Your Ultimate Guide to Sourcing Way Of Wade Basketball Shoes

Guide to Way Of Wade Basketball Shoes

- Introduction: Navigating the Global Market for way of wade basketball shoes

- Understanding way of wade basketball shoes Types and Variations

- Key Industrial Applications of way of wade basketball shoes

- Strategic Material Selection Guide for way of wade basketball shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for way of wade basketball shoes

- Comprehensive Cost and Pricing Analysis for way of wade basketball shoes Sourcing

- Spotlight on Potential way of wade basketball shoes Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for way of wade basketball shoes

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the way of wade basketball shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of way of wade basketball shoes

- Strategic Sourcing Conclusion and Outlook for way of wade basketball shoes

Introduction: Navigating the Global Market for way of wade basketball shoes

In the highly competitive landscape of basketball footwear, Way of Wade shoes have established themselves as a premium brand synonymous with innovation, style, and performance. For international B2B buyers—especially from Africa, South America, the Middle East, and Europe—understanding the nuances of this brand is crucial to unlocking profitable sourcing opportunities. With increasing global demand for authentic, high-quality basketball sneakers, sourcing the right products at optimal costs can significantly impact your market positioning and customer satisfaction.

This comprehensive guide is designed to empower you with actionable insights into the types of Way of Wade shoes, their material composition, manufacturing and quality control standards, and reliable supplier networks. It also covers critical aspects such as cost structures, market dynamics, and answers common FAQs to facilitate informed decision-making. Whether you are looking to import for retail, wholesale, or private label purposes, understanding these elements will enable you to navigate complex supply chains confidently.

By leveraging this guide, B2B buyers from diverse regions can identify authentic suppliers, evaluate product quality, and optimize costs—ultimately ensuring competitive advantage in local markets. Navigating the global market requires strategic sourcing, and this resource equips you with the knowledge to make well-informed, sustainable purchasing decisions that align with your business goals.

Illustrative Image (Source: Google Search)

Understanding way of wade basketball shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Signature Series Models | Customized designs aligned with Wade’s signature style, high-end materials | Retailers targeting premium markets, sports specialty stores | High brand appeal and exclusivity; higher procurement costs but strong consumer demand. |

| Performance/Pro Models | Engineered for athletic performance, lightweight, enhanced grip | Sports stores, athletic outlets, bulk sports programs | Offer superior performance; may require bulk purchasing commitments. Higher R&D investment. |

| Lifestyle/Casual Variants | Fashion-forward, versatile designs, often with trendy aesthetics | Fashion boutiques, casual footwear retailers | Broader appeal beyond athletes; lower technical specs but higher market versatility. |

| Limited Edition Releases | Special collaborations, unique colorways, limited quantities | Collector shops, high-end boutiques, online exclusives | Drive exclusivity and premium pricing; limited stock can impact consistent supply. |

| Youth/Junior Lines | Smaller sizes, vibrant designs, targeted at younger demographics | Youth sports stores, school sports programs | Tap into emerging markets; lower price points but require smaller inventory management. |

Signature Series Models

Signature series Way of Wade shoes are the pinnacle of brand collaboration, featuring Wade’s personal design inputs and premium materials. These models appeal to high-end consumers seeking exclusivity, making them ideal for specialty sports stores and boutiques targeting affluent customers. B2B buyers should consider higher procurement costs balanced by strong brand loyalty and margins. Limited editions within this line can further boost exclusivity, but require careful inventory planning to avoid overstocking.

Performance/Pro Models

Designed with athletes in mind, these models emphasize advanced cushioning, lightweight construction, and superior grip. They are suitable for sports stores, especially those catering to professional or semi-professional teams. These shoes typically involve higher R&D costs and longer lead times for development, but they command premium prices due to their technical features. Bulk purchasing agreements can help mitigate costs, and consistent quality assurance is crucial for maintaining brand reputation.

Lifestyle/Casual Variants

Lifestyle versions of Way of Wade shoes blend athletic aesthetics with streetwear trends, broadening appeal beyond athletes to fashion-conscious consumers. Retailers in fashion boutiques and casual footwear markets should focus on trendy colorways and collaborations that resonate with local tastes. These models generally have lower technical specifications, but their versatility can lead to higher sales volumes. B2B buyers should evaluate market demand for trendy footwear and consider flexible inventory strategies.

Limited Edition Releases

Limited editions are often released in collaboration with artists or for special events, featuring unique colorways and designs. These are highly attractive to collectors and high-end consumers, offering premium pricing opportunities. However, their limited nature requires precise inventory management and marketing to maximize sales. B2B buyers should establish strong relationships with distributors and monitor demand trends to avoid excess stock or missed sales opportunities.

Youth/Junior Lines

Targeted at younger demographics, these lines feature smaller sizes and vibrant, playful designs. They are suitable for youth sports stores, school programs, and emerging markets in Africa, South America, the Middle East, and Europe. Price sensitivity is key; bulk purchasing can reduce unit costs, but inventory turnover must be managed carefully to prevent obsolescence. These lines offer growth potential by cultivating brand loyalty early among younger consumers.

Key Industrial Applications of way of wade basketball shoes

| Industry/Sector | Specific Application of way of wade basketball shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Sports & Athletic Retail | Custom branded basketball shoes for team sponsorships and retail sales | Enhances brand visibility and consumer engagement; boosts sales through exclusive designs | Quality assurance, brand customization capabilities, reliable supply chain |

| Footwear Manufacturing | OEM production of basketball shoes for global brands | Cost-effective manufacturing with high-performance standards; access to innovative designs | Compliance with international standards, flexible MOQ, quality control processes |

| Sports Facility & Equipment Suppliers | Durable footwear for sports academies, gyms, and training centers | Provides athletes with reliable, high-performance shoes; reduces injury risk | Material durability, comfort, and supply consistency to meet high-volume demands |

| Medical & Rehabilitation | Therapeutic footwear for sports injury recovery | Supports injury prevention and rehabilitation; offers specialized cushioning | Material safety, compliance with health standards, customization options |

| Logistics & Distribution | Bulk procurement for international distribution | Cost savings through bulk purchasing; ensures consistent product availability | Competitive pricing, reliable logistics, and certification for international trade |

Sports & Athletic Retail

Way of Wade basketball shoes are highly sought after in the sports retail sector, especially for branding collaborations and exclusive collections. International B2B buyers from Africa, South America, the Middle East, and Europe can leverage these shoes to enhance their product offerings, attracting basketball enthusiasts and athletes. Custom branding and limited editions can significantly boost retail margins and consumer loyalty. Buyers should focus on sourcing from suppliers with proven quality assurance, flexible customization options, and reliable logistics to meet seasonal demand spikes.

Footwear Manufacturing

Manufacturers engaged in OEM or ODM production can incorporate Way of Wade shoes into their portfolios, especially for private label brands targeting international markets. These shoes offer high-performance features suitable for competitive sports, making them attractive for global sportswear brands. For B2B buyers in regions like Turkey or Italy, ensuring strict quality control and compliance with international standards (e.g., ISO, REACH) is critical. Maintaining flexible minimum order quantities and establishing long-term supplier relationships can optimize production costs and lead times.

Sports Facility & Equipment Suppliers

Suppliers serving sports academies, gyms, and training centers in emerging markets can utilize Way of Wade basketball shoes to provide durable, high-performance footwear to athletes. These shoes help reduce injury risks and improve athletic performance, making them valuable for training programs. International buyers should prioritize sourcing shoes with proven durability, proper cushioning, and comfort. Establishing partnerships with manufacturers that can supply consistent inventory at competitive prices will support scalable distribution in regions with growing sports infrastructure.

Illustrative Image (Source: Google Search)

Medical & Rehabilitation

In the medical sector, Way of Wade shoes can be adapted for therapeutic purposes, especially for athletes recovering from injuries. Their advanced cushioning and support features aid in injury prevention and rehabilitation processes. B2B buyers in healthcare and sports medicine should focus on sourcing shoes that meet health and safety standards, offer customization for specific therapeutic needs, and provide consistent supply to clinics and rehabilitation centers globally.

Logistics & Distribution

Bulk procurement of Way of Wade basketball shoes for international distribution allows wholesalers and distributors to capitalize on rising demand in emerging markets. These shoes appeal to basketball fans and sports retailers seeking premium, recognizable brands. Key considerations include securing competitive pricing, reliable logistics networks, and certifications for international trade compliance. Establishing strong relationships with manufacturers ensures steady supply and the ability to meet regional demand fluctuations efficiently.

Strategic Material Selection Guide for way of wade basketball shoes

Material Analysis for Way of Wade Basketball Shoes

Selecting the appropriate materials for manufacturing Way of Wade basketball shoes is critical for ensuring optimal performance, durability, and cost-efficiency. For international B2B buyers from Africa, South America, the Middle East, and Europe, understanding the key properties, advantages, limitations, and regional considerations of common materials helps streamline procurement and compliance processes.

Synthetic Leather (PU and PVC)

Synthetic leather remains a popular choice for the upper part of basketball shoes due to its balance of cost and aesthetics. Polyurethane (PU) and polyvinyl chloride (PVC) are the primary variants.

- Key Properties: Both materials offer good flexibility, moderate breathability, and water resistance. PU tends to be softer and more pliable, while PVC is more rigid but highly resistant to chemicals and abrasion.

- Pros & Cons: PU provides a premium look with better flexibility, but it can be more expensive and less resistant to UV degradation over time. PVC is more affordable, highly durable, and easier to manufacture, but it may feel stiffer and less breathable.

- Impact on Application: Suitable for indoor and outdoor use, especially in environments with variable weather conditions. PVC’s chemical resistance makes it ideal for humid or salty climates.

- International Considerations: Buyers should verify compliance with regional standards such as REACH (Europe), ASTM F963 (US), or local regulations on phthalates and chemical safety. PU and PVC are generally accepted globally, but eco-labels and sustainability certifications are increasingly valued, especially in Europe.

Mesh Fabrics

Mesh is extensively used in the upper or lining of basketball shoes to enhance breathability and reduce weight.

- Key Properties: Lightweight, highly breathable, quick-drying, and flexible. Mesh materials vary from polyester to nylon blends.

- Pros & Cons: Mesh offers excellent ventilation, improving comfort during intense play. However, it can be less durable against abrasion and tearing, especially in high-stress areas.

- Impact on Application: Ideal for performance-focused shoes used in warm climates or indoor courts. Mesh’s permeability helps manage moisture and temperature.

- International Considerations: Mesh fabrics should meet standards like OEKO-TEX or ISO 9001 for quality assurance. Buyers in regions with strict import regulations should ensure the fabric is free from harmful dyes or chemicals, particularly for markets in Europe and the Middle East.

Rubber Outsoles

Rubber is the primary material for the outsole, providing grip, shock absorption, and durability.

- Key Properties: High wear resistance, excellent grip, and flexibility. Types include natural rubber, synthetic rubber, and thermoplastic elastomers.

- Pros & Cons: Natural rubber offers superior grip and resilience but can be more expensive and susceptible to temperature variations. Synthetic variants are more consistent in performance and cost-effective but may have slightly reduced grip.

- Impact on Application: Essential for outdoor courts and high-impact indoor play, where durability and traction are critical.

- International Considerations: Compliance with standards such as ASTM D2240 (hardness testing) and environmental regulations on volatile organic compounds (VOCs) is important. Buyers should verify supplier certifications to ensure consistent quality suitable for various climates.

Foam Padding and Midsole Materials

Foam is used in midsoles for cushioning and shock absorption, with EVA and polyurethane being the most common.

- Key Properties: Lightweight, resilient, and capable of absorbing impact. EVA offers flexibility and softness, while polyurethane provides higher durability and support.

- Pros & Cons: EVA is cost-effective and lightweight but can compress over time, reducing cushioning. Polyurethane is more durable and maintains cushioning longer but is heavier and more expensive.

- Impact on Application: Critical for player comfort and injury prevention, especially in high-impact zones.

- International Considerations: Material safety certifications such as ISO 9001 or environmental standards like REACH are vital. Buyers should also consider local preferences for cushioning firmness and durability.

Summary Table of Common Materials

| Material | Typical Use Case for Way of Wade Basketball Shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Synthetic Leather (PU/PVC) | Upper material providing durability and style | Cost-effective, water-resistant, customizable aesthetics | Less breathable (PVC), environmental concerns (PVC) | Med |

| Mesh Fabrics | Ventilation panels and linings | Excellent breathability, lightweight | Less durable against abrasion | Low |

| Rubber Outsoles | Traction and durability in outsole | Superior grip, wear resistance | Can be temperature-sensitive, more costly (natural rubber) | Med to High |

| Foam (EVA/Polyurethane) | Midsole cushioning and shock absorption | Lightweight, impact protection | Compression over time (EVA), heavier (PU) | Low to Med |

This comprehensive understanding of material properties and regional considerations enables B2B buyers to make informed procurement decisions, ensuring product quality, compliance, and market competitiveness across diverse international markets.

In-depth Look: Manufacturing Processes and Quality Assurance for way of wade basketball shoes

Manufacturing Processes of Way of Wade Basketball Shoes

The production of Way of Wade basketball shoes involves a series of meticulously managed stages, each critical to ensuring high-quality output. For B2B buyers, understanding these processes helps in assessing supplier capabilities and compliance with international standards.

Material Preparation

The process begins with sourcing premium raw materials, including synthetic leathers, mesh fabrics, rubber compounds, and specialized foams. Suppliers often leverage globally recognized material standards such as ISO 9001 to ensure consistency and quality. Advanced material testing—such as tensile strength, flexibility, and moisture resistance—is conducted before acceptance. B2B buyers should verify suppliers’ certifications and request detailed material datasheets and test reports, especially when importing to regions with strict safety standards like Europe or Turkey.

Forming and Molding

The upper components of the shoe are typically formed using cutting-edge computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies. Laser cutting and automated stitching are common to ensure precision and repeatability. Midsole and outsole components undergo injection molding or compression molding, often utilizing thermoplastic polyurethane (TPU) or rubber compounds. Suppliers employing advanced molding techniques can better control dimensional accuracy and material uniformity, which are critical for performance footwear.

Assembly

Assembly integrates the upper, midsole, and outsole through various bonding methods, including adhesive bonding, heat welding, or stitching, depending on the design specifications. Automated assembly lines enhance consistency, reduce defect rates, and improve productivity. During this phase, critical checks—such as fit, alignment, and bonding strength—are performed. B2B buyers should inquire about the automation level and quality control measures implemented during assembly to ensure uniformity across batches.

Finishing and Packaging

The finishing process includes quality detailing such as logo application, color consistency, and final cleaning. Surface treatments like polishing or coating may be applied to enhance aesthetics and durability. Packaging adheres to international shipping standards, often with custom branding options. Suppliers with integrated quality management systems ensure that each shoe meets specified tolerances before packaging, which minimizes returns and warranty claims.

Quality Assurance (QA) and Control Systems

Robust quality assurance is fundamental for maintaining brand reputation and compliance with international standards. For B2B buyers, especially from regions with rigorous import regulations, understanding the QA landscape is essential.

International Standards and Industry Certifications

- ISO 9001: Most reputable manufacturers adhere to ISO 9001 standards, emphasizing a quality management system (QMS) that covers all production aspects, from raw material procurement to final inspection. ISO 9001 certification signals a supplier’s commitment to consistent quality.

- CE Marking (Europe): Ensures compliance with health, safety, and environmental protection standards within the European Economic Area. Suppliers targeting European markets should possess CE certification, which involves rigorous testing and documentation.

- Other Certifications: Depending on the destination country, additional certifications such as SGS inspection reports, ASTM standards, or region-specific safety approvals (e.g., TUV, BSCI) may be relevant.

Quality Control Checkpoints

- Incoming Quality Control (IQC): Raw materials and components are inspected upon arrival using visual checks, dimensional measurements, and material testing to verify conformity with specifications.

- In-Process Quality Control (IPQC): Continuous inspection during manufacturing ensures that each stage adheres to quality standards. Techniques include dimensional verification, bond strength testing, and process monitoring via statistical process control (SPC).

- Final Quality Control (FQC): Before packaging, finished shoes undergo comprehensive inspection, including visual assessment, functional testing (e.g., sole adhesion, flexibility), and durability testing.

Testing Methods

- Mechanical Testing: Tensile, compression, and peel tests verify bonding strength and material resilience.

- Environmental Testing: Shoes are subjected to temperature, humidity, and UV exposure simulations to assess durability.

- Performance Testing: Athletic footwear is tested for grip, shock absorption, and overall performance, often using specialized equipment to simulate gameplay conditions.

Verifying Supplier Quality for International B2B Transactions

B2B buyers should adopt a multi-faceted approach to verify and ensure supplier quality:

- Audits: Conduct comprehensive on-site audits, focusing on manufacturing facilities, quality management practices, and compliance procedures. For international buyers, engaging third-party inspection agencies (e.g., SGS, Intertek) provides unbiased assessments.

- Documentation Review: Request and scrutinize all relevant certifications, test reports, and quality manuals. Ensure these documents are current and verifiable.

- Sample Testing: Before large orders, perform independent testing of samples based on international standards relevant to the target market.

- Third-party Inspections: Employ reputable inspection firms to conduct pre-shipment inspections, verifying product quality, packaging, and labeling.

Special Considerations for B2B Buyers in Africa, South America, the Middle East, and Europe

Different regions impose varying standards and expectations, influencing quality assurance processes:

- Europe (e.g., Italy): Buyers should prioritize suppliers with CE certification, ISO 9001, and compliance with REACH regulations to avoid import delays or legal issues. Certification audits and detailed documentation are critical.

- Turkey and Regional Markets: Suppliers often adhere to ISO standards, but buyers should verify local compliance requirements, such as TUV or BSCI certifications, and conduct on-site audits when feasible.

- Africa and South America: Importers should emphasize verifying supplier certifications, conducting third-party inspections, and requesting compliance documentation, as regional standards may vary widely. Establishing long-term relationships with transparent suppliers reduces risks.

- General Advice: For all regions, fostering clear communication regarding quality expectations, detailed contractual quality clauses, and establishing quality benchmarks upfront are vital. Utilizing global trade assurance programs and quality partnerships can further mitigate risks.

Conclusion

For B2B buyers sourcing Way of Wade basketball shoes, a thorough understanding of manufacturing and quality assurance processes is essential. Emphasizing supplier certifications, rigorous QC checkpoints, and independent verification methods ensures product quality and compliance with international standards. Tailoring these practices to regional requirements enhances trust, reduces risks, and positions buyers for successful international trade partnerships.

Comprehensive Cost and Pricing Analysis for way of wade basketball shoes Sourcing

Cost Structure Breakdown for Way of Wade Basketball Shoes

Understanding the detailed cost components is vital for international buyers aiming to optimize procurement strategies. The primary cost drivers include:

-

Materials: High-quality synthetic leathers, mesh fabrics, rubber soles, and cushioning foams form the core material costs. Premium materials or specialized features (e.g., enhanced grip, moisture-wicking properties) can significantly elevate costs, often ranging from $15 to $35 per pair depending on specifications.

-

Labor: Manufacturing wages vary notably by country—factories in Southeast Asia (e.g., Vietnam, China) tend to offer lower labor costs ($1–$4 per pair), whereas Eastern European or Middle Eastern factories might command higher wages, influencing total costs.

-

Manufacturing Overhead: This includes equipment depreciation, utilities, and factory operational costs, typically adding 10-20% to direct labor costs. Efficient factories with high automation can reduce overheads.

-

Tooling and Setup: Initial mold creation and tooling costs are upfront investments ranging from $5,000 to $20,000 per model, amortized over production volume. Higher MOQs dilute these costs per unit.

-

Quality Control and Certifications: Ensuring compliance with international standards (e.g., ISO, ASTM, REACH) can add $1–$3 per pair but is crucial for market access, especially in Europe and the Middle East.

-

Logistics and Shipping: FOB (Free on Board) prices typically range from $3 to $8 per pair, depending on shipment volume, destination port, and shipping method. Bulk shipments via sea are more cost-effective than air freight but entail longer lead times.

-

Profit Margin: Suppliers generally mark up prices by 15-35%, factoring in market competitiveness, buyer volume, and long-term relationships.

Key Price Influencers

Several factors significantly impact the final FOB or ex-works price:

-

Order Volume & MOQ: Larger orders (e.g., 10,000+ pairs) often attract lower unit prices due to economies of scale, with discounts of 5-15% on standard pricing.

-

Customization & Specs: Special colorways, branding, or unique design features increase costs—customization can add 10-25% to base prices, especially if it requires new tooling or molds.

-

Material Choices: Opting for premium or sustainable materials raises costs, but can also open premium market segments.

-

Quality Certifications: Certifications such as CE, ISO, or specific regional standards in Europe and the Middle East can add to costs but are often necessary for market acceptance.

-

Supplier Factors: Factory reputation, production capacity, and negotiation power influence pricing. Established suppliers with proven quality tend to command higher prices but offer reliability.

-

Incoterms & Delivery Terms: FOB, CIF, DDP—each impacts total landed cost. Buyers should consider additional costs like customs duties, VAT, and local taxes, especially relevant for European and Middle Eastern markets.

Strategic Tips for International B2B Buyers

-

Negotiate for Volume Discounts: Leverage large order sizes to negotiate better unit prices, especially when ordering from Asian manufacturers.

-

Assess Total Cost of Ownership (TCO): Don’t focus solely on unit price; consider shipping, customs, taxes, and potential rework costs. European buyers, for instance, should account for VAT and compliance costs.

-

Build Long-term Relationships: Reliable, consistent suppliers often offer better pricing, priority production slots, and flexible payment terms.

-

Understand Pricing Nuances: Be aware that initial quotes may exclude hidden costs like import duties, certification fees, or warehousing. Clarify all costs upfront.

-

Leverage Incoterms Wisely: For buyers in Africa and South America, FOB is common, but DDP (Delivered Duty Paid) can simplify logistics—though at higher initial costs.

Price Range Estimates (Indicative Only)

- Base FOB Price: $20–$40 per pair for standard models

- Customized or Premium Models: $40–$70+ per pair

- Additional Costs: Shipping, duties, taxes vary by destination; European markets may face 10–25% import duties plus VAT, while African and South American markets often encounter complex customs procedures and tariffs.

Disclaimer: Prices are indicative and can fluctuate based on market conditions, supplier negotiations, and specific product requirements. Conduct detailed quotations and supplier audits before finalizing any deal.

By comprehensively understanding these cost components and influencing factors, B2B buyers from Africa, South America, the Middle East, and Europe can make more informed procurement decisions, optimize their supply chain, and negotiate effectively for competitive pricing.

Spotlight on Potential way of wade basketball shoes Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for way of wade basketball shoes.)*

Essential Technical Properties and Trade Terminology for way of wade basketball shoes

Critical Technical Properties of Way of Wade Basketball Shoes

1. Material Grade and Composition

The quality of materials used directly impacts durability, performance, and customer satisfaction. High-grade synthetic leathers, mesh fabrics, and rubber compounds are preferred for their resilience and breathability. For B2B buyers, understanding the material specifications ensures consistency across batches and helps in assessing product longevity.

2. Cushioning System

This refers to the midsole technology, such as EVA foam or proprietary foam blends, designed to absorb impact during high-intensity play. Advanced cushioning enhances athlete comfort and reduces injury risk. When sourcing, verify the type and density of cushioning to match the performance expectations of your target market.

3. Outsole Tread Pattern and Rubber Quality

The outsole must provide optimal grip and durability. Tread patterns influence traction on various court surfaces, while the rubber quality determines wear resistance. Suppliers should specify the rubber’s durometer (hardness) and tread design to ensure performance consistency, especially in regions with different playing surfaces.

4. Fit and Flexibility Specifications

Proper fit is crucial for athlete performance. Technical specs such as toe box width, collar height, and flex zones are essential for ensuring comfort and mobility. B2B buyers should request detailed sizing charts and flexibility tests to align with regional consumer preferences.

5. Tolerance Levels in Manufacturing

Tolerance refers to permissible deviations in dimensions or weight during production. Tight tolerances (e.g., ±1mm) indicate high precision, leading to better fit and function. B2B buyers should specify acceptable tolerances to avoid issues like poor fit or manufacturing inconsistencies.

6. Weight and Balance

The overall weight influences agility and fatigue. Lightweight shoes are preferred for high-performance basketball, but must not compromise stability. Clear specifications on weight ranges and balance points assist buyers in selecting products that meet athlete needs.

Essential Industry and Trade Terminology

1. OEM (Original Equipment Manufacturer)

Refers to companies that produce basketball shoes under a brand’s specifications. Understanding OEM capabilities helps buyers assess whether a supplier can customize designs, branding, or features to meet regional market demands.

2. MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to produce per order. Knowing MOQ helps buyers plan inventory levels and negotiate pricing, especially in regions with fluctuating demand like Africa or South America.

3. RFQ (Request for Quotation)

A formal process where buyers solicit price and technical details from suppliers. An RFQ ensures transparency and competitive pricing, enabling buyers to compare multiple manufacturers effectively.

4. Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and customs clearance. Familiarity with Incoterms like FOB (Free On Board) or CIF (Cost, Insurance, Freight) helps buyers manage logistics costs and timelines accurately across different regions.

5. Lead Time

The period from order placement to product delivery. Awareness of lead times is vital for planning inventory, especially when dealing with international suppliers where customs and shipping delays are common.

6. Certification Standards

Includes compliance with regional safety, quality, and environmental standards (e.g., ISO, CE, or local certifications). Ensuring products meet these standards reduces import barriers and enhances market acceptance.

Summary:

Understanding these technical properties and trade terms equips international B2B buyers with the knowledge to evaluate product quality accurately, negotiate effectively, and streamline logistics. Tailoring specifications to regional demands—such as durability in rugged African terrains or lightweight designs for European courts—can provide a competitive edge in the global basketball shoe market.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the way of wade basketball shoes Sector

Market Overview & Key Trends

The global market for Way of Wade basketball shoes is influenced by a combination of technological innovation, shifting consumer preferences, and evolving sourcing practices. As a premium brand associated with Wade’s legacy, these shoes appeal to both athletes and sneaker enthusiasts worldwide, creating opportunities for B2B buyers seeking high-quality, innovative products.

Emerging trends include the integration of advanced materials such as lightweight foams, responsive cushioning, and durable synthetics designed for enhanced performance. Digitalization is also reshaping sourcing and distribution channels, with e-commerce platforms enabling direct B2B transactions and real-time inventory management. For regions like Africa, South America, the Middle East, and Europe—particularly Italy and Turkey—local demand for authentic, high-performance basketball footwear remains strong, driven by increasing sports participation and a growing appreciation for premium brands.

Market dynamics are further shaped by geopolitical factors, tariffs, and trade agreements, which influence sourcing costs and lead times. Sourcing trends are shifting toward diversification, with many international buyers seeking to reduce dependency on traditional manufacturing hubs in Asia by exploring regional manufacturing options or near-shore alternatives. This approach can mitigate risks and improve supply chain resilience.

For B2B buyers, understanding these trends is crucial for aligning procurement strategies with market demands, optimizing inventory, and maintaining competitive advantage. Leveraging data-driven insights and establishing strong relationships with certified suppliers can facilitate access to authentic, high-quality Way of Wade products while navigating the complexities of international trade.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a central pillar in the footwear industry, influencing sourcing decisions and brand reputation. For Way of Wade basketball shoes, emphasizing environmentally responsible practices offers B2B buyers a strategic advantage, particularly in markets with increasing consumer awareness about environmental and social issues.

Eco-conscious sourcing involves selecting suppliers committed to reducing carbon footprints, minimizing waste, and utilizing sustainable materials. Certifications such as Global Organic Textile Standard (GOTS), Forest Stewardship Council (FSC), and Bluesign® are increasingly sought after to verify ethical practices and environmental compliance. Utilizing recycled plastics, natural rubber, and organic cotton can significantly lower the environmental impact of production.

In addition, transparent supply chains and adherence to fair labor practices are vital. Buyers should prioritize suppliers with rigorous audits and certifications, ensuring ethical labor conditions and responsible sourcing of raw materials. Incorporating ‘green’ materials not only aligns with global sustainability standards but also appeals to environmentally conscious consumers and institutional buyers.

For international B2B buyers from regions like Europe and the Middle East, sustainability certifications serve as critical differentiators, facilitating market entry and brand positioning. Establishing partnerships with suppliers committed to sustainability can mitigate regulatory risks, enhance brand reputation, and contribute to long-term business resilience. Moreover, adopting eco-friendly packaging and logistics practices further reinforces a company’s commitment to sustainability, creating added value in global markets.

Brief Evolution/History

The evolution of Way of Wade basketball shoes reflects a strategic blend of innovation, athlete endorsement, and market adaptation. Originally launched as part of Wade’s collaboration with Li-Ning, the brand quickly gained recognition for its performance-oriented design and cultural relevance. Over time, the product line expanded, incorporating cutting-edge technologies and embracing sustainability trends, aligning with global market shifts.

For B2B buyers, understanding this history highlights the brand’s trajectory toward premium quality, innovation, and ethical practices. Recognizing the brand’s evolution can assist in assessing long-term supplier reliability and product authenticity, especially crucial in markets vulnerable to counterfeiting.

This background underscores the importance of sourcing from authorized distributors or certified suppliers to ensure product integrity. As the brand continues to innovate and expand globally, maintaining alignment with its core values—performance, innovation, and sustainability—can enhance market competitiveness and customer trust across diverse regions.

Frequently Asked Questions (FAQs) for B2B Buyers of way of wade basketball shoes

1. How can I verify the reliability and authenticity of a Way of Wade basketball shoe supplier?

To ensure supplier reliability, conduct thorough due diligence by requesting verified business licenses, certifications, and references from previous international clients. Look for suppliers with a proven track record in exporting to your region, preferably with positive reviews or testimonials. Request samples and inspect product quality firsthand or through third-party inspectors. Additionally, verify their compliance with international standards such as ISO, CE, or relevant safety certifications. Engaging in transparent communication and using reputable trade platforms or third-party verification services can further mitigate risks associated with counterfeit or unreliable suppliers.

2. What are the customization options available for Way of Wade shoes, and how do they impact lead times and costs?

Most reputable suppliers offer customization options including branding (logos, tags), color schemes, packaging, and sometimes design modifications. Customization typically involves additional costs and longer lead times—ranging from 4 to 12 weeks—depending on complexity. For large orders, negotiate clear terms on branding rights, minimum order quantities (MOQs), and sample approvals. Early engagement with the supplier’s design team and detailed specifications can help streamline processes. Always factor in potential delays and costs into your procurement planning to ensure timely delivery and brand consistency.

3. What are the typical MOQs, lead times, and payment terms for international B2B orders of Way of Wade shoes?

MOQ requirements vary but generally start around 500 to 1,000 pairs for initial orders, with larger batches offering better pricing. Lead times are usually between 30 to 60 days post-order confirmation, depending on customization and stock availability. Payment terms often include 30% upfront via bank transfer or letter of credit, with the remaining balance payable before shipment or upon delivery. Negotiate flexible terms based on order volume and your relationship with the supplier. Establish clear contractual agreements to avoid misunderstandings and ensure smooth transactions.

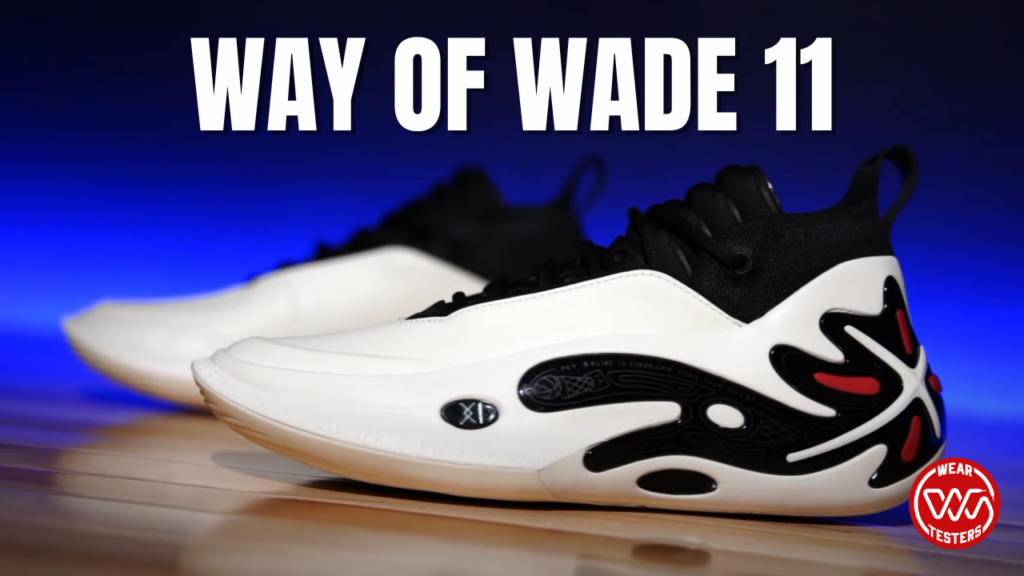

Illustrative Image (Source: Google Search)

4. What certifications and quality assurance measures should I look for when sourcing Way of Wade shoes internationally?

Ensure the supplier provides relevant certifications such as ISO quality management, CE marking for safety, and environmental compliance (e.g., REACH, OEKO-TEX). Request detailed quality control procedures, including pre-shipment inspections, testing reports, and factory audit reports. Consider engaging third-party inspection services to verify product quality, especially for bulk orders. Additionally, check if the supplier complies with international labor standards and environmental regulations, which can mitigate risks related to legal compliance and brand reputation in your market.

5. How can I manage logistics and shipping to my country effectively when importing Way of Wade shoes?

Coordinate with suppliers experienced in international freight to optimize shipping routes and costs. Choose reliable logistics partners or freight forwarders familiar with your region’s import regulations, tariffs, and customs procedures. Consider shipping via sea for large orders to reduce costs or air freight for urgent deliveries. Ensure all necessary documentation—commercial invoices, packing lists, certificates of origin—is complete to facilitate customs clearance. Track shipments actively and establish contingency plans for delays or customs issues. Building a strong logistics network helps ensure timely delivery and cost control.

6. What should I do if I encounter disputes or quality issues with my Way of Wade shoe order?

Address disputes promptly through clear communication with the supplier, referencing your contract and agreed specifications. Document all correspondence, inspection reports, and photographic evidence of quality issues. If disputes cannot be resolved directly, consider engaging third-party mediators or arbitration services specializing in international trade. Always include dispute resolution clauses in your contracts specifying jurisdiction and procedures. Establish quality assurance checkpoints during production and before shipment to prevent issues. Maintaining professional, transparent dialogue is key to resolving conflicts efficiently and preserving long-term relationships.

7. How do I ensure compliance with local import regulations and standards when bringing Way of Wade shoes into my country?

Research your country’s import tariffs, customs duties, and product standards applicable to footwear and sports apparel. Engage local customs brokers or legal consultants to navigate complex regulations and ensure all documentation—permits, certificates, and invoices—is accurate and complete. Verify if your market requires specific safety or environmental certifications and secure them in advance. Staying informed about changes in import policies helps prevent delays or penalties. Building relationships with local authorities and trade associations can provide valuable insights and support for smooth import processes.

8. What strategies can I use to build a long-term partnership with Way of Wade shoe suppliers for sustainable sourcing?

Focus on establishing transparent, mutually beneficial relationships through consistent communication and reliable payment practices. Regularly review supplier performance based on quality, delivery, and compliance metrics. Consider volume-based discounts or exclusivity agreements to incentivize loyalty. Share market insights and forecast needs to help suppliers plan production, reducing lead times and costs. Invest in supplier audits and capacity-building initiatives to foster trust and continuous improvement. A long-term partnership enhances supply stability, quality consistency, and potential for customized product development, ultimately supporting your competitive positioning in your local markets.

Strategic Sourcing Conclusion and Outlook for way of wade basketball shoes

Strategic Sourcing Conclusion and Outlook for way of wade basketball shoes

Effective strategic sourcing is essential for international B2B buyers aiming to capitalize on the growing demand for premium basketball footwear like Way of Wade shoes. By prioritizing reliable supply chain partnerships, quality assurance, and cost efficiencies, buyers can secure competitive advantages in diverse markets such as Africa, South America, the Middle East, and Europe. Leveraging local manufacturing options or established overseas suppliers can enhance flexibility, reduce lead times, and improve market responsiveness.

Looking ahead, the evolving landscape of global trade, coupled with increasing consumer demand for innovative and authentic athletic products, presents significant opportunities. Buyers should focus on building strong relationships with trusted suppliers, while also exploring sustainable sourcing practices to meet rising environmental standards. Staying ahead of industry trends—such as technological advancements in footwear and consumer preferences—will be critical for maintaining a competitive edge.

International B2B buyers are encouraged to actively engage with manufacturers and distributors who demonstrate transparency, quality control, and scalability. Proactive sourcing strategies will enable you to meet market demands efficiently, foster brand loyalty, and expand your footprint in these dynamic regions. Embrace strategic sourcing as a key driver of growth and competitiveness in the global basketball footwear market.