Your Ultimate Guide to Sourcing Shoes That Make You Taller

Guide to Shoes That Make You Taller

- Introduction: Navigating the Global Market for shoes that make you taller

- Understanding shoes that make you taller Types and Variations

- Key Industrial Applications of shoes that make you taller

- Strategic Material Selection Guide for shoes that make you taller

- In-depth Look: Manufacturing Processes and Quality Assurance for shoes that make you taller

- Comprehensive Cost and Pricing Analysis for shoes that make you taller Sourcing

- Spotlight on Potential shoes that make you taller Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for shoes that make you taller

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the shoes that make you taller Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of shoes that make you taller

- Strategic Sourcing Conclusion and Outlook for shoes that make you taller

Introduction: Navigating the Global Market for shoes that make you taller

In today’s competitive global marketplace, footwear that enhances stature—commonly known as “height-increasing shoes”—has emerged as a significant niche with substantial commercial potential. For international B2B buyers, understanding the nuances of this specialized segment is crucial to capitalize on rising demand across diverse markets, especially in regions like Africa, South America, the Middle East, and Europe, including key manufacturing hubs such as Turkey and Spain.

This comprehensive guide offers vital insights into the entire supply chain—covering product types, materials, manufacturing processes, quality control, and sourcing strategies. It aims to equip buyers with the knowledge needed to identify reliable suppliers, evaluate costs, and navigate regulatory considerations effectively. Whether sourcing discreet elevator shoes, platform sneakers, or custom-designed height-enhancing footwear, buyers will find actionable advice to optimize procurement and mitigate risks.

By delving into market trends, consumer preferences, and supplier landscapes, this guide empowers B2B buyers to make informed, strategic decisions. It emphasizes the importance of quality assurance, sustainable sourcing, and cost management, ensuring that buyers can meet the rising global demand with confidence. Ultimately, this resource supports buyers in unlocking new growth opportunities in a specialized yet expanding footwear segment, fostering resilient international partnerships and competitive advantage.

Understanding shoes that make you taller Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Elevated Platform Shoes | Thick sole with uniform height, often with added heel lift | Fashion retail, specialty boutiques, online stores | Pros: High visual impact, broad style options. Cons: Bulkier, higher manufacturing costs. |

| Hidden Lift Shoes | Discreet lifts integrated within the shoe structure | Custom footwear, discreet height enhancement | Pros: Subtle appearance, versatile for various markets. Cons: Complex manufacturing, quality control challenges. |

| Elevator Shoes | Shoes designed with internal lifts, often with formal or casual styles | Formalwear, corporate gifting, luxury markets | Pros: Natural look, high customer satisfaction. Cons: Slightly higher price point, need for precise sizing. |

| Customizable Height Shoes | Adjustable lifts or removable inserts for personalized height | Niche markets, bespoke orders, promotional items | Pros: Flexibility for different needs, high customization. Cons: Inventory complexity, longer lead times. |

| Athletic Height Shoes | Sport-oriented shoes with added height features | Sportswear brands, active lifestyle markets | Pros: Combines function with height, appeals to active consumers. Cons: Design constraints, higher R&D costs. |

Elevated Platform Shoes

Elevated platform shoes feature a thick, uniform sole that can significantly increase height. They are popular in fashion-forward segments and are often available in various styles, from casual to avant-garde. For B2B buyers, these shoes are ideal for retail outlets targeting trend-conscious consumers or specialty boutiques. The main considerations include manufacturing complexity and higher costs due to the bulkier design. Quality control is critical to ensure stability and comfort, especially for mass production.

Hidden Lift Shoes

Hidden lift shoes incorporate discreet internal lifts or insoles that elevate the wearer without altering the shoe’s external appearance. This variation is suitable for markets demanding subtlety, such as professional settings or discreet enhancement needs. B2B buyers should evaluate the quality of internal lifts, as poor integration can compromise comfort and durability. They are ideal for online or custom orders where discretion is paramount, but manufacturing complexity and quality assurance are key considerations.

Elevator Shoes

Designed with internal lifts that are seamlessly integrated, elevator shoes offer a natural appearance while providing height benefits. They are popular in formalwear and luxury markets, making them suitable for corporate gifting or high-end retail. These shoes require precise craftsmanship and sizing accuracy, which can influence production costs. B2B buyers should focus on establishing reliable supply chains for quality materials and skilled artisans to meet customer expectations.

Customizable Height Shoes

This category includes shoes with removable or adjustable lifts, allowing consumers to personalize their height incrementally. They serve niche markets such as promotional events, bespoke fashion, or specialized clientele. For B2B buyers, offering customization can be a competitive advantage but demands flexible inventory management and longer lead times. Ensuring consistent quality across different configurations is essential to maintain brand reputation and customer satisfaction.

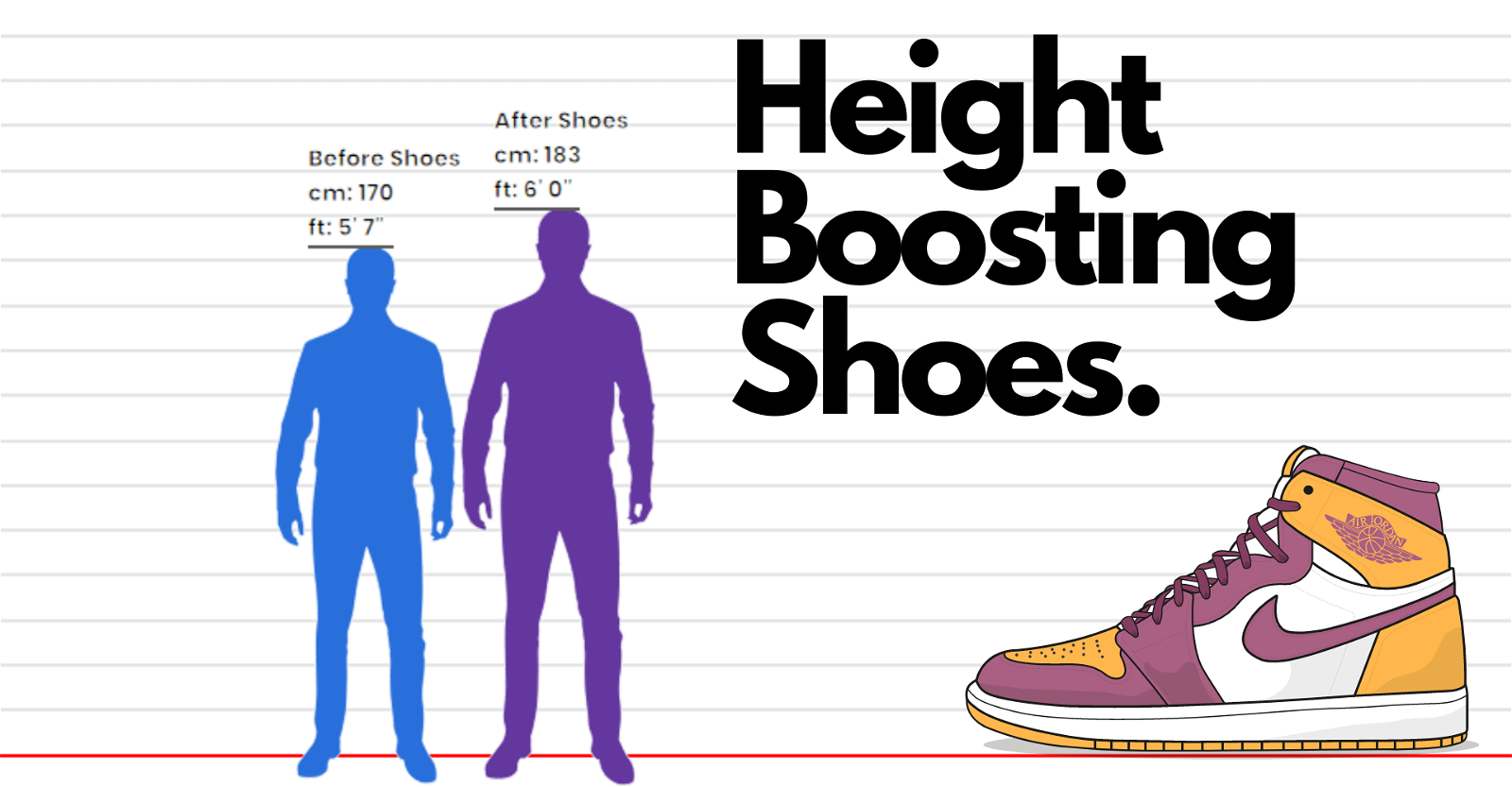

Illustrative Image (Source: Google Search)

Athletic Height Shoes

Blending sports performance with height enhancement, these shoes are engineered for active consumers who seek both functionality and increased stature. They are suitable for sportswear brands expanding into height-enhancing footwear or active lifestyle markets. Design and R&D costs are higher due to the need for durability, comfort, and performance standards. B2B buyers should consider partnerships with innovative manufacturers capable of balancing athletic features with discreet height-increasing elements to meet market demands effectively.

Key Industrial Applications of shoes that make you taller

| Industry/Sector | Specific Application of shoes that make you taller | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Apparel | Customizable height-enhancing footwear for luxury and casual markets | Differentiates product offerings, attracts niche markets, increases sales | Material quality, comfort, durability, and aesthetic versatility |

| Hospitality & Tourism | Height-boosting shoes for staff uniforms in upscale hotels and resorts | Enhances staff appearance, boosts brand image, improves guest perception | Comfort for long shifts, slip resistance, ease of cleaning |

| Sports & Fitness | Elevation-enhancing shoes for athletes and fitness enthusiasts | Improves performance perception, offers competitive edge, boosts confidence | Lightweight construction, stability, impact absorption |

| Corporate & Professional | Formal shoes with discreet height increase for executives and professionals | Supports confidence and authority, discreet for professional settings | Subtle design, comfort, quality craftsmanship |

| Security & Law Enforcement | Discreet height-enhancing footwear for personnel in security roles | Enhances presence and authority, discreet for operational needs | Durability, comfort, discreet design, slip resistance |

Fashion & Apparel

In the fashion industry, height-enhancing shoes serve as a premium accessory that allows brands to offer customizable and stylish options to consumers seeking subtle height boosts. B2B buyers from regions like Europe and Turkey can source innovative, high-quality materials that combine aesthetics with comfort. These shoes help brands differentiate in a competitive market, appealing to luxury and niche segments, especially where fashion-forward consumers value both style and discreet height enhancement. Ensuring the shoes are durable and versatile for various fashion lines is critical for sustained success.

Hospitality & Tourism

Upscale hotels and resorts increasingly adopt height-boosting shoes for their staff uniforms to project a more commanding and polished appearance. For international B2B buyers in Africa and South America, sourcing comfortable, slip-resistant footwear that maintains a professional look is vital. These shoes enhance the staff’s stature subtly, contributing to a more authoritative presence without compromising comfort during long shifts. Proper sourcing involves ensuring materials withstand frequent cleaning and wear, aligning with hospitality standards.

Sports & Fitness

In the sports and fitness sectors, height-enhancing shoes are gaining popularity among athletes and enthusiasts aiming to improve their perceived performance and confidence. B2B buyers from Europe and the Middle East can focus on sourcing lightweight, impact-absorbing shoes that provide discreet elevation while maintaining stability. These shoes must meet rigorous safety standards, be breathable, and cater to active lifestyles, making quality and performance-critical factors in sourcing decisions.

Corporate & Professional

For professionals and executives, discreet height-increasing shoes offer a strategic advantage by boosting confidence and authority subtly. B2B buyers in regions like Spain and Turkey should prioritize sourcing high-quality, comfortable formal shoes that incorporate subtle lifts without compromising style or comfort. These shoes are often used in corporate settings, where appearance impacts perception. Discretion, craftsmanship, and comfort are key sourcing considerations, ensuring the shoes align with professional standards.

Security & Law Enforcement

In security roles, height can influence authority and presence. Discreet height-enhancing footwear allows personnel to appear taller without obvious modifications, which is crucial for operational discretion. B2B buyers in the Middle East and Africa should focus on sourcing durable, slip-resistant shoes that withstand tough environments while providing comfort for extended wear. The design must balance discreetness with functionality, ensuring personnel can perform their duties effectively without discomfort or compromise.

Strategic Material Selection Guide for shoes that make you taller

Material Analysis for Shoes that Make You Taller

Selecting the appropriate materials for shoes designed to increase height requires a comprehensive understanding of their physical properties, manufacturing implications, and compliance standards across different regions. Here, we analyze four common materials—leather, EVA foam, thermoplastic polyurethane (TPU), and carbon fiber—focusing on their suitability for taller shoes from a B2B perspective.

Leather

Key Properties:

Leather remains a traditional choice for high-quality footwear due to its durability, breathability, and aesthetic appeal. It offers moderate flexibility, good abrasion resistance, and natural moisture-wicking properties, making it suitable for the upper parts of shoes. However, for height-increasing insoles or lifts, the material’s properties are less critical.

Pros & Cons:

Leather’s main advantage is its durability and premium feel, which appeals to high-end markets across Europe, the Middle East, and South America. It is also biodegradable and can meet various environmental standards. Conversely, leather production involves significant resource consumption, and sourcing quality leather can be costly. Manufacturing requires skilled labor, and the material’s weight can influence overall shoe comfort.

Impact on Application:

Leather performs well in environments requiring breathability and aesthetic appeal but is less suitable for insoles or structural lifts that demand high flexibility or specific mechanical properties.

International Buyer Considerations:

European and Middle Eastern markets favor high-quality, ethically sourced leather, often requiring compliance with REACH or other environmental standards. African and South American buyers may prioritize cost-effective, locally available leather options, but still expect adherence to quality standards like ASTM or ISO. Transparency in sourcing and eco-labeling can enhance market acceptance.

EVA Foam

Key Properties:

EVA (ethylene-vinyl acetate) foam is lightweight, flexible, and shock-absorbent, making it ideal for insoles or lifts in taller shoes. It exhibits excellent energy return and cushioning, with moderate resistance to temperature variations.

Pros & Cons:

EVA is cost-effective and easy to mold, enabling rapid manufacturing of custom height-increasing components. Its lightweight nature enhances overall comfort, especially important in regions with hot climates like the Middle East or tropical Africa. However, EVA can degrade over time under UV exposure or extreme heat, leading to reduced durability. It also tends to compress with prolonged use, potentially affecting height-increasing effectiveness.

Impact on Application:

EVA’s ease of molding makes it suitable for mass production of lifts and insoles, especially in markets demanding affordability and quick turnaround. Its chemical compatibility is broad, but suppliers must ensure the foam’s stability in different environmental conditions.

International Buyer Considerations:

Buyers in Europe and South America often require compliance with REACH and other safety standards for foam materials. In Africa and the Middle East, cost and supply chain stability are critical, with a preference for suppliers offering consistent quality at competitive prices. Proper labeling and testing for off-gassing are essential to meet regulatory requirements.

Thermoplastic Polyurethane (TPU)

Key Properties:

TPU is a versatile, durable polymer known for excellent abrasion resistance, elasticity, and chemical stability. It can be formulated to provide high flexibility, making it suitable for structural components or flexible lifts within shoes.

Pros & Cons:

TPU offers high durability and resistance to oils, greases, and UV light, making it suitable for outdoor and industrial environments. It can be injection-molded into complex shapes, facilitating innovative design features. However, TPU’s higher material cost and more complex manufacturing process can increase production expenses. Its stiffness varies depending on formulation, impacting comfort.

Impact on Application:

TPU is ideal for reinforcing structural elements or creating custom-height lifts that require longevity and resistance to environmental factors. It performs well in regions with high temperature fluctuations, such as Europe and parts of the Middle East.

International Buyer Considerations:

Buyers in Europe and Turkey often demand high-performance, eco-friendly TPU formulations aligned with strict environmental standards like REACH or RoHS. In emerging markets, cost considerations might favor alternative materials unless the added durability justifies the investment.

Carbon Fiber

Key Properties:

Carbon fiber is a high-strength, lightweight composite material with excellent stiffness and fatigue resistance. It provides significant height increase with minimal added weight, making it highly desirable for premium footwear.

Pros & Cons:

The primary advantage is its exceptional strength-to-weight ratio, enabling discreet height enhancement without compromising comfort. It is highly resistant to environmental factors such as moisture and temperature extremes. However, carbon fiber is expensive, and manufacturing requires specialized equipment and expertise, which can elevate costs substantially. It is also brittle under certain impacts, requiring careful design considerations.

Impact on Application:

Ideal for high-end, custom, or performance-oriented shoes where durability and aesthetics are paramount. Its use in mass-market shoes is limited by cost but can appeal to luxury segments across Europe and the Middle East.

International Buyer Considerations:

Buyers seeking premium, innovative products must ensure suppliers adhere to strict quality controls and environmental regulations. Import tariffs and logistical complexities related to carbon fiber components should be factored into procurement strategies, especially in regions with complex import policies.

Summary Table

| Material | Typical Use Case for shoes that make you taller | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather | Upper material, aesthetic, premium shoes | Durability, aesthetic appeal | Costly, resource-intensive, heavier | Med |

| EVA Foam | Insoles, lifts, cushioning components | Lightweight, cost-effective, shock absorption | Degrades over time under UV/heat, compresses | Low |

| Thermoplastic Polyurethane (TPU) | Structural reinforcements, flexible lifts, overlays | High durability, chemical stability | Higher cost, manufacturing complexity | Med |

| Carbon Fiber | Discreet height-increasing inserts, premium lifts | High strength-to-weight ratio, longevity | Very high cost, specialized manufacturing | High |

This detailed analysis enables B2B buyers across diverse regions to make informed decisions aligned with their market demands, manufacturing capabilities, and compliance requirements. Selecting the right material is crucial for balancing performance, cost, and regional standards to succeed in the competitive footwear industry.

In-depth Look: Manufacturing Processes and Quality Assurance for shoes that make you taller

Manufacturing Processes for Taller Shoes

The production of shoes designed to increase height involves meticulous manufacturing processes, often requiring specialized techniques to ensure both functionality and comfort. The process typically unfolds in four main stages: material preparation, forming, assembly, and finishing.

Material Preparation

High-quality materials are foundational. For taller shoes, manufacturers often select lightweight yet durable materials such as EVA foam, polyurethane, or thermoplastic elastomers for internal lifts, combined with premium leathers, textiles, or synthetics for the outer shell. Material sourcing should adhere to international standards like ISO 9001 to ensure consistency and safety. Suppliers from regions like Turkey and Spain often have established networks for sourcing compliant raw materials.

Forming

This stage involves shaping the shoe components. Injection molding, thermoforming, and CNC machining are common techniques used to produce the internal lifts and structural components. For taller shoes, the internal height-increasing elements are precisely molded to ensure uniformity and integration with the shoe’s outer shell. Advanced CAD/CAM software is frequently employed for design accuracy, especially when customizing height increments.

Assembly

Assembly integrates the various components—upper, midsole, insole, internal lifts, and outsole—into a cohesive product. Automated and semi-automated assembly lines enhance precision and efficiency. Special attention is given to bonding internal lifts securely within the shoe, often through adhesives complying with international standards such as ISO 9001, or through mechanical fastening techniques. Seam sealing, reinforcement, and quality checks during assembly prevent defects and ensure durability.

Finishing

The final steps include surface treatment, coloring, polishing, and quality checks. Finishing ensures aesthetic appeal and functional integrity. For footwear intended to make users taller, precise measurement of internal height and overall shoe dimensions is critical. The finishing process also involves applying protective coatings or waterproofing, especially for outdoor-use models.

Quality Assurance Protocols for Taller Shoe Manufacturing

Quality assurance (QA) in the production of height-enhancing shoes is vital to meet international safety, comfort, and durability standards. B2B buyers should pay close attention to the quality management systems and testing protocols employed by suppliers.

International Standards and Certifications

– ISO 9001: The cornerstone for quality management systems, ensuring consistent product quality and process control. Most reputable manufacturers, especially in Turkey, Spain, and other European countries, maintain ISO 9001 certification.

– CE Marking (European Economic Area): Indicates compliance with EU safety, health, and environmental requirements, critical for footwear exported to Europe.

– API (American Petroleum Institute): Relevant if the shoes incorporate specific synthetic materials requiring certification for safety and quality.

Quality Control Checkpoints

– Incoming Quality Control (IQC): Raw materials and components are inspected upon arrival. Checks include dimensional accuracy, material integrity, and compliance with specifications.

– In-Process Quality Control (IPQC): Continuous monitoring during manufacturing. Techniques include visual inspections, dimensional checks, and functional testing of internal lifts and structural elements.

– Final Quality Control (FQC): Thorough inspection of finished shoes before packaging. Tests include visual examination, dimensional verification, and functional assessments of height-increasing features.

Common Testing Methods

– Dimensional Measurement: Ensures the internal lift height and overall shoe dimensions meet specifications.

– Adhesion Tests: Verify the strength of bonds between internal lifts and outer shells, crucial for durability.

– Drop and Wear Tests: Simulate real-world conditions to assess durability under stress and repeated use.

– Comfort and Fit Testing: Includes ergonomic assessments and pressure distribution analysis to prevent discomfort or injuries.

Third-Party Inspections and Audits

B2B buyers should consider engaging third-party inspection agencies such as SGS, Bureau Veritas, or Intertek to verify supplier quality claims. These audits assess manufacturing practices, review QC documentation, and conduct on-site inspections. Regular audits help mitigate risks, especially when dealing with suppliers in emerging markets like Africa and South America, where QC standards may vary.

Tailoring QC for International B2B Buyers

When sourcing taller shoes internationally, buyers from Africa, South America, the Middle East, and Europe face unique challenges and opportunities in quality assurance:

-

Regional Standards Compatibility: Buyers should verify that products comply with local regulations such as the EU’s REACH regulations or South American safety standards. For example, European buyers must ensure CE conformity, while Middle Eastern markets may require GCC compliance.

-

Supplier Certifications and Documentation: Require suppliers to provide comprehensive QC reports, test certificates, and ISO 9001 certifications. Transparent documentation facilitates compliance verification and simplifies customs clearance.

-

Sampling and Batch Testing: Implement strict sampling protocols for each batch, including destructive and non-destructive testing. Consider third-party testing for critical parameters like adhesion strength and dimensional accuracy.

-

On-Site Audits and Continuous Improvement

Conduct periodic audits to assess manufacturing practices and enforce quality standards. Establish clear communication channels with suppliers for continuous improvement based on audit findings. -

Customization and Flexibility

Given regional preferences and market demands, work with suppliers capable of customizing internal lift heights, materials, and finishes. Ensure that QC processes accommodate these variations without compromising quality.

Final Recommendations for B2B Buyers

- Vet Suppliers Rigorously: Prioritize manufacturers with proven ISO 9001 certification, relevant regional certifications, and a track record of producing height-increasing footwear.

- Engage in Transparent Communication: Clearly specify quality expectations, testing requirements, and documentation standards upfront.

- Leverage Technology: Use digital tools like quality management software and virtual audits to streamline supplier assessments.

- Build Long-Term Partnerships: Collaborate with suppliers committed to continuous improvement and compliance, reducing risks and ensuring consistent quality over time.

By understanding and implementing rigorous manufacturing and quality assurance protocols, B2B buyers from diverse regions can secure reliable suppliers capable of delivering high-quality, safe, and compliant shoes that make users taller.

Comprehensive Cost and Pricing Analysis for shoes that make you taller Sourcing

Cost Structure Breakdown for Taller Shoes Sourcing

Understanding the comprehensive cost structure is vital for international buyers seeking the best value. The primary cost components include:

-

Materials: High-quality insoles, supportive midsoles, durable outer materials (leather, synthetic, or innovative composites), and height-enhancing inserts. Material costs vary significantly based on quality, sourcing region, and customization needs. Premium materials can increase unit costs but may justify higher retail prices and better margins.

-

Labor: Manufacturing labor costs differ widely across regions. Countries like Turkey and certain Eastern European nations offer competitive wages with skilled craftsmanship, while Asian suppliers may offer lower rates due to economies of scale. For African and South American suppliers, wages are often moderate, but quality standards may influence costs.

-

Manufacturing Overhead: Includes equipment, factory utilities, and maintenance. Efficient factories with modern machinery can reduce overhead costs, but initial investments may be higher.

-

Tooling & Molds: Custom molds for unique designs or sizing require upfront investment. For small MOQ orders, tooling costs are amortized over fewer units, increasing per-unit price. Larger volumes reduce per-unit tooling costs, offering economies of scale.

-

Quality Control & Certifications: International standards like ISO, CE, or ASTM certification can add to costs but are essential for market acceptance, especially in Europe and the Middle East. Rigorous QC ensures product consistency, reducing returns and reputation risks.

-

Logistics & Shipping: Shipping costs are influenced by order volume, destination, shipping mode (air or sea), and Incoterms. For African and South American buyers, sea freight is often more economical but slower, while European and Middle Eastern buyers may opt for faster air freight for smaller, urgent orders.

-

Margins & Markup: Suppliers typically add a markup to cover risks and profit. Margins vary based on order volume, supplier relationship, and product complexity. Negotiating favorable terms can significantly impact final prices.

Price Influencers and Market Dynamics

Several factors influence the final FOB (Free On Board) or CIF (Cost, Insurance, Freight) prices:

-

Order Volume & MOQ: Larger orders benefit from bulk discounts, reducing per-unit costs. Buyers should negotiate for flexible MOQ terms, especially if they plan to test new markets.

-

Customization & Specifications: Unique designs, branding, or specialized height-increasing features increase costs due to additional tooling, materials, and QC requirements. Standard models tend to be more cost-effective.

-

Materials & Quality Levels: Higher-grade materials and certifications (e.g., eco-friendly, vegan) elevate costs but can open premium market segments. Buyers should align material choices with target markets’ expectations and regulatory standards.

-

Supplier Factors: Established suppliers with reliable quality, certifications, and capacity may command higher prices but offer better consistency. Newer or smaller manufacturers might offer lower prices but with increased risks.

-

Incoterms & Delivery Terms: FOB terms favor buyers to control logistics, but CIF or DDP may be preferred for ease. Shipping costs and import duties vary widely, impacting total landed cost.

Strategic Tips for International B2B Buyers

-

Negotiate Bulk & Long-term Contracts: Leverage volume commitments to obtain better pricing, especially for recurring orders. Establishing ongoing relationships can lead to preferential terms and priority production.

-

Focus on Total Cost of Ownership (TCO): Beyond unit price, consider import duties, taxes, shipping, customs clearance, and after-sales support. A slightly higher unit cost might be offset by lower logistics or certification expenses.

-

Understand Pricing Nuances: Prices may fluctuate due to raw material costs, currency exchange rates, or geopolitical factors. Maintain open communication with suppliers to anticipate and mitigate cost increases.

-

Leverage Local Expertise: Engage local agents or sourcing agents familiar with regional suppliers to negotiate effectively and navigate logistical complexities.

-

Sample & Pilot Orders: Always request samples before large commitments to verify quality and fit. Pilot runs help identify potential cost overruns or quality issues early.

Disclaimer

Indicative prices for ‘shoes that make you taller’ can range broadly, typically from $15 to $50 per pair FOB depending on volume, complexity, and quality standards. Final prices are highly dependent on specific product features, supplier negotiations, and logistical arrangements. Buyers should conduct detailed quotes and consider all associated costs to accurately assess their total investment.

By meticulously analyzing these factors and employing strategic negotiation, international buyers from Africa, South America, the Middle East, and Europe can optimize their sourcing costs and maximize profitability in the taller shoe market.

Spotlight on Potential shoes that make you taller Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for shoes that make you taller.)*

Essential Technical Properties and Trade Terminology for shoes that make you taller

Essential Technical Properties for Shoes That Make You Taller

Understanding the technical specifications of shoes designed to increase height is crucial for effective sourcing and quality assurance. Here are key properties to consider:

1. Material Grade and Composition

High-quality materials directly influence durability, comfort, and safety. Common materials include genuine leather, synthetic leather, or specialized textiles. For height-increasing shoes, the inner lifts or insoles often use dense foam or thermoplastic elastomers (TPE). A superior material grade ensures the shoe maintains structural integrity over prolonged use and meets safety standards, especially when used in different climates prevalent in Africa, South America, the Middle East, or Europe.

2. Lift/Heel Height Tolerance

The precise measurement of added height—whether through insoles or elevated soles—is critical. Tolerance levels (e.g., ±1mm) specify how accurately the manufacturer can produce the intended height. Consistency in height ensures customer satisfaction and reduces return rates. For B2B buyers, confirming tolerances helps in assessing manufacturing quality and meeting market expectations.

3. Flexibility and Comfort Ratings

Shoes that make users taller must balance height enhancement with comfort. Flexibility is measured through bend tests, indicating how well the shoe adapts to foot movement. Comfort ratings often derive from shock absorption capacity and arch support. Proper flexibility and comfort are essential for user satisfaction, especially for daily wear.

4. Weight and Balance Specifications

Lighter shoes reduce fatigue, especially when worn for extended periods. The weight distribution, particularly around the lift area, impacts stability and gait. Precise specifications on weight and balance are vital for ensuring the shoes do not compromise posture or cause discomfort, which is a concern across diverse markets.

5. Durability and Wear Resistance

Given the varying terrains across target regions, shoes must withstand different environmental conditions. Specifications such as abrasion resistance, sole wear, and water resistance are critical. Durable shoes reduce replacement frequency, providing better value for bulk buyers and retailers.

Key Industry and Trade Terms for Shoes That Make You Taller

Familiarity with common trade terminology enhances communication and negotiation efficiency in international markets:

1. OEM (Original Equipment Manufacturer)

Refers to manufacturers producing shoes under a buyer’s brand name. Engaging with OEMs allows buyers to customize designs, materials, and features, ensuring the product aligns with regional market preferences and branding strategies.

2. MOQ (Minimum Order Quantity)

The smallest quantity of shoes a manufacturer is willing to produce per order. Understanding MOQ helps buyers plan procurement volumes, negotiate better pricing, and manage inventory effectively, especially when entering new markets like Africa or South America.

3. RFQ (Request for Quotation)

A formal request sent by buyers to manufacturers asking for pricing, lead times, and terms for specific shoe models. An RFQ facilitates clear communication of product specifications and helps compare suppliers across different regions.

4. Incoterms (International Commercial Terms)

Standardized trade terms published by the International Chamber of Commerce, defining responsibilities for shipping, insurance, and tariffs. Common Incoterms like FOB (Free on Board) or CIF (Cost, Insurance & Freight) clarify costs and risks, vital for international transactions involving complex logistics.

5. Lead Time

The duration from order placement to shipment readiness. Accurate knowledge of lead times helps buyers plan inventory and avoid stockouts, especially in regions with logistical challenges or customs delays.

6. Quality Assurance (QA) and Testing Standards

Protocols and tests to verify product quality, such as ASTM standards or ISO certifications. Ensuring products meet regional safety and quality standards minimizes compliance issues and enhances market acceptance.

By understanding these technical properties and trade terms, international B2B buyers can make informed decisions, negotiate effectively, and establish reliable supply chains for shoes that make users taller across diverse markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the shoes that make you taller Sector

Market Overview & Key Trends

The global market for shoes that make you taller is experiencing dynamic shifts driven by evolving consumer preferences, technological advancements, and supply chain innovations. Increasing urbanization and a growing desire for elevated aesthetics are fueling demand across diverse regions, especially in emerging markets such as Africa and South America, alongside established markets in Europe and the Middle East.

Technological integration, including 3D printing and advanced manufacturing techniques, is enabling manufacturers to produce more customized, lightweight, and durable products efficiently. Moreover, digital platforms and B2B e-commerce are transforming sourcing practices, allowing buyers from Africa, Turkey, Spain, and beyond to access a broader range of suppliers with greater transparency and competitive pricing.

Emerging sourcing trends include a shift towards nearshoring and regional manufacturing hubs to reduce lead times and mitigate geopolitical risks. Countries like Turkey and Spain are becoming pivotal sourcing centers due to their well-developed footwear industries, skilled labor, and strategic proximity to European and Middle Eastern markets. Meanwhile, Africa and South America are gaining traction as cost-effective sourcing destinations, especially for eco-friendly and ethically produced components.

Illustrative Image (Source: Google Search)

Market dynamics are also influenced by increasing consumer awareness around quality and sustainability. Buyers are now prioritizing suppliers who can meet stringent environmental standards and adhere to fair labor practices. The integration of smart manufacturing and traceability technologies is helping to meet these demands, fostering trust and compliance in international trade relationships.

Sustainability & Ethical Sourcing in the Sector

Sustainability has become a critical factor in sourcing shoes that make you taller, with a growing emphasis on environmental impact and ethical practices. This sector’s environmental footprint primarily stems from material production, manufacturing processes, and transportation. Eco-conscious buyers from Africa, South America, and Europe are demanding transparency about supply chains and the adoption of sustainable materials.

Certifications such as Global Organic Textile Standard (GOTS), Forest Stewardship Council (FSC), and Bluesign are gaining prominence among B2B buyers seeking verified sustainable practices. These certifications ensure that materials like recycled plastics, natural fibers, and eco-friendly adhesives are used, reducing the ecological footprint of the final product.

In addition to raw materials, ethical sourcing encompasses fair labor practices, safe working conditions, and community engagement. Manufacturers who can demonstrate compliance with standards like SA8000 or Fair Trade are better positioned to secure long-term contracts with international buyers. Incorporating ‘green’ materials such as biodegradable insoles, plant-based dyes, and low-impact manufacturing processes not only aligns with global sustainability goals but also enhances brand reputation in competitive markets.

Investing in transparent supply chains and sustainability reporting can provide a significant competitive advantage, especially as consumers and regulators increasingly scrutinize environmental and social credentials. B2B buyers should prioritize partnerships with suppliers committed to continuous improvement and certification compliance, ensuring both ecological responsibility and social integrity.

Brief Evolution/History (Optional)

The footwear industry’s evolution towards sustainability and innovation has been shaped by rising consumer awareness and regulatory pressures over the past two decades. Initially driven by fashion trends, the sector gradually integrated eco-friendly practices as environmental concerns gained prominence globally. The adoption of recycled and biodegradable materials, along with automation and digital tracking, marked key milestones.

For the ‘shoes that make you taller’ niche, this evolution has been influenced by technological breakthroughs enabling lightweight and customizable designs while reducing waste. As sustainability standards tighten, manufacturers are increasingly embedding eco-conscious principles into their core operations, making responsible sourcing a baseline requirement rather than an option. This historical shift underscores the importance for international B2B buyers to align with forward-thinking suppliers who are committed to innovation and sustainability, ensuring resilience and competitiveness in a rapidly changing market landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of shoes that make you taller

1. How can I verify the credibility and reliability of international suppliers for taller shoes?

To ensure supplier credibility, conduct thorough due diligence by requesting comprehensive company documentation, including business licenses, export licenses, and certifications. Check for industry reputation through trade associations, online reviews, and references from other buyers. Request samples to assess product quality firsthand. Additionally, consider visiting supplier facilities if feasible or engaging third-party inspection services before committing. Establish clear communication channels and verify their responsiveness. Partnering with reputable sourcing platforms or trade shows can also help identify verified manufacturers with proven track records in producing high-quality taller shoes.

2. What customization options are typically available for taller shoes, and how do these impact lead times and costs?

Most suppliers offer customization in areas such as height increments, design, materials, and branding. Customization can include varying the internal lift height, sole design, and aesthetic features like logos or colors. Keep in mind that extensive customization usually increases lead times—often by 2-6 weeks—and can raise unit costs due to tooling and design adjustments. To optimize costs and timelines, specify your requirements clearly upfront and negotiate minimum order quantities (MOQs). Working with suppliers experienced in OEM/ODM services can streamline the process and ensure your specifications are met efficiently.

3. What are typical MOQs, lead times, and payment terms for importing taller shoes?

MOQ requirements vary widely but generally range from 300 to 1,000 pairs per style, especially for customized products. Lead times are typically 4-8 weeks from order confirmation, depending on complexity and production capacity. Common payment terms include 30% upfront as a deposit, with the remaining balance payable before shipment or upon receipt of goods. Some suppliers may offer flexible terms for repeat orders or larger volumes. Establish clear agreements on payment conditions, and consider using secure payment methods like letters of credit or escrow services to mitigate risks.

4. What quality assurance measures and certifications should I look for in tall shoe suppliers?

Ensure suppliers adhere to recognized quality standards such as ISO 9001 or BSCI certifications, which demonstrate compliance with quality management and social responsibility. Request detailed quality control procedures, including in-process inspections, pre-shipment testing, and third-party audits. Ask for test reports on materials used, including sole durability, internal lifts, and overall safety. Certifications related to footwear safety, such as CE marking (for European markets), can also be crucial. Regular QC checks and transparent documentation help mitigate risks of defective products reaching your market.

5. How can I manage logistics effectively when importing taller shoes to my country?

Coordinate with suppliers to determine the most suitable shipping methods—air freight for urgent deliveries or sea freight for larger volumes at lower costs. Clarify Incoterms (e.g., FOB, CIF) to define responsibilities and costs associated with shipping, customs clearance, and insurance. Work with experienced freight forwarders familiar with your destination country’s import regulations to avoid delays and additional costs. Maintain clear communication and tracking throughout transit. Additionally, consider warehousing options near your market to facilitate faster distribution and inventory management.

6. What common disputes might arise, and how can I protect myself during international transactions?

Disputes often relate to product quality, delivery delays, payment issues, or intellectual property rights. To mitigate these risks, draft clear contracts specifying product specifications, inspection rights, delivery timelines, and dispute resolution procedures—preferably through arbitration clauses in neutral jurisdictions. Use escrow or letter of credit payments to secure transactions. Regular communication and documented agreements help prevent misunderstandings. Engaging legal experts familiar with international trade laws can further protect your interests and provide guidance on enforcing contracts if disputes occur.

7. How do cultural and language differences impact international sourcing, and how can I overcome them?

Cultural differences can affect communication styles, negotiation approaches, and expectations. Language barriers may lead to misunderstandings about specifications or terms. To overcome these challenges, employ bilingual staff or professional translators during negotiations. Establish clear, written agreements in mutually understood languages. Build relationships through regular, respectful communication and consider visiting supplier facilities when possible. Leveraging local agents or partners with regional expertise can also facilitate smoother interactions and ensure alignment on quality, timelines, and business practices.

8. What are key considerations for ensuring compliance with import regulations and standards in my target market?

Research your country’s import regulations, tariffs, and standards for footwear, including safety, labeling, and environmental requirements. Ensure suppliers provide necessary documentation such as certificates of origin, safety test reports, and compliance labels. Stay updated on changes in trade policies or import duties that could impact costs. Working with customs brokers or compliance consultants can streamline clearance processes. Regularly audit your supply chain to verify ongoing compliance, and establish procedures for handling non-compliance issues to avoid legal penalties or shipment delays.

Illustrative Image (Source: Google Search)

Strategic Sourcing Conclusion and Outlook for shoes that make you taller

Conclusion and Future Outlook

Effective strategic sourcing is paramount for international buyers seeking to capitalize on the growing demand for shoes that enhance height. By establishing strong relationships with reliable manufacturers—particularly in key sourcing hubs like Turkey, Spain, and emerging markets across Africa and South America—buyers can secure high-quality products at competitive prices while maintaining supply chain resilience. Emphasizing due diligence, quality control, and supplier diversification can mitigate risks and foster long-term partnerships.

Looking ahead, the footwear industry for height-enhancing shoes is poised for innovation driven by technological advances and evolving consumer preferences. Buyers should stay attuned to emerging trends such as sustainable materials and customization options, which can differentiate their offerings in competitive markets.

Actionable Takeaway:

International B2B buyers from Africa, South America, the Middle East, and Europe are encouraged to leverage local industry insights, foster strategic alliances, and continuously optimize sourcing strategies. Doing so will not only secure a competitive edge but also position them as leaders in this niche market. Embracing a proactive, strategic approach today ensures sustainable growth and market relevance tomorrow.