Your Ultimate Guide to Sourcing Shoe Molding Vs Quarter

Guide to Shoe Molding Vs Quarter Round

- Introduction: Navigating the Global Market for shoe molding vs quarter round

- Understanding shoe molding vs quarter round Types and Variations

- Key Industrial Applications of shoe molding vs quarter round

- Strategic Material Selection Guide for shoe molding vs quarter round

- In-depth Look: Manufacturing Processes and Quality Assurance for shoe molding vs quarter round

- Comprehensive Cost and Pricing Analysis for shoe molding vs quarter round Sourcing

- Spotlight on Potential shoe molding vs quarter round Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for shoe molding vs quarter round

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the shoe molding vs quarter round Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of shoe molding vs quarter round

- Strategic Sourcing Conclusion and Outlook for shoe molding vs quarter round

Introduction: Navigating the Global Market for shoe molding vs quarter round

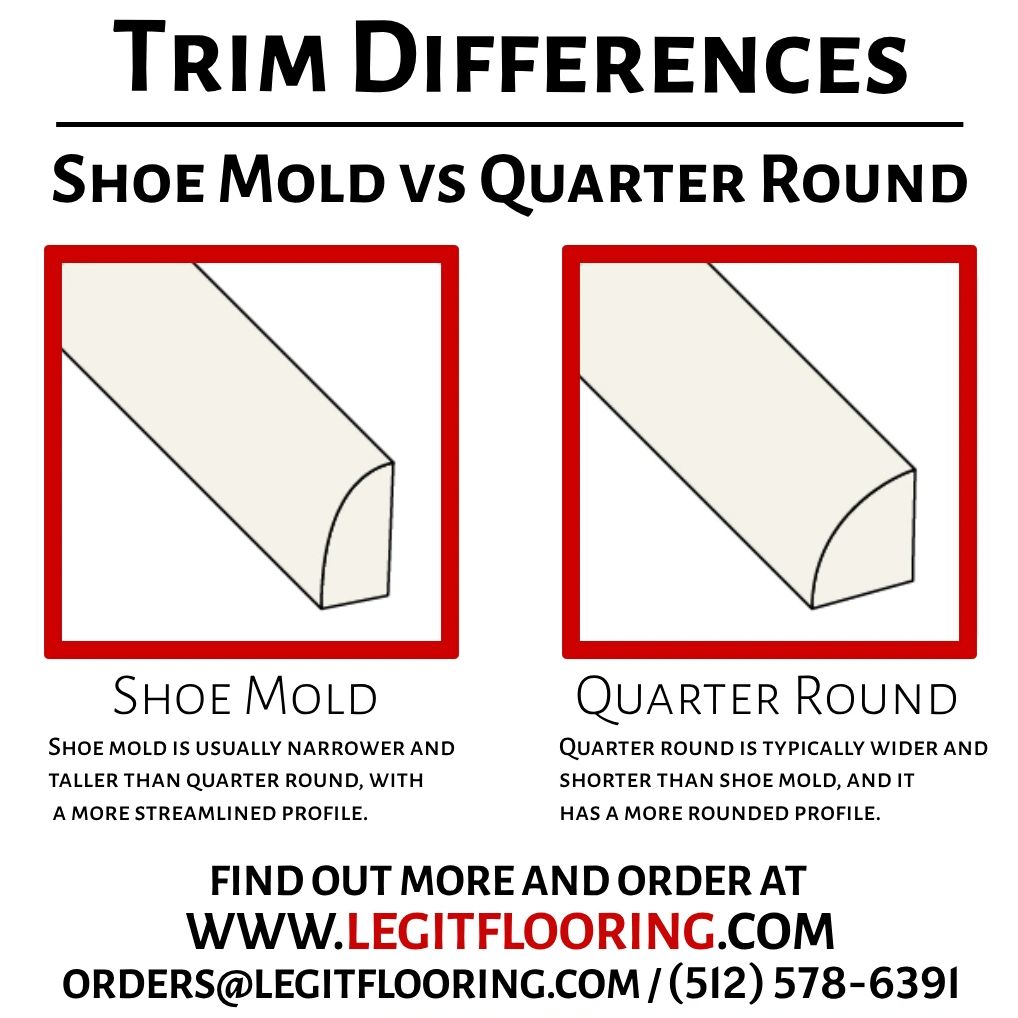

In today’s competitive global construction and interior finishing markets, understanding the nuances between shoe molding and quarter round is essential for international B2B buyers aiming to optimize project outcomes and procurement strategies. These trim profiles, while seemingly similar, serve distinct aesthetic and functional purposes, influencing both design flexibility and cost-efficiency. As sourcing decisions directly impact project timelines, material quality, and overall budget, mastering the complexities of these products is critical for buyers across Africa, South America, the Middle East, and Europe—including regions like Spain and Indonesia.

This comprehensive guide offers a strategic overview of the key differences, including types, materials, manufacturing standards, and quality assurance practices. It also provides actionable insights into sourcing reliable suppliers, evaluating cost considerations, and navigating market dynamics in diverse regions. Whether you’re seeking sustainable options, bulk procurement solutions, or local manufacturing options, this resource empowers you to make informed, confident decisions aligned with your project requirements and regional specifications.

By understanding market trends, supplier capabilities, and quality benchmarks, B2B buyers can mitigate risks, enhance supply chain resilience, and capitalize on emerging opportunities in the global shoe molding and quarter round markets. This guide is designed to equip you with the knowledge needed to navigate international trade complexities and secure the best value for your investments.

Understanding shoe molding vs quarter round Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Shoe Molding | Slightly taller profile, often 3/4″ to 1″ in height, with a rounded or beveled top edge | Interior finishing in residential and commercial spaces | Pros: Classic aesthetic, versatile for various decor styles. Cons: Slightly more expensive; requires precise installation. |

| Quarter Round | Rounded, quarter-circle profile, typically 1/4″ radius or height | Covering gaps between baseboards and flooring, especially in renovation projects | Pros: Cost-effective, easy to install, hides minor imperfections. Cons: Less decorative, may require additional finishing. |

| Cove Molding | Curved, concave profile with smooth, flowing lines | Modern interiors, transitional spaces, decorative accents | Pros: Elegant, adds architectural interest. Cons: More complex to install, higher material costs. |

| Bullnose Molding | Rounded, convex profile, often with a larger radius | Commercial settings, high-traffic areas, where durability is key | Pros: Durable, hides uneven cuts well. Cons: Heavier, may be more costly to source. |

| Custom/Architectural Profiles | Unique, bespoke shapes tailored to specific design needs | High-end projects, bespoke interiors, or historic restorations | Pros: Highly customizable, enhances aesthetic appeal. Cons: Higher lead times and costs, complex installation. |

Characteristics, Suitability, and B2B Purchasing Considerations

Traditional Shoe Molding

This classic profile typically measures around 3/4″ to 1″ in height with a gentle, rounded or beveled top. Its versatility makes it suitable for a wide range of interior styles, from traditional to transitional. For B2B buyers, sourcing high-quality wood or composite materials ensures durability and ease of installation across large projects. Suppliers should offer a variety of finishes and profiles to meet diverse client demands. Bulk purchasing can reduce costs, but careful attention to material consistency and finish quality is essential to avoid costly rework or returns.

Quarter Round

The quarter round is characterized by its simple, rounded profile with a 1/4″ radius, making it the most economical and straightforward to install. It is particularly effective in covering gaps between baseboards and flooring, especially during renovation projects where concealment of uneven cuts is necessary. B2B buyers should prioritize sourcing quarter rounds made from moisture-resistant materials or composites for high-humidity environments. Bulk orders benefit from standardized sizing and consistent quality, minimizing installation issues and customer complaints.

Cove Molding

Cove molding features a smooth, concave curve that adds a refined, flowing aesthetic to interior spaces. Its suitability extends to modern and transitional designs where subtle architectural details are desired. For wholesale buyers, selecting cove moldings with precise curvature and a variety of wood or MDF options is crucial. Due to its complex profile, installation may require skilled labor, and material costs are typically higher. Offering a range of sizes and finishes can help suppliers meet the nuanced needs of high-end projects.

Bullnose Molding

With its rounded, convex profile, bullnose molding is favored in commercial and high-traffic areas for its durability and ease of hiding imperfections. It provides a softer edge that reduces injury risks and enhances safety. B2B buyers should focus on sourcing robust, impact-resistant materials such as PVC or hardwood composites for longevity. Volume discounts are available for large commercial orders, but ensuring consistent radius and finish quality is vital to meet project specifications and reduce installation time.

Custom/Architectural Profiles

These bespoke moldings are designed for specific architectural or historical restoration projects, offering unique shapes and intricate detailing. They are ideal for high-end developments or renovation projects requiring precise aesthetic matching. For B2B buyers, establishing relationships with specialized manufacturers or artisans ensures access to custom options with reliable lead times. While costs are higher, offering customization can significantly differentiate a supplier’s portfolio and attract premium clients, provided quality control is maintained throughout the process.

This detailed understanding of the major types and variations enables international B2B buyers to optimize sourcing strategies, select suitable profiles for different project types, and negotiate effectively with manufacturers and distributors worldwide.

Key Industrial Applications of shoe molding vs quarter round

| Industry/Sector | Specific Application of shoe molding vs quarter round | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Interior Finishing | Finishing baseboards and wall-to-floor transitions in commercial and residential projects | Enhances aesthetic appeal, provides a clean finish, and covers gaps or imperfections | Material durability, ease of installation, availability in various sizes and finishes |

| Furniture Manufacturing | Edge finishing on cabinetry, shelving, and custom furniture pieces | Protects edges from damage, improves visual quality, and adds a polished look | Compatibility with different wood types, finish options, and supply lead times |

| Marine & Offshore | Covering gaps and transitions on boat interiors and decks | Resists moisture, reduces water ingress, and improves safety and aesthetics | Material resistance to water, UV stability, compliance with marine standards |

| Automotive & Transportation | Interior trim around floors and door panels | Provides a seamless appearance, protects wiring and panels, reduces noise | Material flexibility, fire retardancy, and sourcing from certified suppliers |

| Retail & Commercial Spaces | Decorative moldings around display units and flooring transitions | Creates a professional look, conceals uneven edges, and enhances brand presentation | Customization options, sourcing for bulk orders, and adherence to safety standards |

Construction & Interior Finishing

In the construction sector, shoe molding and quarter round are primarily used to finish baseboards and wall-to-floor transitions in both residential and commercial buildings. Shoe molding (larger, more prominent) is often chosen to add an elegant touch, while quarter round (smaller, rounded profile) is favored for its subtlety. For international B2B buyers, especially in regions like Europe and Indonesia, sourcing high-quality, durable materials that can withstand local climate conditions is critical. These moldings help hide gaps and imperfections, providing a clean, professional finish that enhances property value. Suppliers should prioritize materials with easy installation properties and a variety of finishes to match diverse interior styles.

Furniture Manufacturing

In the furniture industry, shoe molding and quarter round serve as edge bandings for cabinetry, shelving, and custom furniture. These moldings protect edges from chipping and damage while delivering a refined appearance. For buyers in South America and Africa, sourcing options that offer compatibility with various wood types and finishes is essential to meet diverse design requirements. Additionally, moldings that are easy to cut, install, and finish can reduce production time and costs. High-quality, consistent supply of these moldings ensures manufacturing efficiency and product longevity.

Marine & Offshore

Marine applications demand moldings that combine aesthetic appeal with resilience against harsh environmental conditions. Shoe molding and quarter round are used to cover gaps and transitions on boat interiors, decks, and cabins. For international buyers from the Middle East and Europe, sourcing marine-grade materials with excellent water resistance, UV stability, and compliance with marine safety standards is paramount. These moldings help prevent water ingress, reduce maintenance needs, and improve safety by eliminating tripping hazards. Suppliers should offer corrosion-resistant, moisture-proof options suitable for prolonged exposure to saltwater and sunlight.

Automotive & Transportation

In automotive and transportation sectors, moldings around floors, door panels, and interior trims serve both functional and aesthetic purposes. Shoe molding and quarter round are selected based on flexibility, ease of installation, and safety standards such as fire retardancy. For buyers in regions like Spain and Indonesia, sourcing moldings that can be custom-molded to fit complex geometries while maintaining durability under vibration and temperature fluctuations is vital. Reliable supply chains and materials that meet automotive industry certifications are critical to ensuring seamless integration into vehicle assembly lines.

Illustrative Image (Source: Google Search)

Retail & Commercial Spaces

Retail environments utilize shoe molding and quarter round to create polished, professional displays and seamless flooring transitions. These moldings help conceal uneven edges, gaps, and subfloor irregularities, enhancing visual appeal and safety. For international buyers, especially those sourcing for large-scale projects in Europe or South America, flexibility in customization—such as color, finish, and profile—is important. Sourcing from suppliers with the capacity for bulk orders, consistent quality, and compliance with safety standards ensures a smooth procurement process and a high-end finish that reflects brand quality.

Strategic Material Selection Guide for shoe molding vs quarter round

Material Considerations for Shoe Molding and Quarter Round

Selecting the appropriate material for shoe molding and quarter round is crucial for ensuring durability, aesthetic appeal, and compliance with regional standards. Different materials offer distinct advantages and limitations depending on environmental conditions, application requirements, and manufacturing considerations. For international B2B buyers, understanding these nuances can optimize procurement strategies, reduce costs, and improve product performance across diverse markets such as Africa, South America, the Middle East, and Europe.

Wood-Based Materials (Solid Hardwood and MDF)

Key Properties:

Solid hardwood (e.g., oak, maple, cherry) provides natural strength, stability, and a premium finish. MDF (Medium-Density Fiberboard) offers a smooth surface suitable for painting and molding, with consistent density and size. Both materials are sensitive to moisture and temperature fluctuations, which can cause warping or swelling.

Pros & Cons:

Hardwood is highly durable, aesthetically versatile, and suitable for high-end applications but tends to be costly and challenging to machine. MDF is more affordable, easier to work with, and offers excellent surface smoothness but is less resistant to moisture unless specially treated. Both materials require proper finishing to prevent moisture ingress, especially in humid regions.

Impact on Application:

Hardwood is ideal for regions with stable climates or where a natural wood finish is desired. MDF is better suited for interior applications in controlled environments, but it may require sealing in humid or variable climates to prevent swelling.

International Considerations:

Compliance with regional standards such as FSC (Forest Stewardship Council) certification in Europe or PEFC in South America can influence sourcing. Buyers from Africa and the Middle East should verify that imported wood materials meet local phytosanitary regulations. Additionally, European markets often favor sustainably sourced hardwood, while MDF must meet formaldehyde emission standards like CARB or E1.

PVC (Polyvinyl Chloride)

Key Properties:

PVC is a synthetic plastic material known for its excellent moisture resistance, chemical inertness, and ease of fabrication. It maintains its shape and color over a wide temperature range and resists corrosion and pests.

Pros & Cons:

PVC is cost-effective, lightweight, and requires minimal maintenance. It can be produced in various finishes and colors, making it versatile for different aesthetic preferences. However, it has lower structural strength compared to wood or metal and can become brittle over time under UV exposure unless stabilized with additives.

Impact on Application:

PVC is highly suitable for humid or wet environments, such as coastal regions in Africa or tropical climates in South America. It performs well in applications where moisture resistance is critical, but it may not provide the same premium look or feel as wood.

International Considerations:

PVC must comply with regional standards such as REACH in Europe or ASTM F963 in the US. Buyers should ensure that PVC products are free from hazardous phthalates and meet local environmental regulations. In regions with strict VOC emission standards, low-VOC formulations are preferred.

Aluminum

Key Properties:

Aluminum offers a lightweight, corrosion-resistant, and strong material option. It can be anodized or painted for enhanced durability and aesthetic appeal. Aluminum’s thermal expansion properties are well-understood, making it suitable for a range of climates.

Pros & Cons:

Aluminum provides excellent longevity, especially in outdoor or high-moisture environments, with minimal maintenance. It is more expensive than PVC or MDF and requires specialized manufacturing processes. Its recyclability aligns with sustainability goals, which are increasingly important globally.

Impact on Application:

Ideal for regions with high humidity, salt exposure (e.g., coastal Middle East or South America), or where long-term durability is essential. Aluminum can be fabricated into intricate profiles, offering design flexibility.

International Considerations:

Compliance with standards such as ASTM B221 or EN 573 is necessary. Buyers should verify that aluminum products are sourced from certified suppliers adhering to environmental and safety standards. Recycling and sustainability certifications can also influence purchasing decisions.

Summary Table of Material Options

| Material | Typical Use Case for shoe molding vs quarter round | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Wood (Hardwood & MDF) | Interior applications, premium finishes | Natural aesthetic, high durability (hardwood), smooth surface (MDF) | Susceptible to moisture, warping, higher cost for hardwood | Med-High |

| PVC | Wet areas, humid climates, interior applications | Moisture-resistant, low maintenance, cost-effective | Lower structural strength, UV degradation without stabilization | Low |

| Aluminum | Exterior, high-moisture, high-durability needs | Corrosion-resistant, lightweight, long-lasting | Higher initial cost, requires specialized fabrication | High |

| Steel (e.g., stainless or galvanized) | Industrial or high-strength applications | Excellent strength and corrosion resistance (stainless) | Heavier, more expensive, potential for rust if not properly coated | Med-High |

This comprehensive understanding of material properties and regional considerations enables international B2B buyers to make informed procurement decisions, ensuring product longevity, compliance, and cost efficiency tailored to specific market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for shoe molding vs quarter round

Manufacturing Processes for Shoe Molding and Quarter Round

The manufacturing of shoe molding and quarter round involves several critical stages, each demanding precision and quality control to meet international standards.

Material Preparation

Both products are predominantly made from wood (solid, engineered, or MDF), PVC, or composite materials. Material sourcing must adhere to sustainable and quality standards, especially for export markets. Suppliers often procure raw materials from certified vendors compliant with FSC or PEFC standards, ensuring environmental responsibility.

Forming and Profiling

Profiling is the core manufacturing process, typically achieved through extrusion (for PVC or composite materials) or molding techniques for wood-based products.

– PVC and Composite Profiles: Extrusion involves heating raw material to a molten state and forcing it through dies shaped precisely to the desired profile. This process allows high-volume production with consistent cross-sections.

– Wood-Based Profiles: Shaping wood involves CNC routing, molding, or sawing, often followed by surface smoothing techniques such as planing or sanding to achieve precise dimensions.

Assembly and Joining

For products with multiple components—such as layered or laminated shoe moldings—assembly might include gluing, nailing, or mechanical fastening. Adhesive selection (e.g., formaldehyde-free options) is critical for meeting environmental standards and ensuring product safety.

Finishing Processes

Finishing enhances appearance, durability, and resistance to environmental factors. Common finishing steps include:

– Sanding and surface smoothing

– Priming and coating (lacquer, paint, or UV coatings)

– Texturing or embossing for aesthetic appeal

– Applying protective sealants to prevent moisture ingress and physical wear

Advanced manufacturing facilities incorporate automation and robotics for consistency and efficiency, especially when producing large quantities for international markets.

Quality Control (QC) Standards and Practices

International and Industry-specific Standards

Manufacturers targeting global markets must comply with rigorous standards:

– ISO 9001: The foundational quality management system standard, ensuring consistent quality, process improvement, and customer satisfaction.

– CE Marking (Europe): Indicates compliance with EU safety, health, and environmental requirements.

– Other standards: API (American Petroleum Institute) for specific industrial applications, and regional standards like SASO (Saudi Standards) or IEC certifications for electrical components integrated into smart moldings.

QC Checkpoints and Methodologies

– Incoming Quality Control (IQC): Raw materials are inspected upon receipt for physical defects, dimensional accuracy, moisture content, or chemical composition (for PVC and composite materials).

– In-Process Quality Control (IPQC): During manufacturing, key parameters such as extrusion die temperature, profile dimensions, and surface quality are monitored regularly. Techniques include laser scanning, caliper measurements, and visual inspections.

– Final Quality Control (FQC): Finished products undergo comprehensive testing, including dimensional accuracy, surface finish, and adhesion tests for coatings. For wood-based products, moisture content and structural integrity are also verified.

Testing Methods

– Dimensional Tolerance Testing: Using coordinate measuring machines (CMM) or precision calipers to ensure profiles meet specified tolerances (typically ±0.2 mm).

– Surface Quality Inspection: Visual and tactile assessments, supplemented by microscopy or gloss meters for finish uniformity.

– Environmental Resistance Tests: Accelerated aging, UV exposure, and moisture tests to verify durability, especially for outdoor applications.

Third-party Inspections and Audits

B2B buyers should engage third-party inspection agencies—such as SGS, Bureau Veritas, or Intertek—to verify supplier quality claims. These audits assess manufacturing processes, review QC records, and verify compliance with contractual and regulatory standards.

QC Nuances for International B2B Buyers from Africa, South America, the Middle East, and Europe

Cultural and Regulatory Considerations

Buyers from diverse regions face varying regulatory landscapes:

– Europe (e.g., Spain): Strict compliance with REACH, RoHS, and CE standards necessitates thorough documentation and testing. Certification bodies often require detailed technical files and conformity assessments.

– Africa and South America: Regulatory frameworks vary; some countries may lack comprehensive standards. Buyers should prioritize suppliers with ISO 9001 certification and independent third-party testing reports to mitigate risks.

– Middle East: Emphasis on compliance with local standards like SASO or Gulf Standards. Suppliers should demonstrate adherence through certificates and test reports.

Verification Strategies

– Supplier Audits: Conduct on-site inspections focusing on QC processes, record-keeping, and material sourcing.

– Review of Quality Documentation: Request detailed QC reports, test certificates, and batch records.

– Sample Testing: Independently test samples received from suppliers in accredited laboratories to verify compliance with specifications.

Addressing Supply Chain Risks

International buyers should consider establishing long-term relationships with certified manufacturers who maintain transparent QC documentation. Implementing periodic audits and fostering open communication can help ensure ongoing compliance and quality consistency.

Summary of Best Practices for B2B Buyers

- Specify Clear Quality Standards: Incorporate relevant standards (ISO 9001, CE, etc.) into procurement contracts and specify acceptable tolerances and testing requirements.

- Engage in Pre-shipment Inspections: Use third-party inspectors for spot checks or full audits before shipment to ensure compliance.

- Demand Traceability Documentation: Require detailed material sourcing and production records to verify sustainable practices and quality integrity.

- Leverage Technology: Utilize digital platforms for QC reporting, real-time monitoring, and supplier audits, especially when managing multiple suppliers across regions.

- Build Strategic Partnerships: Develop long-term collaborations with reputable manufacturers committed to continuous improvement and compliance.

By understanding the detailed manufacturing stages and QC practices, international B2B buyers can make informed decisions, mitigate risks, and establish reliable supply chains for shoe molding and quarter round products across diverse markets.

Comprehensive Cost and Pricing Analysis for shoe molding vs quarter round Sourcing

Cost Structure Analysis: Shoe Molding vs Quarter Round

Understanding the comprehensive cost components involved in sourcing shoe molding and quarter round is vital for international buyers. Typically, the material costs constitute a significant portion, with options ranging from MDF, solid wood, PVC, to composite materials, each influencing pricing based on quality and durability. Labor costs vary substantially depending on manufacturing location—factories in Asia (e.g., Indonesia, China) often offer lower wages, while European or Middle Eastern suppliers may have higher labor costs but potentially better craftsmanship.

Manufacturing overhead includes factory utilities, equipment depreciation, and quality control expenses. These are generally embedded within the unit price but can differ based on production scale and efficiency. Tooling costs are crucial for custom profiles or sizes; initial investment can be high but amortized over larger orders, reducing unit costs. Quality assurance (QC) processes, including certifications such as FSC or ISO, add to costs but are essential for markets demanding high standards, especially in Europe.

Logistics and shipping represent a significant variable influenced by distance, mode (air vs sea), and Incoterms. FOB (Free on Board) or CIF (Cost, Insurance, Freight) terms impact who bears transportation costs and risks. Margins are typically negotiated based on volume, supplier relationship, and market conditions, with larger orders generally securing better pricing.

Price Influencers and Market Dynamics

- Order Volume & MOQ: Larger volume orders reduce unit costs through economies of scale. Many suppliers offer tiered pricing, incentivizing bulk purchases—particularly advantageous for buyers in Africa, South America, or the Middle East seeking cost efficiency.

- Customization & Specifications: Custom profiles or higher-grade materials increase costs due to specialized tooling and quality requirements. Standard quarter round profiles are cheaper but less versatile than custom shoe molding.

- Material Selection: PVC-based options tend to be cheaper and more moisture-resistant, suitable for humid climates, while hardwood or MDF options may command premium prices for aesthetic or durability reasons.

- Quality & Certifications: Suppliers with certifications (e.g., FSC, CARB compliance) often charge a premium, but this can be a competitive advantage, especially in European markets with strict standards.

Strategic Buyer Tips for Cost Optimization

- Negotiate Volume Discounts & Long-term Contracts: Establishing ongoing relationships can unlock better prices and priority production slots.

- Evaluate Total Cost of Ownership (TCO): Consider not just unit price but also durability, maintenance, and installation costs. For example, PVC might be cheaper upfront but less durable than hardwood, impacting long-term expenses.

- Leverage Incoterm Choices: FOB terms often lower initial costs but shift logistics responsibility to the buyer. CIF might simplify import processes but can be more expensive.

- Request Detailed Cost Breakdowns & Samples: Transparency helps identify hidden costs and ensures product quality aligns with market standards, especially critical when sourcing from regions with variable manufacturing capabilities.

- Consider Lead Times & Flexibility: Longer lead times might reduce costs but impact project timelines. Flexibility in order quantities can also influence pricing.

Indicative Price Range (as of 2023)

- Standard Quarter Round: USD 0.50 – 1.50 per linear foot

- Standard Shoe Molding: USD 1.00 – 3.00 per linear foot

-

Premium or Custom Profiles: USD 3.00+ per linear foot

-

Note:* Prices vary significantly based on material, volume, customization, and supplier location. Always request detailed quotes and compare multiple sources to ensure the best value.

In summary, international B2B buyers should focus on balancing initial costs with long-term value, negotiating effectively, and understanding the nuanced influences on pricing. A strategic approach to sourcing—considering all cost components and market factors—can lead to significant savings and better market positioning.

Spotlight on Potential shoe molding vs quarter round Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for shoe molding vs quarter round.)*

Essential Technical Properties and Trade Terminology for shoe molding vs quarter round

Essential Technical Properties for Shoe Molding and Quarter Round

Understanding key technical specifications is crucial for B2B buyers when sourcing shoe molding and quarter round. These properties directly impact product quality, compatibility, and overall project success.

Material Grade:

The most common materials are hardwood (e.g., oak, maple), softwood (e.g., pine), or MDF. Higher-grade materials typically offer better durability and finish quality. For commercial or high-traffic applications, premium grades reduce the risk of warping or damage over time.

Profile Dimensions:

Accurate measurements of width, height, and length are essential. Shoe molding typically features a taller profile (around 0.5-1 inch), while quarter rounds are smaller (approximately 0.5 inch diameter). Precise dimensions ensure proper fit and seamless integration with existing flooring or wall structures.

Tolerance Levels:

Tolerance refers to allowable variation in dimensions during manufacturing. Tight tolerances (e.g., ±0.1 mm) are preferred for consistent quality and ease of installation, especially across large orders. Variations beyond specified tolerances can lead to gaps, misalignments, or the need for additional adjustments.

Finish Quality:

Surface smoothness, paintability, and coating durability are vital. A high-quality finish minimizes the need for additional sanding or finishing at the site, saving time and costs. For international buyers, understanding the finishing standards helps ensure the product meets local aesthetic and durability expectations.

Moisture Content:

Properly kiln-dried wood with controlled moisture levels (typically 6-8%) prevents warping, twisting, or cracking after installation. This is particularly important in regions with high humidity, such as parts of Africa, South America, or Southeast Asia.

Durability and Resistance Properties:

Depending on environmental exposure, some products may require treatments for resistance to pests, decay, or moisture. For example, treated wood can withstand humid climates, extending the lifespan of the molding.

Industry and Trade Terms for Shoe Molding and Quarter Round

Familiarity with common trade terminology enhances communication and negotiation efficiency in international markets.

OEM (Original Equipment Manufacturer):

Refers to manufacturers producing moldings under a brand or specification provided by the buyer. Understanding OEM capabilities helps buyers assess production flexibility, branding options, and quality control.

MOQ (Minimum Order Quantity):

The smallest quantity a supplier is willing to produce or sell. For custom moldings, MOQs can range from small batches to large container loads. Clarifying MOQs early avoids supply chain delays and helps plan procurement budgets.

RFQ (Request for Quotation):

A formal document sent to suppliers requesting price quotes, lead times, and terms for specific products. An RFQ ensures competitive pricing and clear communication of technical specifications.

Incoterms (International Commercial Terms):

Standardized trade terms defining responsibilities for shipping, insurance, and customs duties. Common Incoterms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) help clarify cost responsibilities between buyer and seller in cross-border transactions.

Lead Time:

The period from order placement to product delivery. Accurate lead time estimates are critical for project planning, especially when coordinating with multiple suppliers or managing tight schedules.

Cutting and Finishing Tolerances:

Specifications regarding the precision of cuts and surface finishes. Tight tolerances reduce the need for rework and ensure seamless installation, especially important for high-end or architectural projects.

B2B Insights for International Buyers

For buyers across Africa, South America, the Middle East, and Europe, understanding these technical and trade terms ensures effective communication, quality assurance, and cost control. Prioritize suppliers who clearly specify material grades, tolerances, and finishing standards aligned with your regional needs. Leverage trade terms like RFQ and Incoterms to streamline procurement and minimize misunderstandings. Recognizing MOQ and lead times helps in planning logistics, especially when dealing with large or custom orders. By mastering these properties and terms, buyers can make informed decisions that enhance project quality and foster long-term supplier relationships.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the shoe molding vs quarter round Sector

Market Overview & Key Trends

The global shoe molding and quarter round sectors are experiencing dynamic shifts driven by evolving construction standards, technological innovations, and shifting consumer preferences. Increasing urbanization, especially in emerging markets across Africa, South America, and parts of Asia, fuels demand for efficient, durable, and aesthetically versatile finishing solutions. European markets, led by countries like Spain, are emphasizing premium, customizable options that meet stringent building codes and sustainability standards.

Emerging B2B sourcing trends include the integration of digital platforms and supply chain transparency tools, enabling buyers from diverse regions to access real-time product data, certifications, and supplier credentials. E-commerce platforms and online marketplaces facilitate streamlined procurement processes, especially critical for buyers in geographically dispersed markets like Indonesia or Brazil.

Illustrative Image (Source: Google Search)

Technological advancements such as CNC machining, automated finishing, and eco-friendly adhesives are enhancing product consistency and quality. Additionally, the shift toward modular and lightweight profiles aligns with modern construction and renovation needs, making products more adaptable to varied architectural styles.

Market dynamics are also shaped by fluctuating raw material costs, geopolitical trade policies, and tariffs. For instance, sourcing from regions with favorable trade agreements or lower tariffs—such as certain African or South American manufacturing hubs—can offer competitive advantages. Conversely, increased tariffs or import restrictions in Europe or the Middle East may necessitate strategic sourcing adjustments, including local manufacturing or diversified supply chains.

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, understanding these trends enables proactive sourcing strategies. Emphasizing suppliers with digital transparency, innovation capacity, and sustainable practices can mitigate risks and capitalize on emerging opportunities in the shoe molding and quarter round markets.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a critical criterion in sourcing decisions within the shoe molding and quarter round sectors. Environmentally conscious buyers prioritize products made from responsibly sourced materials that minimize ecological impact throughout their lifecycle. For example, choosing wood-based profiles from FSC-certified forests or recycled composite materials can significantly reduce deforestation and waste.

The environmental footprint of manufacturing processes—such as the use of low-VOC adhesives, water-based finishes, and energy-efficient production methods—is increasingly scrutinized by importers and consumers alike. Certification schemes like LEED, Green Seal, or ISO 14001 serve as valuable indicators of a supplier’s commitment to sustainability and ethical practices.

Ethical sourcing extends beyond environmental considerations to encompass fair labor practices, transparent supply chains, and social responsibility. Suppliers adhering to fair trade standards and providing traceability reports help mitigate risks associated with unethical labor practices, which can lead to reputational damage and legal complications.

For B2B buyers, engaging with suppliers who possess recognized environmental certifications and demonstrate a clear commitment to ethical practices is essential. Incorporating ‘green’ certifications into procurement criteria can also provide a competitive edge, especially in markets with stringent sustainability regulations or consumer preferences, such as Europe or parts of South America. Investing in sustainable sourcing not only aligns with global environmental goals but also enhances brand reputation and long-term supply chain resilience.

Brief Evolution/History

The shoe molding and quarter round sectors have evolved significantly over the past century, transitioning from simple, locally produced wood profiles to sophisticated, engineered solutions. Initially driven by basic carpentry needs, the industry has embraced technological innovations like CNC machining, composite materials, and eco-friendly manufacturing processes. This evolution has been shaped by changing architectural styles, stricter building codes, and increasing environmental awareness.

In recent decades, globalization has expanded sourcing options, allowing international buyers to access a broader array of materials and manufacturers. The rise of digital platforms has further transformed procurement, enabling real-time communication, certifications verification, and streamlined supply chain management.

Understanding this historical trajectory is vital for B2B buyers seeking to navigate current market complexities. Recognizing the shift toward sustainable, technologically advanced, and customizable profiles can inform strategic sourcing decisions, helping buyers leverage innovations while aligning with evolving industry standards.

Frequently Asked Questions (FAQs) for B2B Buyers of shoe molding vs quarter round

1. How can I verify the reliability and quality standards of shoe molding and quarter round suppliers internationally?

Ensuring supplier reliability involves thorough vetting processes. Start by requesting certifications such as ISO 9001, FSC, or other relevant quality standards. Review their product samples and request third-party inspection reports when possible. Conduct virtual factory audits or visit suppliers if feasible, especially in regions like Indonesia or Spain. Engage with existing clients or industry networks for references. A supplier’s responsiveness and transparency during negotiations are also indicators of reliability. Establish clear quality benchmarks in your contracts and include provisions for third-party QA inspections before shipment to mitigate risks.

2. What are the key factors to consider when customizing shoe molding or quarter round for international markets?

Customization factors depend on regional preferences, building codes, and usage requirements. Consider dimensions, finishes, and materials compatible with local construction standards. For instance, some markets favor water-resistant or eco-friendly materials, especially in humid climates like Southeast Asia or the Middle East. Communicate your specifications clearly, including tolerances and packaging needs. Verify if the supplier offers in-house customization or partners with local finishing facilities. Additionally, ensure they can handle sample approval processes efficiently to avoid delays and meet your project timelines.

3. What are typical minimum order quantities (MOQs) and lead times for international shipments of shoe molding and quarter round?

MOQs vary widely based on supplier capacity and product complexity, ranging from 1,000 to 10,000 units or more. For smaller projects or trial orders, negotiate for lower MOQs, but expect higher unit costs. Lead times typically range from 4 to 12 weeks, depending on production complexity and destination logistics. Factors influencing lead times include manufacturing capacity, customs clearance, and shipping method (air vs. sea). Planning ahead and establishing long-term supplier relationships can help secure better terms, flexible MOQs, and consistent delivery schedules aligned with your project timelines.

4. How do I evaluate and ensure compliance with international standards and certifications for these products?

Start by identifying the specific standards relevant to your target markets—such as CE marking in Europe or local fire safety regulations in South America. Request suppliers’ certification documentation and verify their validity through official bodies. Incorporate compliance checks into your quality assurance process, including third-party testing when necessary. Consider working with suppliers experienced in exporting to your region, as they are more likely to be familiar with local standards. Regular audits and sampling can help ensure ongoing compliance, reducing the risk of product rejection or legal issues in your markets.

5. What logistics considerations should I be aware of when importing shoe molding or quarter round internationally?

Key considerations include choosing between air or sea freight, with sea freight generally being more cost-effective for large volumes but slower. Factor in customs procedures, tariffs, and import duties specific to your country—Spain, Indonesia, or others—as these impact overall costs. Work with experienced freight forwarders familiar with your destination region to optimize routing and documentation. Packaging must protect products during transit, especially for long shipments. Establish clear lead times and contingency plans for delays, customs holds, or unforeseen disruptions. Collaborate closely with logistics providers to ensure smooth clearance and timely delivery.

6. How should I handle quality assurance and product certifications during international trade?

Implement a multi-tiered QA process that includes pre-shipment inspections, random sampling, and testing against agreed standards. Engage third-party inspection agencies with regional expertise, especially for shipments to Africa or South America, where local standards may differ. Require suppliers to provide test reports, certificates of compliance, and material safety data sheets (MSDS) as applicable. Incorporate quality clauses into your contracts, including penalties for non-conformance. Regular communication and site visits (if possible) help maintain quality standards and build supplier accountability, reducing the risk of costly rejections or delays.

7. What dispute resolution mechanisms are effective for international B2B transactions involving shoe molding and quarter round?

Establish clear contractual clauses specifying dispute resolution methods, such as arbitration or mediation, preferably under internationally recognized frameworks like ICC or UNCITRAL. Specify the jurisdiction and language for resolving disputes—consider neutral venues like Singapore or Switzerland for impartiality. Incorporate escalation procedures and detailed documentation requirements to facilitate transparent resolution. Engage legal counsel familiar with international trade laws and regional regulations. Building strong communication channels and maintaining detailed records throughout the transaction can prevent misunderstandings and expedite dispute resolution processes.

8. What are best practices for building long-term relationships with international suppliers in this industry?

Develop mutual trust through consistent communication, prompt payments, and transparent negotiations. Invest in understanding your supplier’s capabilities, constraints, and cultural nuances—especially important in regions like the Middle East or South America. Establish clear expectations regarding quality, lead times, and pricing, and revisit these regularly through performance reviews. Consider establishing partnership agreements or long-term contracts that incentivize supplier loyalty and stability. Attending industry trade shows and maintaining regular visits or virtual check-ins can foster stronger relationships, leading to better pricing, priority production, and collaborative problem-solving.

Strategic Sourcing Conclusion and Outlook for shoe molding vs quarter round

Final Insights and Future Outlook

Effective strategic sourcing is crucial for international buyers aiming to optimize costs, quality, and supply chain resilience in the shoe molding and quarter round markets. Understanding regional manufacturing strengths, supplier capabilities, and logistical considerations enables more informed procurement decisions—especially for buyers from Africa, South America, the Middle East, and Europe.

Illustrative Image (Source: Google Search)

By prioritizing supplier diversity and building strong relationships with reliable manufacturers, buyers can mitigate risks associated with geopolitical shifts, tariffs, or supply disruptions. Additionally, staying attuned to emerging trends—such as eco-friendly materials and innovative manufacturing techniques—will provide a competitive edge.

Looking ahead, the demand for high-quality, customizable molding solutions is expected to grow globally. Buyers should leverage digital sourcing platforms, attend international trade shows, and foster strategic partnerships to access a broader supplier network. Proactive, data-driven sourcing strategies will position buyers to capitalize on market opportunities, ensure sustainable supply chains, and achieve long-term cost efficiencies.

Act now—embrace strategic sourcing as a core business practice to secure a resilient, innovative supply chain that meets evolving global market demands.