prevalent, allowing for complex, ergonomic shapes. Suppliers may employ CNC cutting or automated patterning to enhance precision, especially when producing customized or branded designs.

Forming and Assembly

The core of manufacturing involves shaping the sole and upper components. Injection molding or compression molding techniques are frequently used to produce the rocker bottom sole, ensuring consistent curvature and structural integrity. The rocker shape is critical for the shoe’s biomechanical function, requiring tight process controls.

Assembly integrates the sole with the upper, often through adhesive bonding, mechanical fasteners, or a combination of both. Automated robotic systems are increasingly used for precise placement, especially for high-volume production. Additional features such as cushioning inserts, arch supports, or anti-slip pads are installed during this stage, adhering to design specifications.

Finishing and Quality Control

The finishing phase includes surface treatment, color application, and surface protection. Techniques such as heat embossing, painting, or lamination are employed, with strict controls to prevent defects like bubbling, uneven coloring, or surface imperfections.

Final inspection involves cleaning, packaging, and detailed quality checks to meet both aesthetic and functional standards. Suppliers may employ automated inspection systems for surface defects and dimensional accuracy, complemented by manual reviews for finer details.

Quality Assurance Protocols and Standards

Quality assurance (QA) is integral throughout the manufacturing cycle, with adherence to both international standards and industry-specific certifications. For B2B buyers, especially those from Africa, South America, the Middle East, and Europe, verifying a supplier’s QA practices is vital for minimizing risks and ensuring product consistency.

International and Industry Standards

- ISO 9001: The foundational standard for quality management systems, ensuring systematic processes, continual improvement, and customer satisfaction. Suppliers compliant with ISO 9001 demonstrate a structured approach to quality.

- CE Marking (European Conformity): For shoes sold within Europe, CE certification confirms compliance with safety, health, and environmental requirements, including materials safety and manufacturing processes.

- Industry-specific certifications: Some manufacturers may also hold certifications like ASTM standards for footwear durability or specific medical device standards if shoes are designed for therapeutic purposes.

QC Checkpoints and Testing Methods

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival for physical properties, dimensional accuracy, and compliance with specifications. Suppliers often perform tensile tests, hardness testing, and visual inspections.

- In-Process Quality Control (IPQC): During manufacturing, critical stages such as molding, assembly, and surface finishing are monitored. Techniques include dimensional checks, weight measurements, and surface defect detection via automated vision systems.

- Final Quality Control (FQC): The finished shoes undergo comprehensive testing, including:

- Durability testing: Simulating wear cycles to assess sole resilience.

- Flexibility tests: Ensuring the rocker bottom maintains its biomechanical function.

- Slip resistance: Conducted on various surfaces to meet safety standards.

- Comfort and ergonomic assessments: To verify the intended biomechanical benefits.

Verification and Auditing for B2B Buyers

International buyers should request detailed QA reports and third-party inspection certificates. Conducting supplier audits, either in person or via trusted inspection agencies, provides insights into manufacturing practices, cleanliness, safety protocols, and compliance records. For regions like Africa and South America, leveraging local inspection firms familiar with regional manufacturing nuances can be advantageous.

Nuances for International B2B Buyers

Regional Regulatory Considerations

Buyers from Europe and Turkey must ensure products meet CE and REACH regulations, emphasizing chemical safety and environmental impact. Suppliers should provide declarations of conformity and test reports aligned with these standards.

In Africa and South America, regulatory requirements may vary significantly. Buyers should verify local compliance, such as import permits or regional safety standards, and insist on suppliers providing detailed documentation to facilitate customs clearance.

Quality Control Nuances

- Traceability: Ensure suppliers maintain comprehensive batch records, enabling traceability from raw materials to finished products—crucial for recalls or quality issues.

- Third-party inspections: Engage independent inspection firms, especially for high-volume orders, to conduct pre-shipment audits and verify QC reports.

- Sample testing: Request sample batches for independent testing to validate claimed quality parameters, particularly when sourcing from new or less established suppliers.

Building Long-term Supplier Relationships

Developing a relationship based on transparency and shared quality expectations encourages continuous improvement. Regular audits, quality feedback, and joint development initiatives can lead to more consistent product quality and better compliance with international standards.

In conclusion, understanding the detailed manufacturing processes and implementing rigorous quality assurance protocols are essential for B2B buyers seeking reliable suppliers of rocker bottom shoes. By focusing on standardized procedures, compliance with international standards, and thorough verification practices, buyers from diverse regions can mitigate risks and ensure the delivery of high-quality, compliant footwear tailored to their markets.

Comprehensive Cost and Pricing Analysis for rocker bottom shoes Sourcing

Cost Structure Breakdown

Understanding the comprehensive cost structure for rocker bottom shoes is essential for effective sourcing and pricing negotiations. The primary components include:

-

Materials: The choice of materials—such as EVA foam, rubber, or synthetic uppers—significantly influences costs. High-quality, certified eco-friendly or specialized materials tend to be more expensive but can justify premium pricing. Material costs typically account for 30-50% of the manufacturing expense.

-

Labor: Labor costs vary widely based on the manufacturing country. Countries like Turkey and Eastern European nations generally offer moderate labor rates, whereas Asian suppliers (e.g., China, Vietnam) often provide lower wages, impacting overall costs. Skilled labor for quality control and assembly can add a premium.

-

Manufacturing Overhead: This includes factory utilities, machinery depreciation, and maintenance. Efficient, well-maintained facilities tend to have higher upfront costs but can result in better product consistency and quality, reducing rework and waste.

-

Tooling & Molds: Initial investments in molds and tooling are significant but are amortized over large production runs. Custom designs or high-volume orders can reduce per-unit tooling costs, whereas small batches will carry higher tooling expenses.

-

Quality Control (QC): Rigorous QC processes, including testing for durability, safety certifications, and compliance standards, add to costs but are crucial for international markets, especially where regulations are strict.

-

Logistics & Shipping: International sourcing involves freight costs, customs duties, and insurance. Costs depend on shipment volume, weight, destination port, and chosen Incoterms (e.g., FOB, CIF). Bulk shipments reduce per-unit logistics costs but require higher upfront capital.

-

Margins: Suppliers typically add a markup to cover risk, currency fluctuations, and profit. Markups can range from 10% to 30%, depending on the supplier’s competitiveness and relationship with the buyer.

Price Influencers

Several factors impact the final pricing of rocker bottom shoes in international markets:

-

Order Volume & MOQ: Larger orders often unlock better unit prices due to economies of scale. Minimum Order Quantities (MOQs) can range from 500 to 5,000 pairs, with higher volumes reducing per-unit costs significantly.

-

Specifications & Customization: Custom designs, branding, or unique features increase manufacturing complexity and costs. Suppliers may charge setup fees or premiums for tailored specifications.

-

Materials & Certifications: Premium, sustainable, or specialized materials (e.g., anti-slip soles, orthotic-grade components) elevate costs. Certification requirements (e.g., ISO, CE, or local standards) can also influence pricing.

-

Quality & Certifications: Higher quality standards, certifications, and testing requirements add costs but are often necessary for access to certain markets, notably Europe and the Middle East.

-

Supplier Factors: Supplier reputation, production capacity, and geographic location affect pricing. Suppliers from regions with higher labor costs (e.g., Turkey, Europe) tend to have higher base prices but may offer better quality or shorter lead times.

-

Incoterms & Shipping Conditions: FOB (Free on Board) prices are common, giving buyers control over logistics, while CIF (Cost, Insurance, Freight) includes shipping costs. Understanding these terms helps evaluate the true landed cost.

Buyer Tips for Cost Optimization

-

Negotiate for Better Terms: Leverage larger orders and long-term relationships to negotiate discounts or better payment terms. Be clear about quality expectations and delivery schedules to avoid hidden costs.

-

Focus on Total Cost of Ownership (TCO): Consider not only unit price but also shipping, customs, tariffs, and after-sales service. Sometimes a slightly higher unit price from a reliable supplier results in lower overall costs.

-

Standardization & Bulk Purchasing: Standardizing designs and ordering in bulk can significantly reduce per-unit costs and lead times, especially advantageous for buyers from Africa and South America seeking economies of scale.

-

Understand Pricing Nuances: Be aware that prices fluctuate due to currency exchange rates, raw material costs, and geopolitical factors. Regularly review quotes and market conditions.

-

Market-Specific Considerations: For regions like Colombia, Turkey, or Middle Eastern countries, factor in local import duties and regulations. Tailoring your sourcing strategy to regional trade agreements can yield cost savings.

Indicative Price Ranges (Disclaimer)

As of late 2023, typical FOB prices for rocker bottom shoes range from approximately $3 to $8 per pair for standard models in moderate volumes (1,000+ pairs). Premium or customized options can push prices higher, especially if high-quality certifications or specialized materials are involved. Import duties, taxes, and logistics costs will vary by destination, so always factor these into your total landed cost calculations.

By thoroughly analyzing these cost components and market influences, international buyers from Africa, South America, the Middle East, and Europe can develop strategic sourcing plans that optimize costs while ensuring quality and compliance.

Spotlight on Potential rocker bottom shoes Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for rocker bottom shoes.)*

Essential Technical Properties and Trade Terminology for rocker bottom shoes

Critical Technical Properties of Rocker Bottom Shoes

1. Material Grade and Composition

The core material used for the sole and upper components significantly impacts durability, flexibility, and weight. High-quality materials such as thermoplastics, EVA foam, or rubber compounds are preferred. For B2B transactions, specifying the material grade ensures consistency—e.g., EVA with a density of 30kg/m³ for lightweight comfort. Suppliers must adhere to recognized standards (ISO, ASTM) to guarantee product reliability, especially when catering to healthcare or orthotic markets.

2. Tolerance Levels

Tolerance defines the permissible deviation in dimensions during manufacturing, critical for ensuring proper fit and performance. Typical tolerances for rocker soles are within ±0.5mm for key dimensions like height and width. Precise tolerances reduce returns, improve customer satisfaction, and facilitate compatibility with orthotic inserts or customization. Clear specifications on tolerances should be part of the purchase agreement to prevent discrepancies.

3. Flexural and Compression Strength

These properties determine how well the sole withstands repetitive stresses and weight-bearing loads. Flexural strength ensures the rocker sole maintains its shape over time, while compression strength relates to its ability to absorb impact. For B2B buyers, selecting soles with appropriate strength ratings (e.g., ISO 178 for flexural testing) guarantees longevity, especially in markets with high demand for durable footwear.

4. Surface Finish and Traction

The outsole surface finish affects slip resistance and aesthetic appeal. A textured or patterned finish enhances grip, reducing slip hazards—an essential factor for safety-critical applications in healthcare or industrial settings. Ensuring the finish meets specific standards (e.g., ASTM C1028 for slip resistance) is vital for compliance and brand reputation.

5. Weight and Balance

Lightweight shoes reduce fatigue, especially for orthotic or daily wear. Precise weight measurement (per pair or per unit) allows buyers to compare products effectively. Proper balance ensures comfort and stability; manufacturers should provide detailed weight specifications and balance assessments to meet ergonomic standards.

6. Compliance Certifications

Certifications such as CE (European Conformity), ASTM, or ISO compliance confirm that products meet safety, environmental, and quality standards. B2B buyers in regulated markets like Europe or the Middle East should verify these certifications to avoid legal issues and facilitate import procedures.

Industry and Trade Terminology for Rocker Bottom Shoes

1. OEM (Original Equipment Manufacturer)

Refers to companies that produce shoes based on a buyer’s specifications and branding. Understanding whether a supplier offers OEM services helps buyers customize designs, branding, and features to meet regional preferences or specific health requirements.

2. MOQ (Minimum Order Quantity)

The smallest number of units a supplier is willing to produce or sell per order. Clarifying MOQ is essential for planning inventory, managing costs, and negotiating pricing, especially for new or niche markets with limited initial demand.

3. RFQ (Request for Quotation)

A formal document sent by buyers to suppliers requesting price, lead time, and technical details for specific products. Effective RFQs should include detailed technical specifications, material requirements, and delivery timelines to obtain accurate and competitive quotes.

4. Incoterms (International Commercial Terms)

Standardized trade terms published by the ICC that define responsibilities in international shipments—e.g., FOB (Free on Board), CIF (Cost, Insurance, and Freight). Knowledge of Incoterms helps buyers understand cost responsibilities, risk transfer points, and delivery obligations across different regions.

5. Lead Time

The period from order placement to product delivery. Shorter lead times are often preferable for market responsiveness, but they may come at higher costs. Clear communication about lead times enables better inventory and sales planning.

6. Quality Assurance (QA) & Testing

Refers to procedures and tests conducted to verify product quality, safety, and compliance with standards. Buyers should specify required QA processes, such as third-party testing or factory audits, to ensure consistent product quality across batches and regions.

Summary:

Understanding these technical properties and trade terms enables B2B buyers from Africa, South America, the Middle East, and Europe to make informed procurement decisions. Clear specifications and industry jargon familiarity facilitate smoother negotiations, ensure product compliance, and foster long-term supplier relationships—key factors for success in the global rocker bottom shoe market.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the rocker bottom shoes Sector

Market Overview & Key Trends

The global rocker bottom shoes sector is experiencing dynamic shifts driven by evolving consumer preferences, technological advancements, and supply chain innovations. Traditionally popular among healthcare and wellness markets, these shoes are now gaining traction in mainstream footwear segments across Europe, the Middle East, South America, and Africa. For international B2B buyers, understanding these market drivers is crucial.

Illustrative Image (Source: Google Search)

Emerging trends include the integration of smart technologies—such as sensors for gait analysis—enhancing functional appeal. Additionally, sourcing trends favor lightweight, durable materials that improve comfort and longevity, with a notable shift toward eco-friendly components. For instance, natural rubber, recycled plastics, and bio-based foams are increasingly adopted to meet sustainability demands.

Market dynamics are also influenced by regional factors. Europe, particularly Turkey, remains a significant manufacturing hub due to advanced footwear production capabilities and proximity to key markets. South American countries like Colombia are emerging as both manufacturing and sourcing centers, offering competitive costs and access to local markets. In Africa and the Middle East, demand is rising, driven by healthcare sectors and an aging population seeking supportive footwear solutions.

International B2B buyers from these regions should leverage digital sourcing platforms, which now facilitate real-time supplier verification, quality assurance, and transparent logistics tracking. Moreover, establishing long-term relationships with local manufacturers can mitigate risks associated with geopolitical fluctuations and supply chain disruptions.

In sum, the rocker bottom shoes market is characterized by innovation, sustainability, and regional diversification, presenting numerous opportunities for strategic sourcing and market expansion. Staying informed about technological trends and regional capabilities will enable B2B buyers to capitalize on emerging opportunities effectively.

Sustainability & Ethical Sourcing

Sustainability is increasingly a decisive factor in the B2B procurement of rocker bottom shoes. Consumers globally are demanding products that align with environmental and social responsibility, prompting brands to prioritize eco-conscious sourcing and manufacturing practices.

Eco-friendly materials such as recycled rubber, biodegradable foams, and plant-based leathers are gaining prominence. These materials reduce reliance on fossil fuels and lower carbon footprints, making them attractive options for B2B buyers aiming to meet green certification standards. Certifications like Global Organic Textile Standard (GOTS), Forest Stewardship Council (FSC), and OEKO-TEX are valuable indicators of ethical and environmentally responsible sourcing.

Furthermore, establishing transparent supply chains is vital. Ethical sourcing involves verifying that raw materials are harvested without exploiting labor or violating human rights. Suppliers with fair labor practices and traceable supply chains are preferred, especially for markets with strict regulatory standards like Europe and the Middle East.

Investing in sustainable manufacturing processes—such as water-efficient dyeing techniques and waste reduction initiatives—can enhance brand reputation and compliance with international standards. B2B buyers should conduct rigorous audits and seek suppliers with documented sustainability commitments. Collaborative partnerships with eco-conscious manufacturers can also facilitate innovation in materials and production methods, ensuring products meet both functional and environmental criteria.

In conclusion, integrating sustainability into sourcing strategies not only aligns with global market expectations but also offers competitive advantages through brand differentiation, risk mitigation, and access to premium markets that prioritize green products.

Brief Evolution/History (Optional)

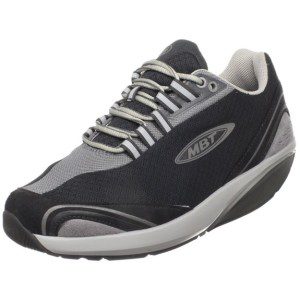

The evolution of rocker bottom shoes reflects a convergence of health, comfort, and fashion trends. Originally developed for therapeutic purposes, such as improving gait and reducing joint stress, these shoes gained popularity in the early 2000s with brands like MBT and Skechers introducing mass-market models. Over time, technological innovations—like enhanced cushioning, lightweight materials, and smart features—have expanded their appeal beyond medical use.

For B2B buyers, understanding this evolution underscores the importance of innovation and adaptation in product development. The shift from purely functional footwear to fashion-forward, sustainable options highlights opportunities for differentiation in competitive markets. Suppliers who have evolved their offerings by incorporating eco-friendly materials and smart technologies are better positioned to meet contemporary consumer demands, thus providing strategic value to international buyers seeking innovative, responsible products.

Frequently Asked Questions (FAQs) for B2B Buyers of rocker bottom shoes

- How can I effectively vet and verify international suppliers of rocker bottom shoes?

Ensuring supplier credibility is crucial to mitigate risks. Start by requesting comprehensive company documentation, including business licenses, export licenses, and manufacturing certifications (e.g., ISO, CE, or local quality standards). Conduct online research, review supplier websites, and check references or client testimonials. Utilize third-party verification services or trade associations for background checks. Request product samples before large orders to assess quality firsthand. Additionally, consider visiting the supplier’s facilities if feasible or engaging local agents or inspectors to verify operations, especially when sourcing from regions with varying regulatory standards.

Illustrative Image (Source: Google Search)

-

What customization options are typically available for rocker bottom shoes, and how can I communicate my specific needs effectively?

Manufacturers often offer customization in design, materials, colors, branding, and sole firmness. Clearly define your target market preferences and technical specifications, including size ranges and ergonomic features. Provide detailed design files, material specifications, and branding guidelines upfront. Engage with suppliers who have dedicated R&D teams or design departments capable of handling custom requests. Regular communication via detailed specifications and prototypes helps ensure alignment. Establish clear timelines and feedback loops to facilitate iterative adjustments, reducing the risk of miscommunication and ensuring the final product meets your market’s expectations. -

What are typical MOQ (Minimum Order Quantity) requirements, lead times, and payment terms for international orders of rocker bottom shoes?

MOQ varies depending on the manufacturer, typically ranging from 500 to 5,000 pairs for customized shoes, but some suppliers may accept smaller quantities for standard models. Lead times generally span 4 to 12 weeks, influenced by order complexity and production capacity. Payment terms are often 30% upfront deposit, with the balance payable before shipment or upon delivery. Negotiating flexible terms, especially for initial orders, can help mitigate risk. Establish clear agreements on payment methods (bank transfer, letter of credit, etc.) and ensure these are aligned with your financial policies and the supplier’s capabilities. -

What quality assurance measures and certifications should I look for in rocker bottom shoe suppliers?

Reliable suppliers should adhere to recognized quality standards such as ISO 9001, CE marking, or ASTM certifications, depending on your target markets. Request detailed QA protocols, including raw material testing, in-process inspections, and pre-shipment audits. Suppliers with ISO certification demonstrate consistent quality management. For products destined for specific markets, ensure compliance with regional safety and environmental standards (e.g., REACH in Europe). Ask for test reports, factory audits, and third-party inspection options. Implementing quality agreements and periodic audits helps maintain standards and reduces the risk of defective shipments reaching your customers. -

How can I manage international logistics effectively when importing rocker bottom shoes?

Efficient logistics require early planning and collaboration with experienced freight forwarders familiar with your region. Choose shipping modes based on cost, speed, and order size—air freight for urgent deliveries, sea freight for large volumes. Consolidate shipments to reduce costs and consider FOB (Free on Board) or CIF (Cost, Insurance, and Freight) terms to clarify responsibilities. Verify supplier’s packaging standards to prevent damage during transit. Maintain clear communication on customs documentation, tariffs, and import regulations specific to your country. Tracking shipments and establishing contingency plans for delays or customs issues are essential for timely market entry. -

What strategies should I adopt to resolve disputes related to product quality, delivery, or payment with international suppliers?

Establish clear contractual terms covering product specifications, quality standards, delivery schedules, and payment conditions. Use detailed purchase agreements and include dispute resolution clauses, preferably specifying arbitration in neutral jurisdictions. Maintain thorough documentation of communications, inspections, and shipping records. In case of issues, negotiate directly with the supplier first, referencing contractual obligations. If unresolved, escalate through arbitration or local trade chambers. Building strong relationships and maintaining open, transparent communication can prevent misunderstandings. Consider engaging legal counsel familiar with international trade laws to guide dispute resolution effectively. -

What are the key factors to consider when selecting suppliers from regions like Turkey, Colombia, or Middle Eastern countries?

Regional factors include manufacturing expertise, regional trade agreements, tariffs, and logistical infrastructure. Turkey, for example, offers proximity to Europe with strong manufacturing capabilities and favorable trade agreements. Colombia provides access to South American markets with competitive costs. Middle Eastern countries often serve as strategic hubs with advanced logistics networks. Evaluate supplier experience with international exports, compliance with regional standards, and their ability to meet your quality and volume requirements. Local business practices, language barriers, and cultural differences also impact communication and negotiations. Visiting suppliers or engaging regional agents can provide valuable insights into their operations and reliability. -

How do I ensure compliance with regional regulations and standards when importing rocker bottom shoes into my country?

Research your country’s import regulations, safety standards, and labeling requirements specific to footwear. Ensure suppliers provide necessary certifications, such as CE, ASTM, or regional standards compliance documents. Collaborate with customs brokers or import consultants to navigate tariffs, duties, and documentation processes efficiently. Keep updated on changes in regulations, especially concerning product safety, environmental impact, and labeling. Implement quality control checks aligned with regional standards before shipment. Establish a compliance checklist and conduct regular audits of supplier documentation to avoid delays or penalties at customs, ensuring smooth market entry and consumer safety.

This FAQ section provides strategic, actionable insights tailored to international B2B buyers, equipping them with the knowledge needed to navigate sourcing, quality assurance, logistics, and dispute resolution effectively in the global rocker bottom shoe market.

Strategic Sourcing Conclusion and Outlook for rocker bottom shoes

Strategic Sourcing Outlook and Key Takeaways

Effective sourcing of rocker bottom shoes requires a strategic approach that balances quality, cost-efficiency, and supply chain resilience. For international buyers in regions such as Africa, South America, the Middle East, and Europe, establishing strong partnerships with reliable manufacturers—whether in Turkey, China, or local suppliers—can significantly enhance competitiveness. Emphasizing due diligence, quality assurance, and flexible logistics options will mitigate risks and ensure consistent product delivery.

As demand for ergonomic and health-conscious footwear continues to grow, forward-looking buyers should prioritize innovation and supplier collaboration to stay ahead of market trends. Diversifying sourcing channels and leveraging regional manufacturing advantages can also reduce dependency on single sources, adding resilience to your supply chain.

Looking ahead, the global marketplace offers ample opportunities for strategic partnerships that foster sustainable growth. By adopting a proactive sourcing strategy, B2B buyers can secure high-quality rocker bottom shoes that meet evolving consumer needs while optimizing costs. Now is the time to deepen supplier relationships, explore emerging markets, and invest in supply chain agility to capitalize on the expanding demand for ergonomic footwear worldwide.