Your Ultimate Guide to Sourcing World Industries Shoes

Guide to World Industries Shoes

- Introduction: Navigating the Global Market for world industries shoes

- Understanding world industries shoes Types and Variations

- Key Industrial Applications of world industries shoes

- Strategic Material Selection Guide for world industries shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for world industries shoes

- Comprehensive Cost and Pricing Analysis for world industries shoes Sourcing

- Spotlight on Potential world industries shoes Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for world industries shoes

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the world industries shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of world industries shoes

- Strategic Sourcing Conclusion and Outlook for world industries shoes

Introduction: Navigating the Global Market for world industries shoes

In the fiercely competitive landscape of global footwear manufacturing, understanding the intricacies of world industries shoes is essential for international B2B buyers seeking reliable suppliers, cost efficiencies, and high-quality products. Shoes are not merely a commodity; they are a vital component of the fashion, sports, and industrial markets, making sourcing decisions pivotal to business success. For buyers in regions such as Africa, South America, the Middle East, and Europe—including key markets like Colombia and Turkey—navigating this complex industry can unlock significant growth opportunities and competitive advantages.

This comprehensive guide offers an in-depth overview of the entire footwear supply chain—from different types of shoes and materials to manufacturing processes and quality control standards. It provides actionable insights on identifying reputable suppliers, understanding cost structures, and evaluating market trends to inform smarter procurement decisions. Additionally, it addresses frequently asked questions to clarify common concerns around compliance, lead times, and customization options.

By equipping you with detailed industry knowledge and strategic sourcing tips, this guide empowers international B2B buyers to make informed, confident decisions. Whether you are seeking to diversify your supplier base, optimize costs, or ensure product quality, understanding the nuances of world industries shoes is critical to thriving in the global footwear market. This resource is designed to help you navigate complexities with clarity and precision, ensuring your sourcing strategies align with your business goals.

Understanding world industries shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Steel-Toe Work Shoes | Reinforced toe caps, durable materials, slip-resistant soles | Construction, manufacturing, heavy industry | Highly durable and protective; higher cost but essential for safety. |

| Dress Shoes (Formal) | Sleek design, premium leather, refined finishes | Corporate offices, hospitality, retail | Enhances professional image; lower durability; suitable for formal settings. |

| Athletic/Performance Shoes | Lightweight, breathable materials, specialized soles for activity | Sports, logistics, warehousing | Promotes comfort and productivity; may lack heavy-duty protection. |

| Safety Boots | High ankle support, reinforced midsoles, anti-slip features | Mining, oil & gas, outdoor construction | Superior safety features; bulkier and more expensive. |

| Industrial Rubber Shoes | Rubberized soles, waterproof, chemical-resistant features | Chemical plants, sanitation, agriculture | Excellent for wet/dangerous environments; less stylish, limited for formal use. |

Steel-Toe Work Shoes

Steel-toe shoes are designed with reinforced toe caps to protect against impact and compression hazards. Made from durable materials like steel or composite, they are essential in environments where foot injuries are prevalent, such as construction sites and manufacturing plants. B2B buyers should prioritize certifications like ASTM or EN standards, ensuring compliance with local safety regulations. Bulk purchasing can reduce costs, but buyers should also consider comfort features to promote worker compliance and productivity.

Dress Shoes (Formal)

Formal shoes in the industry sector are crafted from high-quality leather with refined finishes, catering to professional settings like corporate offices, hospitality, and retail. While they may not offer heavy-duty protection, their role in projecting a professional image is vital. When sourcing for B2B needs, buyers should evaluate durability, brand reputation, and potential for customization (e.g., branding or specific sizing). Bulk orders benefit from negotiated discounts, especially for uniform or corporate branding purposes.

Athletic/Performance Shoes

Designed for comfort and agility, athletic shoes feature lightweight, breathable materials and specialized soles for activities like warehouse work or logistics. They are suitable where mobility and comfort are prioritized over heavy-duty safety features. B2B buyers should assess the shoe’s durability relative to its cost, considering the intensity of use. Volume purchasing and supplier reliability are key, especially in regions with high turnover or seasonal demand.

Safety Boots

Safety boots are engineered with high ankle support, reinforced midsoles, and anti-slip features, making them ideal for hazardous outdoor environments such as mining, oil fields, and outdoor construction. They often include additional safety features like electrical hazard resistance. When sourcing, buyers should verify compliance with international safety standards and consider durability versus weight, as heavier boots can impact worker fatigue. Bulk procurement can leverage economies of scale, but quality consistency is crucial.

Industrial Rubber Shoes

Rubber shoes excel in environments requiring waterproofing, chemical resistance, and slip prevention. Commonly used in chemical plants, sanitation, and agriculture, they are vital for worker safety in wet or corrosive conditions. Their affordability and practicality make them attractive for large-scale procurement. However, they lack the aesthetic appeal and formal versatility of leather shoes, limiting their use outside industrial settings. B2B buyers should evaluate material quality and supplier certifications to ensure safety compliance and longevity.

Key Industrial Applications of world industries shoes

| Industry/Sector | Specific Application of world industries shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil & Gas | Downhole drilling equipment components | Ensures durability and high-pressure resistance in harsh environments | Material compatibility with hydrocarbons, API/ISO certifications, supply chain reliability |

| Chemical Processing | Seals and gaskets in corrosive chemical environments | Provides chemical resistance and long service life | Resistance to specific chemicals, compliance standards, supplier experience |

| Power Generation | Turbine and valve sealing solutions | Maintains operational integrity under extreme temperatures and pressures | Thermal stability, precision manufacturing, certification requirements |

| Heavy Machinery & Construction | Wear-resistant shoes for excavators and bulldozers | Enhances equipment longevity and operational efficiency | Mechanical strength, abrasion resistance, adherence to industry standards |

| Automotive & Transportation | Sealing components in manufacturing and maintenance processes | Ensures leak-proof performance, reducing downtime and maintenance costs | Compatibility with automotive fluids, quality certifications, supply consistency |

Oil & Gas Industry

In the oil and gas sector, world industries shoes are primarily used in downhole drilling equipment, such as packers and blowout preventers. These shoes are designed to withstand extreme pressures, high temperatures, and corrosive hydrocarbons, ensuring safety and operational continuity. International B2B buyers from Africa, South America, the Middle East, and Europe seek suppliers who can provide certified, high-performance materials that meet API standards. Reliable sourcing is critical to prevent costly downtime and ensure compliance with industry regulations.

Chemical Processing Industry

Within chemical processing plants, world industries shoes serve as critical seals and gaskets. They are engineered to resist aggressive chemicals, high temperatures, and mechanical wear. For international buyers, especially in regions with diverse chemical profiles like Colombia or Turkey, sourcing shoes with proven chemical resistance and industry certifications ensures safety and longevity. Establishing relationships with suppliers capable of delivering consistent quality and complying with environmental standards is vital to mitigate operational risks.

Power Generation Sector

In power plants, especially those utilizing turbines and high-pressure valves, world industries shoes function as sealing components that maintain system integrity under demanding conditions. These shoes must withstand thermal cycling, high pressures, and corrosive environments. For B2B buyers across Europe and the Middle East, sourcing shoes with proven thermal stability, precision manufacturing, and certifications such as ISO or IECEx is essential. This ensures reliable performance, reduces maintenance costs, and supports compliance with international safety standards.

Heavy Machinery & Construction

Heavy machinery used in construction and mining relies on wear-resistant shoes to protect vital components like excavators and bulldozers. These shoes are designed to resist abrasion, impacts, and mechanical stress, prolonging equipment lifespan. For buyers in Africa and South America, sourcing shoes with superior mechanical strength and adherence to industry standards ensures operational efficiency and reduces downtime. Partnering with suppliers offering high-quality, certified products guarantees compatibility and durability in rugged environments.

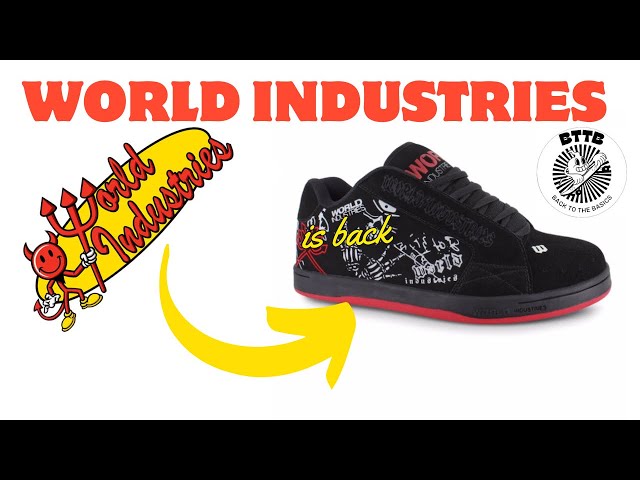

Illustrative Image (Source: Google Search)

Automotive & Transportation

In automotive manufacturing and maintenance, world industries shoes are used as sealing components within engines, gearboxes, and hydraulic systems. They provide leak-proof performance, essential for safety and operational efficiency. International B2B buyers from Europe and Turkey prioritize sourcing shoes with chemical compatibility, high-quality standards, and consistent supply to meet production schedules. Ensuring supplier transparency and certification helps mitigate risks associated with quality variations and supply chain disruptions.

Strategic Material Selection Guide for world industries shoes

Material Analysis for World Industries Shoes

Selecting the appropriate materials for manufacturing shoes in global industries demands a nuanced understanding of each material’s properties, advantages, limitations, and compliance considerations. For international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, these factors are compounded by regional standards, import regulations, and market preferences. Below is a detailed analysis of three common materials used in shoe manufacturing, tailored to support strategic procurement decisions.

Leather

Key Properties:

Leather remains a traditional and highly valued material in shoe manufacturing due to its natural durability, breathability, and aesthetic appeal. It offers good flexibility and molds well to the foot over time. Depending on treatment, it can resist water and environmental elements to varying degrees.

Pros & Cons:

– Pros: Excellent durability, high comfort, premium appearance, and good aging characteristics. Leather also aligns with luxury and high-end market segments, especially in Europe and Middle Eastern markets.

– Cons: High manufacturing complexity and cost, susceptibility to water damage if untreated, and environmental concerns related to tanning processes. Tanning standards (e.g., REACH compliance in Europe) are critical for market acceptance.

Impact on Application:

Leather performs well in applications requiring flexibility and breathability, such as dress shoes and casual footwear. However, it may be less suitable for extreme environments involving water exposure unless treated appropriately.

International Buyer Considerations:

Buyers from Africa and South America should prioritize suppliers with environmentally compliant tanning processes to meet local regulations and consumer preferences. European markets often demand strict adherence to environmental standards like REACH or OEKO-TEX. Additionally, sourcing from regions with skilled leather tanners, such as Turkey or Italy, can ensure quality and compliance.

Thermoplastics (e.g., Thermoplastic Polyurethane – TPU)

Key Properties:

Thermoplastics like TPU are versatile, offering a good balance of flexibility, abrasion resistance, and ease of manufacturing. They can withstand a broad temperature range and are resistant to chemicals and oils.

Pros & Cons:

– Pros: Cost-effective, lightweight, easy to mold into complex shapes, and highly resistant to environmental factors like moisture and UV exposure.

– Cons: Lower breathability compared to natural materials, potential environmental concerns due to plastic origin, and limited aesthetic luxury appeal.

Impact on Application:

Ideal for sports, casual, and work shoes where durability and cost are prioritized. Their resistance to water and chemicals makes them suitable for industrial environments.

International Buyer Considerations:

Buyers from regions with strict plastic import regulations should verify compliance with standards like ASTM or REACH. The environmental impact of plastics is increasingly scrutinized, so sourcing from manufacturers with sustainable practices or recycled TPU options can be advantageous. Cost-wise, TPU offers a medium-cost solution suitable for mass production.

Rubber (Natural and Synthetic)

Key Properties:

Rubber provides excellent elasticity, shock absorption, and water resistance. Natural rubber offers superior resilience, while synthetic variants like SBR or NBR can be tailored for specific chemical or temperature resistances.

Pros & Cons:

– Pros: High durability, excellent grip, and impact absorption. Suitable for soles and protective elements.

– Cons: Can be heavy, susceptible to ozone and UV degradation unless stabilized, and synthetic variants may involve complex manufacturing processes.

Impact on Application:

Primarily used in outsole manufacturing, rubber is essential for safety and traction. Its chemical resistance makes it suitable for industrial or outdoor footwear.

International Buyer Considerations:

Buyers should ensure rubber materials meet regional standards such as DIN or ASTM for safety and performance. Sourcing from regions like Turkey or South America, known for rubber manufacturing, can offer cost advantages. Additionally, environmental considerations regarding synthetic rubber production should be evaluated, especially for European markets emphasizing sustainability.

Summary Table

| Material | Typical Use Case for world industries shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather | Dress shoes, casual footwear, luxury segments | Natural comfort, premium appearance | High cost, environmental concerns, maintenance | High |

| Thermoplastics (TPU) | Sports, casual, work shoes | Cost-effective, durable, versatile | Less breathable, environmental impact | Medium |

| Rubber | Outsoles, safety shoes, industrial footwear | Excellent grip, impact absorption | Heavy, susceptible to UV/Ozone damage | Medium |

This analysis aims to guide international B2B buyers in making informed, regionally sensitive decisions about material sourcing, ensuring compliance, sustainability, and market suitability for world industries shoes.

In-depth Look: Manufacturing Processes and Quality Assurance for world industries shoes

Manufacturing Processes in the Shoe Industry

The manufacturing of shoes for global industries involves a multi-stage process that emphasizes precision, efficiency, and adherence to international standards. For B2B buyers, understanding these stages helps in evaluating supplier capabilities and ensuring product consistency.

1. Material Preparation

This initial phase involves sourcing and preparing raw materials such as leather, synthetic fabrics, rubber, and adhesives. Suppliers often import high-quality materials from renowned regions like Italy for leather, or China and Vietnam for synthetics, depending on the target market. Material inspection at this stage includes checking for defects, consistency in thickness, and compliance with safety standards. B2B buyers should request material certificates and test reports (e.g., ASTM, ISO standards) to verify quality.

2. Forming and Component Production

During this stage, components such as soles, uppers, linings, and insoles are produced. Techniques such as injection molding for soles, cutting, and patterning for uppers are prevalent. Automated CNC cutting machines enhance precision and reduce waste. For high-volume production, manufacturers often use CAD/CAM systems to ensure uniformity across batches. It’s essential for buyers to confirm whether suppliers use modern machinery, which directly impacts quality and consistency.

3. Assembly

Assembly combines the various components into a finished product. This process involves stitching, lasting (shaping the upper to the sole), and attaching the sole to the upper. Techniques vary from traditional hand-stitching to automated robotic assembly, with a trend toward automation in factories serving large international markets. The use of durable adhesives or heat-pressing methods is also common. Buyers should inquire about the assembly line’s operational standards and worker training to assess craftsmanship quality.

4. Finishing

The final step includes surface treatments, polishing, and quality checks before packaging. Finishing ensures aesthetic appeal, proper fit, and durability. Additional processes such as branding, labeling, and packaging are also performed here. Modern finishing techniques include computerized color matching and laser branding, which improve consistency. B2B buyers should verify that finished products meet specified color, size, and branding standards through sample inspections.

Illustrative Image (Source: Google Search)

Quality Control (QC) Framework

Effective QC in the shoe manufacturing process is critical to meet international standards and satisfy customer expectations. Manufacturers adhering to global best practices typically implement multiple checkpoints throughout production.

1. International Standards and Industry Certifications

- ISO 9001: Most reputable manufacturers operate under ISO 9001 certification, ensuring a quality management system that promotes continuous improvement.

- Industry-specific certifications: Depending on the target market, suppliers might also hold CE marking (European conformity), ASTM compliance (North America), or other certifications like the American Petroleum Institute (API) for specialized footwear applications.

2. QC Checkpoints and Techniques

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival. Checks include visual assessment, dimensional accuracy, and material testing (e.g., tensile strength, colorfastness). Suppliers should provide detailed IQC reports.

- In-Process Quality Control (IPQC): Conducted during production, focusing on stitching quality, component fit, and adherence to specifications. Techniques involve visual inspections, measurement gauges, and functional testing (e.g., flexibility, adhesion strength).

- Final Quality Control (FQC): Before packaging, finished shoes are inspected for defects such as surface blemishes, sizing inconsistencies, and structural faults. Random sampling methods like AQL (Acceptable Quality Level) standards are typically used.

3. Testing Methods

- Durability Testing: Simulates wear conditions to assess sole adhesion, upper resilience, and overall durability.

- Comfort and Fit Testing: Ensures ergonomic standards are met, including arch support and flexibility.

- Environmental Testing: Resistance to water, UV exposure, and temperature variations, especially for outdoor or specialized footwear.

- Color Fastness and Aesthetic Checks: Ensuring consistent appearance after exposure to light, water, and rubbing.

4. Verification by B2B Buyers

Buyers should actively verify supplier QC through:

– Factory audits: Conducted by in-house teams or third-party inspectors, focusing on production processes, cleanliness, worker conditions, and QC procedures.

– Inspection reports: Detailed documentation of QC outcomes, including test results, defect rates, and compliance certificates.

– Third-party inspections: Engaging agencies like SGS, Bureau Veritas, or Intertek provides unbiased quality assessments and ensures adherence to international standards.

– Sample approvals: Requiring pre-production samples for approval to establish quality benchmarks.

Nuances for International B2B Buyers from Different Regions

Different regions have distinct expectations, standards, and logistical considerations that influence QC and manufacturing relationships:

-

Africa and South America: Buyers should prioritize suppliers with ISO 9001 and industry-specific certifications, given varying local regulations. Close audits and third-party inspections help mitigate risks associated with inconsistent QC practices. Emphasize supplier transparency in documentation and testing results.

-

Middle East: Market-specific standards like GCC compliance and CE marking are essential. Suppliers should demonstrate adherence to these standards, especially for exports to the EU or Gulf countries. Verify that QC processes incorporate environmental and safety testing aligned with regional regulations.

-

Europe (e.g., Colombia, Turkey): European buyers often require strict compliance with CE standards, REACH regulations, and sustainability certifications. Suppliers should provide comprehensive documentation, including supply chain transparency and eco-friendly manufacturing practices. Regular audits and third-party testing are vital to ensure ongoing compliance.

Practical Recommendations for B2B Buyers

- Establish Clear Specifications: Define quality parameters, certifications, and testing standards before engaging suppliers.

- Conduct Regular Audits: Schedule periodic factory visits and process audits to ensure continuous adherence to quality standards.

- Leverage Third-party Inspection Agencies: Use reputable inspectors to verify QC reports and product compliance, especially when dealing with new suppliers.

- Request Detailed Documentation: Certificates of compliance, test reports, and QC checklists should be part of the supplier’s portfolio.

- Sample Approval and Pilot Orders: Before large shipments, approve samples and conduct trial runs to confirm quality consistency.

- Monitor Post-Delivery Performance: Establish feedback loops to address quality issues promptly and maintain long-term supplier relationships.

By understanding the detailed manufacturing workflows and robust quality assurance practices, international B2B buyers can mitigate risks, ensure product consistency, and foster successful partnerships in the global footwear industry.

Comprehensive Cost and Pricing Analysis for world industries shoes Sourcing

Cost Structure Breakdown for World Industries Shoes

Understanding the comprehensive cost components involved in sourcing shoes from global manufacturers is critical for international B2B buyers. The primary cost elements include:

-

Materials: The type and quality of raw materials—such as leather, synthetic fabrics, rubber, and adhesives—significantly influence costs. Premium materials or those with specific certifications (e.g., eco-friendly, cruelty-free) tend to elevate material expenses.

-

Labor: Labor costs vary widely by country. For example, manufacturing in Turkey or Colombia generally offers moderate wages, whereas some Asian countries may provide lower-cost labor. However, ethical labor practices and compliance with standards like ISO or SA8000 can add to costs.

-

Manufacturing Overhead: This encompasses factory utilities, machinery depreciation, and indirect labor. Countries with advanced manufacturing infrastructure may have higher overheads but often deliver consistent quality.

-

Tooling & Setup: Initial tooling costs—molds, dies, and fixtures—are typically one-time expenses but can be substantial, especially for customized or complex shoe designs. These costs are amortized over large production runs.

-

Quality Control & Certification: Ensuring product quality involves inspection, testing, and certification processes, especially when targeting markets with strict standards (e.g., Europe’s REACH, US safety standards). These add to upfront and ongoing costs.

-

Logistics & Shipping: Transportation costs depend on shipment volume, destination, and mode (air, sea, or land). Incoterms like FOB or CIF influence who bears these costs and at what stage, impacting overall pricing.

-

Profit Margin: Manufacturers typically add a markup to cover risks and ensure profitability, often ranging from 10% to 30%, depending on the supplier and order size.

Key Price Influencers for International Sourcing

Several factors directly impact the final pricing and sourcing viability:

-

Order Volume & MOQ: Larger orders often attract discounts, reducing unit costs. Buyers from Africa or South America should negotiate for favorable MOQs, especially for custom designs, to optimize economies of scale.

-

Specifications & Customization: Higher customization, special materials, or unique designs increase tooling and development costs, leading to higher unit prices. Clear, detailed specifications help prevent costly revisions.

-

Material Choices: Opting for cost-effective, locally available materials can significantly lower costs. However, premium or imported materials with certifications will elevate pricing.

-

Quality & Certifications: Suppliers with international certifications or compliance with safety standards often charge premium but offer assurance of quality, reducing risk and potential delays.

-

Supplier Factors: Established suppliers with strong reputations may command higher prices but provide better reliability, quality, and lead times. New or less-known suppliers may offer lower prices but pose higher risks.

-

Incoterms & Shipping Terms: FOB (Free on Board) terms transfer shipping responsibility to the buyer from the port of origin, potentially reducing upfront costs but increasing logistical involvement. CIF (Cost, Insurance, Freight) includes shipping, simplifying the process but adding to the cost.

Strategic Tips for B2B Buyers

-

Negotiate for Volume Discounts: Larger orders generally lead to better unit prices. Building long-term relationships can unlock preferential pricing and terms.

-

Assess Total Cost of Ownership (TCO): Consider not just the purchase price but also logistics, customs, quality assurance, and potential rework costs. A cheaper unit price may not always translate into lower TCO.

-

Leverage Local Sourcing & Diversification: Diversify suppliers across regions like Turkey, Colombia, and Asian countries to mitigate risks and take advantage of regional cost advantages.

-

Understand Pricing Nuances: Prices can fluctuate based on raw material costs, exchange rates, and geopolitical factors. Regular market intelligence helps in timing negotiations and procurement.

-

Focus on Quality & Certifications: While these may increase upfront costs, they reduce long-term risks related to returns, rejections, or market access barriers, especially in Europe and North America.

Price Range & Indicative Costs

As a guideline, the FOB price for standard casual shoes from mid-range manufacturers can range from $8 to $15 per pair, depending on order volume, material quality, and customization level. Premium or highly customized shoes may cost $20 or more per pair. Keep in mind that additional costs like shipping, customs duties, taxes, and certification fees can add 20-30% to the final landed cost.

- Disclaimer:* These figures are indicative and can vary significantly based on specific product specifications, supplier negotiations, and market conditions. Conduct thorough due diligence and request detailed quotations tailored to your requirements for precise budgeting.

Spotlight on Potential world industries shoes Manufacturers and Suppliers

- (No specific manufacturer data was available or requested for detailed profiling in this section for world industries shoes.)*

Essential Technical Properties and Trade Terminology for world industries shoes

Critical Technical Properties of Shoes in Global Industries

Understanding key technical specifications is essential for international buyers to ensure product quality, compatibility, and compliance. Here are the most important properties to evaluate:

1. Material Grade and Composition

Material selection impacts durability, comfort, and compliance with safety standards. Common materials include genuine leather, synthetic leather, textiles, and rubber. High-grade materials typically indicate longer-lasting products and better consumer perception. For B2B transactions, specifying the exact material grade (e.g., full-grain leather vs. corrected-grain) helps avoid misunderstandings and ensures the product meets your quality expectations.

2. Tolerance and Dimensional Accuracy

Tolerance refers to the permissible variation in shoe dimensions such as length, width, and height. Precise tolerances are vital for consistent fit, especially when scaling production or sourcing from different manufacturers. Buyers should specify acceptable tolerances (e.g., ±1mm) to prevent sizing issues that could lead to returns or dissatisfaction.

3. Sole and Outsole Specifications

The material and design of the sole influence grip, durability, and suitability for different environments. Common sole materials include rubber, polyurethane, and EVA foam. For industrial or outdoor shoes, durability and slip resistance are critical. Clear specifications ensure the shoes meet functional requirements across various markets.

4. Stitching and Construction Quality

The stitching type, density, and overall construction directly affect shoe strength and longevity. Double-stitched seams, reinforced heel counters, and quality bonding are indicators of durability. These technical details are crucial for buyers looking to ensure product longevity in demanding environments.

5. Weight and Flexibility

Weight impacts comfort, especially for work or athletic shoes. Flexibility, determined by material choice and construction, influences mobility and user comfort. Accurate specifications allow buyers to select shoes optimized for specific use cases, reducing fatigue and enhancing performance.

6. Certifications and Compliance Standards

Global markets often require adherence to safety and quality standards such as ISO, ASTM, or regional certifications (e.g., CE marking in Europe). Verifying these ensures the shoes meet health, safety, and environmental regulations, reducing legal risks and facilitating smooth customs clearance.

Essential Industry and Trade Terminology

Familiarity with common trade terms enhances communication and negotiation efficiency in international transactions:

1. OEM (Original Equipment Manufacturer)

Refers to companies that produce shoes based on the buyer’s design and specifications. Understanding OEM arrangements helps buyers control branding and product features, often at lower costs due to large-scale production.

2. MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to produce or sell in a single order. Knowledge of MOQ is critical for planning procurement budgets and inventory management, especially when entering new markets or testing new designs.

3. RFQ (Request for Quotation)

A formal request sent to suppliers to obtain pricing, lead times, and terms for specific shoe models. Efficient RFQ processes enable buyers to compare offers accurately and negotiate better deals.

4. Incoterms (International Commercial Terms)

Standardized trade terms published by the International Chamber of Commerce, defining responsibilities for shipping, insurance, and customs clearance. Familiarity with Incoterms (e.g., FOB, CIF) helps clarify costs, risks, and obligations during transportation.

5. Lead Time

The period from order confirmation to product delivery. Accurate knowledge of lead times allows buyers to plan inventory and avoid stockouts, especially important in seasonal markets or for large orders.

6. Quality Inspection and Certification Terms

Terms such as “pre-shipment inspection” or “third-party testing” refer to quality assurance processes. Ensuring these are understood and included in contracts helps maintain product standards and reduces the risk of receiving defective goods.

By mastering these technical properties and trade terms, international B2B buyers from Africa, South America, the Middle East, and Europe can streamline procurement, ensure product quality, and negotiate more effectively in the global shoes industry.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the world industries shoes Sector

Market Overview & Key Trends

The global footwear industry is experiencing rapid transformation driven by technological innovation, shifting consumer preferences, and evolving supply chain dynamics. For international B2B buyers from regions such as Africa, South America, the Middle East, and Europe—especially countries like Colombia and Turkey—understanding these drivers is crucial for strategic sourcing and market positioning.

Emerging B2B trends include the adoption of digital sourcing platforms, blockchain traceability, and data-driven demand forecasting. These technologies enhance transparency, reduce lead times, and lower costs, making them increasingly vital for international procurement. Additionally, regional hubs like Turkey and Colombia have become prominent manufacturing centers due to competitive labor costs, skilled craftsmanship, and proximity to key markets.

Market dynamics are also influenced by fluctuating raw material prices, geopolitical shifts, and trade policies. For instance, tariffs or import restrictions can impact sourcing decisions, prompting buyers to diversify suppliers or invest in local manufacturing capabilities. Sustainability is increasingly shaping procurement strategies, with buyers prioritizing suppliers committed to eco-friendly practices and ethical labor standards.

For Africa and South America, sourcing opportunities are expanding in response to global demand for affordable yet quality footwear. These regions benefit from growing infrastructure and government incentives aimed at boosting manufacturing sectors. Meanwhile, Middle Eastern buyers are exploring partnerships with emerging Asian and African suppliers to enhance supply chain resilience. European buyers focus on balancing cost efficiency with sustainability commitments, often seeking suppliers that align with stringent environmental standards.

Overall, international B2B buyers must stay agile, leveraging digital tools and regional insights to navigate complex market dynamics, optimize sourcing, and capitalize on emerging opportunities.

Sustainability & Ethical Sourcing in B2B

Sustainability is no longer a peripheral concern but a core criterion in sourcing decisions within the footwear industry. Environmental impacts—such as water consumption, chemical use, and carbon emissions—are scrutinized by buyers seeking to align with global climate goals and consumer expectations.

Illustrative Image (Source: Google Search)

Ethical sourcing practices are critical for maintaining brand reputation and ensuring supply chain integrity. B2B buyers should prioritize suppliers with verifiable certifications like Fair Trade, SA8000, or B Corp, which demonstrate compliance with labor rights and fair wages. Transparent supply chains, traceability systems, and regular audits are essential tools for verifying supplier adherence to ethical standards.

In terms of materials, there is a growing shift toward ‘green’ options such as recycled plastics, organic textiles, and biodegradable components. Suppliers offering eco-friendly materials can provide a competitive advantage, especially for buyers targeting environmentally conscious markets in Europe and the Middle East.

For regions like Colombia and Turkey, adopting sustainability initiatives can enhance market access and meet import regulations that increasingly favor green products. Collaborating with suppliers committed to sustainability not only reduces environmental impact but also mitigates risks associated with supply chain disruptions and non-compliance penalties.

In summary, integrating sustainability and ethical sourcing into procurement strategies enables B2B buyers to foster resilient, responsible supply chains that resonate with modern consumer values and regulatory frameworks.

Brief Evolution/History (Optional)

The footwear industry has historically been characterized by low-cost manufacturing and mass production, primarily driven by Western markets. Over the past two decades, globalization and technological advancements have shifted this paradigm, enabling emerging markets in Asia, Latin America, and Africa to become significant players.

The rise of sustainable practices and ethical sourcing reflects a broader industry transformation, driven by consumer demand for transparency and corporate responsibility. Countries like Turkey and Colombia have evolved from simple manufacturing hubs to centers of innovation, integrating eco-friendly processes and modern supply chain management.

This evolution underscores the importance for B2B buyers to adapt to changing industry standards, emphasizing quality, sustainability, and ethical compliance alongside cost competitiveness. Recognizing this progression allows for strategic partnerships that align with long-term industry trends and regulatory developments, ensuring resilient and responsible sourcing in the dynamic world footwear market.

Frequently Asked Questions (FAQs) for B2B Buyers of world industries shoes

1. How can I effectively vet suppliers of world industries shoes to ensure quality and reliability?

Effective vetting begins with comprehensive research: review supplier websites, certifications, and client testimonials. Request references from their existing clients, especially from similar markets. Verify their compliance with international standards such as ISO, BSCI, or SEDEX, which indicate adherence to quality and ethical practices. Consider visiting their manufacturing facilities or engaging third-party inspection services for on-site audits. Additionally, evaluate their communication responsiveness and transparency regarding production processes, lead times, and quality control measures. Establishing clear contractual terms upfront minimizes risks and fosters long-term trust.

2. What customization options are typically available for bulk orders, and how do they impact lead times and costs?

Most suppliers offer customization in design, branding (e.g., logos, packaging), and materials. Custom features like specific colorways or unique sole designs usually require additional setup costs and longer lead times—often 4-8 weeks depending on complexity. Bulk orders with standard designs benefit from economies of scale, reducing per-unit costs and lead times. Communicate your exact specifications early, and request detailed quotations including setup fees, minimum order quantities (MOQs), and production timelines. Proper planning and early engagement with suppliers facilitate smoother customization processes and cost management.

3. What are typical MOQs, lead times, and payment terms I should expect when sourcing from international suppliers?

MOQs for world industries shoes vary widely, typically ranging from 300 to 1,000 pairs, but can be lower for smaller suppliers or specific models. Lead times usually span 4-12 weeks, depending on order complexity, customization, and supplier location. Common payment terms include 30% upfront payment with the balance before shipment, or letters of credit for larger transactions. Negotiating flexible terms is possible, especially for repeat orders. Establish clear timelines and payment schedules early, and consider escrow or trade finance options to mitigate risks associated with international transactions.

4. What certifications and quality assurance measures should I verify before placing an order?

Key certifications include ISO 9001 (quality management), SEDEX (ethical production), and specific safety standards relevant to footwear, such as REACH compliance for chemical safety. Request documentation of these certifications and ask for recent audit reports. Quality assurance measures should encompass pre-production samples, in-line inspections, and final quality checks before shipment. Some suppliers offer third-party inspection services—utilize these to ensure compliance with your quality standards. Implementing strict QA protocols reduces the risk of defective products and enhances brand reputation in your target markets.

5. How can I manage logistics effectively when importing shoes from overseas, especially considering customs and delivery risks?

Partner with experienced freight forwarders familiar with your target markets—Turkey, Colombia, or Middle Eastern countries—to optimize shipping routes and costs. Choose reliable shipping methods—sea freight for large volumes, air freight for urgent orders—and ensure proper packaging to prevent damage. Clarify Incoterms (e.g., FOB, CIF) to define responsibilities and costs. Work closely with customs brokers to ensure compliance with import regulations, tariffs, and documentation requirements. Track shipments proactively and maintain open communication with logistics providers to address delays swiftly, minimizing supply chain disruptions.

6. How should I handle disputes or quality issues with international suppliers?

Establish clear contractual clauses outlining quality standards, inspection procedures, and dispute resolution methods before signing agreements. In case of disputes, document issues thoroughly with photos, inspection reports, and correspondence. Engage in direct negotiations initially, aiming for amicable solutions such as product replacements or refunds. If unresolved, consider arbitration under international trade laws or mediation services. Building strong supplier relationships and maintaining transparent communication can prevent conflicts. Always include dispute resolution clauses in contracts to facilitate a structured approach should issues arise.

7. What are the best practices for ensuring compliance with local import regulations and standards?

Research each target market’s import regulations, tariffs, and product standards—Colombia, Turkey, and Middle Eastern countries have specific requirements. Work with local customs brokers and legal advisors to understand documentation needs, labeling laws, and safety standards. Ensure your products meet regional chemical, safety, and environmental regulations, which may require testing and certification. Incorporate compliance checks into your supplier vetting process and request relevant documentation upfront. Staying informed about policy updates and maintaining open communication with authorities helps avoid delays and penalties, ensuring smooth market entry.

8. How can I build long-term, mutually beneficial relationships with suppliers of world industries shoes?

Start with transparent communication and clear expectations regarding quality, delivery, and payment terms. Invest in supplier development by providing feedback, sharing market insights, and encouraging continuous improvement. Consider establishing long-term contracts or volume agreements to secure better pricing and priority service. Regular visits, virtual meetings, and participation in supplier audits foster trust and collaboration. Recognize and reward reliable suppliers through timely payments and constructive engagement. Building strong relationships reduces lead times, enhances product quality, and creates a resilient supply chain adaptable to market changes.

Strategic Sourcing Conclusion and Outlook for world industries shoes

Strategic Sourcing Outlook for the Global Shoe Industry

Effective strategic sourcing remains a cornerstone for international B2B buyers aiming to capitalize on the evolving footwear landscape. Key insights highlight the importance of diversifying supplier bases, leveraging emerging markets such as Turkey, Colombia, and other regional hubs to mitigate risks and enhance supply chain resilience. Prioritizing quality, sustainability, and innovation can differentiate offerings in a competitive global market.

For buyers in Africa, South America, the Middle East, and Europe, establishing strong partnerships with reliable manufacturers is crucial. This involves thorough due diligence, fostering long-term collaborations, and utilizing digital procurement tools to streamline sourcing processes. Additionally, understanding regional manufacturing strengths can unlock cost efficiencies and faster time-to-market.

Looking ahead, the footwear industry is poised for continued transformation driven by technological advancements and shifting consumer preferences. International buyers should proactively adapt their sourcing strategies to harness these trends, ensuring agility and competitiveness. Embracing a strategic, forward-thinking approach will enable buyers to secure sustainable supply chains and capitalize on emerging opportunities in the global footwear market.