Your Ultimate Guide to Sourcing Shai Gilgeous Alexander

Guide to Shai Gilgeous Alexander Shoes

- Introduction: Navigating the Global Market for shai gilgeous alexander shoes

- Understanding shai gilgeous alexander shoes Types and Variations

- Key Industrial Applications of shai gilgeous alexander shoes

- Strategic Material Selection Guide for shai gilgeous alexander shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for shai gilgeous alexander shoes

- Comprehensive Cost and Pricing Analysis for shai gilgeous alexander shoes Sourcing

- Spotlight on Potential shai gilgeous alexander shoes Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for shai gilgeous alexander shoes

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the shai gilgeous alexander shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of shai gilgeous alexander shoes

- Strategic Sourcing Conclusion and Outlook for shai gilgeous alexander shoes

Introduction: Navigating the Global Market for shai gilgeous alexander shoes

In the competitive landscape of global footwear, Shai Gilgeous-Alexander shoes have emerged as a significant trendsetter, blending performance, style, and brand appeal. For international B2B buyers—especially those based in Africa, South America, the Middle East, and Europe—understanding the nuances of sourcing these specialized products is crucial for capitalizing on market opportunities and meeting rising consumer demand. This guide provides a comprehensive overview of the entire supply chain, from product varieties and materials to manufacturing, quality control, and supplier selection, equipping buyers with the insights needed for confident decision-making.

Given the increasing popularity of athlete-endorsed footwear and premium sports-inspired designs, sourcing authentic Shai Gilgeous-Alexander shoes can enhance your product portfolio and strengthen your market position. However, navigating the complexities of global sourcing—such as verifying authenticity, managing costs, and ensuring quality—requires strategic knowledge and reliable supplier partnerships. This guide aims to empower B2B buyers with actionable insights on sourcing options, competitive pricing, and market dynamics, tailored specifically to regions like Mexico, Italy, and emerging markets across Africa, South America, and the Middle East.

By understanding these critical factors, international buyers can optimize their procurement strategies, mitigate risks, and unlock new growth avenues in the evolving landscape of athlete-inspired footwear. This resource is designed to help you make informed, strategic decisions that align with your business goals and regional market demands.

Understanding shai gilgeous alexander shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Performance Basketball Shoes | High-top or low-top design with advanced cushioning, grip, and support | Sportswear retailers, athletic teams | Pros: High demand among athletes, premium branding potential. Cons: Higher procurement costs, rapid seasonal turnover. |

| Casual Lifestyle Sneakers | Stylish, versatile design with limited technical features | Fashion retailers, casual footwear suppliers | Pros: Broader market appeal, easier inventory management. Cons: Lower margins compared to performance models. |

| Customizable/Limited Edition Shoes | Unique designs, limited runs, often with personalized options | Specialty boutiques, collector markets | Pros: High profit margins, brand prestige. Cons: Limited volume, longer lead times. |

| Signature Athlete Collection | Branded shoes associated with Shai Gilgeous Alexander, often with exclusive features | Brand licensing, premium sports retailers | Pros: Strong brand loyalty, premium pricing. Cons: Licensing complexities, inventory risks. |

| Eco-Friendly and Sustainable Shoes | Made from recycled or sustainable materials, eco-conscious branding | Green retail channels, international markets | Pros: Growing global demand, aligns with sustainability trends. Cons: Potentially higher production costs, limited supplier options. |

Performance Basketball Shoes

Performance basketball shoes are engineered for athletic excellence, featuring high-top or low-top designs integrated with advanced cushioning, ankle support, and grip-enhancing soles. These shoes are ideal for sportswear retailers and athletic teams seeking to capitalize on Shai Gilgeous Alexander’s reputation as a basketball star. B2B buyers should consider the seasonal demand cycles, as performance shoes often experience surges around major tournaments or athlete endorsements. Pricing tends to be premium, but this model offers high margins in markets with active sports communities, especially in Africa and Europe where basketball is rapidly growing.

Casual Lifestyle Sneakers

Casual sneakers inspired by Shai Gilgeous Alexander’s style combine aesthetic appeal with everyday comfort. These shoes typically feature trendy designs, versatile colorways, and limited technical features, making them suitable for fashion-focused retailers. They are easier to stock and manage due to broader consumer appeal across demographics. For B2B buyers, understanding regional fashion trends and consumer preferences is crucial, especially in markets like Mexico or Italy, where style influences purchasing decisions. These shoes tend to have lower margins but benefit from higher turnover and volume sales.

Customizable/Limited Edition Shoes

Limited edition or customizable shoes allow brands to create exclusivity and cater to niche markets or collectors. These shoes often feature unique materials, special collaborations, or personalized options, appealing to high-end boutiques and specialty stores. For B2B buyers, managing inventory and production timelines is vital, as these products typically involve longer lead times and lower volume. However, the premium pricing and brand enhancement potential can significantly boost profit margins, especially in markets with a strong collector culture, such as Europe or South America.

Signature Athlete Collection

Shai Gilgeous Alexander’s signature shoes are branded collections that leverage his athlete image, often incorporating exclusive features or designs. These collections are sold through premium sports retailers and licensed brand outlets. For international buyers, licensing agreements and brand positioning are key considerations, alongside ensuring authenticity and quality control. These shoes command higher price points and foster brand loyalty, making them a lucrative segment for B2B partners aiming to target dedicated fans and sports enthusiasts globally.

Eco-Friendly and Sustainable Shoes

With increasing global emphasis on sustainability, eco-friendly shoes made from recycled or biodegradable materials are gaining traction. These shoes appeal to environmentally conscious consumers and align with global sustainability initiatives. B2B buyers should evaluate suppliers’ certifications and material quality, as well as the scalability of production. Markets such as Europe and parts of Africa are particularly receptive to sustainable products, offering opportunities for differentiation and premium pricing. However, higher production costs and limited supplier options necessitate careful sourcing strategies.

Key Industrial Applications of shai gilgeous alexander shoes

| Industry/Sector | Specific Application of shai gilgeous alexander shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Sports & Athletic Footwear | Custom performance shoes for professional athletes and sports teams | Enhances athletic performance, brand differentiation, and athlete satisfaction | Material durability, performance technology, customization options |

| Retail & E-commerce | Premium sneaker collections for direct consumer sales | Drives brand prestige, higher profit margins, and global market appeal | Authenticity verification, supply chain transparency, regional distribution channels |

| Corporate & Promotional Events | Branded shoes for promotional campaigns and corporate gifting | Strengthens brand visibility, fosters client loyalty, and enhances corporate image | Customization flexibility, lead times, packaging, and regional branding preferences |

| Medical & Rehabilitation | Specialized shoes for injury recovery and orthopedics | Supports patient recovery, reduces injury risk, and improves comfort | Medical-grade materials, compliance with health standards, regional medical regulations |

| Manufacturing & Logistics | Shoe components or molds for manufacturing processes | Cost-effective production, quality control, and faster lead times | Compatibility with manufacturing equipment, regional sourcing options, quality standards |

Sports & Athletic Footwear

shai gilgeous alexander shoes are highly sought after in the sports industry, especially for elite athletes and teams aiming for peak performance. B2B buyers in regions like Europe, South America, and Africa often source these shoes for sponsorship deals, team kits, or custom athlete gear. The key is ensuring the shoes meet high-performance standards such as lightweight construction, superior grip, and durability under intense conditions. International buyers should prioritize sourcing from suppliers offering customization and regional distribution to reduce lead times and ensure timely delivery.

Retail & E-commerce

In the retail sector, particularly in markets like Mexico, Italy, and Middle Eastern countries, shai gilgeous alexander shoes are positioned as premium lifestyle products. These shoes appeal to consumers seeking fashionable, high-quality sneakers that symbolize modern athleticism. For B2B buyers, the focus should be on authentic sourcing, establishing reliable supply chains, and regional warehousing. This approach helps maintain brand integrity, meet local demand swiftly, and optimize profit margins through direct-to-consumer channels.

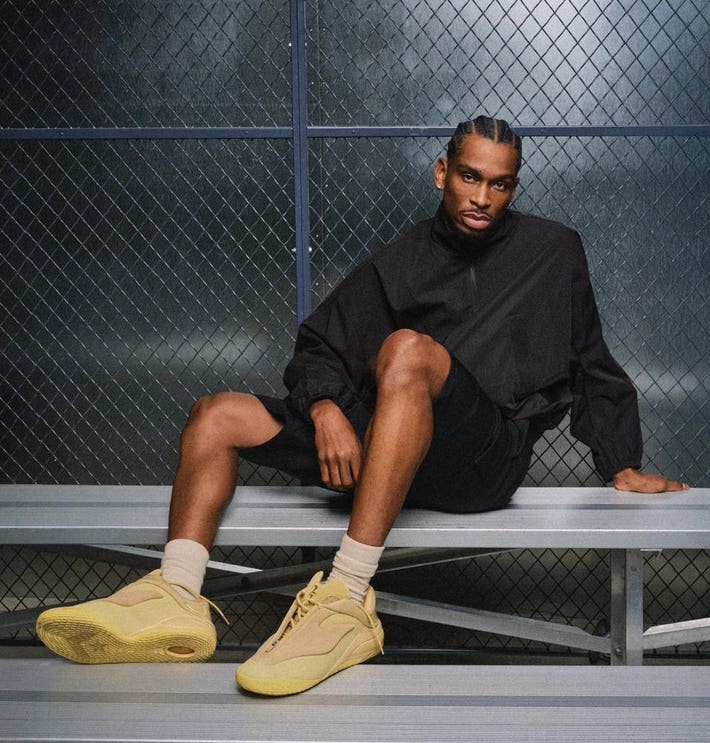

Illustrative Image (Source: Google Search)

Corporate & Promotional Events

Many international corporations leverage branded shai gilgeous alexander shoes as part of promotional campaigns or corporate gifting strategies. These shoes can serve as memorable promotional items that reinforce brand identity and foster loyalty among clients or employees. B2B buyers in Europe and the Middle East should consider customization options, regional branding preferences, and efficient logistics to ensure timely distribution. High-quality packaging and regional compliance also enhance the perceived value of these promotional assets.

Medical & Rehabilitation

The medical sector increasingly incorporates specialized footwear for injury prevention and recovery. Shoes designed with advanced orthopedics or injury-recovery features from shai gilgeous alexander can be sourced for hospitals, clinics, and rehabilitation centers across Africa, South America, and Europe. Buyers should prioritize materials that meet health standards, including medical-grade insoles and supportive structures. Regional regulations and certification requirements must be considered to ensure compliance and effective patient outcomes.

Manufacturing & Logistics

In the manufacturing domain, shai gilgeous alexander shoes or their components—such as molds, soles, or upper parts—are essential for local production facilities. B2B buyers should focus on sourcing high-quality, regionally available materials that match manufacturing standards, reducing costs and lead times. This approach is particularly relevant for markets seeking to develop local sneaker brands or expand existing production capacities, especially in regions like Mexico and parts of Africa and Europe where manufacturing infrastructure is evolving.

Strategic Material Selection Guide for shai gilgeous alexander shoes

Material Analysis for Shai Gilgeous Alexander Shoes

Selecting the optimal materials for Shai Gilgeous Alexander shoes requires a nuanced understanding of their properties, manufacturing complexities, and suitability across diverse international markets. Below is an analysis of three common materials—leather, synthetic textiles, and rubber—focusing on their performance attributes, advantages, limitations, and considerations for global B2B procurement.

Leather

Key Properties:

Leather remains a premier choice for high-end athletic and casual footwear, offering excellent durability, breathability, and a premium aesthetic. It possesses natural flexibility and molds to the wearer’s foot over time, enhancing comfort. Leather also exhibits good resistance to abrasion but requires proper treatment to withstand moisture and environmental factors.

Pros & Cons:

Leather’s durability and classic appeal make it highly desirable, especially in markets like Europe and Italy, where craftsmanship and quality are prioritized. However, it involves higher manufacturing complexity, demanding skilled labor and quality control. Cost-wise, leather is generally high, influenced by raw material quality and tanning processes. Additionally, leather production raises environmental concerns, which can impact compliance with sustainability standards in certain regions.

Impact on Application:

Leather performs well in varying climates, but it can be susceptible to water damage if not properly treated. It is suitable for both indoor and outdoor shoes, provided adequate waterproofing treatments are applied. Leather’s natural properties also align with consumer preferences in markets emphasizing luxury and durability.

International Considerations:

For buyers in Africa, South America, the Middle East, and Europe, sourcing ethically tanned leather adhering to international standards like ISO 14001 or EU regulations is crucial. Compliance with import tariffs and environmental standards influences procurement costs and brand reputation. Leather suppliers with certifications (e.g., Leather Working Group) can facilitate smoother customs clearance and consumer trust.

Synthetic Textiles

Key Properties:

Synthetic textiles such as mesh, nylon, and polyester are lightweight, flexible, and moisture-wicking. They are engineered for breathability, quick drying, and ease of manufacturing. These materials can be designed to meet specific performance criteria, including UV resistance and colorfastness.

Pros & Cons:

Synthetic textiles offer cost advantages, ease of mass production, and consistency in quality. They are less labor-intensive to produce than natural materials, enabling faster turnaround times. However, they tend to have lower durability compared to leather, especially under abrasive or prolonged outdoor exposure. Environmental concerns are also significant, as many synthetics are derived from petrochemicals and are less biodegradable.

Impact on Application:

Ideal for performance-oriented shoes, synthetic textiles excel in athletic and casual segments. They are suitable for markets demanding lightweight and breathable footwear, such as in warmer climates of Africa and South America. Proper finishing and reinforcement can mitigate some durability issues.

International Considerations:

Buyers should verify compliance with regional standards like REACH in Europe or JIS in Japan. Sourcing from suppliers with transparent supply chains and eco-friendly certifications (e.g., OEKO-TEX) can enhance market acceptance. Cost-effective sourcing from Asia or local manufacturers can also optimize margins.

Rubber

Key Properties:

Rubber is essential for outsoles due to its excellent grip, flexibility, and shock absorption. It can be natural or synthetic, with each offering distinct performance traits. Rubber withstands temperature variations and provides resistance to wear and chemicals.

Pros & Cons:

Rubber’s high resilience makes it highly durable and suitable for high-traffic outdoor shoes. It is relatively cost-effective and can be molded into complex tread patterns. However, the manufacturing process can be energy-intensive, and synthetic variants may degrade faster under UV exposure. Natural rubber’s supply can be affected by environmental factors, impacting availability and pricing.

Impact on Application:

Rubber outsoles are critical for outdoor and sports shoes, especially in regions with rugged terrains or high moisture levels. They perform well in diverse climates, including the Middle East and Europe, where durability against environmental stressors is valued.

International Considerations:

Compliance with standards such as ASTM D2000 or ISO 4649 ensures quality and safety. Buyers should consider sourcing from regions with sustainable rubber plantations to meet environmental standards. Import tariffs and local manufacturing capabilities influence overall costs and lead times.

Summary Table

| Material | Typical Use Case for shai gilgeous alexander shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather | Casual, premium sneakers, high-end athletic shoes | Durability, breathability, aesthetic | High cost, environmental concerns, manufacturing complexity | High |

| Synthetic Textiles | Performance sneakers, lightweight casual shoes | Cost-effective, lightweight, moisture-wicking | Lower durability, environmental impact | Medium |

| Rubber | Outsoles for outdoor, sports, and casual shoes | Excellent grip, shock absorption | Environmental impact, energy-intensive manufacturing | Medium |

This comprehensive analysis aims to guide international B2B buyers in selecting materials that align with regional standards, environmental considerations, and market preferences, ensuring optimal product performance and compliance across diverse markets.

Illustrative Image (Source: Google Search)

In-depth Look: Manufacturing Processes and Quality Assurance for shai gilgeous alexander shoes

Manufacturing Processes of Shai Gilgeous Alexander Shoes

The production of Shai Gilgeous Alexander shoes involves a series of meticulously controlled stages, each critical to ensuring product quality and consistency. For international B2B buyers, understanding these processes provides insight into supplier capabilities and potential collaboration points.

1. Material Preparation

The manufacturing process begins with sourcing high-quality raw materials, including premium leathers, synthetic fabrics, rubber compounds, and specialized adhesives. Suppliers often establish long-term relationships with certified vendors to ensure material traceability and compliance with international standards such as ISO 9001. Material inspection at this stage involves visual checks, thickness measurements, and testing for contaminants or defects, which are crucial to prevent downstream issues.

2. Forming and Cutting

The next stage involves pattern cutting, where materials are precision-cut using computer-controlled cutting machines or die-cutting techniques. This ensures minimal waste and high accuracy, which is vital for maintaining design integrity across large production volumes. Advanced CAD/CAM systems are employed to optimize material usage and facilitate rapid adjustments to designs or sizes.

3. Assembly and Stitching

Assembling components—such as uppers, linings, insoles, and outsoles—is performed through a combination of automated machinery and skilled manual work. Stitching quality is paramount; industrial sewing machines equipped with specialized needles and threads are used to ensure durability. The assembly process often involves bonding techniques like heat sealing or cementing, particularly for synthetic materials, to enhance strength and flexibility.

4. Finishing and Quality Checks

The final stages include surface finishing, cleaning, and quality refinement. This involves applying dyes, coatings, or protective finishes, followed by polishing and detailing. Automated inspection systems are increasingly used to detect surface imperfections, color inconsistencies, or assembly defects. After finishing, shoes undergo rigorous quality control before packaging.

Quality Assurance (QA) and Control Standards

1. International and Industry Standards

Manufacturers aiming for global markets typically adhere to standards such as ISO 9001 for quality management systems, ensuring consistent processes and continuous improvement. For specific regions, additional certifications are relevant:

– CE Marking (Europe): Indicates compliance with EU safety, health, and environmental requirements.

– API (Middle East): For certain product standards, especially in specialized markets.

– SABS (South Africa), INMETRO (Brazil), and other regional certifications may also be relevant depending on the destination country.

2. Inspection Points and Testing Methods

Quality checks are integrated throughout the production cycle, following the principles of IQC, IPQC, and FQC:

– Incoming Quality Control (IQC): Raw materials are inspected for defects, color consistency, and material specifications before entering production.

– In-Process Quality Control (IPQC): Continuous monitoring during manufacturing includes checking seam strength, dimensional accuracy, and assembly alignment. Automated vision systems and tactile inspections are common.

– Final Quality Control (FQC): Finished shoes are subjected to comprehensive testing, including:

– Durability Tests: Flexing, abrasion, and adhesion tests.

– Color Fastness: Ensuring dyes do not bleed or fade.

– Comfort and Fit: Trial wear testing for ergonomic validation.

– Safety Checks: Slip resistance, sole adhesion, and non-toxic materials.

3. Common Testing Methods

International laboratories and third-party testing agencies evaluate products against standards such as ASTM, ISO, and EN benchmarks. Tests include:

– Tensile and shear testing for sole adhesion.

– Environmental testing for resistance to moisture, temperature variations, and UV exposure.

– Chemical analysis to confirm absence of harmful substances (REACH compliance).

How B2B Buyers Can Verify Supplier QC

1. Conduct Supplier Audits

On-site audits remain the most effective method for verifying QC processes. Buyers should evaluate:

– Facility cleanliness and organization.

– Documentation of QC procedures and records.

– Calibration and maintenance logs of testing equipment.

– Employee training and qualification records.

2. Review Quality Reports and Certifications

Request detailed QC reports, test certificates, and audit findings. Reputable manufacturers will maintain comprehensive records aligned with international standards like ISO 9001, ISO 14001 (environment), and ISO 45001 (health & safety).

3. Engage Third-Party Inspection Services

Employ independent inspection agencies such as SGS, Bureau Veritas, or Intertek to perform pre-shipment inspections, random sampling tests, and compliance verification. These inspections help mitigate risks associated with substandard products and provide credibility to quality claims.

4. Establish Long-Term Quality Partnerships

Develop ongoing relationships with trusted suppliers who demonstrate transparency and consistent quality. Regular communication, joint quality improvement initiatives, and supplier development programs foster higher standards and reduce defect rates.

Considerations for International B2B Buyers from Diverse Markets

Africa & South America:

Manufacturers should demonstrate compliance with regional standards (e.g., INMETRO, SABS) and possess robust traceability systems. Given varying infrastructure, suppliers with flexible QC protocols and local testing partnerships are advantageous.

Middle East:

Regional certifications like CE and adherence to safety standards are critical. Suppliers should also be capable of demonstrating compliance with environmental regulations and providing detailed documentation for customs clearance.

Europe & Mexico:

Stringent regulations necessitate adherence to REACH, CE, and other EU directives. B2B buyers should prioritize suppliers with ISO 9001 certification, extensive testing reports, and proven experience exporting to European markets. Additionally, transparency regarding supply chain sustainability is increasingly valued.

Final Insights

For international B2B buyers, establishing a comprehensive understanding of manufacturing processes and QC protocols is essential to ensure product quality, compliance, and market acceptance. Due diligence through audits, third-party inspections, and certification reviews minimizes risks and fosters long-term supplier relationships. Tailoring verification approaches to regional standards and market expectations further enhances supply chain reliability for Shai Gilgeous Alexander shoes or similar premium footwear products.

Comprehensive Cost and Pricing Analysis for shai gilgeous alexander shoes Sourcing

Cost Structure Breakdown for Shai Gilgeous Alexander Shoes

Understanding the comprehensive cost components involved in sourcing Shai Gilgeous Alexander shoes is essential for international B2B buyers. The primary costs include raw materials, manufacturing labor, overhead expenses, tooling, quality control, logistics, and profit margins. Typically, materials such as synthetic or genuine leather, mesh fabrics, and specialized soles constitute 40-50% of the manufacturing cost, with premium materials driving higher prices. Labor costs vary significantly depending on the sourcing country—Asian manufacturers often offer lower wages, while European or Middle Eastern suppliers may charge a premium for craftsmanship and quality assurance.

Illustrative Image (Source: Google Search)

Manufacturing overheads encompass factory utilities, equipment depreciation, and administrative costs, generally adding 10-15% to the total production expense. Tooling and setup costs are usually incurred upfront, especially for customized designs or limited editions, and can range from a few hundred to several thousand dollars depending on complexity. Quality control processes, including certifications and testing, further influence costs, especially if high standards or compliance with international standards are required.

Logistics costs—covering transportation, customs duties, and taxes—are highly variable based on the sourcing location and destination. For Africa, South America, the Middle East, and Europe, shipping expenses can range from 5-15% of the product’s FOB (Free on Board) price, influenced by shipment volume and mode (air vs. sea). Margins depend on the supplier’s pricing strategy, order volume, and negotiation power, typically ranging from 10-30%.

Price Influencers and Key Factors

Several factors significantly influence the final pricing of these shoes in international markets:

- Order Volume and MOQ: Larger quantities usually reduce per-unit costs through economies of scale. Buyers should negotiate for flexible MOQs, especially when testing new markets or suppliers.

- Customization and Specs: Custom designs, branding, or specific material requirements increase costs. Standard models are more cost-efficient but may limit brand differentiation.

- Material Choices: Premium materials like full-grain leather or eco-friendly fabrics elevate the price but can enhance product appeal and value.

- Quality Certifications: International standards such as ISO, REACH, or environmental certifications can add to costs but improve marketability, especially in Europe and the Middle East.

- Supplier Factors: Supplier reputation, production capacity, and reliability influence pricing. Established manufacturers with quality certifications often command higher prices but offer greater assurance.

- Incoterms and Shipping Terms: FOB, CIF, or DDP terms impact total landed costs. Buyers should clearly specify Incoterms to understand and compare total costs accurately.

Strategic Tips for International B2B Buyers

- Negotiate for Volume Discounts: Engage in bulk purchasing to leverage economies of scale. Suppliers may offer better rates for larger orders, especially when establishing long-term partnerships.

- Focus on Total Cost of Ownership (TCO): Beyond unit price, consider shipping, customs, taxes, storage, and potential rework costs. For example, sourcing from Europe might have higher manufacturing costs but lower logistics expenses if near the target market.

- Leverage Certifications and Quality Standards: Ensuring suppliers meet international standards can reduce risks and facilitate smoother customs clearance, ultimately lowering overall costs.

- Assess Lead Times and Flexibility: Longer lead times might reduce costs but can impact market responsiveness. Flexibility in order quantities and delivery schedules can optimize cost efficiency.

- Pricing Nuances for Different Regions: African and South American markets may benefit from lower manufacturing costs but face higher logistics and import duties. European buyers often pay premium prices but benefit from higher quality standards and quicker turnaround.

Disclaimer

Indicative pricing for Shai Gilgeous Alexander shoes can vary widely based on specifications, order volume, and sourcing country. For example, manufacturing costs might range from $20 to $50 per pair for standard models in Asia, while premium, customized shoes could exceed $70. Logistics and duties could add 10-25% to the landed cost depending on the destination. Always conduct detailed supplier quotations and consider all components of TCO before finalizing sourcing decisions.

By thoroughly analyzing these cost factors and strategic considerations, international buyers from Africa, South America, the Middle East, and Europe can optimize their sourcing process, achieve better margins, and ensure a competitive edge in their respective markets.

Spotlight on Potential shai gilgeous alexander shoes Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for shai gilgeous alexander shoes.)*

Essential Technical Properties and Trade Terminology for shai gilgeous alexander shoes

Key Technical Properties for Shai Gilgeous Alexander Shoes

1. Material Grade and Composition

The quality of materials used in manufacturing Shai Gilgeous Alexander shoes is fundamental. This includes the grade of leather, synthetic fabrics, or mesh components. Higher-grade materials ensure durability, comfort, and a premium appearance, which are critical for brand reputation and customer satisfaction. B2B buyers should specify the required material standards (e.g., full-grain leather or breathable mesh) to ensure consistency and meet market expectations.

2. Manufacturing Tolerance

Tolerance levels refer to the allowable variation in dimensions, weight, and construction of each shoe. Tight tolerances (e.g., ±0.5 mm for sole thickness) indicate high precision and quality control, reducing returns and defects. For international buyers, understanding tolerance standards helps in assessing the reliability of production processes and aligning expectations across supply chains.

3. Flexibility and Cushioning Specifications

These properties impact comfort and performance, especially for athletic or casual shoes. Technical specifications such as the flexibility index or cushioning material type (e.g., EVA foam, gel inserts) should meet the end-user requirements. B2B buyers should verify these properties to match regional market preferences and usage scenarios.

4. Water Resistance and Breathability Ratings

Water resistance ratings (e.g., waterproof membrane certification) are crucial for shoes intended for outdoor or variable climates. Breathability metrics (such as moisture vapor transmission rate – MVTR) affect wearer comfort, especially in hot or humid regions. Suppliers should provide clear ratings to facilitate compliance with regional standards and customer expectations.

5. Sole Composition and Traction Coefficients

The outsole material (rubber, TPU, etc.) and its traction coefficient determine slip resistance and durability. For different markets, selecting appropriate sole properties ensures safety and longevity, minimizing warranty claims and enhancing brand trust.

6. Certification and Compliance Standards

International markets often require compliance with specific standards, such as ISO certifications, REACH for chemical safety, or regional safety standards. Confirming these certifications during procurement minimizes legal risks and facilitates smoother customs clearance.

Essential Industry and Trade Terms

1. OEM (Original Equipment Manufacturer)

Refers to companies that produce shoes based on the buyer’s specifications and branding. Understanding OEM terms helps buyers manage production customization, branding rights, and quality control.

2. MOQ (Minimum Order Quantity)

The smallest quantity a manufacturer is willing to produce per order. Knowledge of MOQ is vital for planning inventory and negotiating prices, especially for emerging markets with smaller retail chains.

3. RFQ (Request for Quotation)

A formal process where buyers solicit price and lead-time estimates from suppliers. Effective RFQs allow buyers to compare suppliers accurately and secure competitive pricing aligned with technical specifications.

4. Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and tariffs. Familiarity with Incoterms (like FOB, CIF) ensures clarity on who bears costs and risks during transit, essential for international logistics planning.

5. Quality Assurance (QA) & Quality Control (QC)

Processes that verify whether the shoes meet specified standards before shipment. For international buyers, understanding QA/QC procedures ensures consistent product quality and reduces post-delivery disputes.

6. Lead Time

The duration from order placement to shipment readiness. Knowing lead times helps in planning inventory replenishment and aligning production schedules, especially critical for seasonal or promotional launches in diverse markets.

Summary:

For B2B buyers across Africa, South America, the Middle East, and Europe, mastering these technical properties and trade terms ensures efficient sourcing, compliance, and quality management. Clear specifications and understanding of industry jargon foster stronger supplier relationships, optimize procurement costs, and facilitate market-specific product adaptations.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the shai gilgeous alexander shoes Sector

Market Overview & Key Trends

The global market for high-performance, athlete-inspired footwear, including products associated with prominent figures like Shai Gilgeous-Alexander, is experiencing dynamic growth driven by evolving consumer preferences and technological advancements. International B2B buyers from Africa, South America, the Middle East, and Europe—particularly countries like Mexico and Italy—are increasingly seeking innovative sourcing options to meet rising demand for premium, stylish, and functional footwear.

Emerging trends include the integration of smart technology, such as embedded sensors and connected features, which enhance athlete and casual wearability. Additionally, digital supply chain management tools—like blockchain for traceability and AI-driven demand forecasting—are transforming sourcing strategies, enabling buyers to optimize inventory and reduce lead times.

Market dynamics are influenced by fluctuating raw material costs, geopolitical factors, and regional trade agreements. For instance, Africa’s abundant leather and textile resources present opportunities for cost-effective sourcing, while Europe’s advanced manufacturing capabilities support high-quality production standards. Middle Eastern markets are increasingly prioritizing luxury branding and exclusivity, creating niche opportunities for premium collaborations.

For B2B buyers, staying ahead requires leveraging data analytics for market insights, establishing diversified sourcing channels, and fostering relationships with innovative manufacturers. Emphasizing agility in supply chain operations and understanding regional market preferences will be crucial to capitalize on growth opportunities and mitigate risks associated with global disruptions.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a pivotal factor in the footwear industry, influencing procurement decisions and brand positioning. Buyers in regions like Africa, South America, the Middle East, and Europe are increasingly prioritizing suppliers committed to environmentally responsible practices, driven by consumer demand and regulatory pressures.

Environmental impacts of shoe production—such as water consumption, carbon emissions, and waste generation—necessitate the adoption of ‘green’ materials and processes. Sourcing from manufacturers that utilize recycled plastics, organic textiles, and biodegradable components can significantly reduce ecological footprints. Certifications like Global Organic Textile Standard (GOTS), Forest Stewardship Council (FSC), and ISO 14001 are valuable indicators of a supplier’s commitment to sustainability.

Ethical sourcing also encompasses fair labor practices, transparency, and supply chain traceability. Buyers should seek partners adhering to standards like Fair Trade or SA8000, which ensure workers’ rights and safe working conditions. Incorporating third-party audits and blockchain-based tracking systems enhances accountability and reduces the risk of supply chain violations.

For international buyers, establishing long-term relationships with suppliers committed to sustainability not only aligns with global environmental goals but also enhances brand credibility and consumer trust. Investing in eco-friendly materials and ethical manufacturing processes can also open access to premium markets and facilitate compliance with emerging regulations across regions.

Brief Evolution/History (Optional)

The ‘Shai Gilgeous-Alexander shoes’ sector has evolved from basic athletic footwear into a sophisticated segment blending sports performance with lifestyle fashion. Initially driven by endorsement deals and athlete collaborations, the industry now emphasizes innovation, sustainability, and regional customization. This evolution reflects broader shifts in consumer behavior, where authenticity, sustainability, and technological integration are highly valued.

Understanding this trajectory helps B2B buyers identify innovative manufacturing partners and stay ahead of emerging trends. Recognizing the importance of athlete influence and brand storytelling can also enhance product appeal across diverse markets, especially as regional preferences for style and functionality continue to evolve globally.

Frequently Asked Questions (FAQs) for B2B Buyers of shai gilgeous alexander shoes

1. How can I verify the credibility and quality standards of suppliers offering Shai Gilgeous Alexander shoes?

To ensure supplier credibility, start by reviewing their certifications, such as ISO or other quality management standards. Request detailed product samples and inspect them against international quality benchmarks. Verify their business licenses and seek references from previous international clients, especially those in your region. Conduct virtual or on-site audits if feasible, focusing on manufacturing processes, quality control procedures, and compliance with safety standards. Utilizing third-party inspection services prior to shipment can further mitigate risks. Building strong supplier relationships based on transparency and documented quality assurance processes is essential for reliable sourcing.

2. What customization options are typically available for bulk orders of Shai Gilgeous Alexander shoes?

Suppliers often offer a range of customization options to align with your branding and market needs. Common options include logo placement, colorways, material choices, and packaging. Some suppliers can customize shoe design elements, such as sole type or decorative accents, especially for large orders. Clarify minimum order quantities (MOQs) for each customization level and request prototypes before mass production. Ensure your supplier provides clear timelines for customization processes and confirms that modifications meet your quality standards. Effective communication and detailed specifications are key to achieving desired results without delays.

3. What are typical minimum order quantities (MOQs), lead times, and payment terms for international B2B purchases?

MOQs for Shai Gilgeous Alexander shoes usually range from 500 to 2,000 pairs, depending on the supplier and customization complexity. Lead times vary from 4 to 12 weeks, influenced by order size and production schedules. Payment terms commonly include a 30% deposit upfront, with the balance payable before shipment or upon delivery. Some suppliers may offer flexible terms for repeat buyers or large orders. Negotiate clear contract terms covering payment schedules, penalties for delays, and cancellation policies to protect your investment. Establishing reliable communication channels ensures timely updates throughout the process.

4. What quality assurance certifications should I look for when sourcing these shoes internationally?

Key certifications include ISO 9001 for quality management, OEKO-TEX for safety of textiles, and environmental standards like REACH compliance in Europe. Additionally, certifications related to labor practices, such as SA8000, demonstrate ethical manufacturing. Request suppliers’ test reports for durability, colorfastness, and material safety. For regions with strict import regulations, ensure compliance with relevant standards, such as CE marking for European markets or ASTM standards in the U.S. Verifying these certifications helps mitigate compliance risks and reassures your customers about product safety and quality.

5. How do I manage logistics and shipping costs when importing Shai Gilgeous Alexander shoes from overseas suppliers?

Begin by selecting suppliers experienced in international freight, offering options like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) terms to understand your total costs. Work with reliable freight forwarders who can advise on optimal shipping routes and consolidate shipments to reduce costs. Consider customs duties, taxes, and import regulations specific to your country—these can significantly impact overall expenses. Establish clear timelines and tracking systems to monitor shipments. Building strong logistics partnerships minimizes delays and unexpected costs, ensuring a smooth supply chain from supplier to your market.

6. What are common dispute resolution mechanisms in international B2B transactions for footwear sourcing?

Disputes often arise over quality, delivery delays, or payment issues. To mitigate risks, include detailed dispute resolution clauses in your contracts, specifying arbitration (preferably in neutral jurisdictions), jurisdiction, and applicable law. Mediation can serve as an initial step before arbitration or litigation. Working with suppliers who are transparent and communicative reduces misunderstandings. Maintaining comprehensive documentation, such as contracts, correspondence, and inspection reports, provides evidence should disputes escalate. Engaging legal counsel familiar with international trade laws ensures your rights are protected and resolutions are efficient.

7. How can I ensure compliance with regional import regulations and standards for Shai Gilgeous Alexander shoes?

Research your country’s specific import regulations, including tariffs, labeling requirements, and safety standards. In Europe, CE marking and compliance with REACH are crucial; in Africa and South America, local certifications may be required. Work with suppliers familiar with export documentation and customs procedures to streamline clearance. Providing detailed product specifications and certifications in advance helps avoid delays or fines. Consider hiring local customs brokers or trade consultants to navigate complex regulations. Staying updated on regulatory changes ensures ongoing compliance and reduces the risk of shipment holds or penalties.

8. What steps should I take if I encounter quality issues or disputes after receiving the shoes?

Immediately document the issues with detailed photographs and descriptions. Communicate directly with your supplier, referencing the original order specifications and quality standards agreed upon. Request a resolution, such as replacement, repair, or refund, based on your contractual terms. If an agreement cannot be reached, utilize arbitration or dispute resolution clauses outlined in your contract. Keep all correspondence and inspection reports as evidence. For ongoing relationships, work collaboratively to address root causes and prevent recurrence. Establishing a clear, fair process helps maintain trust and ensures your supply chain remains resilient.

Strategic Sourcing Conclusion and Outlook for shai gilgeous alexander shoes

Strategic Sourcing Outlook and Final Recommendations

Effective strategic sourcing of Shai Gilgeous-Alexander shoes presents a significant opportunity for international B2B buyers seeking to capitalize on high-demand, innovative athletic footwear. Key takeaways include prioritizing suppliers with proven quality control, sustainable manufacturing practices, and reliable supply chain logistics to meet global market expectations. Diversifying sourcing channels—such as exploring emerging manufacturers in Africa, South America, and Eastern Europe—can mitigate risks and optimize costs.

For buyers in regions like Mexico, Italy, and the Middle East, establishing strong partnerships with trusted suppliers will ensure product authenticity, compliance with regional standards, and the ability to adapt quickly to market trends. Leveraging strategic sourcing not only enhances competitiveness but also enables customization and faster time-to-market, critical in the dynamic footwear industry.

Looking ahead, proactive engagement with innovative suppliers and embracing sustainable sourcing practices will be vital. International B2B buyers should continuously monitor market developments, strengthen supplier relationships, and explore new sourcing geographies to stay ahead of evolving consumer preferences. By adopting a strategic, future-focused approach, buyers can unlock sustained growth and secure a competitive edge in the global athletic footwear landscape.