Your Ultimate Guide to Sourcing Shoe Market

Guide to Shoe Market

- Introduction: Navigating the Global Market for shoe market

- Understanding shoe market Types and Variations

- Key Industrial Applications of shoe market

- Strategic Material Selection Guide for shoe market

- In-depth Look: Manufacturing Processes and Quality Assurance for shoe market

- Comprehensive Cost and Pricing Analysis for shoe market Sourcing

- Spotlight on Potential shoe market Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for shoe market

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the shoe market Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of shoe market

- Strategic Sourcing Conclusion and Outlook for shoe market

Introduction: Navigating the Global Market for shoe market

In today’s interconnected economy, the global shoe market represents a dynamic and vital sector with extensive opportunities for international B2B buyers. From luxury footwear in Italy to mass-market production in Turkey and innovative designs emerging from emerging markets in Africa, South America, and the Middle East, the industry offers a diverse landscape of products, materials, and manufacturing capabilities. Understanding these nuances is crucial for making informed sourcing decisions that align with your business goals, quality standards, and market demands.

This comprehensive guide is designed to empower B2B buyers by providing deep insights into the entire shoe supply chain—from identifying reliable suppliers and understanding manufacturing processes to evaluating materials, costs, and quality control measures. It also covers critical market trends, regional sourcing advantages, and frequently asked questions to address common challenges faced by international buyers. Whether you are seeking to expand your product portfolio, optimize costs, or ensure compliance with quality standards, this guide offers actionable strategies tailored for buyers from Africa, South America, the Middle East, and Europe—especially key sourcing hubs like Italy and Turkey.

Illustrative Image (Source: Google Search)

By navigating the complexities of the global shoe market with confidence, you can establish strategic partnerships, mitigate risks, and capitalize on emerging opportunities. Ultimately, this resource aims to streamline your sourcing process and enhance your competitive edge in an increasingly globalized industry.

Understanding shoe market Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Casual and Lifestyle Shoes | Designed for everyday wear, comfort-focused, versatile styles | Retail, wholesale distribution, OEMs | Pros: Wide market appeal, high repeat demand; Cons: Lower margins, high competition |

| Formal and Dress Shoes | Elegant, tailored for professional or special occasions | Specialty retailers, bespoke manufacturers | Pros: Higher price points, premium branding; Cons: Limited seasonal demand, higher production costs |

| Athletic and Sports Shoes | Performance-driven, technology-enhanced, sport-specific | Sports retailers, OEMs, private label brands | Pros: Growing global demand, innovation-driven; Cons: Rapid fashion cycles, high R&D costs |

| Work and Safety Shoes | Heavy-duty, safety standards compliance, durable materials | Industrial suppliers, safety equipment distributors | Pros: Steady demand, regulatory-driven market; Cons: Niche market, strict quality requirements |

| Eco-friendly and Sustainable Shoes | Made from sustainable materials, eco-conscious design | Niche eco brands, specialty retailers | Pros: Growing consumer awareness, premium pricing; Cons: Higher material costs, limited supplier options |

Casual and Lifestyle Shoes

This segment encompasses a broad range of comfortable, everyday footwear suitable for various casual settings. Typically characterized by flexible materials, trendy designs, and affordability, these shoes appeal to mass markets globally. For B2B buyers, sourcing this category requires attention to seasonal trends, material quality, and manufacturing scalability. The high volume nature offers steady sales but often involves intense price competition, making margin management crucial. Suppliers with reliable production capacity and flexible designs are preferred to meet fluctuating consumer preferences.

Formal and Dress Shoes

Formal shoes focus on elegance, craftsmanship, and premium materials like leather and fine finishes. They cater to professional, ceremonial, or special occasions, attracting a niche but high-value customer base. B2B buyers should prioritize sourcing from established manufacturers with strong quality control and branding capabilities. While the profit margins are generally higher, the market is seasonal and sensitive to economic shifts affecting luxury spending. Ensuring consistent quality and timely delivery is vital for maintaining reputation and customer satisfaction.

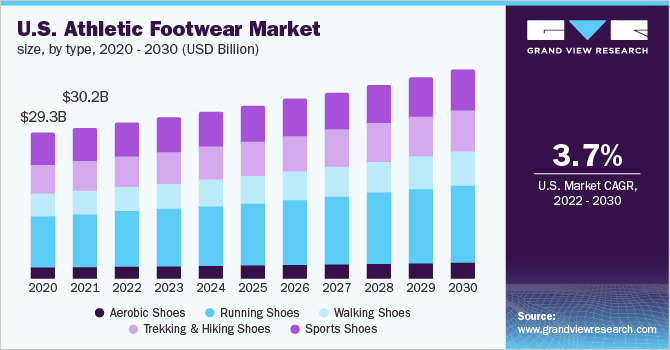

Athletic and Sports Shoes

This category is driven by innovation, comfort, and performance features such as advanced cushioning, stability, and moisture control. The global sportswear market continues to expand, especially in emerging markets, making this a lucrative segment for B2B buyers. Sourcing requires a focus on R&D capabilities, reliable supply chains for technical materials, and compliance with international standards. The fast-paced fashion cycles demand agility in production and inventory management, while technological investments can offer differentiation in competitive markets.

Work and Safety Shoes

Designed to meet industrial safety standards, these shoes prioritize durability, slip resistance, and protective features such as steel toes or puncture-resistant soles. They serve a consistent, regulated demand across sectors like construction, manufacturing, and logistics. For B2B buyers, key considerations include sourcing from certified manufacturers, understanding regional safety standards, and ensuring supply chain reliability. The niche nature often translates to steady demand, but strict quality and compliance requirements can pose entry barriers.

Eco-friendly and Sustainable Shoes

This emerging segment focuses on environmentally conscious materials, ethical production practices, and transparent supply chains. Consumers increasingly favor brands with sustainability credentials, creating opportunities for B2B buyers to tap into premium markets. Sourcing sustainable shoes involves identifying reliable suppliers of eco-materials such as recycled plastics, organic cotton, or plant-based leathers. Although costs are higher, the premium pricing potential and brand differentiation make this segment attractive. Buyers should evaluate suppliers’ certifications and environmental impact to mitigate risks and ensure authenticity.

Key Industrial Applications of shoe market

| Industry/Sector | Specific Application of shoe market | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Heavy Industry | Safety and protective footwear for workers in hazardous environments | Ensures worker safety, reduces injury-related liabilities, and complies with safety regulations | Durability, slip resistance, puncture protection, and compliance with international safety standards (e.g., EN ISO 20345) |

| Logistics & Warehousing | Anti-fatigue and ergonomic footwear for long shifts | Enhances worker comfort, reduces fatigue, and boosts productivity | Ergonomic design, lightweight materials, breathable fabrics, and availability of bulk sourcing options |

| Healthcare & Emergency Services | Specialized footwear for medical and emergency personnel | Provides comfort, hygiene, and slip resistance critical in sensitive environments | Antimicrobial properties, slip resistance, ease of cleaning, and compliance with health safety standards |

| Sports & Recreational Activities | Performance shoes for athletes and outdoor enthusiasts | Improves performance, comfort, and injury prevention | High-performance materials, specialized cushioning, and customization options for different sports |

| Fashion & Retail | Designer and branded footwear for consumer markets | Adds value through branding, aesthetic appeal, and trend alignment | Trend responsiveness, quality craftsmanship, and reliable supply chain for diverse styles |

Construction & Heavy Industry

Safety footwear is essential in construction and heavy industry sectors, where workers face risks from falling objects, sharp debris, and slippery surfaces. B2B buyers from regions like Africa, South America, and the Middle East prioritize footwear that offers high durability, puncture resistance, and slip-proof soles. Suppliers must ensure compliance with international safety standards such as EN ISO 20345, facilitating cross-border procurement. Sourcing reliable, certified safety shoes helps companies reduce workplace accidents and liability, ensuring workforce safety and regulatory adherence.

Logistics & Warehousing

In logistics hubs and warehousing operations, employees often stand or walk for extended hours. Anti-fatigue and ergonomic shoes are vital for maintaining productivity and reducing health-related absenteeism. Buyers from Europe, Turkey, and Latin America seek footwear that combines comfort with durability, often requiring lightweight, breathable materials that withstand tough working conditions. Sourcing options should include bulk procurement capabilities, consistent quality, and suppliers with certifications for ergonomic standards, ensuring long-term operational efficiency.

Healthcare & Emergency Services

Healthcare workers and emergency responders demand footwear that balances hygiene, comfort, and safety. Anti-slip soles are critical in preventing falls in hospitals, clinics, or emergency scenes. B2B buyers in Middle Eastern and European markets focus on antimicrobial properties, ease of cleaning, and compliance with health safety standards such as ASTM or EN ISO. Reliable sourcing from established manufacturers guarantees consistent quality, essential for maintaining high safety and hygiene standards in sensitive environments.

Sports & Recreational Activities

The sports and outdoor recreation market requires high-performance footwear tailored for specific activities like running, hiking, or trail sports. Buyers from Africa, South America, and Europe look for shoes that enhance athletic performance while preventing injuries. Key sourcing considerations include advanced cushioning, lightweight materials, and customization options. Suppliers offering innovative designs and materials can help B2B buyers differentiate their product lines and meet the growing demand for specialized sports footwear.

Fashion & Retail

Fashion-forward footwear remains a significant segment, especially in European and Middle Eastern markets. Retailers and brands seek trendy, high-quality shoes that align with current fashion trends. Sourcing from manufacturers with strong craftsmanship, quick turnaround times, and flexible production capabilities allows buyers to respond rapidly to market shifts. Building reliable supply chains ensures consistent product availability, brand reputation, and the ability to capitalize on seasonal trends and consumer preferences.

Strategic Material Selection Guide for shoe market

Material Analysis for Shoe Market Applications

Selecting the appropriate materials for shoe manufacturing is crucial for ensuring product performance, durability, and compliance with international standards. For B2B buyers across Africa, South America, the Middle East, and Europe, understanding the properties, advantages, and limitations of common materials can facilitate better sourcing decisions and optimize supply chain efficiency.

Leather

Leather remains the most traditional and widely used material in high-quality footwear, especially in Europe (notably Italy) and Turkey. It offers excellent breathability, flexibility, and aesthetic appeal, making it ideal for dress shoes, boots, and luxury footwear. Leather’s key properties include high durability, natural moisture regulation, and a capacity to age well with proper care.

Pros & Cons:

– Pros: Superior comfort, aesthetic versatility, natural appearance, and good aging characteristics.

– Cons: High cost, labor-intensive processing, and susceptibility to environmental damage such as water and extreme humidity. Leather production also raises sustainability concerns, which may impact compliance with eco-friendly standards in some markets.

Impact on Application:

Leather performs well across various media but requires treatments to enhance water resistance. It is compatible with standard finishing processes and adheres to many international standards like ASTM and DIN.

International Considerations:

Buyers from Africa and South America should consider sourcing from suppliers adhering to sustainability certifications (e.g., LWG). European buyers often prioritize eco-friendly and ethically sourced leather, aligning with stricter regulations. Compliance with local import standards and tariffs is essential, especially where customs procedures are stringent.

Synthetic Polymers (e.g., Polyurethane, PVC)

Synthetic materials like polyurethane (PU) and polyvinyl chloride (PVC) are prevalent in mid-range and budget footwear. They offer a versatile alternative to leather, with customizable properties such as color, texture, and flexibility.

Pros & Cons:

– Pros: Cost-effective, lightweight, resistant to water and environmental factors, and easier to manufacture at scale.

– Cons: Generally less durable than leather, prone to cracking over time, and may emit volatile organic compounds (VOCs) during production and use.

Impact on Application:

Synthetic materials are suitable for casual shoes, sports footwear, and fashion items. They can be engineered for specific media compatibility, such as water resistance or breathability, but may require additional treatments or coatings.

International Considerations:

Buyers in regions with strict environmental regulations (e.g., Europe) should verify VOC compliance and eco-labeling. In emerging markets, cost and manufacturing ease often drive preference, but quality consistency and environmental standards are increasingly scrutinized.

Rubber

Rubber is extensively used in soles, waterproof components, and sometimes uppers for specialized footwear. Its key properties include excellent elasticity, impact absorption, and resistance to water and abrasion.

Pros & Cons:

– Pros: Exceptional durability, flexibility, and resistance to environmental elements.

– Cons: Heavier than other materials, can be prone to degradation under UV exposure, and manufacturing complexity varies depending on grade.

Impact on Application:

Ideal for outsole manufacturing, especially in work boots, hiking shoes, and sports footwear. Compatibility with various adhesives and finishes is well-established, but attention to chemical resistance standards is necessary.

International Considerations:

Regional buyers should ensure rubber suppliers meet safety standards like REACH (Europe) or local chemical safety regulations. For African and Middle Eastern markets, sourcing from reputable suppliers ensures compliance with import standards and reduces risks of counterfeit or substandard materials.

Thermoplastic Elastomers (TPE)

TPEs combine the processing ease of plastics with the flexibility of rubbers, making them increasingly popular in modern footwear, especially for midsoles and flexible components.

Pros & Cons:

– Pros: Recyclable, lightweight, and easy to process, with good flexibility and shock absorption.

– Cons: Generally higher cost than traditional plastics and may have limited long-term UV stability depending on formulation.

Impact on Application:

Suitable for performance footwear and innovative designs requiring flexibility and lightweight features. Compatibility with various manufacturing techniques, such as injection molding, is advantageous.

International Considerations:

Buyers should verify TPE formulations meet environmental and safety standards, especially for export to Europe and North America. In regions like Africa and South America, cost considerations may influence material choice, but quality assurance remains critical for durability.

Summary Table

| Material | Typical Use Case for shoe market | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather | Dress shoes, luxury footwear, boots | Natural breathability, aesthetic appeal, durability | High cost, environmental concerns, processing complexity | High |

| Synthetic Polymers (PU, PVC) | Casual shoes, sports footwear, fashion items | Cost-effective, water-resistant, lightweight | Less durable, environmental VOC emissions | Medium |

| Rubber | Outsoles, waterproof components, specialized footwear | Excellent durability, impact absorption | Heavyweight, UV degradation risk | Medium |

| Thermoplastic Elastomers (TPE) | Midsoles, flexible components, performance footwear | Recyclable, lightweight, flexible | Higher cost, UV stability concerns | High |

This comprehensive understanding of material properties and regional considerations enables international B2B buyers to make informed sourcing decisions, align with compliance standards, and meet market-specific preferences effectively.

In-depth Look: Manufacturing Processes and Quality Assurance for shoe market

Manufacturing Processes in the Shoe Industry

The manufacturing of shoes is a complex, multi-stage process that combines traditional craftsmanship with modern technology. For B2B buyers, understanding these stages is crucial for evaluating supplier capabilities and ensuring product quality.

1. Material Preparation

This initial phase involves sourcing and preparing raw materials such as leather, synthetic textiles, rubber, foam, and adhesives. High-quality raw materials are fundamental to final product durability and comfort. Suppliers often source from specialized tanneries or material suppliers compliant with international standards like ISO 9001 or ISO 14001 to ensure sustainability and quality.

2. Forming and Cutting

The prepared materials are cut into patterns using manual or automated cutting machines, including CNC or laser cutters. Automation enhances precision and reduces waste, which is particularly important for consistent sizing and fit. For high-volume orders, suppliers with advanced cutting technology tend to provide more uniform products.

3. Assembly and Stitching

This stage involves assembling the cut components—such as uppers, soles, linings—through stitching, gluing, or a combination of both. Automated stitching machines improve efficiency and consistency, but skilled craftsmanship remains essential for complex designs. Adhesive bonding, often using heat-activated or solvent-based glues, is common in modern manufacturing.

4. Lasting and Shaping

The upper is shaped over a mold called a last, which determines the shoe’s final form. This process can be manual or machine-assisted, with lasting machines providing uniformity. Proper lasting impacts comfort and aesthetic appeal, making this a critical step for quality.

5. Finishing

Final touches include trimming excess material, polishing, branding, and quality checks. The outsole is attached, and additional features such as waterproofing or decorative elements are added. Finishing ensures the shoe meets both aesthetic standards and functional requirements.

Quality Assurance (QA) and Control (QC) in Shoe Manufacturing

Effective QC is vital for B2B buyers to mitigate risks associated with international sourcing, especially given diverse market standards in Africa, South America, the Middle East, and Europe.

International Standards and Industry Certifications

– ISO 9001: The most widely adopted quality management system, ensuring consistent product quality and supplier process control. Many reputable factories hold ISO 9001 certification, which is a baseline for quality assurance.

– ISO 14001: Focuses on environmental management, increasingly valued in markets with sustainability concerns.

– CE Marking (European Conformity): Required for shoes sold within the European Economic Area, indicating compliance with health, safety, and environmental standards.

– Other Certifications: API (American Petroleum Institute) or REACH compliance for chemical safety, particularly for shoes with specialized components or eco-labels.

QC Checkpoints in Manufacturing

– Incoming Quality Control (IQC): Inspection of raw materials and components before entering production. This includes visual inspection, dimensional checks, and chemical testing to verify compliance with specifications.

– In-Process Quality Control (IPQC): Continuous monitoring during manufacturing, including machine calibration, stitch tension, and assembly accuracy. Random sampling and testing ensure process stability.

– Final Quality Control (FQC): Inspection of finished shoes for defects, measurements, and overall conformity. This often involves visual checks for surface defects, stitching quality, and sole attachment.

Testing Methods

– Durability Tests: Flex testing, wear resistance, and sole adhesion tests to assess product longevity.

– Comfort Tests: Fit and cushioning assessments, often through standardized testing methods.

– Chemical Testing: Ensures materials meet safety standards regarding volatile organic compounds (VOCs), heavy metals, and other hazardous substances.

– Environmental Tests: Resistance to water, UV exposure, and temperature variations.

Verifying Supplier QC for International B2B Buyers

To ensure suppliers maintain rigorous QC standards, B2B buyers should adopt a proactive approach:

- Factory Audits: Conduct comprehensive audits focusing on manufacturing processes, quality management systems, and compliance with international standards. Third-party inspection agencies can provide impartial evaluations.

- Review of Quality Reports and Certifications: Request up-to-date quality certificates, test reports, and audit summaries. These documents verify adherence to specified standards.

- Sample Testing: Obtain samples for independent testing, especially for critical performance parameters like durability, chemical safety, and comfort.

- Third-party Inspection Services: Engage firms such as SGS, Bureau Veritas, or Intertek to perform pre-shipment inspections, ensuring product quality matches specifications before shipment.

- Ongoing Monitoring: Establish long-term relationships with suppliers that include regular audits, quality scorecards, and feedback loops to maintain consistent standards.

Quality Assurance Nuances for Different Markets

Africa and South America

In these regions, buyers should emphasize supplier compliance with local import regulations and safety standards, which may vary significantly. Many countries require specific certifications or testing for chemical safety and environmental impact. B2B buyers should verify that suppliers have experience exporting to these markets and understand regional standards.

Middle East

Market preferences often include high-end fashion and luxury standards. Suppliers should demonstrate adherence to CE standards, and quality audits should focus on craftsmanship and finishing details. Additionally, durability testing for extreme climate conditions (heat, humidity) is advisable.

Europe (e.g., Italy, Turkey)

European buyers prioritize sustainability, chemical safety, and high craftsmanship. Suppliers should provide detailed documentation of compliance with REACH, OEKO-TEX standards, and ISO certifications. Regular third-party audits and product testing are critical to meet strict regulatory requirements and consumer expectations.

Final Recommendations for B2B Buyers

- Prioritize Transparent Communication: Establish clear quality expectations and request detailed documentation.

- Leverage Third-party Verification: Use independent inspection agencies for audits and testing.

- Implement a Quality Management System: Integrate supplier QC reports, audits, and testing results into your procurement process.

- Build Long-term Partnerships: Continuous engagement with high-quality manufacturers fosters consistency and innovation.

- Stay Informed on Regional Standards: Regularly update your knowledge of local regulations and standards to ensure compliance and smooth market entry.

Understanding the intricacies of manufacturing and quality assurance in the shoe industry enables B2B buyers to mitigate risks, ensure product reliability, and build a resilient supply chain across diverse international markets.

Comprehensive Cost and Pricing Analysis for shoe market Sourcing

Understanding the Cost Structure of Shoe Manufacturing

A thorough grasp of the cost components involved in shoe production is essential for international buyers aiming to optimize procurement strategies. The primary cost drivers include:

-

Materials: Leather, synthetic fabrics, rubber, and other raw materials vary significantly in cost based on quality, origin, and supplier relationships. Premium materials or sustainable options generally command higher prices but can differentiate products in competitive markets.

-

Labor: Manufacturing labor costs differ widely across sourcing regions. For instance, Asian countries like Vietnam and China typically offer lower labor costs, whereas Turkey and Italy may have higher wages but benefit from skilled craftsmanship.

-

Manufacturing Overheads: These encompass factory operations, machinery depreciation, and energy costs. Efficient factories with advanced technology can reduce overheads, impacting overall pricing.

-

Tooling & Molds: Initial investments in tooling are often substantial, especially for customized designs or molds for specific shoe styles. These costs are amortized over production volume, making high-volume orders more cost-effective.

-

Quality Control (QC): Stringent QC processes ensure product consistency and compliance with certifications. While adding to costs, robust QC reduces returns and reputational risks.

-

Logistics & Shipping: Transportation costs depend on shipment mode (sea, air, land), volume, and destination. For Africa and South America, shipping can be expensive due to distance and infrastructure, whereas Europe and Turkey benefit from more developed logistics networks.

-

Margins & Markups: Suppliers typically add margins to cover risks and profit, often ranging from 10% to 30%, influenced by order volume and relationship strength.

Factors Influencing Shoe Pricing

Several dynamic factors shape the final price:

-

Order Volume & MOQ: Larger orders benefit from economies of scale, reducing per-unit costs. Minimum order quantities (MOQs) can vary from 500 to several thousand pairs, impacting pricing significantly.

-

Specifications & Customization: High levels of customization, such as bespoke designs, unique materials, or special finishes, increase costs. Buyers should weigh customization against volume to optimize pricing.

-

Material Choices: Premium materials and sustainable or certified options (e.g., vegan leather, eco-friendly fabrics) tend to elevate costs but can command premium retail prices.

-

Certifications & Standards: Meeting international standards (ISO, REACH, etc.) or acquiring certifications (Fair Trade, organic) can add to costs but enhance marketability, especially in Europe and the Middle East.

-

Supplier Factors: Supplier reputation, production capacity, and reliability influence pricing. Established manufacturers may charge higher prices but offer better quality assurance and shorter lead times.

-

Incoterms & Delivery Terms: Terms like FOB, CIF, or DDP impact landed costs. Buyers should negotiate Incoterms that align with their logistics capabilities and risk management preferences.

Strategic Tips for B2B Buyers

-

Negotiate Beyond Unit Price: Focus on total landed cost, including duties, taxes, and logistics, to avoid surprises. Leverage larger orders or longer-term relationships to negotiate better terms.

-

Optimize for Cost-Efficiency: Consider nearshoring or sourcing from regions with favorable labor and material costs, such as Turkey or Eastern Europe, especially when factoring in shipping and lead times.

-

Assess Total Cost of Ownership: Beyond initial costs, evaluate supplier reliability, quality consistency, and after-sales support. Higher upfront costs may be justified if they lead to fewer defects and faster turnaround.

-

Understand Pricing Nuances: Prices can fluctuate based on raw material market trends, currency exchange rates, and geopolitical stability. Maintain ongoing communication with suppliers to stay informed.

-

Leverage Volume & Relationships: Building strong supplier relationships can unlock better pricing, flexible MOQs, and priority production slots, especially in high-demand seasons.

Price Range Indicators

Indicative FOB prices for standard men’s casual shoes typically range from $10 to $25 per pair for large-volume orders from countries like China, Vietnam, or Turkey. Premium or customized shoes, especially those with eco-friendly materials or intricate designs, may command $30 to $50+ per pair. European manufacturers, such as Italy, often operate at higher costs, reflecting craftsmanship and quality standards, with prices potentially exceeding $50 per pair for high-end products.

Disclaimer: These prices are indicative and can vary based on specific product specifications, order volume, and market conditions. Buyers should conduct detailed quotes and negotiate directly with suppliers for accurate pricing aligned with their requirements.

Spotlight on Potential shoe market Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for shoe market.)*

Essential Technical Properties and Trade Terminology for shoe market

Key Technical Properties in the Shoe Market

1. Material Grade

Material quality is fundamental in determining the durability, comfort, and aesthetic appeal of shoes. Common materials include leather, synthetic leather, textiles, and rubber. Suppliers often specify grades (e.g., full-grain leather vs. corrected-grain) to indicate quality levels. For B2B buyers, understanding material grades helps assess product longevity and aligns with target market expectations, whether for luxury, mid-range, or budget segments.

2. Tolerance and Precision

Tolerance refers to the allowable deviation in manufacturing dimensions, such as shoe length, width, and component fit. Tight tolerances (e.g., ±0.5mm) ensure consistency and reduce post-production adjustments. For international buyers, specifying tolerances prevents issues like poor fit or assembly problems, especially when sourcing from different regions with varying manufacturing standards.

3. Sole Flexibility and Thickness

The flexibility of the sole affects comfort, especially for active or casual footwear. Thickness impacts durability and cushioning. Suppliers often specify material types (e.g., EVA, rubber) and measurements (e.g., 3mm thickness). Buyers should evaluate these properties based on end-use, ensuring the shoes meet performance standards demanded by their target consumers.

4. Water Resistance and Breathability

Waterproofing levels and breathability influence shoe suitability for different climates. Waterproof shoes utilize specific membrane technologies or treatments, while breathable materials facilitate moisture escape. Understanding these properties enables buyers to select shoes appropriate for environments such as rainy regions or hot climates, reducing returns and enhancing customer satisfaction.

5. Weight and Load Capacity

Lightweight shoes improve comfort, especially for sports or travel segments. Load capacity is critical for work or safety footwear, where shoes must support specific weight or impact levels. Clear specifications help buyers match products to the intended use, ensuring safety compliance and customer comfort.

Essential Trade Terms in the Shoe Industry

1. OEM (Original Equipment Manufacturer)

Refers to manufacturers producing shoes under a brand’s design and specifications. OEM agreements allow brands or importers to outsource production while maintaining brand identity. Understanding OEM relationships helps buyers negotiate production costs and ensure quality control.

2. MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to produce per order. MOQs impact inventory planning and pricing. Buyers should negotiate MOQs that align with their market size, balancing cost efficiency with inventory risks.

3. RFQ (Request for Quotation)

A formal process where buyers solicit detailed price proposals from suppliers. An RFQ typically includes technical specifications, quantities, and delivery timelines. Properly prepared RFQs streamline sourcing and help compare supplier offerings effectively.

4. Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and tariffs. Common Incoterms like FOB (Free on Board) or CIF (Cost, Insurance, Freight) clarify who bears costs and risks at each stage of transportation. Mastery of Incoterms ensures clear negotiations and reduces misunderstandings during international shipments.

5. Lead Time

The period from order placement to delivery. Lead time influences inventory planning, especially in markets with seasonal fluctuations or high demand variability. Buyers should establish realistic lead times to avoid stockouts or excess inventory.

6. Quality Certification Standards

Industry standards such as ISO, REACH, or specific country certifications (e.g., CE marking in Europe) ensure compliance with safety and environmental regulations. Confirming supplier certifications mitigates legal risks and enhances product credibility in target markets.

Actionable Insights for B2B Buyers

- Prioritize understanding material grades and tolerances to ensure product quality aligns with your market demands.

- Clarify technical specifications related to sole flexibility, water resistance, and weight to match end-user expectations.

- Use RFQs and well-defined technical sheets to compare suppliers effectively, ensuring transparency.

- Negotiate MOQs that suit your inventory strategy, especially when entering new markets or testing new product lines.

- Familiarize yourself with Incoterms to optimize logistics costs and responsibilities, reducing risk during transit.

- Verify supplier compliance with relevant quality standards and certifications to ensure legal and safety adherence, facilitating smoother market entry.

By mastering these technical properties and trade terms, international B2B buyers can make more informed decisions, foster stronger supplier relationships, and better serve their end markets across Africa, South America, the Middle East, and Europe.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the shoe market Sector

Market Overview & Key Trends

The global shoe industry is experiencing rapid transformation driven by evolving consumer preferences, technological advancements, and geopolitical factors. For international B2B buyers from Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for strategic sourcing and market positioning.

Emerging trends include the integration of digital technologies such as 3D design, AI-driven inventory management, and e-commerce platforms that facilitate direct-to-consumer sales. These innovations streamline supply chains, reduce lead times, and enable customization—key advantages for buyers seeking agility and differentiation.

Sourcing trends are increasingly shifting toward sustainable and ethical practices. Countries like Turkey and Italy remain dominant hubs for high-quality, artisanal production, while regions such as Vietnam, Bangladesh, and Ethiopia are expanding as low-cost manufacturing bases. For buyers in Africa and South America, leveraging local or regional suppliers can reduce logistical costs and foster economic development, but it requires thorough vetting for quality assurance.

Market dynamics are also influenced by tariffs, trade agreements, and geopolitical stability. For example, recent trade tensions have prompted diversification of sourcing regions, encouraging buyers to explore emerging markets with favorable trade policies. Additionally, the rise of nearshoring—sourcing closer to end markets—offers shorter supply chains and faster turnaround times, vital for responding to seasonal demands.

Overall, the global shoe market is characterized by a balance between traditional craftsmanship and technological innovation, with sustainability increasingly shaping sourcing decisions. Buyers must stay informed about regional capabilities, technological advancements, and regulatory landscapes to optimize their supply chains effectively.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a cornerstone of strategic sourcing in the shoe industry, driven by consumer demand, regulatory pressures, and environmental imperatives. For B2B buyers, prioritizing ethical supply chains not only enhances brand reputation but also mitigates risks associated with compliance violations and reputational damage.

Environmental impacts of shoe manufacturing—such as water consumption, chemical use, and waste generation—are under increased scrutiny. Implementing environmentally friendly practices involves sourcing from suppliers with proven track records in reducing carbon footprints, water usage, and waste. Certifications like ISO 14001 (Environmental Management) and LEED (Leadership in Energy and Environmental Design) are valuable indicators of sustainable operations.

The adoption of ‘green’ materials is crucial. This includes utilizing recycled materials (e.g., recycled PET for uppers, rubber), natural and biodegradable components, and innovative plant-based alternatives like mushroom leather or Piñatex. These materials can significantly reduce environmental impact and appeal to eco-conscious consumers.

Ethical sourcing extends beyond environmental concerns to social responsibility. B2B buyers should ensure suppliers adhere to fair labor practices, safe working conditions, and fair wages. Certifications such as Fair Trade and SA8000 provide assurance of ethical compliance.

Transparency throughout the supply chain is essential. Digital tools like blockchain enable traceability, allowing buyers to verify the origin of materials and labor practices. Collaborating with suppliers committed to continuous improvement in sustainability fosters long-term resilience and aligns with global efforts to combat climate change and social inequities.

Brief Evolution/History

The shoe industry’s evolution from handcrafted artisanal production to globalized manufacturing has significantly impacted B2B sourcing strategies. Historically, Europe—particularly Italy—set the standard for luxury and craftsmanship, fostering long-standing relationships based on quality and tradition. Meanwhile, emerging economies in Asia and Africa became manufacturing powerhouses due to cost advantages, scaling production while maintaining quality standards.

In recent decades, the industry has shifted toward integrating technology, sustainable materials, and ethical practices. This evolution reflects a broader consumer-driven demand for transparency and responsibility. For B2B buyers, understanding this history underscores the importance of balancing heritage craftsmanship with innovation and sustainability in sourcing decisions, ensuring competitiveness in a rapidly changing landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of shoe market

1. How can I effectively vet shoe suppliers to ensure quality and reliability?

Vetting suppliers begins with thorough research and due diligence. Start by requesting references and verifying their business credentials, such as licenses and certifications (e.g., ISO, ethical trade certificates). Review their product samples for quality, consistency, and compliance with your target market standards. Conduct virtual factory audits or on-site visits if feasible, especially for large orders. Evaluate their production capacity, lead times, and responsiveness to inquiries. Additionally, check online reviews, industry reputation, and trade association memberships. Establish clear communication channels and request detailed documentation like quality control processes and compliance certificates before formalizing any agreement.

2. What are the best ways to customize shoes for my target market?

Customization options include design modifications, branding, materials, and packaging tailored to your market preferences. Collaborate closely with suppliers to communicate specific design elements, such as colorways, logos, or unique features that appeal to local consumers. Many manufacturers offer OEM and ODM services—ensure they have experience with your target region’s trends and standards. Use prototypes or samples to verify that customizations meet your expectations before mass production. Also, consider local cultural nuances, sizing standards, and sustainability requirements to maximize market acceptance and brand differentiation.

3. How do I determine appropriate MOQs, lead times, and payment terms with international shoe suppliers?

MOQ and lead times vary depending on supplier capacity and product complexity. Negotiate MOQs that align with your budget and inventory strategy—some suppliers offer lower MOQs for smaller markets or initial orders. Clarify lead times upfront, including production, quality checks, and logistics, to plan your market rollout effectively. Payment terms typically involve deposits (30-50%) upfront with the balance upon shipment or delivery. Negotiate flexible terms, especially for ongoing partnerships, and consider secure payment methods like letters of credit or escrow services to mitigate risk. Building strong communication and trust can facilitate better terms over time.

4. What certifications and quality assurance measures should I look for in a shoe supplier?

Key certifications include ISO quality management standards, ethical trade certifications (e.g., Fair Trade, SA8000), and environmental compliance (e.g., REACH, OEKO-TEX). These demonstrate adherence to international safety, labor, and environmental standards. Ask suppliers for their quality assurance procedures, including raw material sourcing, in-process inspections, and final product testing. Request documentation of third-party lab tests for durability, colorfastness, and safety. Regular audits and transparent quality control reports help ensure consistent product standards. Suppliers with recognized certifications reduce compliance risks and enhance your credibility in regulated markets.

5. How should I handle international logistics and customs to ensure smooth delivery?

Start by choosing reliable freight forwarders experienced in your destination markets, especially in Africa, South America, the Middle East, or Europe. Determine the most cost-effective shipping mode—sea, air, or land—based on urgency, volume, and product type. Ensure all export/import documentation (commercial invoices, packing lists, certificates of origin) are accurate and complete to avoid customs delays. Familiarize yourself with local customs tariffs, import restrictions, and VAT regulations to calculate landed costs precisely. Establish clear communication with logistics providers for tracking and contingency planning. Building relationships with local customs brokers can also streamline clearance processes.

Illustrative Image (Source: Google Search)

6. What are common dispute resolution methods in international shoe sourcing, and how can I minimize risks?

Disputes often arise from quality issues, delayed shipments, or payment disagreements. To minimize risks, include clear terms in your contracts regarding quality standards, delivery timelines, and payment conditions. Use Incoterms to define responsibilities for shipping and customs clearance. Incorporate arbitration clauses specifying neutral venues or international arbitration centers for dispute resolution, which are often faster and more enforceable than local courts. Maintain detailed records of communications, inspections, and agreements. Building trust through transparent communication and phased payments tied to milestones can also reduce potential conflicts.

Illustrative Image (Source: Google Search)

7. How do I ensure compliance with local standards and consumer safety regulations in different regions?

Research the specific standards applicable to your target markets, such as CE marking for Europe, SABS for South Africa, or local safety certifications in Middle Eastern countries. Work with suppliers familiar with these requirements and request compliance documentation early in the sourcing process. Conduct or commission third-party testing to verify safety, chemical content, and labeling standards. Incorporate quality checks at multiple stages and request certificates of conformity before shipment. Staying updated with evolving regulations through industry associations or trade chambers helps ensure ongoing compliance and reduces the risk of product recalls or market bans.

8. How can I build long-term relationships with international shoe suppliers for sustained success?

Establish clear communication, transparency, and consistent quality standards from the outset. Invest in building trust through regular visits, virtual meetings, and prompt responsiveness to inquiries. Offer long-term contracts or volume commitments that incentivize suppliers to prioritize your orders and improve lead times. Provide constructive feedback and recognize supplier efforts to foster mutual loyalty. Stay informed about market trends and share insights with your partners to align your strategic goals. Developing a partnership approach, rather than transactional relationships, ensures supplier commitment, better pricing, and priority treatment—key to sustained success in the competitive international shoe market.

Strategic Sourcing Conclusion and Outlook for shoe market

Conclusion and Future Outlook

Effective strategic sourcing remains a cornerstone for success in the dynamic global shoe market, enabling B2B buyers to optimize costs, improve quality, and mitigate supply chain risks. By diversifying sourcing locations—particularly leveraging strengths in regions like Italy and Turkey—buyers can access innovative designs, superior craftsmanship, and competitive pricing.

In an increasingly complex landscape, fostering strong supplier relationships, embracing sustainable practices, and investing in technological integration are vital for maintaining a competitive edge. As market trends shift toward customization and eco-conscious products, proactive sourcing strategies will be essential for meeting evolving consumer demands.

Looking ahead, international buyers from Africa, South America, the Middle East, and Europe should prioritize building resilient, agile supply networks. This involves continuous market analysis, supplier diversification, and adopting digital procurement tools. By doing so, they can capitalize on emerging opportunities and secure a sustainable advantage in the global shoe industry. Now is the time to refine sourcing strategies—embrace innovation, and position your business for long-term growth in this vibrant market.