Your Ultimate Guide to Sourcing Work Wear Safety Shoes

Guide to Work Wear Safety Shoes

- Introduction: Navigating the Global Market for work wear safety shoes

- Understanding work wear safety shoes Types and Variations

- Key Industrial Applications of work wear safety shoes

- Strategic Material Selection Guide for work wear safety shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for work wear safety shoes

- Comprehensive Cost and Pricing Analysis for work wear safety shoes Sourcing

- Spotlight on Potential work wear safety shoes Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for work wear safety shoes

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the work wear safety shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of work wear safety shoes

- Strategic Sourcing Conclusion and Outlook for work wear safety shoes

Introduction: Navigating the Global Market for work wear safety shoes

In today’s interconnected global economy, the procurement of work wear safety shoes is more than just a compliance measure—it’s a strategic imperative for safeguarding workers, enhancing productivity, and maintaining competitive advantage. For B2B buyers across Africa, South America, the Middle East, and Europe, sourcing the right safety footwear involves navigating diverse markets, regulatory standards, and supplier landscapes. Given the critical role these shoes play in preventing workplace injuries, choosing high-quality, durable, and compliant products is essential for operational success and risk mitigation.

This comprehensive guide equips international buyers with the insights needed to make informed sourcing decisions. It covers a broad spectrum of topics, including the different types of work wear safety shoes, the materials that ensure safety and comfort, and the manufacturing and quality control standards that guarantee reliability. Additionally, the guide explores trusted suppliers worldwide, cost considerations, and emerging market trends—empowering buyers to optimize procurement strategies in a competitive landscape.

Whether sourcing from Egypt’s growing manufacturing hubs, Nigeria’s expanding industrial sector, or established European suppliers, this resource aims to streamline your decision-making process. By understanding the nuances of the global safety shoe market, B2B buyers can confidently select products that meet safety standards, suit local conditions, and deliver long-term value—ultimately fostering safer workplaces and stronger supply chain resilience across diverse regions.

Understanding work wear safety shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Steel Toe Safety Shoes | Reinforced toe caps made of steel for impact protection | Construction, manufacturing, logistics | Pros: High durability and impact resistance; Cons: Heavier, potential thermal discomfort |

| Composite Toe Safety Shoes | Toe caps made from non-metal materials like Kevlar, carbon fiber | Food processing, electronics, environments requiring metal detection | Pros: Lighter, non-conductive; Cons: Slightly less impact resistance than steel |

| Waterproof Work Shoes | Sealed or water-resistant uppers, often with waterproof membranes | Agriculture, outdoor maintenance, marine industries | Pros: Keeps feet dry; Cons: Can be less breathable, potentially uncomfortable in hot climates |

| Slip-Resistant Safety Shoes | Outsoles designed with specialized tread patterns and rubber compounds | Warehousing, hospitality, chemical plants | Pros: Reduced slip risk; Cons: May wear faster on rough surfaces, limited other protective features |

| Electrical Hazard (EH) Shoes | Insulation features to prevent electrical conduction | Electrical utilities, construction near live wires | Pros: Enhanced safety in electrical environments; Cons: Usually more expensive, requires compliance verification |

Steel Toe Safety Shoes

Steel toe safety shoes are among the most common protective footwear in heavy-duty industries. They feature a steel cap that shields toes from falling objects or compression injuries. These shoes are highly durable and suitable for environments with frequent impact hazards, such as construction sites and warehouses. B2B buyers should consider procurement volume, as steel toe shoes tend to be heavier, which might affect worker comfort over long shifts. Additionally, steel can conduct heat or cold, so climate considerations are crucial for selecting appropriate models.

Composite Toe Safety Shoes

Constructed with non-metallic materials like Kevlar or carbon fiber, composite toe shoes offer impact protection without the weight of steel. They are ideal for industries requiring metal detection compliance, such as airports or electronics manufacturing. These shoes are lighter, reducing fatigue for workers, and non-conductive, adding electrical safety benefits. However, they may offer slightly less impact resistance than steel toes, so buyers should evaluate the specific safety standards and impact ratings relevant to their industry. Bulk purchasing should also consider the availability of sizes and styles suitable for diverse workforce needs.

Waterproof Work Shoes

Designed with sealed seams or waterproof membranes, these shoes are essential in environments exposed to water, mud, or chemicals. They are commonly used in agriculture, outdoor maintenance, and marine settings. For B2B buyers, investing in high-quality waterproof shoes can reduce downtime caused by wet feet and related health issues. However, waterproofing can sometimes compromise breathability, leading to discomfort in hot climates. Selecting models with breathable waterproof membranes can optimize worker comfort while maintaining protection.

Slip-Resistant Safety Shoes

Specialized outsoles with tread patterns and rubber compounds designed to prevent slips are vital in environments with wet, oily, or uneven surfaces. Industries like warehousing, hospitality, and chemical processing benefit significantly from slip-resistant footwear. For bulk procurement, durability of the outsole is a key consideration, especially in abrasive environments. While these shoes excel at preventing falls, they may wear out faster on rough terrains and might lack other protective features, so a layered safety approach is advisable.

Electrical Hazard (EH) Shoes

Electrical hazard shoes incorporate insulating materials and construction techniques to prevent electrical conduction, protecting workers in electrical or live-wire environments. These shoes are crucial for utility companies, electricians, and construction firms working near energized equipment. When sourcing EH shoes, B2B buyers should verify compliance with relevant standards (e.g., ASTM, EN) and consider the shoes’ compatibility with other PPE. Although generally more costly, investing in high-quality EH footwear can significantly reduce electrical injury risks and ensure regulatory compliance.

Key Industrial Applications of work wear safety shoes

| Industry/Sector | Specific Application of work wear safety shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Civil Engineering | Heavy-duty site work, scaffolding, and structural assembly | Reduces injury risk from falling objects, slips, and punctures; enhances worker safety and compliance | Durability, slip resistance, toe protection standards (e.g., steel or composite toes), and suitability for rough terrains |

| Oil & Gas / Petrochemical | Offshore platforms, refinery operations, pipeline installation | Ensures protection against chemical spills, slips, and electrical hazards | Certification for hazardous environments, oil-resistant soles, and compatibility with chemical exposure |

| Manufacturing & Industrial Plants | Assembly lines, heavy machinery operation, warehouse logistics | Prevents injuries from dropped tools, machinery, and electrical hazards | Anti-static properties, impact resistance, comfort for prolonged wear, and compliance with industry standards |

| Agriculture & Forestry | Fieldwork, harvesting, and terrain navigation | Protects against punctures, uneven terrain slips, and environmental hazards | Water resistance, slip-resistant soles, and durability against mud, moisture, and rough terrain |

| Mining & Heavy Industries | Underground mining, quarrying, and heavy equipment operation | Critical for protection against falling debris, sharp rocks, and electrical risks | Heavy impact resistance, puncture-proof soles, and high-traction features for unstable surfaces |

Construction & Civil Engineering

Construction sites demand robust safety footwear to safeguard workers from numerous hazards such as falling objects, sharp debris, and uneven surfaces. Work wear safety shoes in this sector are typically reinforced with steel or composite toes, slip-resistant soles, and puncture-proof midsoles. For international buyers, especially from Africa and South America, sourcing shoes that comply with local safety standards (e.g., EN, ASTM) ensures legal compliance and worker safety. Durability is critical, as construction environments are physically demanding, and footwear must withstand harsh conditions over extended periods.

Oil & Gas / Petrochemical

Offshore platforms and refineries expose workers to chemical, electrical, and physical hazards. Safety shoes used in these environments need specialized features such as chemical-resistant materials, anti-static properties, and electrical hazard protection. For B2B buyers in the Middle East and Europe, certification for hazardous environments like ATEX or ISO standards is essential. Shoes must also offer slip resistance on oily or wet surfaces and withstand extreme temperatures, ensuring worker safety and operational continuity in challenging conditions.

Manufacturing & Industrial Plants

In manufacturing settings, safety shoes prevent injuries caused by machinery, falling objects, or accidental contact with electrical components. Buyers should prioritize impact-resistant toe caps, anti-static features, and comfort for long shifts. For European and North African markets, sourcing shoes that meet EN standards ensures compliance. Durability, proper fit, and slip resistance are critical, especially in environments with oily or wet floors, helping reduce downtime and injury-related costs.

Agriculture & Forestry

Agricultural workers often operate in muddy, uneven, and outdoor terrains. Work wear safety shoes here must combine water resistance, slip resistance, and puncture protection. They should also be durable enough to withstand rough handling and exposure to environmental elements. For buyers in South America and Africa, sourcing shoes with high-quality waterproof materials and resilient soles can reduce injury risks and improve productivity, especially in remote or rural locations where access to replacement gear is limited.

Mining & Heavy Industries

Mining operations involve extreme risks from falling rocks, sharp debris, and unstable surfaces. Safety shoes for this sector require heavy impact resistance, puncture-proof soles, and excellent grip for uneven terrain. International buyers from regions like Nigeria or Eastern Europe must ensure that footwear complies with mining safety standards such as ISO 20345 or ASTM F2413. Investing in high-quality, certified safety shoes minimizes accidents, improves worker safety, and aligns with regulatory requirements in demanding environments.

Strategic Material Selection Guide for work wear safety shoes

Material Analysis for Work Wear Safety Shoes

Selecting the appropriate materials for safety shoes is critical for ensuring durability, safety, and compliance across diverse international markets. Different regions, such as Africa, South America, the Middle East, and Europe, present unique challenges and standards that influence material choice. Here, we analyze four common materials—leather, rubber, thermoplastics, and composite materials—highlighting their key properties, advantages, limitations, and considerations for B2B buyers.

Leather

Key Properties:

Leather, especially full-grain and nubuck, offers excellent durability, breathability, and natural flexibility. It provides good resistance to abrasion and can be treated for water resistance. Leather can withstand moderate heat and chemical exposure but is susceptible to prolonged moisture.

Pros & Cons:

Leather’s durability makes it ideal for heavy-duty applications, and it conforms well to the foot over time, enhancing comfort. However, it tends to be more expensive and requires longer manufacturing times due to its processing complexity. Leather shoes are heavier, which might impact user comfort for prolonged wear.

Impact on Application:

Leather shoes are suitable for environments with moderate chemical exposure but less ideal for highly corrosive or wet conditions unless treated. They are compliant with many international standards like ASTM F2413 (U.S.), EN ISO 20345 (Europe), and similar regional standards.

International Considerations:

For markets like Nigeria or Egypt, leather is highly favored due to its traditional acceptance and compliance with local safety standards. However, buyers should ensure leather is sourced from suppliers adhering to sustainable and ethical practices, especially for European markets with strict environmental regulations.

Rubber

Key Properties:

Rubber offers excellent resistance to water, chemicals, and abrasion. It performs well in wet, oily, or corrosive environments and provides good shock absorption. It is inherently flexible and can be manufactured with various formulations to enhance specific properties.

Pros & Cons:

Rubber safety shoes are highly durable and cost-effective. They excel in environments involving liquids, oils, and chemicals. The downside is that rubber can be less breathable, leading to potential discomfort in hot climates, and may require specialized manufacturing processes.

Impact on Application:

Ideal for industries like oil and gas, construction, and agriculture—common in African and Middle Eastern regions—where exposure to moisture and chemicals is high. Rubber shoes typically meet standards such as ASTM D471 (resistance to liquids) and DIN EN ISO 20345.

International Considerations:

For buyers in regions with high humidity or hot climates, such as Nigeria or Egypt, the breathability of rubber shoes may be a concern. They should opt for models with enhanced ventilation or consider hybrid designs. Rubber’s compliance with international standards simplifies procurement across markets.

Thermoplastics (TPU, PVC)

Key Properties:

Thermoplastics like Thermoplastic Polyurethane (TPU) and Polyvinyl Chloride (PVC) are lightweight, resistant to chemicals, and can be molded into various shapes. They offer good impact resistance and can be engineered for flexibility and durability.

Pros & Cons:

These materials are generally low-cost and quick to produce, making them attractive for mass manufacturing. However, their durability can vary based on formulation; some may degrade under prolonged UV exposure or extreme temperatures, especially in hot climates.

Impact on Application:

Thermoplastics are suitable for light to medium-duty safety shoes, often used in environments with chemical exposure or where weight reduction is essential. They are compliant with standards like ASTM F2413 and EN ISO 20345, depending on the formulation.

International Considerations:

In regions like South America and the Middle East, where cost sensitivity is high, thermoplastic shoes offer a practical solution. Buyers should verify the material’s UV and temperature resistance to ensure suitability for local conditions.

Composite Materials

Key Properties:

Composite safety shoes combine various materials such as carbon fiber, fiberglass, and specialized plastics to achieve high strength-to-weight ratios. They are often used for toe caps and midsoles, offering protection without the weight of steel.

Pros & Cons:

These materials provide excellent impact and compression resistance while being lightweight, improving user comfort. The manufacturing process can be complex and costly, which may reflect in higher retail prices. Durability depends on the specific composite used.

Impact on Application:

Ideal for industries requiring high mobility and safety, such as logistics or maintenance. They meet standards like ASTM F2413-18 and EN ISO 20345, often exceeding steel toe performance in weight and comfort.

International Considerations:

For European markets with strict safety and environmental standards, composites are increasingly preferred due to their non-metallic nature and compliance with regulations like REACH. Buyers in Africa and South America should consider local supplier availability and certification to ensure quality.

Summary Table

| Material | Typical Use Case for work wear safety shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather | Construction, industrial, general safety | Durable, breathable, conforms to foot | Expensive, heavy, requires maintenance | High |

| Rubber | Oil & gas, construction, wet environments | Water/chemical resistant, cost-effective | Less breathable, uncomfortable in heat | Med |

| Thermoplastics (TPU, PVC) | Light-duty, chemical exposure environments | Lightweight, versatile, low-cost | UV and temperature sensitivity, less durable | Low |

| Composite Materials | High-impact, lightweight safety shoes | Lightweight, high impact resistance | Higher manufacturing cost, complex supply chain | High |

This comprehensive analysis aims to guide international B2B buyers in selecting the most suitable materials for their specific regional needs, balancing safety standards, environmental conditions, and cost considerations to optimize procurement decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for work wear safety shoes

Manufacturing Processes for Work Wear Safety Shoes

The production of work wear safety shoes involves a complex, multi-stage process designed to ensure durability, safety, and comfort. Understanding these stages helps B2B buyers evaluate supplier capabilities and ensure product compliance with international standards.

Material Preparation

The foundation of quality safety shoes lies in high-grade raw materials. Common materials include:

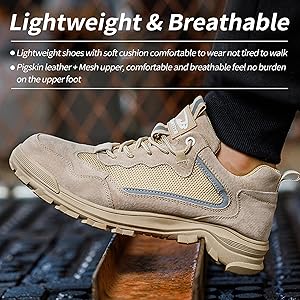

- Uppers: Leather (full-grain, nubuck, or suede) and synthetic fabrics like mesh or microfiber for breathability.

- Solings: Rubber, polyurethane (PU), or thermoplastic polyurethane (TPU), chosen for slip resistance, abrasion resistance, and shock absorption.

- Insole Materials: EVA foam, gel inserts, or specialized cushioning for comfort and impact protection.

- Reinforcements: Steel or composite toe caps, puncture-resistant plates, and anti-static or insulation layers.

Suppliers typically source these materials from certified vendors, ensuring traceability and compliance with safety standards.

Forming and Assembly

The manufacturing process proceeds through several key stages:

-

Cutting & Shaping: Automated cutting machines or manual templates shape uppers and linings to precise patterns. Advanced CAD/CAM systems enhance accuracy and repeatability.

-

Stitching & Bonding: Uppers are stitched using industrial sewing machines, often with reinforced seams in high-stress areas. Bonding techniques, such as heat sealing or adhesive bonding, secure components like soles to uppers.

-

Lasting & Molding: Uppers are stretched over molds (lasts) to achieve the desired shape and fit. This step often involves heat or mechanical pressure to set the form.

-

Adding Safety Features: Toe caps, puncture plates, and other protective elements are integrated during assembly, either by inserting pre-formed components or molding them directly into the sole.

-

Final Assembly & Inspection: Components are assembled into the final product, with quality checks at each step to ensure dimensional accuracy and structural integrity.

Finishing & Packaging

The final steps include:

- Surface Treatments: Polishing, dyeing, or applying protective coatings to enhance appearance and resistance.

- Labeling & Branding: Adding size, safety certification labels, and branding marks.

- Packaging: Shoes are cleaned, packaged in appropriate cartons, and prepared for shipment, often with anti-damage measures.

Quality Assurance (QA) and Control (QC) in Manufacturing

Ensuring consistent quality in safety shoes demands rigorous QC protocols aligned with international standards and industry-specific certifications.

International and Industry Standards

- ISO 9001: The foundational quality management system (QMS) standard applicable globally. It emphasizes process control, continuous improvement, and customer satisfaction.

- CE Marking (European Union): Indicates compliance with EU safety, health, and environmental requirements, including PPE Directive 89/686/EEC.

- ASTM Standards (North America): Such as ASTM F2413, which specifies performance requirements for protective footwear.

- Other Certifications: API (for oil and gas industry), OSHA compliance (for workplace safety), and specific regional standards relevant to Africa, South America, and the Middle East.

QC Checkpoints and Testing Methods

-

Incoming Quality Control (IQC): Raw materials undergo testing for tensile strength, chemical composition, and defect inspection before entering production. Suppliers should provide test reports and certifications.

-

In-Process Quality Control (IPQC): Continuous monitoring during manufacturing includes dimensional checks, seam integrity, sole bonding strength, and safety feature integration. Techniques such as ultrasonic testing or dye penetrant testing are common for detecting hidden flaws.

-

Final Quality Control (FQC): Before shipment, finished shoes undergo comprehensive testing:

– Slip Resistance Tests: Using tribometers to ensure soles meet industry standards.

– Impact & Compression Tests: Verifying toe caps and structural integrity.

– Puncture & Cut Resistance: Testing with standardized blades or probes.

– Water Resistance & Breathability: Using hydrostatic or moisture vapor transmission tests.

– Visual Inspection: Checking for aesthetic defects, labeling accuracy, and packaging integrity.

Illustrative Image (Source: Google Search)

Third-party Inspection & Certification

B2B buyers should leverage independent third-party inspection agencies (e.g., SGS, Intertek, Bureau Veritas) to verify supplier claims. These agencies conduct audits, product sampling, and testing to ensure compliance with specified standards.

How International B2B Buyers Can Verify Supplier QC

- Conduct Factory Audits: On-site visits assess manufacturing capabilities, equipment, quality management systems, and compliance practices.

- Review Test Reports & Certifications: Request detailed documentation for raw materials, in-process checks, and final product testing.

- Sample Testing: Send samples to accredited laboratories for independent testing aligned with relevant standards.

- Demand Traceability & Documentation: Ensure suppliers maintain detailed records of raw materials, production batches, and QC results for each shipment.

- Establish Quality Agreements: Formal agreements should specify quality requirements, inspection protocols, and penalties for non-compliance.

QC Nuances for Different Regions

- Africa & Middle East: Suppliers may face challenges related to infrastructure and raw material sourcing. B2B buyers should prioritize suppliers with robust QC systems and international certifications to mitigate risks.

- South America & Europe: Markets often have stricter regulatory requirements. European buyers, for instance, demand CE certification and adherence to EN standards, while South American buyers should verify compliance with local standards and import regulations.

Practical Tips for B2B Buyers

- Partner with Certified Manufacturers: Look for ISO 9001 and industry-specific certifications.

- Implement Pre-Shipment Inspections: Regular third-party audits reduce the risk of non-compliance.

- Request Transparent QC Documentation: Certificates of conformity, test reports, and inspection logs should accompany each batch.

- Build Long-Term Relationships: Trusted suppliers with proven QC track records are more likely to consistently meet safety and quality standards.

- Stay Updated on Standards: Regional regulations evolve; staying informed helps in evaluating supplier compliance and ensuring product acceptance in target markets.

By understanding the intricacies of manufacturing and quality assurance processes, international B2B buyers from diverse regions can make informed sourcing decisions, mitigate risks, and ensure they receive safety shoes that meet both safety and quality expectations across their markets.

Comprehensive Cost and Pricing Analysis for work wear safety shoes Sourcing

Cost Structure Breakdown for Work Wear Safety Shoes

Understanding the detailed cost components involved in sourcing work wear safety shoes is essential for international buyers aiming to optimize procurement strategies. The primary cost elements include:

-

Materials: Quality safety shoes rely on durable components such as steel or composite toe caps, impact-resistant soles, leather or synthetic uppers, and specialized lining materials. Premium materials increase costs but enhance safety and longevity, which can justify higher pricing or better margins.

-

Labor: Manufacturing labor costs vary significantly across regions. For instance, factories in countries like China or Vietnam may offer lower wages, while European or Middle Eastern producers might have higher labor expenses. Skilled labor for assembly and quality assurance is crucial and influences overall costs.

-

Manufacturing Overheads: These encompass factory utilities, machinery maintenance, and administrative expenses. Overheads tend to be higher in developed regions due to stricter safety and environmental regulations, impacting unit costs.

-

Tooling and Equipment: Initial investments in molds, stamping dies, and specialized machinery are often amortized over large production runs. Larger orders typically reduce per-unit tooling costs, making volume a key factor in pricing.

-

Quality Control (QC): Rigorous testing for safety standards (e.g., EN ISO, ASTM, or local certifications) adds to production costs but is vital for compliance and market acceptance, especially in regulated industries.

-

Logistics & Shipping: Costs vary based on shipment mode (air, sea, land), distance, and fuel prices. For Africa and South America, shipping can represent a significant share of total costs, especially for bulky safety shoes. Incoterms chosen (FOB, CIF, DDP) impact buyer expenses and risk.

-

Profit Margin: Suppliers typically add a margin to cover overheads and desired profit. Margins are influenced by market competitiveness, order volume, and negotiation power.

Key Price Influencers in Sourcing

Several factors shape the final pricing structure:

-

Order Volume & MOQ: Higher volumes generally lead to lower unit prices due to economies of scale. Buyers should negotiate for flexible MOQs to balance inventory costs with unit savings, especially when entering new markets.

-

Specifications & Customization: Customized safety features, branding, or specific standards (e.g., fire-resistant, chemical-resistant) increase costs. Standard models are cheaper but may not meet all regional safety requirements.

-

Materials & Certifications: Premium materials and certifications (e.g., CE marking, OSHA compliance) often come at a premium but are essential for market acceptance and safety compliance, particularly in Europe and the Middle East.

-

Supplier Factors: Established suppliers with proven quality records typically charge higher prices but offer reliability. Emerging manufacturers might offer competitive rates but with higher risks related to quality consistency.

-

Incoterms & Logistics: The choice of Incoterms directly affects who bears shipping, customs, and insurance costs. Buyers should evaluate total landed costs, not just factory prices, especially when importing into Africa, South America, or Europe.

Strategic Tips for International B2B Buyers

-

Negotiate for Total Cost of Ownership: Focus not only on unit price but also on lead times, quality guarantees, after-sales support, and logistics costs. A lower initial quote might incur higher long-term expenses if quality issues or delays occur.

-

Leverage Volume & Long-term Relationships: Building trust can unlock discounts, flexible MOQs, and priority production schedules, which are especially valuable in markets with fluctuating demand.

-

Understand Pricing Nuances by Region: Buyers from Africa, South America, and the Middle East should be aware of regional tariffs, import taxes, and local compliance costs that add to landed prices. European buyers often face stringent certification costs but benefit from higher product standards.

-

Consider Total Landed Cost: Always calculate the comprehensive costs—including customs clearance, duties, taxes, and inland transportation—to accurately compare supplier offers across regions.

Indicative Price Range (Disclaimers Applied)

While prices vary widely based on specifications, volume, and supplier location, typical FOB prices for standard safety shoes range approximately from $10 to $25 per pair for bulk orders of 1,000+ units. Customized or high-spec models can range from $25 to $50 or more per pair. Buyers should approach these figures as indicative, with actual prices influenced by negotiation, order size, and regional factors.

By thoroughly analyzing these cost components and influencers, international buyers can develop strategic sourcing plans, negotiate effectively, and optimize total procurement costs for work wear safety shoes across diverse markets.

Spotlight on Potential work wear safety shoes Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for work wear safety shoes.)*

Essential Technical Properties and Trade Terminology for work wear safety shoes

Key Technical Properties of Work Wear Safety Shoes

Understanding the technical specifications of safety shoes is crucial for international B2B buyers to ensure compliance, durability, and safety standards across different markets. Here are essential properties to consider:

1. Material Grade and Composition

The quality of materials, such as leather, synthetic fabrics, or composite materials, directly impacts durability and comfort. Higher-grade materials often provide better resistance to wear, environmental factors, and chemical exposure. For B2B procurement, specifying material standards (e.g., premium full-grain leather vs. bonded leather) ensures consistency and longevity of the product.

2. Impact and Compression Resistance (EN ISO 20345/EN ISO 20347)

These are standardized tests that measure the shoe’s ability to withstand falling objects and compressive forces. For industries involving heavy machinery or construction, shoes must meet specific impact (e.g., 200 Joules) and compression (e.g., 15 kN) ratings. Ensuring compliance minimizes workplace injuries and legal liabilities.

3. Slip Resistance (SRA, SRB, SRC Ratings)

Slip resistance ratings indicate how well shoes prevent falls on various surfaces. Shoes tested for SRA, SRB, or SRC standards are suitable for different environments—wet, oily, or smooth surfaces. For B2B buyers, selecting shoes with appropriate slip ratings reduces accident risk and liability.

4. Toe Cap Strength and Material

Steel, composite, or aluminum toe caps provide impact protection. The choice depends on industry requirements and weight considerations. For example, composite toe caps are lighter and non-metallic, suitable for environments with metal detectors, whereas steel toe caps offer maximum strength.

5. Waterproofing and Breathability

Proper sealing against water ingress, combined with breathable linings, enhances comfort and safety in wet or humid climates common in Africa, South America, or the Middle East. Material specifications like Gore-Tex or similar membranes indicate quality waterproofing.

6. Tolerance and Fit Specifications

Manufacturers often specify tolerances for dimensions and fit, ensuring consistent sizing across batches. Precise fit reduces discomfort and fatigue, which is critical for workers required to wear safety shoes for extended periods.

Essential Industry and Trade Terms

Familiarity with common trade terminology streamlines communication and negotiation processes in international B2B transactions:

1. OEM (Original Equipment Manufacturer)

Refers to manufacturers producing safety shoes under a brand or specifications provided by the buyer. Understanding OEM terms helps buyers customize products and establish direct supply relationships, often leading to cost efficiencies.

2. MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to produce or sell in a single order. For buyers, negotiating MOQ is vital to balance inventory needs with cash flow, especially when entering new markets or testing new suppliers.

3. RFQ (Request for Quotation)

A formal document sent by buyers to suppliers requesting price, lead times, and terms for specific product specifications. Effective RFQs enable accurate comparisons and faster procurement decisions.

4. Incoterms (International Commercial Terms)

Standardized trade terms published by ICC, defining responsibilities for shipping, insurance, and tariffs. Common Incoterms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) clarify who bears costs at each stage, reducing misunderstandings in cross-border deals.

5. Lead Time

The period between order placement and product delivery. Understanding lead times helps buyers plan inventory and production schedules, especially critical in regions with logistical challenges or customs delays.

6. Certification and Compliance Terms (e.g., CE, ASTM, ISO)

Certifications such as CE (European conformity), ASTM (American standards), or ISO (International Organization for Standardization) indicate adherence to safety and quality standards. Confirming these ensures the products meet regional safety requirements, facilitating smoother market entry.

By comprehending these technical properties and trade terms, international B2B buyers from Africa, South America, the Middle East, and Europe can make more informed procurement decisions, foster clearer communication with suppliers, and ensure that safety shoes meet both local and global standards.

Illustrative Image (Source: Google Search)

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the work wear safety shoes Sector

Market Overview & Key Trends

The global work wear safety shoes sector is experiencing dynamic shifts driven by technological innovation, evolving safety regulations, and increasing demand for sustainable solutions. Key drivers include stringent occupational safety standards across industries such as construction, manufacturing, and logistics, which push companies worldwide to upgrade their protective footwear. Emerging markets, notably Africa, South America, and the Middle East, are witnessing rapid industrialization, creating new opportunities but also presenting sourcing challenges related to quality consistency and supply chain reliability.

For international B2B buyers, especially from regions like Nigeria, Egypt, and other emerging economies, understanding local manufacturing capabilities and regional distribution channels is critical. Advances in digital procurement platforms and supply chain transparency tools are transforming sourcing processes, enabling buyers to evaluate suppliers based on real-time data, certifications, and compliance records. Additionally, the adoption of Industry 4.0 technologies, such as IoT-enabled inventory management and AI-driven demand forecasting, is streamlining procurement and reducing lead times.

Sourcing trends are increasingly favoring integrated supply chains that emphasize quality assurance and rapid response. Many buyers are shifting towards suppliers who can demonstrate compliance with international safety standards (e.g., ASTM, EN ISO), and who can provide customizable, scalable solutions suited to diverse regional needs. Moreover, the rise of regional manufacturing hubs—particularly in Turkey, China, and Southeast Asia—offers cost advantages while maintaining quality, though regional logistics and tariffs remain considerations for importers from Africa and South America.

Overall, the market is characterized by a move towards more sophisticated, tech-enabled sourcing strategies that prioritize flexibility, compliance, and resilience. Buyers who leverage data-driven insights and establish strong local partnerships will be better positioned to navigate market fluctuations and seize emerging opportunities.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a pivotal criterion in sourcing work wear safety shoes, driven by increasing regulatory pressures, consumer awareness, and corporate social responsibility commitments. Environmental impacts of footwear manufacturing—such as carbon emissions, water usage, and waste generation—are under scrutiny, prompting brands and suppliers to adopt greener practices.

For B2B buyers, prioritizing suppliers with recognized environmental certifications (e.g., ISO 14001, LEED, Green Seal) ensures adherence to eco-friendly manufacturing processes. The use of sustainable materials—such as recycled rubber, bio-based leathers, organic cotton linings, and non-toxic adhesives—is gaining traction, reducing the ecological footprint of safety footwear. Additionally, lifecycle assessments and transparency in supply chains are vital for verifying the sustainability claims of suppliers, especially in regions where regulatory oversight may be inconsistent.

Ethical sourcing extends beyond environmental concerns to encompass fair labor practices and human rights. Buyers should seek suppliers committed to fair wages, safe working conditions, and compliance with international labor standards (e.g., SA8000, Fair Labor Association). Establishing long-term partnerships with transparent supply chains minimizes risks associated with child labor, forced labor, and unethical practices.

Furthermore, the adoption of ‘green’ certifications and eco-labels can serve as strategic differentiators in competitive markets. For instance, sourcing from suppliers who utilize biodegradable components or participate in recycling programs aligns with corporate sustainability goals. As regional regulations tighten—particularly in Europe and the Middle East—compliance with environmental and social standards will be essential for market access and brand reputation.

Brief Evolution/History

The safety footwear sector has evolved significantly over the past century, transitioning from basic protective designs to sophisticated, ergonomically optimized solutions. Initially driven by industrial safety mandates in the early 20th century, the market now incorporates advanced materials, smart technology, and sustainability principles. For B2B buyers, understanding this evolution highlights the importance of investing in proven quality and future-proof solutions that meet both safety and environmental standards.

This historical shift underscores a broader trend: safety shoes are no longer merely protective gear but integral components of workforce wellbeing and corporate responsibility initiatives. As regulations tighten and consumer expectations evolve, suppliers are continually innovating to meet the dual demands of safety and sustainability, making modern sourcing strategies more complex but also more rewarding for informed buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of work wear safety shoes

1. How can I effectively vet international suppliers for work wear safety shoes to ensure quality and reliability?

Vetting international suppliers requires a multi-step approach. Start by reviewing their certifications (ISO, CE, ANSI) and requesting recent test reports to verify compliance with safety standards. Conduct virtual audits or request third-party inspection reports, especially if dealing with suppliers in regions with variable quality controls. Check references and seek feedback from other B2B buyers or industry peers. Consider visiting manufacturing facilities if feasible, or partnering with reputable sourcing agents who can verify supplier credentials. Always prioritize suppliers with transparent quality management systems and long-standing industry reputation to mitigate risks.

2. What customization options are typically available, and how do I communicate my specific requirements effectively?

Most suppliers offer customization in terms of branding (logos, labels), color schemes, and specific safety features (e.g., steel toes, slip-resistant soles). Clearly define your requirements upfront with detailed specifications, technical drawings, and material preferences. Use standardized terminology and provide examples where possible to avoid misinterpretation. Establish open communication channels, such as video calls or dedicated account managers, to clarify technical details. Negotiating lead times and minimum order quantities (MOQs) early helps align production schedules with your project timelines, ensuring the final product meets your safety and branding standards.

3. What are typical MOQs, lead times, and payment terms I should expect when sourcing safety shoes internationally?

MOQ requirements vary depending on the supplier’s production capacity but generally range from 500 to 2,000 pairs for standard models. Lead times can span from 4 to 12 weeks, influenced by order complexity, customization, and factory location. Payment terms often include a 30% deposit upfront, with the balance payable before shipment or upon receipt of goods. Some suppliers may offer flexible terms for large or repeat orders, such as letter of credit or open account facilities. Negotiating these terms upfront, especially for bulk or recurring orders, ensures smoother cash flow management and timely delivery.

4. What certifications and quality assurance measures should I verify before purchasing safety shoes internationally?

Ensure the supplier provides relevant safety and quality certifications aligned with your target markets—CE for Europe, ANSI/ASTM for North America, or local standards like SANS in South Africa. Request recent test reports for impact resistance, slip resistance, puncture protection, and electrical hazard compliance. Confirm the supplier’s quality assurance procedures, such as ISO 9001 certification or internal inspection protocols. Consider third-party testing from recognized labs to validate safety claims. These measures help mitigate liability risks and ensure the products meet the regulatory standards of your end markets.

5. How do I manage logistics and shipping when importing work wear safety shoes from overseas suppliers?

Start by selecting suppliers experienced in international shipping, who can assist with customs clearance and documentation. Determine the most cost-effective shipping mode—air freight for urgent needs or sea freight for bulk orders—considering lead times and budget constraints. Work with freight forwarders who specialize in your region to navigate import duties, taxes, and local regulations. Establish clear Incoterms (e.g., FOB, CIF) to define responsibility and costs during transit. Regular communication and tracking updates are essential to avoid delays, and maintaining good relationships with logistics partners can streamline the entire supply chain.

6. What steps should I take if there is a dispute over product quality or delivery terms with an international supplier?

Begin with detailed documentation—photos, test reports, correspondence—to substantiate your claim. Initiate direct communication with the supplier to resolve issues amicably, referencing contractual terms and agreed standards. If unresolved, escalate the matter through formal channels, such as arbitration or mediation, especially if your contract specifies dispute resolution procedures. Consider involving local trade associations or legal counsel familiar with international trade laws. Prevent future disputes by including clear quality benchmarks, inspection clauses, and penalty clauses in your purchase agreements, and conduct pre-shipment inspections to catch issues early.

7. How can I ensure compliance with local safety regulations and standards in my target markets?

Research the specific safety standards applicable in your target markets—such as CE marking in Europe, OSHA in the US, or local certifications in Africa and South America. Communicate these requirements explicitly to your supplier and request compliance documentation. Incorporate compliance checks into your quality assurance processes, including third-party testing where necessary. Staying updated on evolving regulations and maintaining open dialogue with local regulatory bodies can prevent non-compliance issues. Establishing a robust supplier qualification process that emphasizes adherence to local standards reduces legal risks and enhances product acceptance.

8. What are the best practices for building long-term relationships with international safety shoe suppliers?

Foster transparent communication by setting clear expectations, providing detailed feedback, and maintaining regular contact. Develop trust through consistent ordering, prompt payments, and shared commitments to quality. Consider establishing long-term contracts or preferred supplier agreements that include favorable terms, volume discounts, or joint development opportunities. Engage in periodic reviews of supplier performance, including quality, delivery, and responsiveness. Investing in supplier development—such as providing technical feedback or collaborating on product innovations—can lead to better pricing, priority service, and mutual growth, ultimately strengthening your supply chain resilience.

Illustrative Image (Source: Google Search)

Strategic Sourcing Conclusion and Outlook for work wear safety shoes

Final Thoughts and Future Outlook

Effective strategic sourcing for work wear safety shoes is essential for international B2B buyers seeking quality, safety, and cost efficiency. Prioritizing supplier reliability, compliance with safety standards, and sustainable practices can significantly enhance operational resilience and brand reputation across diverse markets.

As global supply chains evolve, embracing innovative sourcing strategies—such as diversifying supplier bases and leveraging regional manufacturing hubs—will become increasingly vital. Buyers from Africa, South America, the Middle East, and Europe should actively seek partnerships that offer flexibility, scalability, and adherence to local safety regulations, thereby minimizing risks and ensuring workforce safety.

Looking ahead, the demand for advanced safety footwear will continue to grow, driven by stricter safety regulations and a focus on worker well-being. International buyers are encouraged to adopt proactive sourcing approaches, invest in supplier relationships, and stay informed on emerging trends and standards. By doing so, they can secure a competitive advantage, ensure consistent quality, and meet the evolving needs of their workforce in an increasingly interconnected global market.