Your Ultimate Guide to Sourcing Saddle Shoes

Guide to Saddle Shoes

- Introduction: Navigating the Global Market for saddle shoes

- Understanding saddle shoes Types and Variations

- Key Industrial Applications of saddle shoes

- Strategic Material Selection Guide for saddle shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for saddle shoes

- Comprehensive Cost and Pricing Analysis for saddle shoes Sourcing

- Spotlight on Potential saddle shoes Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for saddle shoes

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the saddle shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of saddle shoes

- Strategic Sourcing Conclusion and Outlook for saddle shoes

Introduction: Navigating the Global Market for saddle shoes

In the highly competitive landscape of global footwear, saddle shoes occupy a distinctive niche valued for their classic aesthetic and versatile appeal. For international B2B buyers—particularly those from Africa, South America, the Middle East, and Europe—understanding the intricacies of sourcing saddle shoes is crucial to optimizing supply chains, controlling costs, and meeting market demands. This guide provides an authoritative overview of the saddle shoe market, equipping buyers with actionable insights to navigate sourcing, manufacturing, and quality assurance effectively.

Spanning the full spectrum—from traditional and contemporary styles to innovative materials—this resource delves into key aspects such as material selection, manufacturing processes, quality control standards, and supplier landscapes. It also examines cost dynamics, market trends, and regulatory considerations, empowering buyers to make informed decisions aligned with their strategic goals. Whether sourcing from established manufacturing hubs like Vietnam and Italy or exploring emerging supplier regions, this guide ensures you are equipped to identify reliable partners and mitigate risks.

By consolidating industry intelligence, best practices, and frequently asked questions, this comprehensive resource aims to streamline your sourcing process. It supports your efforts to secure high-quality saddle shoes that meet both market expectations and compliance standards, ultimately driving competitive advantage in your target markets. With this knowledge, international buyers can confidently navigate the complexities of the global saddle shoe market and forge resilient, cost-effective supply chains.

Understanding saddle shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Leather Saddle | Traditional leather upper with a distinct saddle-shaped band across the midfoot, often in contrasting colors | Fashion retailers, uniform suppliers, formal footwear | Pros: Timeless appeal, high-quality leather, versatile; Cons: Higher cost, longer lead times for customization |

| Canvas Saddle Shoes | Made with durable canvas uppers, often with rubber soles, featuring a saddle band | Casual footwear brands, school uniforms, promotional items | Pros: Cost-effective, lightweight, easy to produce in bulk; Cons: Less durable, limited formality |

| Patent Finish Saddle | Leather or synthetic upper with glossy patent finish, maintaining the saddle design | Formal events, fashion-forward collections, premium branding | Pros: High-gloss aesthetic, premium look; Cons: More delicate, higher maintenance, limited color options |

| Two-Tone Color Block | Contrasting color schemes between the saddle band and the rest of the shoe, often in bold hues | Youth fashion, branded retail collections, promotional campaigns | Pros: Eye-catching, customizable; Cons: May not suit conservative markets, higher complexity in manufacturing |

| Minimalist Modern Saddle | Simplified design with subtle saddle band, often in sleek materials like suede or nubuck | Trend-focused boutiques, designer collaborations, luxury segments | Pros: Elegant, contemporary appeal; Cons: Niche market, requires premium materials and craftsmanship |

Characteristics and Suitability

Classic Leather Saddle Shoes remain the most recognized and widely produced variation, characterized by high-quality leather uppers and a distinct saddle-shaped band across the midfoot. They are suitable for formal and semi-formal markets, including school uniforms and professional attire. For B2B buyers, sourcing from established manufacturers with reliable quality control ensures consistency, especially when bulk purchasing for uniform or retail distribution. Lead times and MOQ (Minimum Order Quantities) should be considered, as premium leather shoes often involve longer production cycles.

Canvas Saddle Shoes are valued for their affordability and lightweight nature. They are ideal for casual and promotional markets, especially in regions where budget constraints are significant. B2B buyers should focus on sourcing from factories experienced in mass production of canvas footwear to ensure durability and colorfastness. These shoes are suitable for large-scale distribution in markets like youth segments or promotional campaigns but may require careful quality checks to meet durability expectations.

Patent Finish Saddle Shoes appeal to premium segments and fashion-forward brands, offering a glossy, high-shine surface that elevates the classic design. They are best suited for special occasions, fashion collections, or luxury retail. Buyers need to evaluate the sourcing options for high-quality patent leather or synthetic equivalents, considering the delicate nature of patent finishes which may impact shipping and handling. Limited color options and higher costs are typical considerations.

Two-Tone Color Block variations provide bold, customizable options, often used in youth or branded collections to attract attention. They involve complex dyeing and assembly processes, which can increase manufacturing costs and lead times. B2B buyers should work closely with manufacturers capable of precise color matching and multi-step production. These shoes are ideal for promotional campaigns, fashion collaborations, or markets seeking vibrant, statement footwear.

Minimalist Modern Saddle Shoes feature subtle design elements, often crafted from premium suede or nubuck, emphasizing sleekness and contemporary aesthetics. They are suitable for high-end boutiques, designer collaborations, or luxury markets. Sourcing from specialized artisans or premium material suppliers is critical. These shoes appeal to niche markets that value craftsmanship and understated elegance but require higher investment and careful quality assurance.

By understanding these variations, B2B buyers can better align their sourcing strategies with market demands, price points, and quality standards. Selecting the right type involves balancing material costs, manufacturing complexity, and end-user preferences, especially when catering to diverse regional markets across Africa, South America, the Middle East, and Europe.

Related Video: ASICS Running shoes lineup Scheme and Explanation 2024

Key Industrial Applications of saddle shoes

| Industry/Sector | Specific Application of saddle shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Footwear Retailers | Custom-designed saddle shoes for premium collections | Differentiation through unique product offerings, enhanced brand prestige | Material quality, craftsmanship, compliance with safety and environmental standards |

| Hospitality & Entertainment | Themed saddle shoes for costumes and stage performances | Visual impact, durability, and comfort for performers or staff | Colorfastness, comfort, and adherence to safety regulations |

| Corporate Uniforms | Saddle shoes as part of formal or casual workwear | Uniform consistency, durability, and professional appearance | Consistency in sizing, quality assurance, and bulk procurement logistics |

| Educational & Sports Institutions | Athletic or casual saddle shoes for students and athletes | Promotes school branding, comfort, and activity-specific performance | Compliance with safety standards, durability, and cost-effectiveness |

| Military & Law Enforcement | Tactical saddle shoes for training and operational use | Enhanced mobility, durability, and safety in demanding environments | Heavy-duty construction, slip resistance, and compliance with military standards |

Fashion & Footwear Retailers

Saddle shoes are highly valued in the fashion industry for their classic aesthetic and versatility. B2B buyers in this sector source these shoes for premium collections, often customizing colors, materials, and embellishments to appeal to niche markets. For international buyers from regions like Europe and South America, sourcing high-quality saddle shoes can elevate brand differentiation and attract discerning consumers. Ensuring material authenticity, craftsmanship, and compliance with safety standards is crucial to meet global retail expectations and avoid supply chain disruptions.

Hospitality & Entertainment

In the hospitality and entertainment sectors, saddle shoes are frequently used as costumes or stage footwear. They provide a visually appealing, vintage look that enhances thematic performances or uniforms. Durable, comfortable, and visually consistent shoes are essential for performers or staff working long hours. Buyers from the Middle East or Europe should prioritize sourcing saddle shoes with colorfast dyes, slip-resistant soles, and high-quality materials to withstand rigorous use while maintaining aesthetic standards, ensuring a seamless experience for both staff and guests.

Corporate Uniforms

Many companies adopt saddle shoes as part of their formal or casual uniform schemes, especially in sectors like hospitality, retail, or corporate events. These shoes contribute to a professional appearance while offering durability and comfort for daily wear. International B2B buyers from Africa or Asia should focus on sourcing suppliers capable of providing bulk orders with consistent sizing, high-quality finishes, and reliable lead times. Adherence to environmental and safety standards also adds value, reducing liability and ensuring compliance across diverse markets.

Educational & Sports Institutions

Saddle shoes are popular among schools and sports teams for their classic look and functional comfort. They support branding efforts and provide a uniform appearance for students and athletes. Sourcing these shoes for international markets requires attention to durability, slip resistance, and cost efficiency. Buyers from regions like Vietnam or Italy should verify suppliers’ compliance with safety standards, especially for active use, and consider options for custom branding or color schemes to strengthen institutional identity.

Military & Law Enforcement

In demanding environments, saddle shoes are adapted for tactical use, offering a combination of mobility, durability, and safety. They are used in training, ceremonial duties, or operational scenarios where footwear reliability is critical. International buyers from Africa or the Middle East should prioritize sourcing from manufacturers with proven heavy-duty construction, slip resistance, and adherence to military or safety standards. Long-term partnerships with compliant suppliers ensure consistent quality, essential for operational effectiveness and safety.

Related Video: 10 Nifty Uses for Oscillating Multitool Saws

Strategic Material Selection Guide for saddle shoes

Analysis of Common Materials for Saddle Shoes

When selecting materials for saddle shoes, B2B buyers must consider a combination of performance characteristics, manufacturing complexity, cost, and compliance with international standards. Here, we analyze four prevalent materials: Leather, Synthetic Leather, Rubber, and Textile Composites.

Leather

Leather remains the traditional and most preferred material for saddle shoes, especially in high-end markets such as Italy and Europe. It offers excellent durability, breathability, and a premium aesthetic. Leather’s key properties include high tensile strength, moderate flexibility, and resistance to wear and tear, making it ideal for the shoe’s upper saddle panel and overlays. It also provides good resistance to temperature fluctuations, although it can be sensitive to moisture if not properly treated.

Pros & Cons:

– Pros: Durable, breathable, aesthetically premium, biodegradable (if natural).

– Cons: Higher cost, complex manufacturing process (tanning), variable quality depending on source, and environmental concerns related to tanning chemicals.

Impact on Application:

Leather performs well across various media but requires appropriate finishing to enhance water resistance and durability. It is compatible with standard shoe manufacturing processes and meets many international standards like ASTM and DIN, especially when sourced from reputable tanneries adhering to environmental and social compliance.

International Considerations:

For African, South American, Middle Eastern, and European buyers, sourcing leather from suppliers compliant with environmental standards (e.g., REACH, ISO 14001) is crucial. Leather must meet safety and chemical use regulations, especially in the EU. Leather grading and quality certifications influence acceptance in premium markets.

Synthetic Leather

Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), is a popular alternative due to lower costs and simplified manufacturing. It can mimic the appearance of natural leather with a consistent finish and color. Its properties include good flexibility, water resistance, and ease of cleaning.

Pros & Cons:

– Pros: Cost-effective, consistent quality, easier to produce at scale, environmentally friendly options available.

– Cons: Lower breathability, less durable over time, can crack or peel, and environmental concerns related to plastic waste.

Impact on Application:

Synthetic leather is suitable for budget-conscious markets and quick production cycles. It performs well in humid or wet environments if properly coated but may not age as gracefully as genuine leather. It aligns with standards like ASTM D2979 for flexible PVC and PU materials.

International Considerations:

Buyers should verify the chemical safety of synthetic leather, especially regarding phthalates and VOC emissions, to meet European REACH standards and local regulations in Africa and South America. Certifications such as OEKO-TEX can enhance market acceptance.

Rubber

Rubber is primarily used for the sole and sometimes for decorative overlays or reinforcement in saddle shoes. Its key properties include excellent flexibility, impact absorption, water resistance, and temperature stability.

Illustrative Image (Source: Google Search)

Pros & Cons:

– Pros: High durability, excellent grip, waterproof, cost-effective for soles.

– Cons: Limited aesthetic appeal for upper parts, potential environmental concerns with vulcanization chemicals, and possible degradation under UV exposure.

Impact on Application:

Rubber is ideal for outsole construction, especially in markets where durability and slip resistance are prioritized. It complies with standards like ASTM D2000 for rubber materials and can be formulated to meet specific environmental and safety standards.

International Considerations:

Buyers should ensure rubber suppliers adhere to environmental regulations, especially regarding vulcanization agents and chemical emissions. Compatibility with eco-labels (e.g., ISO 14001) is advantageous for markets with strict environmental policies.

Textile Composites

Textile composites, including woven fabrics, mesh, or knit materials reinforced with synthetic fibers, are increasingly used for lightweight, breathable saddle overlays or linings. They offer flexibility and moisture management.

Pros & Cons:

– Pros: Lightweight, breathable, customizable, cost-effective.

– Cons: Less durable, susceptible to fraying, and may require additional coatings for water resistance.

Impact on Application:

Suitable for casual or fashion-oriented saddle shoes, especially in warmer climates or fashion markets. Meets standards like JIS for textiles and can be treated to meet water and stain resistance requirements.

International Considerations:

Textile suppliers should provide certifications for chemical safety (OEKO-TEX Standard 100) and environmental compliance, especially for markets with strict textile regulations like the EU and Japan. Compatibility with eco-labels and sustainability certifications enhances marketability.

Summary Table

| Material | Typical Use Case for saddle shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather | Upper saddle panel, overlays | Durable, breathable, premium appearance | High cost, complex tanning process, environmental concerns | High |

| Synthetic Leather | Budget upper overlays, linings | Cost-effective, consistent quality, easy to produce | Less breathable, lower durability, environmental issues | Medium |

| Rubber | Outsoles, reinforcements | Impact absorption, waterproof, durable | Limited aesthetic for upper, chemical concerns | Low |

| Textile Composites | Decorative overlays, linings | Lightweight, breathable, customizable | Less durable, prone to fraying | Low to Medium |

This detailed analysis provides B2B buyers with a comprehensive understanding of material options, enabling informed decisions aligned with market demands, compliance standards, and cost considerations across diverse international markets.

In-depth Look: Manufacturing Processes and Quality Assurance for saddle shoes

Manufacturing Processes for Saddle Shoes

The production of saddle shoes involves a series of carefully orchestrated stages, each critical to ensuring product quality, durability, and aesthetic appeal. For international B2B buyers, understanding these stages helps in evaluating supplier capabilities and ensuring compliance with quality standards.

Material Preparation

The process begins with sourcing and preparing raw materials, primarily leather or synthetic uppers, rubber or polyurethane soles, and various linings and insoles. High-quality leather, often full-grain or corrected grain, is preferred for durability and appearance. Suppliers typically pre-treat materials through cleaning, cutting, and sometimes coating, to ensure consistency and ease of assembly.

Forming and Cutting

The upper components are cut from prepared leather or synthetic sheets using automated cutting machines or traditional manual methods, depending on the factory’s sophistication. Precision is vital here to ensure uniformity, reduce waste, and facilitate proper fitting during assembly. For saddle shoes, the distinctive saddle-shaped band is cut separately and stitched onto the vamp.

Assembly and Stitching

The assembled upper comprises several parts—vamp, quarters, saddle, and lining—stitched together using industrial sewing machines. Techniques such as lockstitch or double-needle stitching ensure seam strength and aesthetic quality. Adhesives may also be employed for additional bonding, especially in areas requiring flexibility.

Lasting and Sole Attachment

The upper is then shaped over a last—a mold that mimics foot contours—through a process called lasting, which can be manual or machine-assisted. Once shaped, the sole unit, made of rubber or polyurethane, is attached via cementing, vulcanization, or direct injection molding. For saddle shoes, the sole must be firmly affixed to withstand daily wear while maintaining comfort.

Finishing

The final stages include trimming excess material, polishing, dyeing, and applying protective coatings. Details such as laces, eyelets, and decorative elements are added. For high-end suppliers, finishing involves meticulous handwork to ensure a premium appearance, especially for export markets emphasizing quality.

Quality Assurance (QA) and Industry Standards

Robust quality assurance is essential for saddle shoes, especially when exporting to markets with strict compliance requirements. International standards like ISO 9001 form the foundation for quality management systems, ensuring consistency across production cycles. Industry-specific certifications such as CE (for European markets) or API (for certain manufacturing standards) may also be relevant.

Key QC Checkpoints

- Incoming Quality Control (IQC): Raw materials are inspected upon receipt for defects, proper dimensions, and compliance with specifications. Leather is tested for stretch, colorfastness, and grain quality, while soles are checked for thickness and flexibility.

- In-Process Quality Control (IPQC): During manufacturing, checkpoints are established at critical stages—cutting, stitching, lasting, and sole attachment. Visual inspections, dimensional checks, and stitching strength tests are performed regularly.

- Final Quality Control (FQC): The finished saddle shoes undergo comprehensive testing, including visual inspection for defects, measurement verification, and functional tests such as flexing and wear testing.

Testing Methods

- Visual Inspection: Checks for surface blemishes, stitching quality, and overall appearance.

- Dimensional Testing: Ensures size accuracy and consistency across batches.

- Flex and Durability Tests: Simulate wear to assess sole adhesion and upper flexibility.

- Colorfastness Tests: Verify that dyes do not bleed or fade during use.

- Environmental Tests: Assess resistance to moisture, temperature variations, and UV exposure, especially vital for markets with diverse climates.

Verifying Supplier Quality for International Buyers

For B2B buyers from Africa, South America, the Middle East, and Europe, verifying supplier quality involves multiple layers:

- Factory Audits: Conduct comprehensive audits focusing on production capacity, cleanliness, worker conditions, and adherence to quality protocols. Third-party inspection firms with ISO 17020 accreditation are often employed.

- Inspection Reports: Review detailed inspection reports and test certificates for raw materials, semi-finished, and finished products. These documents should align with agreed specifications and standards.

- Third-Party Testing: Engage independent laboratories to perform batch testing, especially for critical aspects like sole adhesion, colorfastness, and environmental resistance.

- Certifications and Compliance: Confirm that the supplier holds relevant certifications such as ISO 9001, CE, or industry-specific standards, and adheres to social compliance codes like SA8000 or BSCI.

- Sample Approval: Request pre-production samples for evaluation before mass production, ensuring the finished product meets aesthetic and functional expectations.

Market-Specific Considerations

- Africa & South America: Suppliers should demonstrate compliance with local import regulations and have experience exporting to these regions. Given possible logistical challenges, verify the supplier’s ability to meet deadlines and handle customs documentation efficiently.

- Middle East: Suppliers must meet environmental and safety standards pertinent to the region, such as REACH compliance for chemicals used in manufacturing.

- Europe (e.g., Italy): Emphasis on high-quality craftsmanship and compliance with stringent environmental and social standards. Certifications like OEKO-TEX for textiles or sustainable sourcing attest to product integrity.

Strategic Recommendations for B2B Buyers

- Develop Clear Quality Specifications: Define precise material, dimensional, and performance criteria aligned with target markets.

- Implement Routine Audits and Inspections: Regular factory visits and third-party audits help ensure ongoing compliance and quality consistency.

- Leverage Certification and Testing: Prioritize suppliers with recognized certifications and verified test reports to mitigate risks.

- Build Long-Term Partnerships: Collaborate with suppliers committed to continuous improvement and transparency, fostering quality stability over time.

- Stay Informed of Regulatory Changes: Keep abreast of evolving standards such as the UFLPA, REACH, and regional import tariffs, and ensure suppliers are compliant.

By understanding and actively managing manufacturing and quality assurance processes, international B2B buyers can confidently source saddle shoes that meet global standards, satisfy market-specific requirements, and foster sustainable, long-term supply relationships.

Related Video: Amazing Shoe Making Process | Footwear Manufacturing Factory | Mass Production | Unbox Engineering

Comprehensive Cost and Pricing Analysis for saddle shoes Sourcing

Cost Components in Saddle Shoe Sourcing

Understanding the comprehensive cost structure is vital for effective pricing and negotiation. Materials typically account for 30-50% of the unit price, with leather or synthetic uppers, rubber or crepe soles, and linings being primary cost drivers. High-quality leather or specialty textiles will naturally elevate costs, especially if sourced from premium suppliers or regions with higher raw material prices, such as Italy or certain South American countries.

Labor costs vary significantly based on the sourcing country. Asian manufacturers, particularly in Vietnam, often offer lower wages, contributing to more competitive prices, whereas European suppliers may have higher labor costs due to stricter labor standards and living wages. Manufacturing overheads—including factory utilities, equipment depreciation, and quality control—generally comprise 10-20% of the total cost and are influenced by factory size, technology, and compliance standards.

Tooling and development costs are usually upfront investments required for molds, lasts, and prototypes, especially if customization or specific design features are involved. These costs are amortized over production volume, making higher MOQ (Minimum Order Quantity) advantageous for reducing per-unit tooling expenses.

Quality control (QC) costs can range from 3-7% of total manufacturing costs, especially when sourcing from regions with strict social compliance standards, such as Italy or certified factories in Vietnam. Ensuring consistent quality reduces rework and returns, impacting overall profitability.

Logistics and tariffs encompass shipping, customs duties, insurance, and inland transport. For African and South American buyers, freight costs can be higher due to less developed logistics infrastructure, while European buyers often benefit from proximity to manufacturing hubs or established trade routes. Incoterms like FOB (Free On Board) or CIF (Cost, Insurance, Freight) significantly influence landed costs and cash flow planning.

Finally, margin varies based on market positioning and volume. Typically, a markup of 20-40% over total landed costs is standard in B2B saddle shoe transactions, but this can be adjusted for premium branding or bulk purchasing power.

Price Influencers and Key Factors

Several factors influence the final pricing of saddle shoes in international trade. Order volume and MOQ are critical—larger quantities usually enable better unit prices due to economies of scale. Customization and specifications, such as unique leathers, branding, or specific sole materials, increase costs and lead times, affecting pricing strategies.

Material choices directly impact costs—premium leathers from Italy or South America are more expensive but appeal to high-end markets, while synthetic options may reduce costs for mass-market segments. Quality certifications (e.g., ISO, environmental standards, social compliance) often come with additional costs but are essential for accessing certain markets, especially in Europe and the Middle East.

Supplier factors, including factory reputation, compliance standards, and production capacity, influence pricing and lead times. Buyers should prioritize suppliers with transparent sourcing practices and strong social compliance records to mitigate risks and ensure consistent quality.

Incoterms dictate who bears transportation and customs costs, affecting the landed price. FOB terms give buyers control over logistics, potentially reducing overall costs, while CIF may simplify processes but often at a premium.

Buyer Tips for Cost-Effective Sourcing

Negotiating effectively requires a clear understanding of the total landed cost, not just the unit price. Focus on total cost of ownership—consider shipping, duties, inspection, and potential rework costs—when comparing quotes. Building long-term relationships with suppliers can yield better prices, priority production slots, and favorable payment terms.

Leverage volume discounts by consolidating orders or establishing minimum commitments. For buyers from Africa, South America, or the Middle East, exploring regional manufacturing hubs like Vietnam or Turkey can offer cost advantages and shorter lead times. European buyers should emphasize quality certifications and sustainable sourcing to justify premium prices.

Be aware of pricing nuances, such as hidden costs in tooling or charges for expedited delivery. Always request detailed quotations breaking down each component, and consider including clauses for price adjustments tied to raw material fluctuations or exchange rate changes.

In conclusion, while indicative saddle shoe prices can range from $10 to $30 per pair depending on quality, volume, and customization, these figures are approximate. A strategic approach combining cost analysis, supplier due diligence, and negotiation acumen will optimize value and profitability in international sourcing endeavors.

Spotlight on Potential saddle shoes Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘saddle shoes’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for saddle shoes

Critical Technical Properties for Saddle Shoes

Material Grade and Composition

The quality of materials used—such as leather, synthetic uppers, and sole compounds—directly impacts durability, comfort, and aesthetic appeal. For saddle shoes, high-grade full-grain leather is often preferred for its longevity and premium look. Industry standards specify material grades (e.g., leather thickness in ounces, synthetic fiber density) to ensure consistency across batches. Buyers should specify acceptable material grades to prevent variability that could affect product performance and compliance.

Dimensional Tolerance and Fit

Precise measurements, including length, width, and heel height, are crucial for ensuring the shoe fits the target market. Tolerance levels (e.g., ±1 mm) specify acceptable deviations during manufacturing, reducing the risk of returns or customer dissatisfaction. For B2B transactions, clear tolerance standards streamline quality control and facilitate large-volume orders without discrepancies.

Sole Composition and Traction Properties

The sole material—such as rubber, thermoplastic, or EVA foam—must meet specific criteria for wear resistance, flexibility, and slip resistance. Industry specifications often include Shore hardness ratings, which influence outsole durability and grip. Proper sole properties are essential for footwear safety, especially in diverse markets where environmental conditions vary.

Colorfastness and Finish Quality

For consistent branding and aesthetic appeal, saddle shoes should adhere to colorfastness standards, resisting fading or bleeding during wear and cleaning. Finish quality, including stitching and surface smoothness, is also critical. These properties influence the product’s marketability and compliance with industry standards like ISO or ASTM.

Environmental and Compliance Standards

Materials should meet environmental regulations such as REACH or CPSIA, especially for markets with strict import standards. For B2B sourcing, verifying supplier certifications ensures the shoes conform to social and environmental standards, minimizing risks related to non-compliance penalties or supply chain disruptions.

Common Industry and Trade Terms

OEM (Original Equipment Manufacturer)

Refers to a manufacturer that produces saddle shoes based on a client’s design and specifications. Understanding OEM relationships helps buyers assess product customization levels, quality assurance processes, and intellectual property considerations.

MOQ (Minimum Order Quantity)

The smallest batch size a supplier is willing to produce. For B2B buyers, negotiating MOQ is vital for balancing inventory costs and production efficiency, especially when entering new markets or testing product acceptance.

RFQ (Request for Quotation)

A formal request sent to suppliers asking for pricing, lead times, and terms for specific saddle shoe models. RFQs enable buyers to compare options, negotiate better terms, and plan procurement strategies effectively.

Incoterms (International Commercial Terms)

Standardized trade terms published by the International Chamber of Commerce that define responsibilities for shipping, insurance, and customs duties. Familiarity with Incoterms (e.g., FOB, CIF) ensures clarity in cost allocation and delivery obligations across borders.

Sample Approval Process

Refers to the stage where buyers review and approve prototype shoes before mass production. This process is critical for verifying technical properties, fit, and finish, reducing the risk of costly rework or recalls later.

Lead Time

The duration from order placement to shipment. Knowing lead times assists buyers in planning inventory levels, aligning production schedules, and managing market demand effectively.

In summary, understanding these technical properties and trade terms enhances communication clarity, reduces risks, and streamlines procurement processes in the saddle shoe supply chain. Clear specifications and familiarity with industry jargon empower international B2B buyers from diverse regions to negotiate confidently and ensure product quality aligns with market expectations.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the saddle shoes Sector

Market Overview & Key Trends

The global saddle shoes market is experiencing a nuanced transformation driven by evolving consumer preferences, technological advancements, and supply chain shifts. Traditionally regarded as a classic footwear style, saddle shoes are now seeing renewed interest driven by niche fashion markets, retro trends, and a growing demand for versatile, durable footwear. For international B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including Vietnam and Italy—understanding these dynamics is crucial for strategic sourcing.

Emerging trends include the integration of sustainable materials and innovative manufacturing processes. Digital sourcing platforms, enhanced by AI and data analytics, are streamlining supplier evaluations, enabling buyers to identify manufacturers with compliance certifications and capacity for customization. The rise of nearshoring and regional manufacturing hubs—particularly in Southeast Asia and Eastern Europe—offers opportunities to reduce lead times and mitigate geopolitical risks. For Africa and South America, local production is gaining traction as governments incentivize footwear manufacturing through trade agreements and investment in infrastructure.

Market dynamics are also influenced by fluctuating raw material costs, notably leather and synthetics, and by the increasing importance of social compliance. Buyers are prioritizing suppliers who demonstrate transparency, adherence to labor standards, and environmental responsibility. For B2B buyers, leveraging real-time import data, such as those provided by FDRA, offers critical insights into global sourcing patterns, helping optimize procurement strategies amid volatile tariffs and trade policies.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a pivotal factor in the saddle shoes supply chain, impacting sourcing decisions across all regions. Environmental concerns are particularly relevant given the leather and synthetic materials used in saddle shoes. Buyers are increasingly demanding suppliers who utilize eco-friendly tanning processes, biodegradable materials, and low-impact dyes, which reduce water and chemical consumption.

Ethical sourcing is equally vital, especially in regions with complex labor landscapes. Ensuring fair wages, safe working conditions, and compliance with international standards like the Fair Labor Association (FLA) or SA8000 is critical for maintaining brand integrity and avoiding reputational risks. Certifications such as Global Organic Textile Standard (GOTS) for natural fibers or Leather Working Group (LWG) for leather sustainability are becoming benchmarks for credible suppliers.

Illustrative Image (Source: Google Search)

In addition, transparency across the supply chain is essential. Digital traceability solutions—blockchain-based or otherwise—are enabling B2B buyers to verify material origins and factory practices. For regions like Vietnam and Italy, integrating sustainability into sourcing criteria not only aligns with global trends but also opens access to premium markets and environmentally conscious consumers. Investing in sustainable materials and fostering partnerships with certified suppliers can lead to long-term cost savings, brand differentiation, and compliance with tightening regulations.

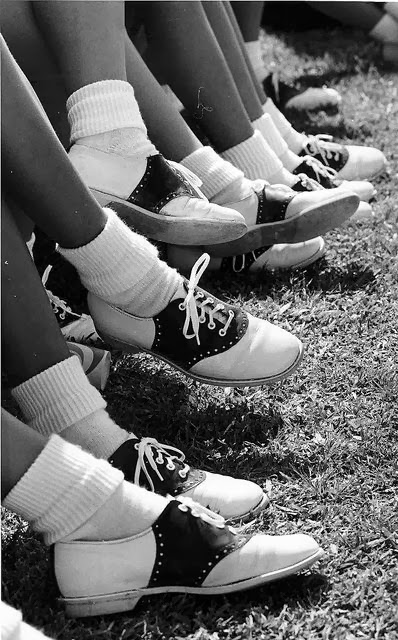

Brief Evolution/History

The saddle shoe’s origins date back to the early 20th century, initially popularized as a casual and athletic footwear choice in the United States. Its distinctive design—typically featuring a contrasting saddle-shaped band across the midfoot—made it a versatile and enduring style. Over decades, saddle shoes transitioned from everyday casual wear to a fashion statement, especially in preppy and retro-inspired trends.

For B2B stakeholders, understanding this evolution highlights the importance of maintaining quality and authenticity in sourcing. The enduring appeal of saddle shoes, coupled with modern design reinterpretations, offers opportunities for brands to blend heritage with innovation. Sourcing partners that appreciate this history can better align production with authentic styling cues, ensuring the product resonates with both traditional markets and contemporary consumers. As sustainability and ethical standards become integral, manufacturers with a historical commitment to craftsmanship and modern compliance practices will be better positioned to capitalize on the market’s evolving demands.

Related Video: International Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of saddle shoes

-

How can I effectively vet saddle shoe suppliers to ensure quality and compliance?

To vet suppliers, start with comprehensive due diligence including factory audits, certifications (e.g., ISO, social compliance standards), and references from other clients. Request samples to assess craftsmanship, materials, and finishing. Utilize third-party verification services or industry-specific compliance platforms to confirm factory conditions and social responsibility practices. Review their production capacity, lead times, and adherence to international labor laws. Establish clear communication channels and ask for detailed documentation on sourcing processes, quality control measures, and previous export experience to ensure reliability and compliance with your market standards. -

What customization options are typically available for saddle shoes, and how do they impact MOQ and lead times?

Customization can include design details such as colorways, stitching patterns, sole types, branding (logos or labels), and material blends. Most suppliers offer tiered customization—standard options with quick turnaround, and bespoke designs requiring larger minimum order quantities (MOQs). Custom projects usually extend lead times by 4-8 weeks due to design approval, sample development, and production adjustments. To optimize timelines, specify your requirements early, collaborate closely with suppliers during design phases, and negotiate flexible MOQs for smaller or pilot orders, especially when entering new markets or testing demand. -

What are typical MOQ, lead times, and payment terms for bulk saddle shoe orders?

MOQs for saddle shoes generally range from 500 to 2,000 pairs, depending on the supplier’s capacity and customization complexity. Lead times vary from 4 to 12 weeks, influenced by order volume, factory workload, and shipping logistics. Standard payment terms often include 30% upfront deposit with the balance payable before shipment; some suppliers may accept letters of credit or open accounts for trusted partners. Building long-term relationships can lead to more flexible terms. Always clarify these terms early and include them in your contracts to avoid delays or cash flow issues.

Illustrative Image (Source: Google Search)

-

What certifications and quality assurance measures should I verify before importing saddle shoes?

Ensure suppliers have relevant certifications such as ISO 9001 for quality management, social compliance certifications like SA8000 or WRAP, and environmental standards such as OEKO-TEX or FSC. Request detailed Quality Assurance (QA) reports, factory inspection reports, and sample approvals before mass production. Consider third-party testing for material safety, durability, and colorfastness, especially for markets with strict regulations. Establish clear quality benchmarks in your contracts, and plan for pre-shipment inspections or third-party audits to mitigate risks of defects, non-compliance, or delays. -

How should I coordinate logistics and customs clearance for international saddle shoe shipments?

Partner with experienced freight forwarders familiar with footwear exports from manufacturing hubs. Decide on Incoterms (e.g., FOB, CIF) that align with your risk management and cost control strategies. Provide suppliers with accurate shipping details and ensure proper documentation, including commercial invoices, packing lists, certificates of origin, and any required import licenses. Stay informed about tariffs, import duties, and trade regulations in your destination country—such as VAT or anti-dumping duties—to avoid surprises. Regularly track shipments and maintain open communication with logistics providers to ensure timely delivery and compliance. -

What common disputes arise in saddle shoe sourcing, and how can they be effectively resolved?

Disputes often involve quality inconsistencies, delayed shipments, or payment disagreements. To mitigate these, have detailed contracts covering specifications, inspection rights, penalties for delays, and dispute resolution clauses (preferably arbitration). Maintain transparent communication and keep thorough documentation of all correspondences, approvals, and inspections. If disputes occur, engage in amicable negotiations first; if unresolved, escalate through arbitration or legal channels in a neutral jurisdiction. Building trust through consistent quality and clear contractual terms reduces the likelihood of conflicts and facilitates smoother resolutions. -

What are best practices for ensuring social and environmental compliance in saddle shoe manufacturing?

Select suppliers committed to social responsibility by reviewing their certifications and conducting regular factory audits. Incorporate social compliance clauses into contracts, emphasizing fair wages, safe working conditions, and prohibition of child labor. Encourage transparency by requesting supply chain traceability reports. Engage third-party auditors for unannounced inspections and verify adherence to environmental standards, such as waste management and sustainable sourcing of materials. Establish ongoing communication and training programs to promote continuous improvement, aligning supplier practices with your company’s sustainability policies and international best practices. -

How can I navigate trade regulations and tariffs impacting saddle shoe imports from different regions?

Stay updated on trade agreements, tariffs, and import restrictions relevant to your sourcing regions by consulting trade advisory platforms or customs authorities. For example, sourcing from Vietnam or Italy may involve different tariff classifications and compliance requirements. Use HS codes accurately to determine applicable duties and explore free trade agreements or preferential tariffs to reduce costs. Engage customs brokers experienced in footwear imports to streamline clearance processes. Planning your sourcing strategy around current trade policies minimizes delays, reduces costs, and ensures compliance, especially amid fluctuating tariffs or trade tensions.

Strategic Sourcing Conclusion and Outlook for saddle shoes

Strategic Sourcing Conclusion and Outlook for saddle shoes

Effective strategic sourcing remains a cornerstone for international B2B buyers seeking to optimize quality, cost-efficiency, and compliance in the saddle shoe market. By forging strong supplier relationships, leveraging global sourcing hubs, and prioritizing social and environmental standards, buyers can mitigate risks associated with supply chain disruptions and regulatory changes. Emphasizing transparency and adherence to industry codes of conduct not only ensures sustainable operations but also enhances brand reputation in competitive markets.

Looking ahead, the evolving landscape—marked by geopolitical shifts, tariff adjustments, and rising consumer expectations—demands agile sourcing strategies. Buyers from Africa, South America, the Middle East, and Europe should capitalize on emerging sourcing regions, invest in supplier development, and utilize data-driven insights to stay ahead of industry trends. Collaborating with experienced partners and participating in industry forums will be vital for navigating complexities and unlocking new growth opportunities.

Ultimately, strategic sourcing is not merely a cost-saving measure but a strategic differentiator. Proactively embracing innovation and sustainability will position your business to thrive in the dynamic saddle shoe marketplace of tomorrow.